-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

In industrial and commercial power systems, pressure transmitters sit quietly in the background while UPS systems, inverters, and protection relays take the spotlight. Yet the stability of those electrical systems often depends on how well you measure pressure in boilers, feedwater lines, steam headers, cooling loops, and fuel gas skids. When a turbine trips on bad steam data or a boiler drum level loop oscillates because of noisy differential pressure, your UPS ends up defending against a disturbance that should never have occurred.

Pressure is one of the four fundamental process variables in a plant, alongside flow, temperature, and level, as Yokogawa emphasizes in its educational material. A differential pressure transmitter can infer flow through an orifice plate or Venturi, hydrostatic head can infer liquid level, and gas pressure in a closed volume can track temperature changes. In every case, the transmitterŌĆÖs accuracy and stability determine whether your control system sees a faithful picture of the process or a distorted one.

The question I hear from power and industrial operators is rarely ŌĆ£What is the published accuracy?ŌĆØ but rather ŌĆ£Is this transmitter accurate enough, stable enough, and safe enough to keep my plant online without driving maintenance crazy?ŌĆØ The answer is not just in a single percentage on a datasheet. It lives in how Yokogawa defines accuracy, how that accuracy holds over time, how diagnostics flag problems before they become trips, and how environmental factors like temperature and vibration are handled.

This article focuses on YokogawaŌĆÖs pressure transmitters, particularly the DPharp-based families such as the EJA110E differential pressure transmitter and EJX530A gauge transmitter, and on how their accuracy and performance data translate into real-world reliability for power and process applications.

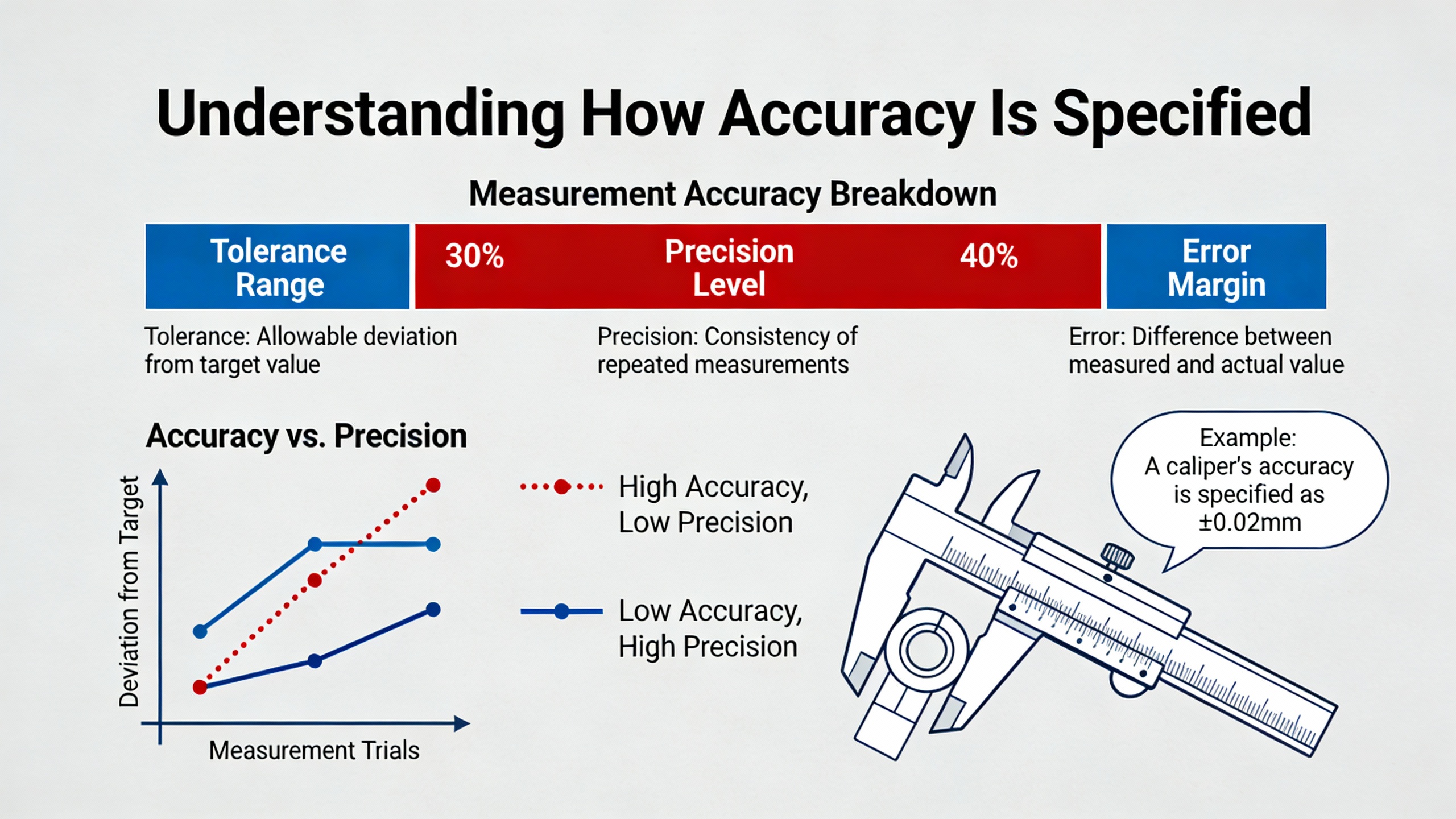

Before comparing models, it helps to unpack what ŌĆ£accuracyŌĆØ means in the context of pressure transmitters. According to technical briefs from instrumentation specialists such as PMC, Solinst, and Yokogawa, accuracy is not a single error but a combined value.

