-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Industrial and commercial power systems live or die on reliability. You can have bulletproof UPS architectures, well-specified inverters, and clean power quality, and still lose a line or a data hall because a compressor quietly failed. Compressed air, refrigeration, and chilled water compressors sit in the background of most facilities, feeding HVAC systems, clean rooms, production tooling, and even critical food or pharmaceutical storage. When one of these machines goes down unexpectedly, everything it supports quickly follows.

From a power system specialistŌĆÖs point of view, that makes compressor health a reliability concern on the same level as switchgear or UPS batteries. The difference is that compressors almost always give you a mechanical early warning, and vibration sensors are the most reliable way to hear it. Across sources such as Blackhawk Equipment, Fluke, Metrix Vibration, MDPI, and others, the consensus is clear: vibration-based condition monitoring is one of the highestŌĆæROI tools you can deploy on critical rotating and reciprocating machinery, and compressors are prime candidates.

This article walks through why vibration sensors matter for compressors, what they actually see, how to choose the right sensing technology, and how to build a practical monitoring program that feeds your maintenance and power reliability strategy instead of drowning you in data.

Condition monitoring research summarized by MDPI defines monitoring as the systematic observation of system behavior and maintenance as the actions that keep equipment in good condition. When you combine the two in a predictive maintenance strategy, you cut unplanned downtime and catastrophic failures. Compressors are a textbook fit for this approach.

In a case study from enDAQ, the Greater Boston Food Bank runs a 117,000 sq ft warehouse that handled over 60.7 million lb of food in a single year. RoofŌĆæmounted compressors keep refrigerated and freezer bays cold. If those compressors fail, product loss and service disruption ripple across 190 cities and towns. That is not just an HVAC nuisance; it is a systemic risk, just like a UPS failure in a data center. UpKeep similarly notes that compressors in HVAC systems, clean rooms, and industrial environments are so critical that vibration sensors are used as a ŌĆ£constant set of eyesŌĆØ feeding alerts into a CMMS whenever motion goes out of bounds.

The economics support taking compressor health seriously. F7i highlights that unplanned downtime in manufacturing frequently costs tens to hundreds of thousands of dollars per hour. Metrix walks through a concrete example: in a 150 MW combined-cycle gas plant with a margin of about $45 per MWh, a single hour of unscheduled outage costs roughly $6,750, and one full day costs about $162,000 in lost margin alone. Even when the failure only clips plant capacity by 20 percent, Metrix shows that you are still losing around $32,400 per day. Those figures were calculated for pumps and motors, but the same reasoning applies to compressors when they limit throughput, chilled-water capacity, or the operation of critical spaces.

For power system engineers and reliability managers, the key point is simple. Even if your electrical protection, UPS, and backup generation are flawless, a compressor failure can still take the plant down. Vibration monitoring is about shifting that risk away from FridayŌĆænight emergencies and toward planned interventions while the lights stay on.

Blackhawk Equipment likens vibration analysis to an EKG for machines. All rotating and reciprocating machinery vibrates. Even a brandŌĆænew compressor has a natural vibration signature that is normal and healthy. Over time, subtle changes in that signature reveal wear, looseness, or damage long before the machine starts to scream audibly, heat up, or trip on protection.

Across Blackhawk, Viking Analytics, MDPI, and Tractian, three core aspects of vibration show up repeatedly.

First, amplitude describes how intense the vibration is. Rising amplitude at particular frequencies is often the clearest sign that a fault is progressing. Second, frequency tells you how often the vibration cycles per second; that is the diagnostic key because different faults excite characteristic frequencies. A motor running around 1,800 RPM typically shows a fundamental near 30 Hz, and specific faults produce peaks at multiples or fractions of that running speed. Third, direction matters. Measuring vibration horizontally, vertically, and axially (along the shaft) helps separate, for example, an unbalance issue from misalignment.

Tractian also emphasizes the pattern in time. Harmonic patterns often point toward unbalance or misalignment, periodic bursts reflect recurring issues within the machine cycle, random patterns can signal structural weaknesses or cavitation, and transient events are brief spikes that may mark an incipient problem or an operational upset.

Under the hood, accelerometers or proximity probes convert mechanical motion into electrical signals. These are processed using techniques described in the MDPI review: FFT to identify frequency content, envelope analysis to expose highŌĆæfrequency bearing or gear faults, and more advanced methods like wavelets and machine learning to detect subtle anomalies. The critical theme is that vibration provides an early indicator along the potentialŌĆætoŌĆæfunctional failure (PŌĆōF) curve discussed by both Fluke and F7i, often months before a compressor can no longer do its job.

