-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

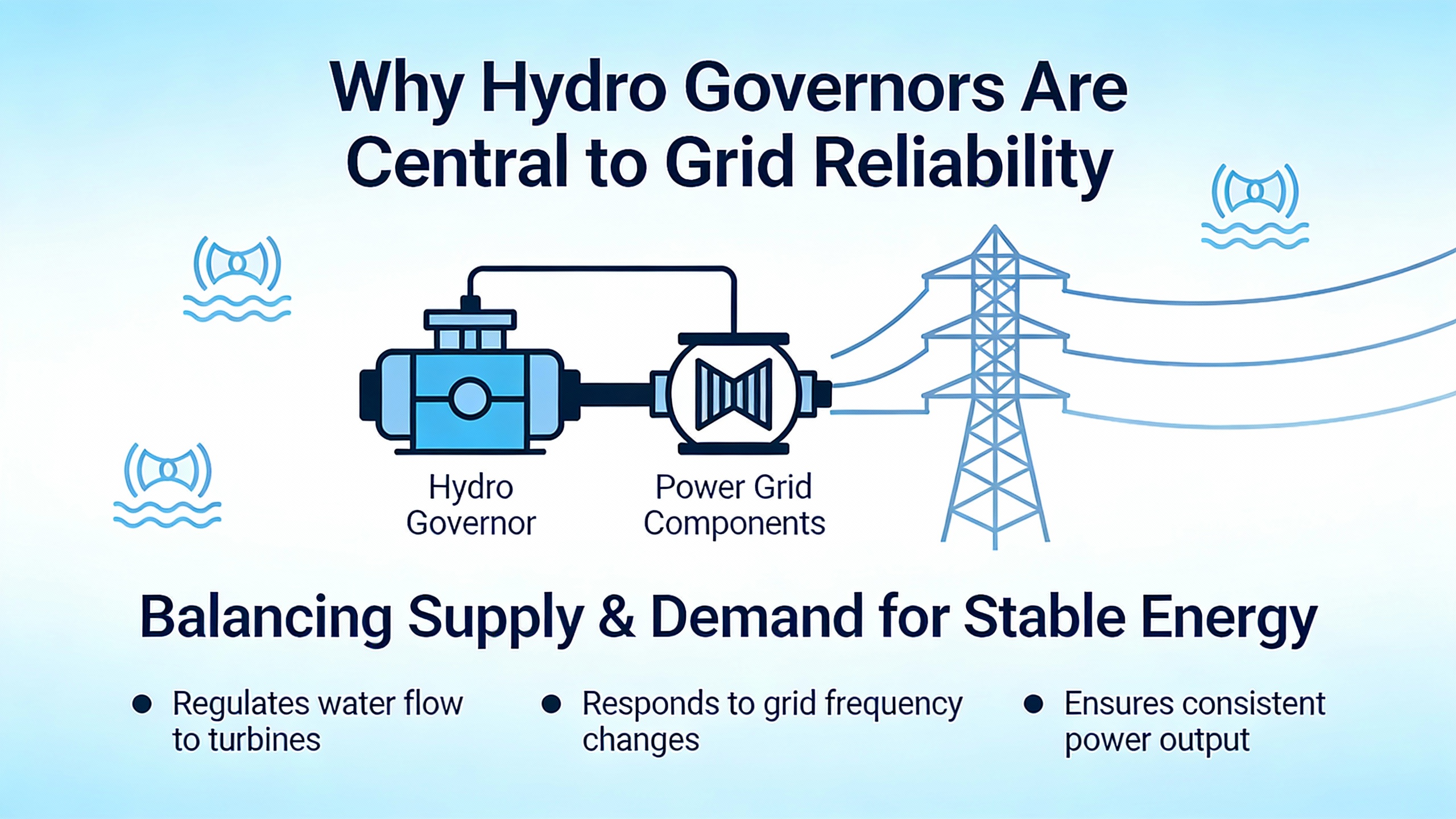

Hydropower supplies roughly 16% of global electricity and remains the largest single renewable source, according to a Petrotech technical case study. In many regions, hydro units are the most controllable generators on the system, providing fast frequency response and flexible load following while wind and solar fluctuate. The device that makes this possible is the turbine governor: a control system that regulates water flow through the turbine to match power output with demand, keep grid frequency stable, and protect highŌĆævalue assets.

From a reliability and power quality standpoint, governor performance is not an abstract control problem. Poorly tuned governors translate directly into frequency excursions, oscillations, and mechanical stress. Those disturbances propagate into industrial and commercial facilities, where sensitive UPS systems, inverters, and process controls have to ride through or disconnect. In my experience, when a site reports frequent UPS transfers or nuisance trips during grid events, it is common to trace at least part of the problem upstream to aggressive or poorly coordinated hydro governor behavior.

Contemporary hydropower optimization literature from Energy Sustainability Directory and Nature Portfolio emphasizes that optimization is no longer just about peak efficiency on a test stand. It is about sustaining efficiency, grid support capability, and asset health over decades in the face of climateŌĆædriven hydrological variability, changing grid codes, and increasingly complex system dynamics. Governor systems sit at the center of that challenge.