Manufacturers commonly define accuracy as the maximum deviation from an ideal straight line across the specified range, usually bundling nonlinearity, hysteresis, and non-repeatability into a single figure. For example, a device might be specified as ┬▒0.04% of span. Some vendors use best-fit straight line methods, others terminal-point methods, and those choices affect what that percentage really means in practice, as PMC explains.

Datasheets also distinguish between different bases for that percentage. Yokogawa and third-party distributors such as Ye┼¤il Grup Enerji describe typical Yokogawa pressure transmitter performance in terms of accuracy around ┬▒0.04% of reading for the high-performance ranges, while individual product pages for devices like the EJA110E state accuracy as a percentage of span and stability as a percentage of upper range limit (URL). This mix is normal, but you must read carefully.

The underlying error components are more than academic. They include zero offset, span error, nonlinearity, hysteresis, thermal drift of zero and span, and long-term drift. SolinstŌĆÖs explanation of accuracy and drift for pressure sensors highlights the same themes. Under reference lab conditions the accuracy might be ┬▒0.05% of full scale, but once you add process temperature swings, static pressure effects, and vibration, the total error band increases.

A useful way to interpret the specs is to convert percentages to engineering units across your planned span. If you configure a differential pressure transmitter like the EJA110E on a span of 0 to 300 psi and use a reference accuracy of ┬▒0.04% of span, the absolute error band is roughly ┬▒0.12 psi. On a 0 to 1500 psi span, the same percentage becomes about ┬▒0.60 psi. The percentages look tiny either way, but expressing the error in psi helps you decide where it matters. For a boiler drum level DP at low head, a fraction of a psi might be critical; for a high-pressure gas line, the same error could be negligible.

Accuracy also has a time dimension. Fuji Electric stresses that long-term stability, often specified as a percentage of URL over several years, is just as important as the initial reference accuracy because drift accumulates and pushes readings away from the truth. YokogawaŌĆÖs DPharp platform is designed with this in mind, guaranteeing long-term stability on the order of ┬▒0.1% for up to 15 years in its platform-level documentation and quoting ┬▒0.1% of URL over 10 years for the EJA110E in more detailed product-oriented sources. That level of stability is what allows you to extend calibration intervals rather than chase drifting instruments.

Yokogawa took a clean-sheet approach in the early 1990s and developed the DPharp digital pressure sensor, a monocrystalline silicon resonant technology. Company literature and third-party summaries agree that more than 11 million transmitters and calibrators using DPharp have been installed worldwide, which is a strong field validation.

Unlike traditional passive analog strain-gauge sensors, DPharp is an active digital sensor. It continuously supplies a digital signal even when the process pressure is steady. If that signal disappears, the transmitterŌĆÖs self-diagnostics recognize the abnormal condition and raise an alarm. From a reliability perspective, that means silence is treated as a fault, not as ŌĆ£zero pressure.ŌĆØ

The monocrystalline silicon resonant structure behaves like a vibrating element whose resonant frequency shifts with applied differential pressure. ZYY InstrumentŌĆÖs technical brief on the EJA110E highlights that this sensor type offers superior temperature stability, minimal drift, and very high repeatability compared to conventional DP sensors. Because the crystal is defect-free and the sensor is fabricated in a controlled manner, its behavior over temperature and pressure is highly predictable and can be compensated digitally.

Ye┼¤il Grup EnerjiŌĆÖs overview of Yokogawa transmitters gives a sense of the overall platform capability. It notes measuring ranges that span from about 0 to 1 mbar (roughly 0 to 0.015 psi) up to 1000 bar (around 14,500 psi), typical accuracy around ┬▒0.04% of reading, and SIL2 or SIL3 certifications for critical safety applications. Add to this the unconditional long-term stability figures from YokogawaŌĆÖs DPharp material and you get a platform designed not just for precision in the lab, but for reliable behavior over decades of industrial service.

Another platform-level feature is multi-sensing. YokogawaŌĆÖs DPharp-based differential pressure transmitters can measure both differential pressure and static pressure with a single device. In many competing architectures, you would need separate DP and gauge transmitters. YokogawaŌĆÖs approach reduces the number of devices, manifolds, and associated wiring, and simplifies maintenance. For power systems where every penetration of a high-pressure line is a potential leak point and every device is another thing to calibrate, this consolidation is not trivial.

The table below summarizes key platform-level performance aspects as described by Yokogawa and its distributors.

| Attribute | Typical DPharp Platform Value or Feature |

|---|---|

| Sensing technology | Monocrystalline silicon resonant digital sensor (DPharp), active rather than passive |

| Accuracy | Around ┬▒0.04% of reading for high-performance ranges |

| Long-term stability | About ┬▒0.1% of URL over 10ŌĆō15 years (depending on source and model) |

| Rangeability | Up to 100:1 turndown on models like EJA110E |

| Pressure range capability | From about 0ŌĆō1 mbar (Ōēł0ŌĆō0.015 psi) up to 1000 bar (Ōēł14,500 psi) across product line |

| Safety certification | SIL2 single, SIL3 in redundant architectures, per Exida and TÜV |

| Communication | 4ŌĆō20 mA with HART or BRAIN; FOUNDATION Fieldbus and PROFIBUS PA; some low-power HART |

From a power-system reliability standpoint, the combination of high accuracy, very long-term stability, and robust safety certification means these transmitters can serve both in control loops and in Safety Instrumented Systems without requiring separate device families.