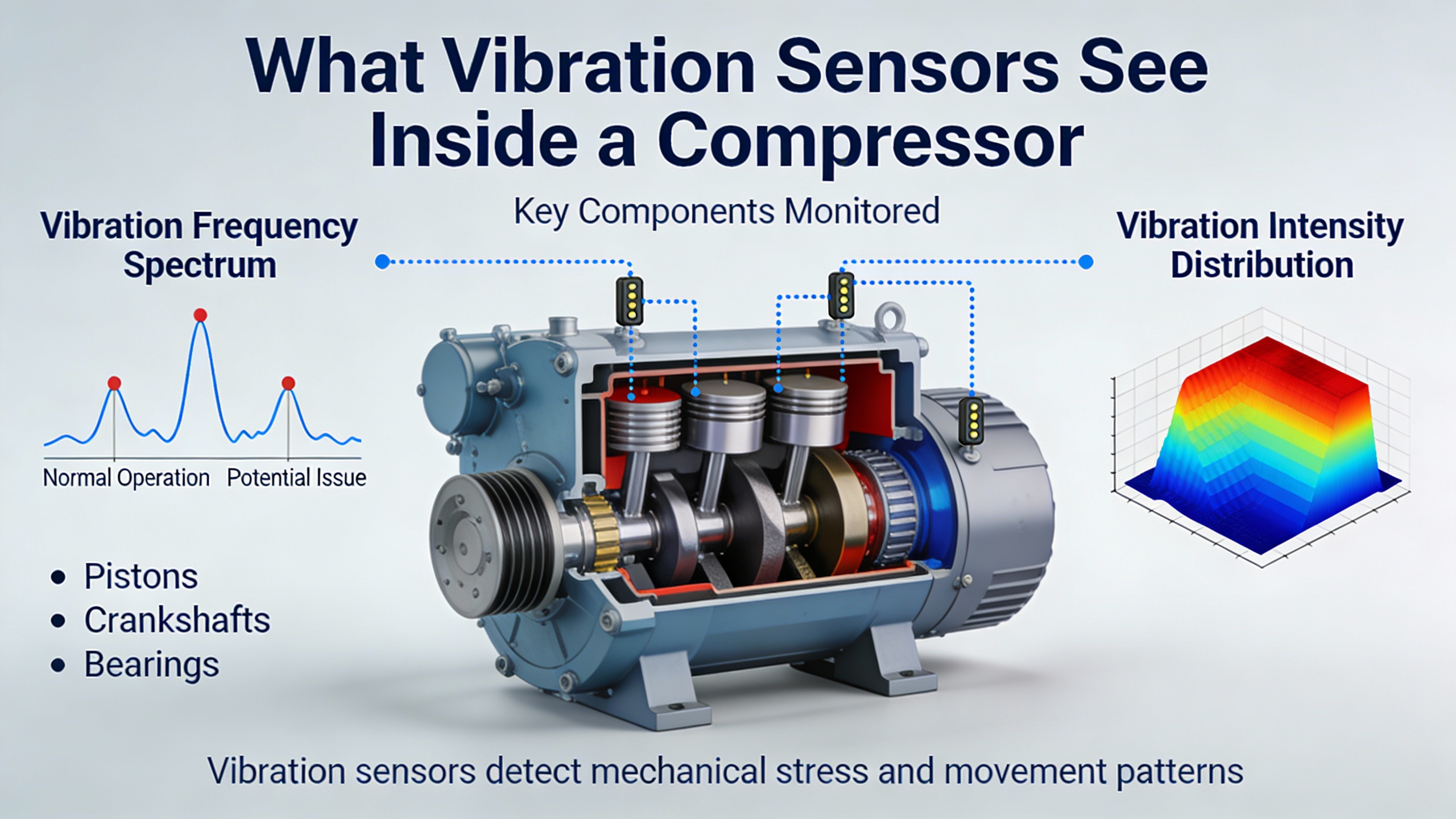

The enDAQ study on the Greater Boston Food BankŌĆÖs warehouse compressors is a useful realŌĆæworld illustration. Engineers mounted four highŌĆæspeed vibration sensors on a compressor cover and recorded 30 minutes of data per run, with acquisition rates up to about 20 kHz. Even though the compressor visibly and audibly shook, measured acceleration on the cover was only about ┬▒5 g because the dominant vibration was at low frequency.

Frequency analysis revealed a fundamental near 30 Hz, corresponding to roughly 1,800 RPM, with strong harmonics at 60 Hz and higher. That harmonic structure indicated asymmetric excitation from the reciprocating motion inside the compressor. Spectrograms showed a very lowŌĆæfrequency modulation near 1 Hz, likely tied to control behavior or fluid dynamics. Vibrations in the X and Y directions emphasized different resonances around a few hundred hertz, reflecting how the compressor casing and mounting structure amplified certain harmonics.

The lesson here, which aligns with MDPI and Viking Analytics, is that what might look like ŌĆ£noiseŌĆØ in broadband vibration is actually a fingerprint of the internal state of the machine. Oil viscosity, bearing condition, gasket behavior, and structural stiffness all leave their imprint on the harmonic content and resonances. Once you capture a baseline when the compressor is healthy, you can track changes over time and see faults evolving long before a technician could detect them by touch or sound.