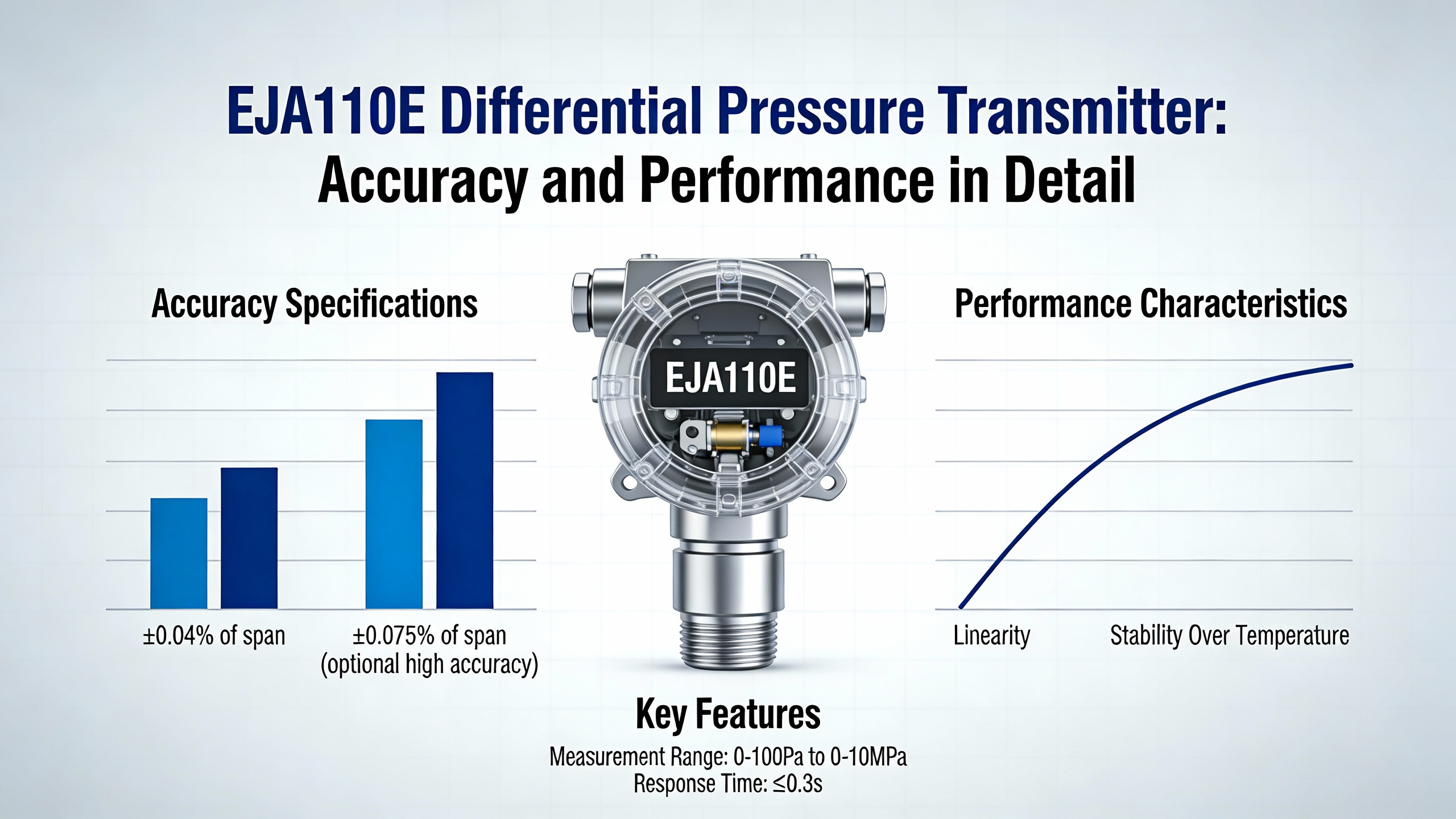

The EJA110E is YokogawaŌĆÖs flagship differential pressure transmitter for liquids, gases, and steam and is widely applied in critical services. Several sources, including Achievers Automation and ZYY Instrument, provide converging details on its performance.

On the measurement side, the EJA110E covers a differential pressure range from about 0.5 kPa to 10 MPa, which corresponds roughly to 0.07 psi up to about 1450 psi. ZYY Instrument describes five optimized measuring cells spanning from 5 mbar to 140 bar, and that upper 140 bar figure equates to about 2030 psi. This coverage and the 100:1 turndown ratio mean a single transmitter can be ranged down by a factor of one hundred while still meeting its specified accuracy. In practice, that lets you standardize on one or two DP capsule sizes for a plant and apply them to both low-head drum level measurements and high-pressure feedwater flow, simply by re-ranging.

For accuracy, ZYY Instrument cites a primary variable accuracy of ┬▒0.055%, with an optional high-precision configuration at ┬▒0.04%. Achievers Automation notes an industry-leading accuracy of around ┬▒0.04% of span and also mentions a figure of ┬▒0.075% of span in some digital communication configurations. Auxiliary static pressure accuracy is about ┬▒0.5%, which is relevant when you use static pressure in flow calculations or diagnostics. Long-term stability is stated as ┬▒0.1% of URL over 10 years, and overpressure influence is limited to about ┬▒0.03% of URL. Those numbers matter in real power applications where overpressure events occur during valve sequencing or startup.

To translate those percentages into a realistic scenario, consider a feedwater differential pressure measurement across an orifice plate where the design span is 0 to 250 psi. At ┬▒0.04% of span, the transmitterŌĆÖs contribution to error is on the order of ┬▒0.10 psi. Even if you derate that figure to account for temperature and static pressure influences, the total instrument uncertainty can remain well inside ┬▒0.5 psi. That level of precision supports tight combustion and feedwater control while allowing protection setpoints to be configured with comfortable margins relative to design limits.

Dynamic performance is also important. Achievers Automation lists a nominal response time of about 90 ms, with user-adjustable damping that can stretch the effective response out to about 0.5 to 64 seconds. That flexibility allows you to use the same transmitter on fast-changing gas flow where you want quick response and on noisy steam lines where you prefer to smooth out pulsations.

Environmental robustness is clearly targeted at demanding services. The EJA110EŌĆÖs operating temperature range is given as ŌłÆ40 to 120 ┬░C, roughly ŌłÆ40 to 248 ┬░F, with process temperature capability up to about 200 ┬░C, roughly 392 ┬░F, when used with remote seals. The enclosure protection is IP67 and NEMA 4X, and vibration resistance is around 2 g in the 10 to 150 Hz band. In power plants, that means the same device can sit near a hot boiler wall or on a vibrating pump skid, provided proper impulse line design and mounting are respected.

On the electrical and communication side, the EJA110E supports a traditional 4ŌĆō20 mA output with HART, as well as BRAIN and FOUNDATION Fieldbus protocols, with power supply ranges around 10.5 to 42 V DC for the HART/BRAIN variants and 9 to 32 V DC for Fieldbus. That range is broad enough to integrate cleanly into typical 24 V DC control-system power buses found in switchgear rooms and distributed I/O panels.

Safety and diagnostics are where this transmitter differentiates itself. YokogawaŌĆÖs documentation emphasizes that the DPharp sensor is an active digital element with continuous self-checking. The transmitter also implements Back-check Technology, which reverse-checks internal calculations in real time. Independent organizations such as Exida and T├£V have verified the safety performance, with the EJA-E series certified for SIL2 in single-transmitter architecture and SIL3 when used in redundant configurations. In a boiler protection loop or a turbine trip system, that means the same EJA110E you use for control can also meet your safety-system requirements, easing spare parts and standardization.

From a maintenance perspective, Yokogawa provides the FieldMate software suite for configuration and asset management, a hand-held communicator, and a Local Parameter Setting function that lets technicians adjust several key parameters at the transmitter without special tools. The local indicator can display differential pressure, static pressure, capsule temperature, alarm codes with short text, and a bar graph, and it is powered from a separate circuit rather than the 4ŌĆō20 mA loop. That design allows the display to remain informative even if the analog output is forced or otherwise abnormal, which is invaluable during troubleshooting.

In a combined-cycle plant I might use EJA110E transmitters on feedwater flow, steam generator drum level, condenser hotwell level via DP, and critical gas fuel flow. The same accuracy, stability, and diagnostic behavior carry across all those loops, simplifying both design and operations.