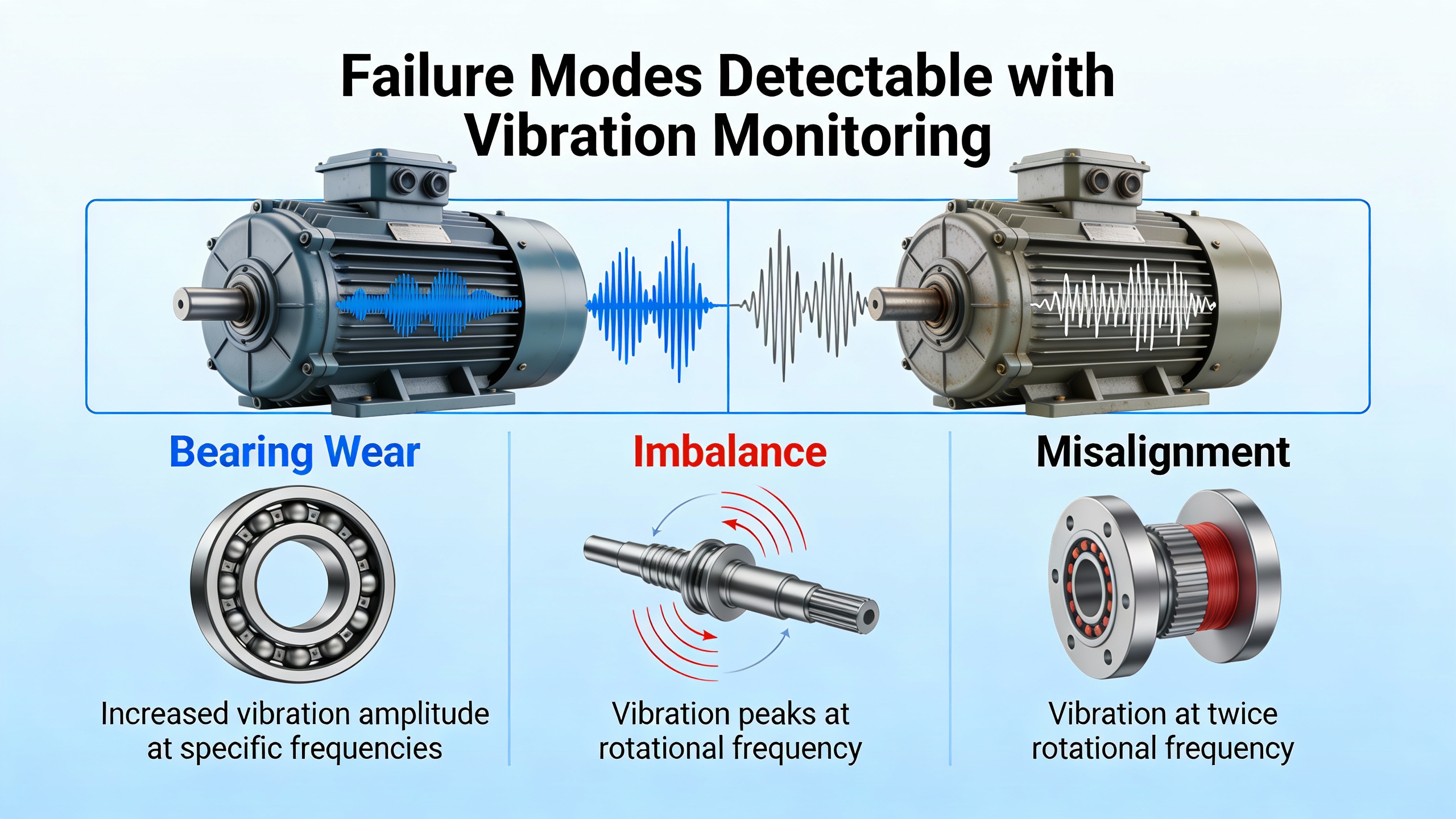

Every major source agrees that vibration is one of the most reliable early warning systems for mechanical failure. Blackhawk, Fluke, Viking Analytics, UpKeep, and Metrix all describe similar fault families that show up on compressors.

For rotating screw and centrifugal compressors, common issues include unbalance, misalignment, looseness, bearing wear, and processŌĆærelated problems like cavitation or flow turbulence. Blackhawk notes that unbalance typically presents as a strong vibration peak at exactly the running speed. Misalignment between motor and compressor shafts tends to generate a significant peak at twice running speed, often with large axial vibration. Mechanical looseness frequently appears as multiple harmonics of running speed, with peaks at one, two, three, and higher multiples.

Bearing defects are where vibration delivers its biggest returns. Blackhawk highlights that microscopic flaws on bearing races or rolling elements create very highŌĆæfrequency, lowŌĆæamplitude signals long before there is any heat or audible noise. F7i connects this to the PŌĆōF curve: bearing and gear faults produce highŌĆæfrequency signatures earliest, giving you the longest planning window. Using envelope analysis and highŌĆæfrequency response sensors, you can often detect these issues months in advance and schedule replacements in a controlled outage instead of waiting for a seizure.

Cavitation and flow turbulence in compressor stages, similar to pump behavior described by Blackhawk and Metrix, create broadband, random vibration and can excite structural resonances. If you are trending vibration over time, a rise in this broadband energy under the same process conditions is a strong clue that net positive suction head or valve conditions are deteriorating.