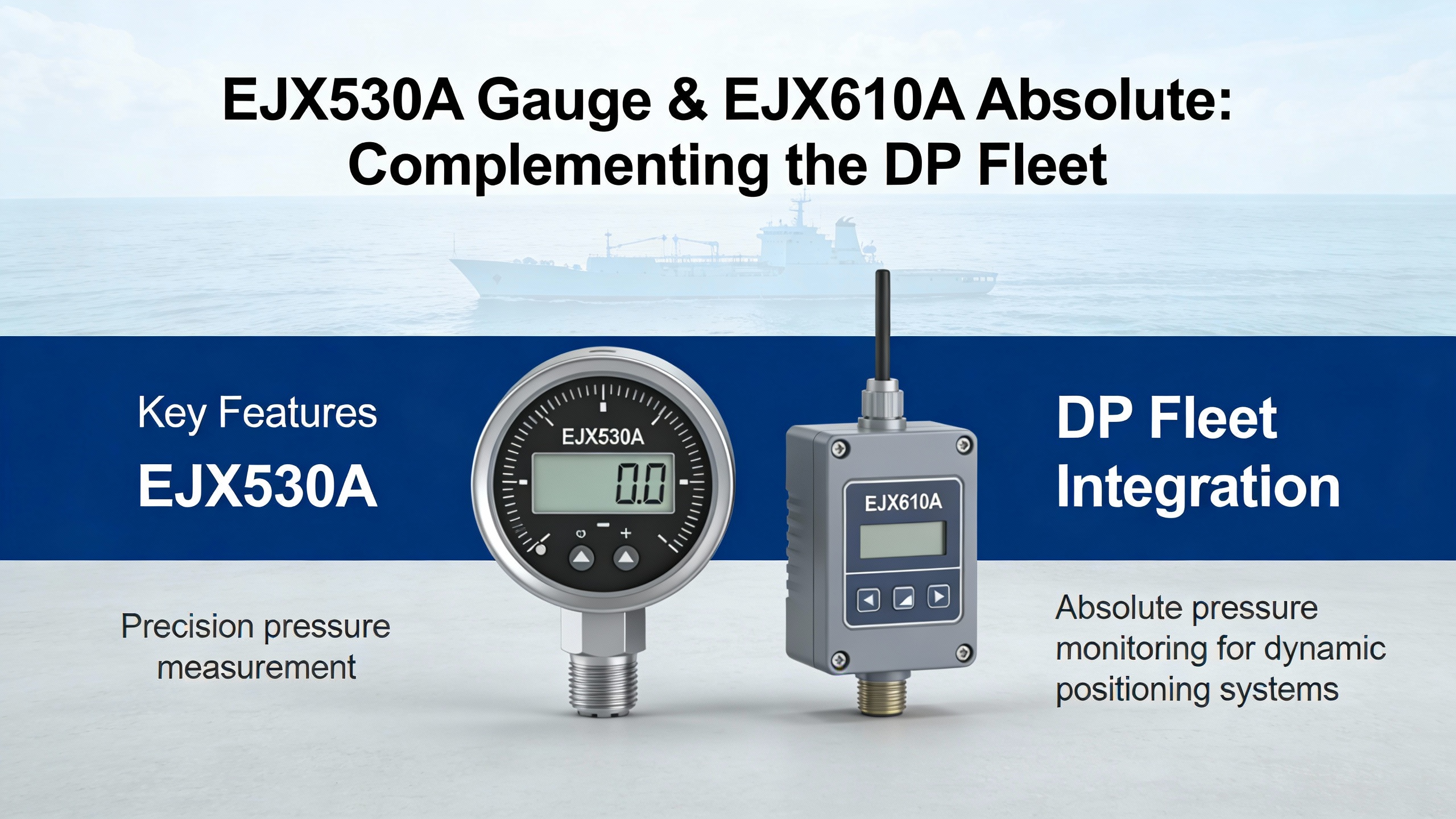

While differential pressure transmitters do much of the heavy lifting in flow and level measurement, gauge and absolute pressure transmitters are just as critical for power and industrial reliability. YokogawaŌĆÖs EJX530A gauge pressure transmitter and EJX610A absolute pressure transmitter share the DPharp foundation and many diagnostic features.

The EJX530A is an in-line mount gauge transmitter designed for direct connection to process lines. Yokogawa highlights that it uses the same DPharp digital sensing technology, with the same underlying history of more than 11 million DPharp devices in service. As with the EJA110E, the EJX530A benefits from an active digital sensor, self-diagnostics, and Back-check Technology for real-time reverse checking of internal calculations. These diagnostics are not subtle; if the sensor signal disappears or internal calculations disagree, the transmitter raises an alarm instead of quietly drifting.

The communication ecosystem is also shared. FieldMate software can configure the EJX530A just as it does the EJA110E, and the Local Parameter Setting function allows modification of several key parameters at the transmitter. The local indicator is fully programmable and can show process variables, alarm codes, and a bar graph; it is driven from a circuit that is separate from the 4ŌĆō20 mA loop, so the display remains meaningful even when the loop is in a simulated or forced condition.

In practical terms, gauge transmitters like the EJX530A are natural fits for pump discharge pressure, gas header pressure feeding burners or gas turbines, and compressed air systems that underpin control valves and balance-of-plant equipment. In those services, high accuracy supports energy efficiency, while rock-solid stability and diagnostics help you detect slowly fouling strainers or creeping leaks before they impact the power supply.

The EJX610A absolute pressure transmitter targets applications where you need pressure referenced to a vacuum rather than to atmosphere. YokogawaŌĆÖs description focuses on the local indicator features: it can display various process variables, show alarm codes with clear text, and present a bar graph that gives technicians an at-a-glance sense of the process state. The indicator runs from an independent circuit rather than the 4ŌĆō20 mA loop, mirroring the EJA110E and EJX530A philosophy that field information should remain available even when signal loops are in an abnormal state.

Absolute transmitters matter in services such as vacuum systems and barometric-compensated measurements, where atmospheric pressure changes would otherwise appear as signal noise. YokogawaŌĆÖs own educational resources explain that gauge-reference measurements are sensitive to weather-related atmospheric changes, while absolute-reference measurements are stable but somewhat more expensive. For condenser vacuum, for example, absolute pressure gives a truer picture of how well the condenser is performing relative to design, which in turn affects turbine efficiency and load-carrying ability for your UPS and downstream power systems.

The impressive numbers on a Yokogawa datasheet assume well-controlled conditions. In the real world, environmental and application factors can double or triple the total measurement error if you do not manage them. Fuji ElectricŌĆÖs discussion of the seven factors influencing pressure transmitter accuracy and other technical sources align on the main culprits.

Temperature is one of the largest. Both ambient and process-fluid temperatures impact sensor behavior. The further you operate toward the extremes of the specified temperature range, the larger the errors. Fuji Electric recommends selecting transmitters whose operating range comfortably brackets your expected process and ambient conditions and prefers devices with robust temperature compensation. YokogawaŌĆÖs EJA110E, with operating capability from about ŌłÆ40 to 248 ┬░F and process temperature tolerance up to about 392 ┬░F when using remote seals, is designed to handle harsh thermal conditions, but you still gain accuracy by avoiding direct exposure to hot lines, using impulse lines with proper heat tracing, and insulating or separating high-temperature sources.

Static pressure is another often-misunderstood factor. In a differential pressure transmitter, static or line pressure is the pressure applied equally to both sides of the sensor. Ideally, equal pressure would produce zero DP, but real devices show static-pressure-induced zero and span errors. Fuji Electric recommends choosing transmitters with static-pressure compensation and, when possible, performing field calibration near actual operating static pressures. YokogawaŌĆÖs DPharp sensor and its digital compensation algorithms are explicitly designed to handle static pressure effects, and ZYY Instrument notes static pressure accuracy and overpressure behavior as part of the EJA110E specifications.

Scale and rangeability are equally critical. If you configure the measurement range outside the transmitterŌĆÖs dynamic range, accuracy degrades. Fuji Electric encourages users to select transmitters with a high dynamic range, for example, a 1:100 turndown ratio, and to set the scale as close as practical to the actual operating pressure. YokogawaŌĆÖs 100:1 turndown on the EJA110E supports exactly this philosophy, but that capability should not be misused. If you range a single transmitter from near-zero up to its full maximum and then operate only at the very low end, your effective accuracy may be much worse than the headline percentage.

Mechanical installation plays a large role as well. Mounting position can affect zero, especially on transmitters with oil-filled cells and diaphragm seals, because the weight of the fill fluid introduces a hydrostatic offset. Fuji Electric advises following manufacturer mounting recommendations and always checking and adjusting zero after installation. Vibration from pumps and fans can introduce noise, degrade repeatability, and even shorten transmitter life. Fuji recommends choosing vibration-resistant transmitters and using anti-vibration mounting where practical. YokogawaŌĆÖs EJA110E, with tested vibration resistance around 2 g across a typical industrial frequency range, directly addresses this concern, but good impulse line design and mechanical support remain essential.

Finally, power supply quality matters. Fuji Electric points out that incorrect or unstable voltage can bias readings or damage sensors. Most industrial transmitters, including YokogawaŌĆÖs DPharp units, are designed for nominal 24 V DC operation with a wide permissible range, such as 10.5 to 42 V DC. In a well-designed power system, that power is supplied through regulated DC circuits backed by UPS and monitored for noise, which aligns with the perspective of a power systems engineer: clean DC to every loop reduces both measurement errors and nuisance trips.

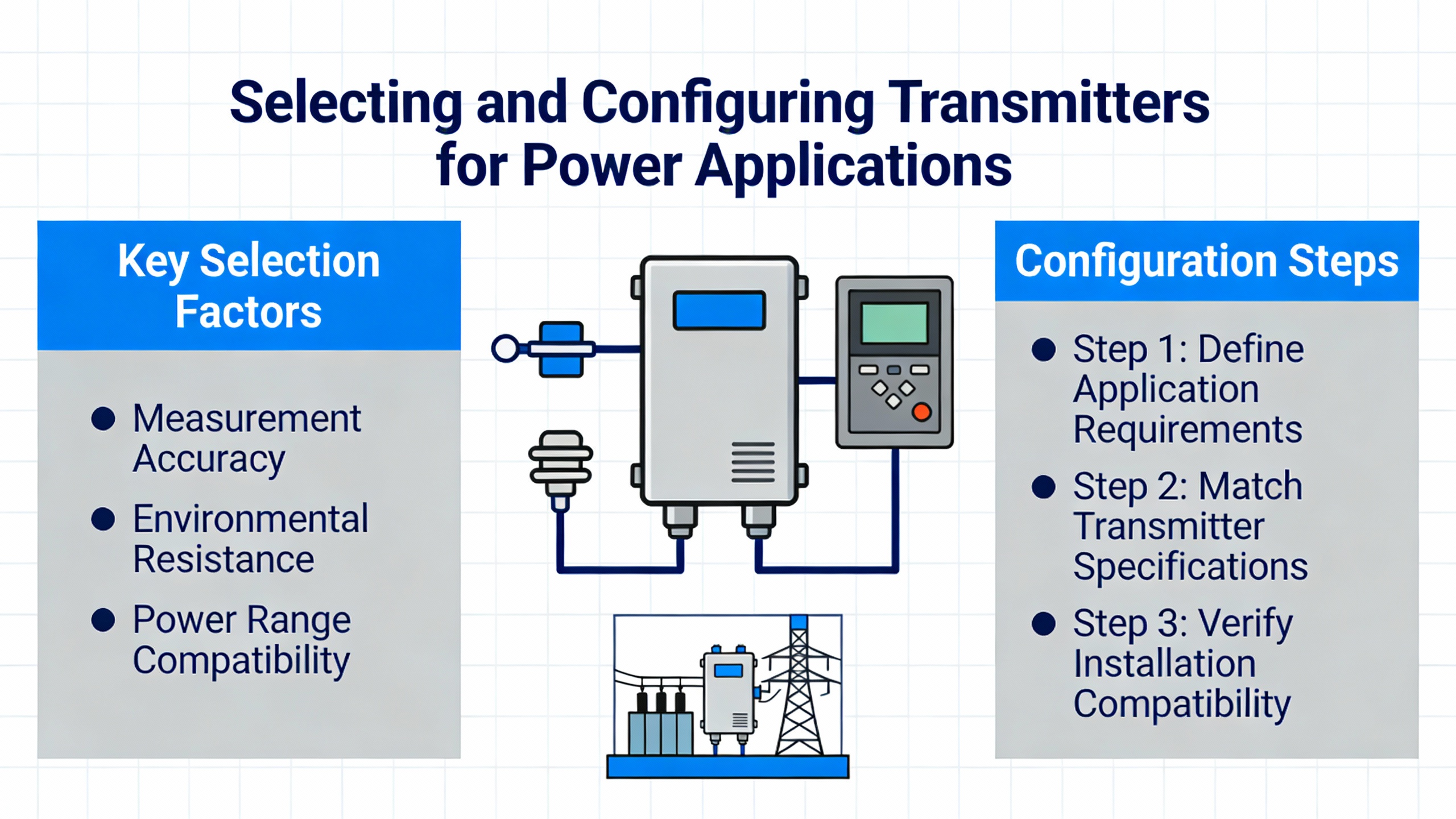

With the platform and environmental effects in mind, the next step is selecting and configuring specific Yokogawa transmitters. Industry guidance from Fuji Electric, ESI, DGFG, and Plant Automation Technology tends to follow a consistent decision sequence that fits power and industrial users well.

The first step is to clarify what you are actually measuring. Is it simply pressure in a feedwater header, differential pressure across a boiler drum level tap, flow through an orifice plate, or hydrostatic level in a condensate storage tank? Fuji Electric and ESI stress distinguishing between gauge, absolute, and differential measurements. Gauge pressure is referenced to atmosphere and is suitable for tank level or pump discharge where atmospheric shifts are acceptable. Absolute pressure is referenced to a vacuum and is preferred where atmospheric changes would distort the measurement. Differential pressure measures the difference between two points and underpins flow measurement and many level calculations.