Reciprocating compressors deserve special attention because their vibration behavior is fundamentally different from smoothŌĆærunning rotating machines. Prognost points out that they have some of the highest damage rates among processŌĆæcritical equipment, yet many units still rely on protection schemes designed for centrifugal machines. By nature, reciprocating compressor frames shake and bend; high frame vibration in itself is not unusual and cannot be treated the same way as on a pump or fan.

API 670, as cited by Prognost, formally established crosshead acceleration as a safety shutdown parameter for reciprocating compressors. The crosshead converts crankshaft rotation into linear piston motion, and mounting acceleration sensors on the crosshead slide gives a direct view of the critical dynamic forces. Under healthy conditions, crosshead acceleration shows a smooth waveform with two distinct impact events per cycle at rodŌĆæload reversal points. Changes in this pattern reveal problems such as wristŌĆæpin issues, crosshead bearing wear, loose connections between crosshead, piston rod, and piston, or even liquid slugging.

Prognost and Metrix both argue that acceleration is the earliest and most sensitive parameter, ahead of velocity or displacement, for detecting emerging faults. Frame velocity and piston rod position (ŌĆ£rod dropŌĆØ) still have value, especially for foundation issues and rider band wear, but they should be treated as secondary layers rather than the primary protective variable.

Metrix proposes a practical priority list for reciprocating compressor sensors: impact or acceleration sensors on each crosshead, rod drop and rod vibration monitoring at each cylinder packing gland, and crankcase velocity sensors at opposite ends of the frame. A minimum conditionŌĆæbased maintenance suite would include crosshead impact monitoring, two velocity sensors on the crankcase, and rod position monitoring, feeding either a protection system or a dedicated monitoring platform.

A case study from USA Dynamics brings this to life. In a diesel hydrotreating unit, their COMPACS realŌĆætime monitoring system combined acceleration sensors on each cylinder, rod drop sensors, and phaseŌĆæsynchronized tachosensors. On November 10, 2024, the system detected an abnormal downward trend and a sudden spike in piston rod drop on compresssor CŌĆæ101B, indicating a developing fracture in the rod and generating an alert in real time. PhaseŌĆæsynchronized vibration analysis tied the anomaly to specific crank angles. Root cause analysis pointed to a piston rod fracture, influenced by valve malfunction and operating modes that did not match the compressorŌĆÖs design valves. That combination of vibration and rodŌĆæposition sensing allowed maintenance teams to intervene based on measured trends rather than waiting for a catastrophic break, and USA Dynamics reports that such systems can reduce downtime and maintenance costs severalfold.

The takeaway for reliability engineers is that compressor type drives sensor strategy. You cannot treat a highŌĆæspeed rotary screw the same way as a slow, highŌĆæforce reciprocating machine and expect protection to be dependable.

A recurring theme in F7iŌĆÖs guidance is ŌĆ£Garbage In, Garbage Out.ŌĆØ If the sensors feeding your analytics cannot see the relevant frequencies or amplitudes, even the best AI or CMMS integration will miss failures or generate false alarms. Several sources, including F7i, RS Components, MDPI, Prognost, Metrix, AssetWatch, and Tractian, outline the main sensor families.

The following table summarizes the most common options in compressor applications.

| Sensor type | Key strengths | Typical compressor use |

|---|---|---|

| Piezoelectric accelerometer | Very wide frequency range, high sensitivity, robust industrial packaging; ideal for highŌĆæfrequency fault detection | Critical highŌĆæspeed compressors, bearings where early fault detection is essential |

| MEMS accelerometer | Low cost, small size, low power, excellent at lowŌĆæfrequency and even DC measurements, often integrated in wireless nodes | Broad coverage on balanceŌĆæofŌĆæplant compressors, HVAC and utility compressors in large fleets |

| Proximity/rodŌĆædrop probe | NonŌĆæcontact displacement measurement of shaft or rod position; excellent for journal bearings and rod bending | Reciprocating compressors with crosshead and piston rods, highŌĆæspeed turbomachinery |

| Triaxial wireless node | Simultaneous X, Y, Z monitoring, often using integrated MEMS, with wireless backhaul and builtŌĆæin analytics | Condition monitoring programs that need scalable, quickŌĆæinstall coverage across multiple compressors |

Piezoelectric accelerometers, as described by F7i and RS Components, use stressed crystals to generate charge proportional to acceleration. They provide extremely wide frequency response, high dynamic range, and rugged packaging, making them the workhorse for critical machines where early detection of highŌĆæfrequency bearing or gear mesh faults matters. The tradeoff is cost and the need for highŌĆæquality cabling.

MEMS accelerometers use micromachined proof masses and capacitive sensing. They are cheaper, smaller, and lower power, and they excel at lowŌĆæfrequency and even static measurements such as tilt. However, F7i notes that they typically have lower upperŌĆæfrequency limits and higher noise floors, so they are best suited for broad IIoT monitoring of less demanding applications rather than the highestŌĆæfrequency fault detection on your most critical machines. AssetWatch and Tractian both embed MEMS accelerometers in compact, wireless nodes designed for harsh industrial environments with ratings such as IP67, battery power, and cellular or WiŌĆæFi connectivity.

Proximity and rodŌĆædrop probes, highlighted by F7i and Prognost, measure displacement directly. NonŌĆæcontact eddyŌĆæcurrent probes are standard on highŌĆæspeed machines with fluidŌĆæfilm bearings and are recommended or required by API standards for critical turbomachinery. For reciprocating compressors, dynamic rodŌĆæposition measurement enables segmented analysis over the crank angle, which Prognost shows can reveal loose rod connections and impending cracks.

Triaxial sensors, described in detail by AssetWatch, measure acceleration in three directions at once. Compared with singleŌĆæaxis sensors, they capture the full vibration vector in a single reading and make continuous monitoring more scalable. AssetWatch emphasizes that rich triaxial data improves lowŌĆæspeed fault detection and supports better diagnosis of imbalance, misalignment, looseness, and bearing wear.

Beyond sensor type, F7i stresses that frequency response is the single most critical spec. If the faultŌĆÖs dominant frequencies lie outside the sensorŌĆÖs usable range, the fault is effectively invisible. A rule of thumb from their guidance is to choose a sensor whose maximum frequency is at least three to four times the highest fault frequency you care about. As an example, consider a motor at about 1,780 RPM, which is roughly 30 Hz. If an outerŌĆærace bearing fault is expected around 160 Hz, the sensor should handle at least about 640 Hz. Standard industrial accelerometers in the 1,000ŌĆō5,000 Hz range easily satisfy that requirement and leave room for harmonics and sidebands.

Sensitivity, typically expressed in mV per g, also matters. F7i notes that 100 mV/g is a common generalŌĆæpurpose choice for machinery above roughly 600 RPM, balancing strong signal levels with adequate dynamic range. Higher sensitivities such as 500 mV/g are reserved for very lowŌĆæamplitude vibrations.

From a compressorŌĆæfocused perspective, piezoelectric accelerometers make sense on your most critical units where early bearing and gear fault detection is nonŌĆænegotiable, especially on highŌĆæspeed screws and centrifugal stages. MEMSŌĆæbased wireless nodes are ideal for creating a wide safety net across HVAC and utility compressors, or as an economical first step for facilities moving from runŌĆætoŌĆæfailure toward predictive maintenance. On reciprocating compressors, combine crosshead acceleration with rodŌĆædrop and rodŌĆævibration probes, as recommended by Prognost and Metrix, and consider adding frame velocity transmitters when foundation issues or highŌĆæenergy impacts must be captured.