Next, define the pressure range. ESI and DGFG recommend avoiding operation close to the sensor limit and suggest transmitter pressure ratings around one and a half times the maximum expected pressure to handle spikes and prevent overload. For example, if a fuel gas header normally runs at 600 psi with occasional surges to 700 psi, a transmitter with a range up to roughly 900 to 1000 psi gives you room for those excursions while keeping the span tight enough for good resolution. In the DP world, you look at both the differential range and the maximum static pressure. ZYY Instrument notes that the EJA110E can handle working pressures up to about 2300 psi, with an optional rating around 3600 psi, which is adequate for many high-pressure steam and feedwater lines.

Then, decide how much accuracy and stability you really need. For many industrial loops, articles from ESI and PMC suggest that ┬▒0.5% of full scale is sufficient. For custody transfer, critical boiler or turbine protection, or emissions-related flows, you may need ┬▒0.1% or better. YokogawaŌĆÖs DPharp-based transmitters, with accuracy figures down near ┬▒0.04% and long-term stability of about ┬▒0.1% of URL over a decade or more, are positioned squarely at the high-performance end. In power applications, that level of accuracy allows you to narrow control bands and still keep trip limits safely away from equipment design boundaries.

Output and communication compatibility come next. Traditional 4ŌĆō20 mA analog with HART remains the default in most plants and is fully supported by YokogawaŌĆÖs EJA and EJX series. FOUNDATION Fieldbus and PROFIBUS PA are available where plants have standardized on digital fieldbuses. The key is to ensure that your chosen transmitter protocol aligns with your DCS or PLC capabilities. DGFG notes that modern smart transmitters bring advanced diagnostics and remote configuration, but those features only deliver value if your host system can interpret and use them.

Environmental and mechanical considerations must also be checked. ESI and Plant Automation Technology highlight media compatibility, enclosure ratings, explosion-proof or intrinsically safe certifications, and mounting constraints. Ye┼¤il Grup Enerji lists stainless steel and optional exotic alloys such as Hastelloy or Monel in YokogawaŌĆÖs portfolio, ingress protection ratings of IP66 or IP67 with optional IP68, and operating ambient temperatures down to about ŌłÆ40 ┬░F and up to about 185 ┬░F. When specifying transmitters for boiler houses or turbine halls, verify that those ratings align with actual field conditions, particularly near hot equipment where radiant heat can push ambient temperatures high.

Finally, consider vendor and support factors. A veteran contributor on Control.com argues that transmitter selection is really about choosing a long-term relationship with a vendor, not buying a commodity part. They recommend evaluating how easily you can access datasheets, manuals, and troubleshooting guides, and how responsive the vendor is on technical forums. YokogawaŌĆÖs strong documentation, the FieldMate configuration suite, and explicit support for on-line diagnostics fit well with that reliability mindset.