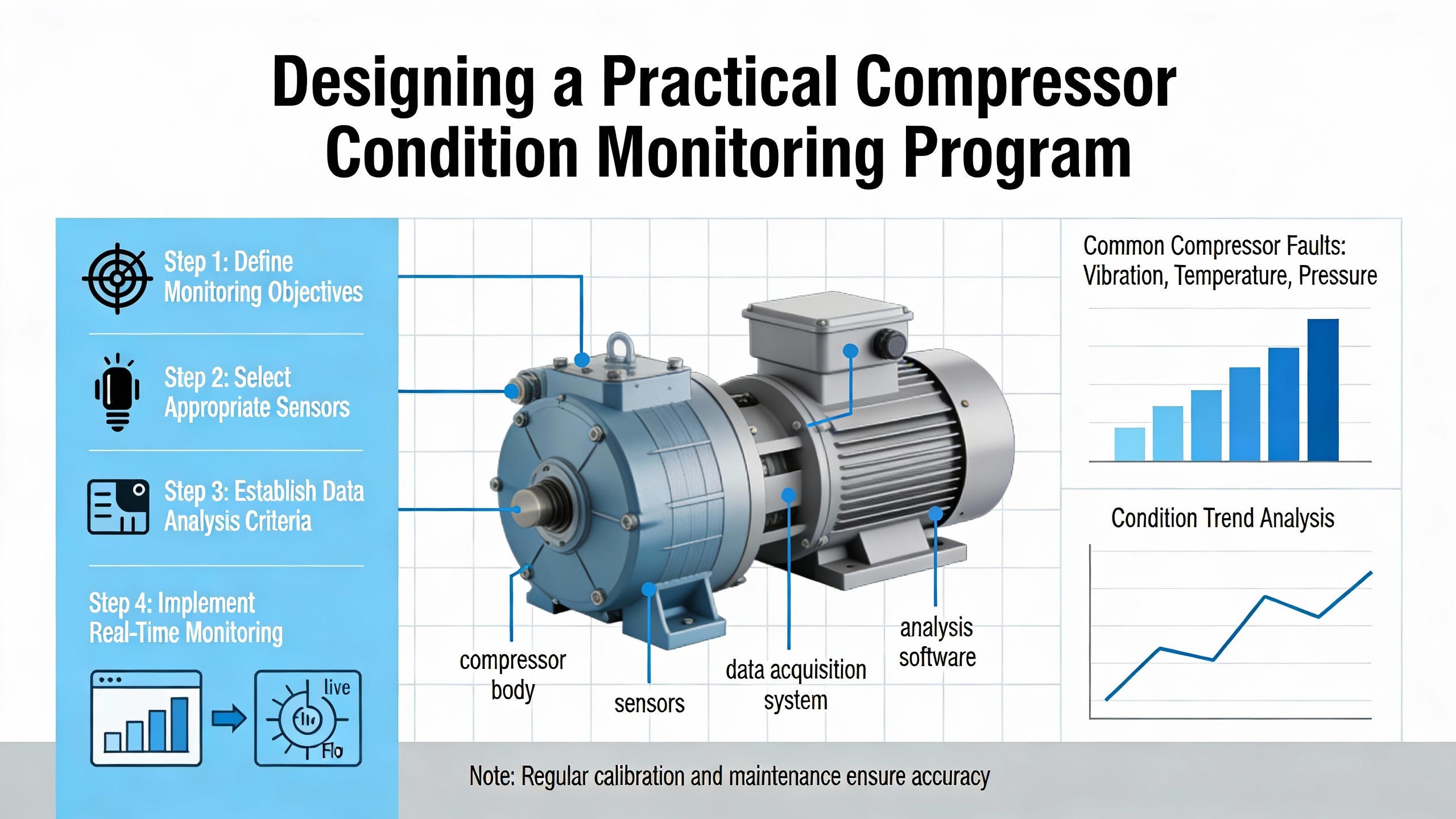

Choosing sensors is only half the problem. The other half is designing a program that delivers actionable decisions instead of dashboards nobody trusts. Blackhawk, Fluke, Balluff, Viking Analytics, Augury, UpKeep, Metrix, and MDPI all provide aligned guidance on what works in practice.

Blackhawk and Balluff both emphasize that you do not need to monitor every machine from day one. Start with compressors whose failure would cause the largest impact on safety, production, quality, or power system stability. That usually means main air compressors feeding production tools, refrigeration compressors in cold chains, HVAC compressors for critical control rooms, and large reciprocating compressors in process units.

UpKeep cites research suggesting that about 90 percent of machinery can benefit from condition monitoring, but a pragmatic rollŌĆæout still begins with a subset. At the same time, Balluff advises thinking in terms of failure modes, not just asset lists. For a critical compressor, list out how it can fail: bearing wear, valve failures, rod fractures, lubrication loss, cavitation, or control malfunctions. That drives which parameters you need to measure. Vibration is excellent for mechanical faults, but in some cases you may also want pressure, flow, temperature, or humidity sensors to get a full picture.

Once you have selected a compressor, the next step is instrumentation and baseline capture. FlukeŌĆÖs fiveŌĆæstep method for adding condition monitoring with vibration sensors starts with secure, consistent sensor mounting at defined points and an initial reading under known good conditions. AssetWatch underscores that accurate vibration readings depend heavily on proper mechanical attachment. Sensors should be mounted on clean, flat surfaces with magnets, threaded studs, or epoxy; poor mounting can distort the vibration profile or even allow the sensor to move independently and generate misleading signals.

For rotating compressors, that usually means placing accelerometers at each bearing housing in directions that best represent shaft motion: horizontal and vertical on the drive end and nonŌĆædrive end, with axial on at least one side. For reciprocating machines, follow the hierarchy recommended by Metrix and Prognost by putting sensors on crossheads, rodŌĆædrop locations, and the crankcase.

A baseline is your compressorŌĆÖs fingerprint when it is healthy. Blackhawk recommends capturing this after a machine is installed or rebuilt and known to be in good condition. From then on, you are not just comparing the compressor to generic alarm limits; you are comparing it to its own past self, which improves sensitivity and reduces false positives.

You now face a strategic choice between handheld, routeŌĆæbased readings and continuous wireless monitoring, or some combination. Blackhawk and Fluke describe traditional programs where technicians walk routes with portable data collectors, taking readings at labeled points, then upload data for offline analysis. Viking Analytics notes that experts ideally prefer weekly checks for critical machines, but acknowledges that a realistic minimum is monthly; monitoring less frequently drifts toward runŌĆætoŌĆæfailure.

Continuous wireless systems, as described by Blackhawk, Fluke, Tractian, AssetWatch, and Augury, flip that model on its head. BatteryŌĆæpowered wireless sensors mounted permanently on compressors sample vibration and temperature automatically, then send data via gateways and cloud platforms. This captures transient events that routeŌĆæbased programs miss and makes it feasible to monitor many more assets with the same number of people.

Alarms and thresholds translate raw data into actionable signals. Metrix notes that vibration levels under constant load and speed often follow a normal distribution. One practical approach is to set alert alarms around two standard deviations from the mean and danger alarms around three standard deviations. A shift beyond three standard deviations indicates a meaningful change that justifies investigation. FlukeŌĆÖs work on the PŌĆōF curve reinforces the idea that you should use these thresholds to trigger inspection, planning, and scheduling, not to force immediate shutdown at the first sign of deviation.

In practice, a compressor program might use lower ŌĆ£warningŌĆØ alarms to flag tasks such as lubrication, alignment checks, or valve inspection, and higher ŌĆ£criticalŌĆØ alarms to either trigger trips or demand immediate evaluation by a condition monitoring specialist.

The best vibration system is the one your maintenance and reliability teams actually act on. Augury, UpKeep, AssetWatch, and Tractian all emphasize the value of integrating vibration data with CMMS and EAM systems so alerts can automatically generate work orders, inspections, and tasks.