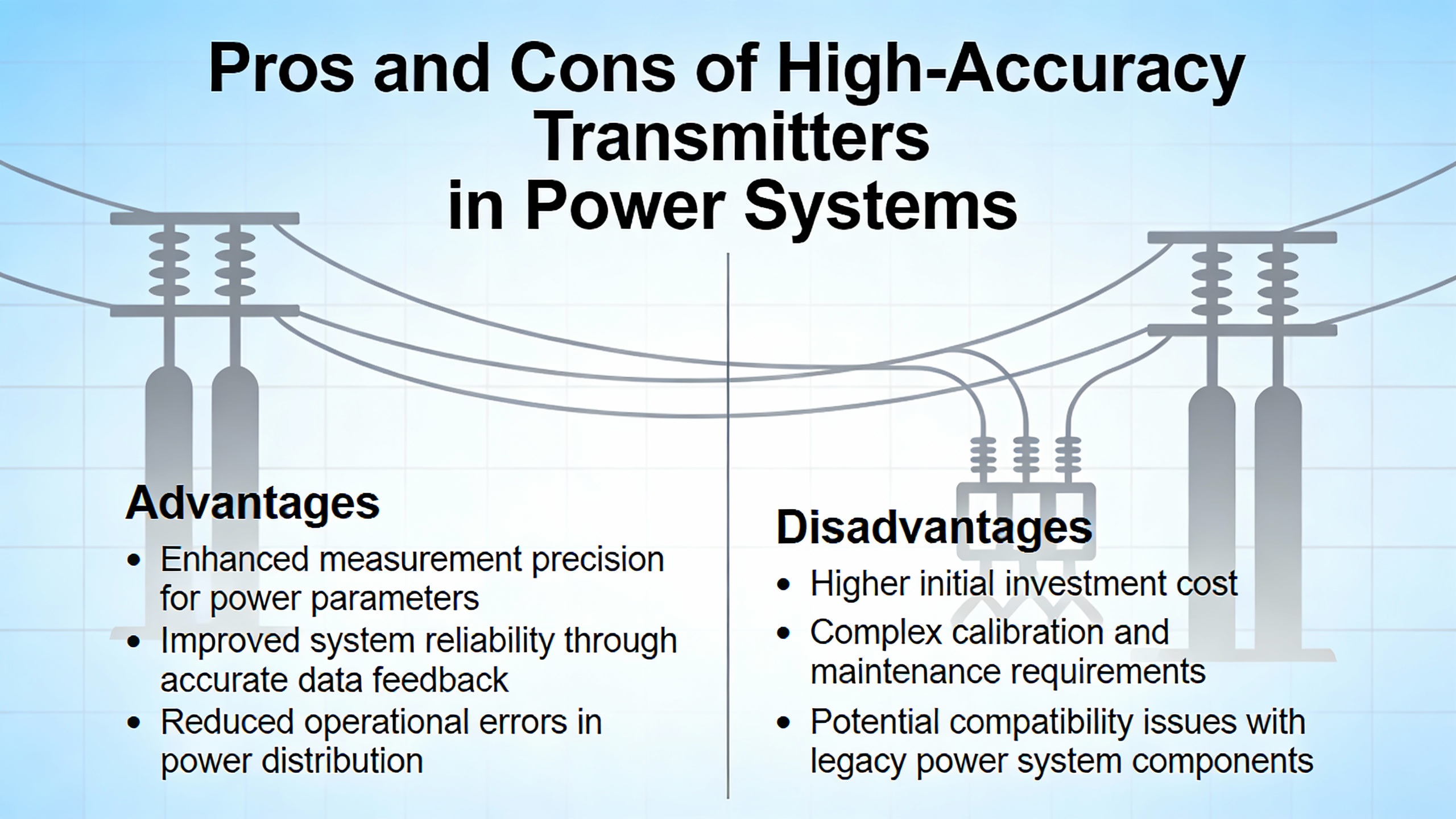

High-performance transmitters like YokogawaŌĆÖs DPharp-based series bring tangible benefits for power and industrial users, but they also introduce considerations you should acknowledge.

On the positive side, accuracy and stability are obvious strengths. With reference accuracies around ┬▒0.04% and long-term stability near ┬▒0.1% of URL over a decade or more, you can design loops with tighter bands and extend calibration intervals. YokogawaŌĆÖs own analysis suggests that such stability can reduce maintenance costs by up to roughly one third over the long term by cutting back on calibration frequency. In systems where every instrument removal requires confined-space permits or scaffolding, that is a non-trivial saving.

Diagnostics and safety are another major advantage. The active digital DPharp sensor, continuous self-diagnostics, and Back-check Technology together provide fast detection of sensor failures or internal inconsistencies. Combined with SIL2 and SIL3 certifications verified by independent bodies, that makes these transmitters suitable for both control and safety functions, reducing the number of different device types you must qualify and maintain.

Mechanical robustness and environmental ratings add to reliability. Features such as four-bolt pressure-retaining designs, dual seals certified to ANSI/ISA standards, IP67 or higher enclosures, and verified vibration resistance support long lifetimes in harsh environments like boiler rooms and turbine basements.

There are trade-offs. High-accuracy, feature-rich transmitters typically come with higher initial purchase costs compared with basic devices, and their digital capabilities require technicians who are comfortable with advanced diagnostics and configuration tools. In non-critical loops, the full performance envelope may not be justified. Also, the very precision that makes these instruments attractive can be undermined if installation practices neglect impulse line design, temperature management, or static pressure effects. In other words, you must treat the installation as a system if you want datasheet performance in the field.

From the perspective of a power system reliability advisor, the balance tends to favor high-performance transmitters on loops whose failure would trip turbines, damage boilers, compromise safety systems, or destabilize major process units that feed your UPS and distribution systems. For low-consequence services, general-purpose transmitters may remain adequate.

Yokogawa specifies long-term stability for its DPharp-based transmitters on the order of ┬▒0.1% of URL over periods up to about 10 to 15 years, and companies like Fuji Electric note that high stability can justify extended calibration intervals. At the same time, PMC and Solinst both emphasize that datasheet stability figures are based on controlled conditions, while real-world drift depends on temperature cycles, overpressure events, and mechanical stress.

In practice, many plants start with conservative calibration intervals such as one year for critical loops and two years for non-critical loops. After collecting historical data and seeing how little a stable transmitter drifts, they may extend intervals in a controlled way. With a DPharp transmitter that consistently shows negligible drift, it is reasonable to stretch intervals to several years, provided your quality system and risk assessment support that decision.

Instrumentation guides from ESI, DGFG, and PMC suggest aligning sensor accuracy with process requirements rather than automatically selecting the tightest spec. For general monitoring, ┬▒0.5% of full scale is often sufficient. For custody transfer, emissions-related flow, and trip-critical loops where process limits are tight, higher accuracy pays off.

A transmitter like the EJA110E, with optional accuracy around ┬▒0.04%, is particularly valuable where small pressure variations directly translate into fuel, steam, or product quality deviations, or where tighter accuracy allows you to reduce safety margins without approaching equipment limits. For instance, in a fuel gas flow transmitter feeding a turbine, higher DP accuracy means your energy accounting is closer to reality and your combustion control can run nearer to the ideal stoichiometry.

YokogawaŌĆÖs DPharp differential pressure transmitters can measure both differential and static pressure simultaneously. DPharp documentation notes that this multi-sensing capability can replace separate DP and gauge transmitters in many applications. The static measurement helps in several ways. In DP flow measurement, static pressure is used to calculate density and correct volumetric flow to mass flow. It also helps diagnose issues like plugged impulse lines or changing fluid properties.

If your application involves compressible flow, such as natural gas to a turbine or gas to burners, or if you want deeper diagnostics on flow profiles, then a multi-sensing DP transmitter that provides both DP and static pressure is worth considering. You reduce hardware count, simplify installation, and enhance diagnostic capability, which all support better reliability.

For power and industrial operators who care about uptime as much as nameplate efficiency, the accuracy and performance data behind YokogawaŌĆÖs pressure transmitters are not abstract marketing values. They are design inputs that determine how tightly you can control critical processes, how often your technicians must recalibrate instruments in difficult locations, and how confidently your safety systems act on pressure data. By understanding how Yokogawa defines accuracy, how the DPharp platform maintains it over time, and how environmental factors affect real-world performance, you can deploy these transmitters where they matter most and ensure that your UPS, inverters, and protection systems are defending a process that is stable by design, not just by reaction.

Leave Your Comment