AssetWatch describes a model where AI analyzes triaxial vibration data in the cloud, learns what ŌĆ£normalŌĆØ looks like, and highlights only anomalies that matter. Human experts with advanced certification then review these alerts, add context about operating modes and layout, and issue clear, prescriptive recommendations. Augury reports similar practices, positioning vibration monitoring systems as enablers of higherŌĆævalue maintenance work rather than replacements for human expertise.

From a business standpoint, MetrixŌĆÖs cost example offers a straightforward way to justify investment. If a monitoring system on a critical compressor can prevent even a single day of unplanned downtime within a threeŌĆæyear period in a plant where a day of lost production is worth six figures, the system has paid for itself. That logic is often easier for leadership to accept than abstract discussions about ŌĆ£dataŌĆØ or ŌĆ£AI.ŌĆØ

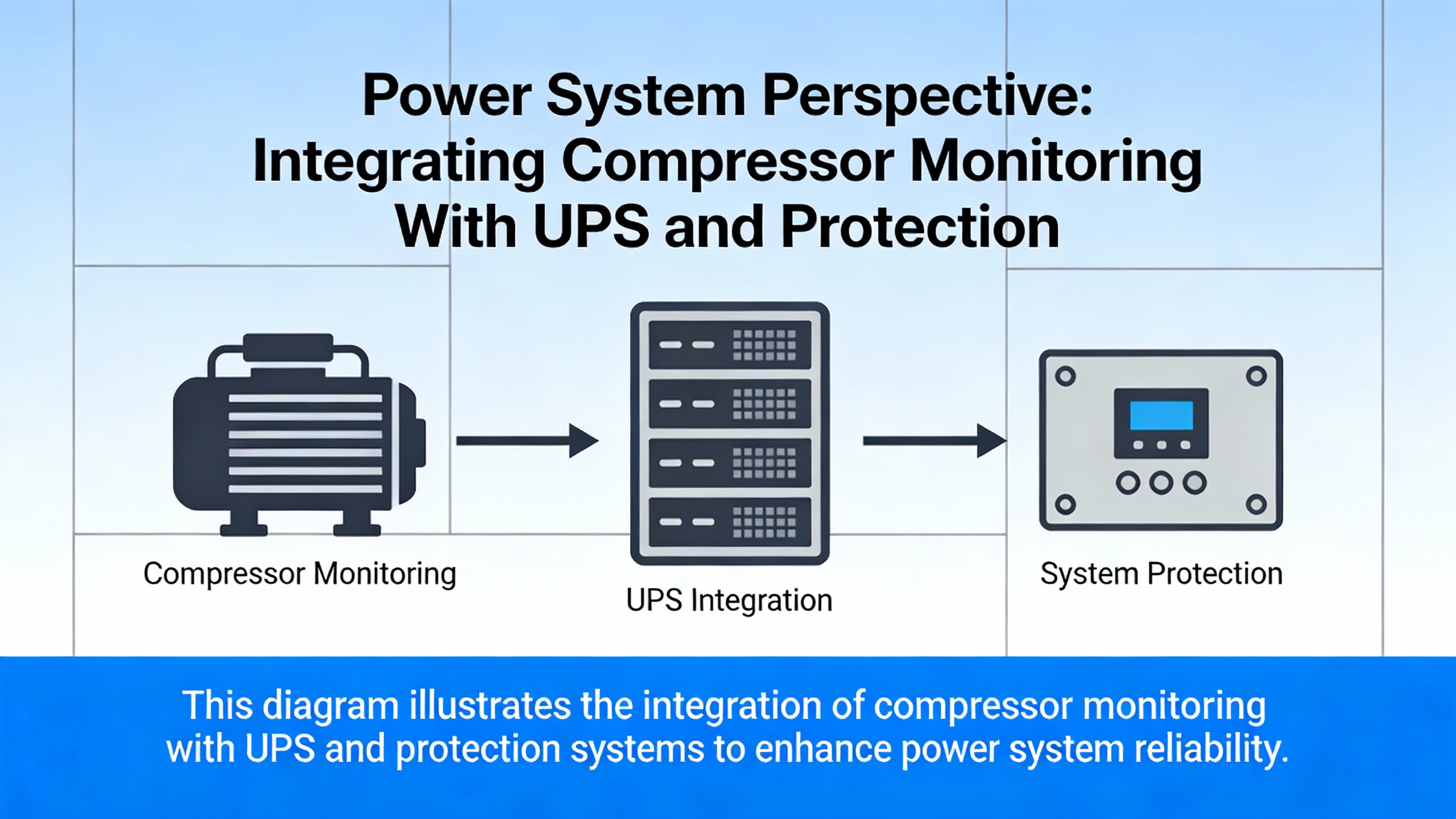

For a power system specialist, compressors are part of the reliability chain, not just mechanical utilities. UpKeep highlights how compressors underpin HVAC systems, clean rooms, and other controlled environments. In many facilities, those environments house switchgear, drives, UPS systems, and inverters that themselves have strict thermal limits. If compressor failures compromise cooling or air quality, electrical reliability suffers even if the grid and backup generation remain perfectly healthy.

This is where vibrationŌĆæbased condition monitoring dovetails with power system design. When you know that a primary chiller or air compressor is developing bearing faults or valve problems weeks in advance, you can schedule repairs during windows when electrical risk is low. You can also coordinate derating plans for UPS and drives if you anticipate reduced cooling capacity.

Wireless vibration systems described by Fluke, AssetWatch, and Tractian typically send data over WiŌĆæFi or cellular networks to cloud platforms. For critical compressors, it is worth ensuring that gateways, network hardware, and at least part of the sensor infrastructure are backed by UPS power so that monitoring continues through utility disturbances. That way, you can correlate mechanical stress eventsŌĆösuch as hard starts after sags or transfer eventsŌĆöwith vibration changes and adjust protection or operating practices accordingly.

From a protection and power quality perspective, this integration supports a more holistic reliability strategy, where mechanical condition and electrical health inform each other instead of living in separate silos.

Several sources warn that condition monitoring programs often fail not because sensors are bad, but because the programŌĆÖs design is incomplete. Balluff observes that many customers treat vibration analysis as their only condition monitoring method, ignoring other parameters like pressure, temperature, level, and humidity that directly tie to certain failure modes. On compressors, that can lead to blind spots. For instance, a worn pump or compressor can exhibit pressure and flow changes before significant vibration changes, as BalluffŌĆÖs air compressor example shows.

Viking Analytics and MDPI highlight another challenge: data overload and complex signal interpretation. Vibration signals are composed of many overlapping sources, and without good baselines, clear alarm strategies, and appropriate software, teams can be overwhelmed by alarms that do not translate into actionable decisions. Starting with a pilot on a few critical compressors, as recommended by Fluke and Balluff, allows you to tune thresholds and workflows before scaling.

Sensor installation quality is a recurring pitfall. The enDAQ compressor study demonstrated how mounting a sensor on a raised cover with doubleŌĆæsided tape can introduce its own resonances, behaving like a spring and altering observed harmonics. AssetWatch stresses the need for proper mounting and loading so that the sensor accurately follows machine motion rather than its own flexible structure.

Finally, both Metrix and Prognost caution against relying solely on frame vibration velocity for reciprocating compressors. Because the frame naturally flexes and vibrates under normal operation, frame velocity alone often fails to detect major failures in time and can cause nuisance trips. A tailored strategy using crosshead acceleration, rodŌĆæposition monitoring, and carefully interpreted frame measurements is essential on those machines.

Blackhawk, Fluke, and Viking Analytics all acknowledge that handheld routeŌĆæbased monitoring can be very effective when done regularly, especially on smaller fleets. Weekly or at least monthly readings at consistent points give you a reasonable trend and can catch most progressing faults. However, continuous wireless monitoring becomes attractive when you have many compressors, remote locations, or highly variable operating conditions. Blackhawk notes that wireless sensors capture transient events routeŌĆæbased checks will miss, and Fluke points out that automated systems can push results to your phone or PC within seconds. In practice, many plants use a hybrid approach: continuous monitoring on the most critical compressors and handheld measurements on others.

The right number depends on compressor type and criticality. For a small rotary compressor in an HVAC system, a single triaxial wireless sensor on the main bearing housing can deliver significant value by tracking overall health and major faults. For larger rotary compressors with separate motor and compressor bearings, it is common to use one or two sensors on each bearing housing to capture horizontal and vertical motion. On reciprocating compressors, field experience compiled by Metrix and Prognost suggests a more comprehensive layout including crosshead acceleration sensors on each throw, rodŌĆæposition probes at each cylinder, and two velocity sensors at the crankcase ends. Rather than chasing a generic ŌĆ£correctŌĆØ number, use the failure modes and criticality of each compressor to drive sensor count.

F7i, MDPI, Tractian, and AssetWatch all indicate that MEMSŌĆæbased wireless sensors can absolutely detect many bearing problems, especially on mediumŌĆæspeed machines and for faults that evolve into midŌĆæfrequency ranges. F7i explains that the key is matching the sensorŌĆÖs frequency range to the fault frequencies you care about and selecting enough bandwidth to capture harmonics. MDPIŌĆÖs review shows that modern signal processing and machine learning can enhance the sensitivity of these sensors, while Tractian and AssetWatch position their wireless MEMS devices as capable of detecting early anomalies and streaming them to analytics engines. For the very earliest stages of highŌĆæfrequency bearing faults on your most critical compressors, piezoelectric accelerometers still have an edge, but wireless MEMS nodes are a powerful and economical way to raise the floor on reliability across a wide fleet.

From a power system and reliability standpoint, treating compressors as monitored, instrumented assets instead of background utilities changes the risk profile of an entire facility. The body of evidence from Blackhawk Equipment, Fluke, Metrix, Prognost, MDPI, and others shows that wellŌĆæchosen vibration sensors, deployed in a disciplined condition monitoring program, routinely convert surprise failures into scheduled work. If you are responsible for keeping both electrons and compressed gas flowing, the next step is straightforward: start with your most critical compressors, instrument them intelligently, wire the data into your maintenance and power strategy, and let the machines tell you how to keep them running.

Leave Your Comment