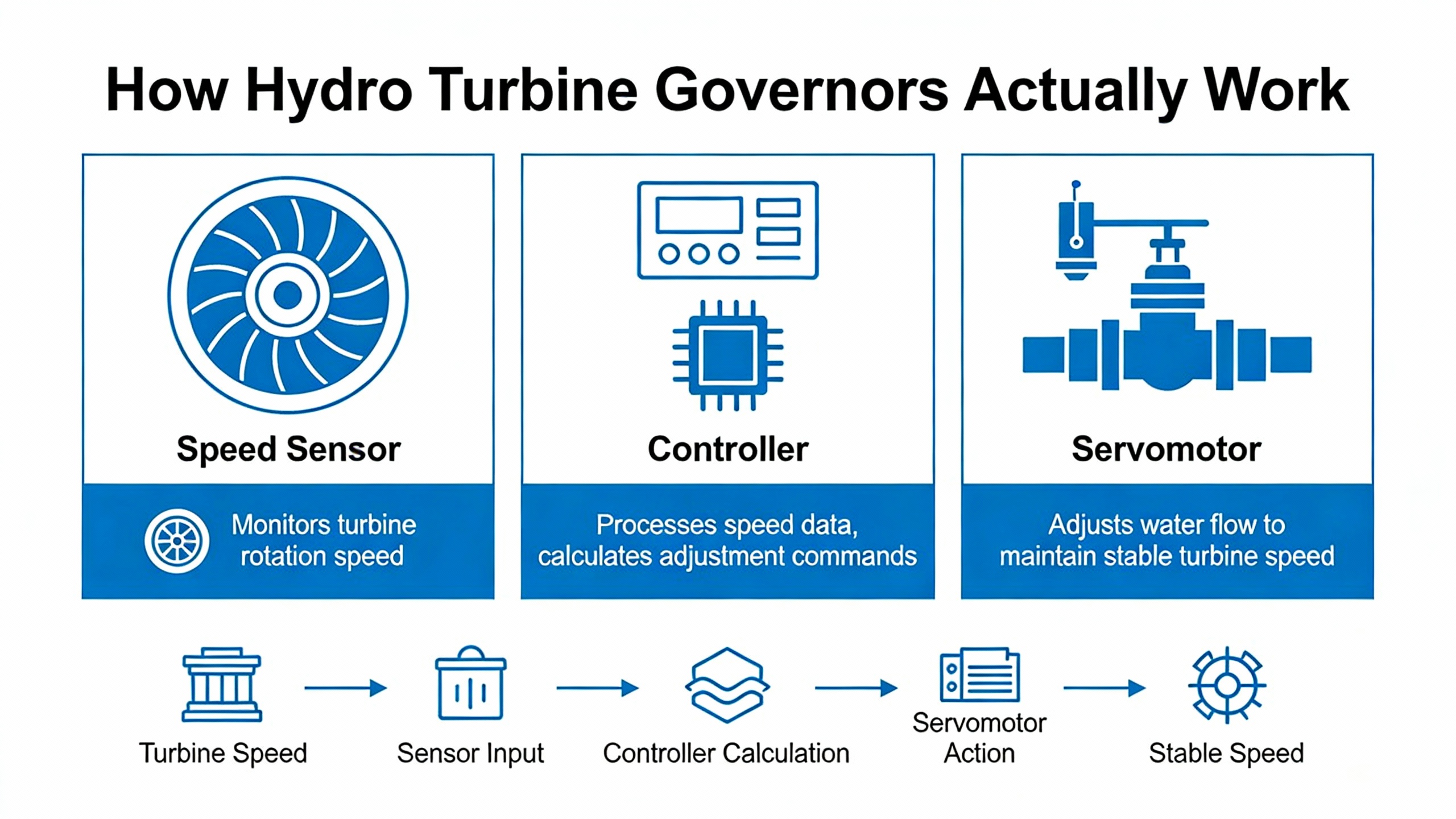

A turbine governor is fundamentally a closedŌĆæloop control system that adjusts water admission to the turbine based on speed and power feedback. In a Petrotech description of turbine load control, the governor continuously monitors head and tailwater levels, flow rates, turbine speed, generator power, and wicket gate positions. Using these inputs, it commands a servoŌĆæhydraulic system that opens or closes the wicket gates (or needle valves in impulse turbines), thereby regulating mechanical torque and generator output.

Hydro.orgŌĆÖs industry guidance on isolated operation highlights the governorŌĆÖs primary role: maintain unit speed so that the generator can synchronize to the grid and then regulate power output while supporting system frequency. Once synchronized, the governor no longer aims for a fixed speed; instead, it uses a speedŌĆōpower characteristic known as droop to deliver primary frequency control.

In classic speedŌĆædroop control, when grid frequency falls below nominal (50 or 60 Hz depending on the system), the governor automatically increases water flow and turbine power. When frequency rises, it reduces power. Petrotech notes typical hydropower settings of about 4% droop, corresponding to approximately a 25% change in turbine power for each 1% change in frequency, and about 5% droop, corresponding to roughly a 20% power change per 1% frequency change. These settings allow multiple units to share frequency regulation proportionally without explicit communication.

From a practical implementation perspective, the core elements of a hydro governor can be summarized as shown below.

| Element | Typical signals or functions | Why it matters for reliability |

|---|---|---|

| Sensing and feedback | Turbine speed, grid frequency, generator power, head and tailwater levels, gate position | Accurate, fast feedback is the foundation for stable control and avoiding hunting or slow response |

| Control algorithm | PID or more advanced controllers implementing droop and compensation | Determines how aggressively the unit responds to frequency deviations and setpoint changes |

| ServoŌĆæhydraulic system | Actuators, servos, and hydraulic power unit to move gates or needles | Physical speed and smoothness of gate movement limit how fast and how cleanly power can be adjusted |

| Operating modes | GridŌĆæconnected droop control, islanded speed control, maintenance and startup modes | Proper mode selection and tuning are essential for safe transitions between Bulk Electric System and islanded |

In an Industrial and Commercial Power Supply context, what matters is that governor response is fast enough to support grid codes and load dynamics, but not so aggressive that it causes oscillations, pressure waves, or overŌĆæcorrection that stress equipment and downstream protection.

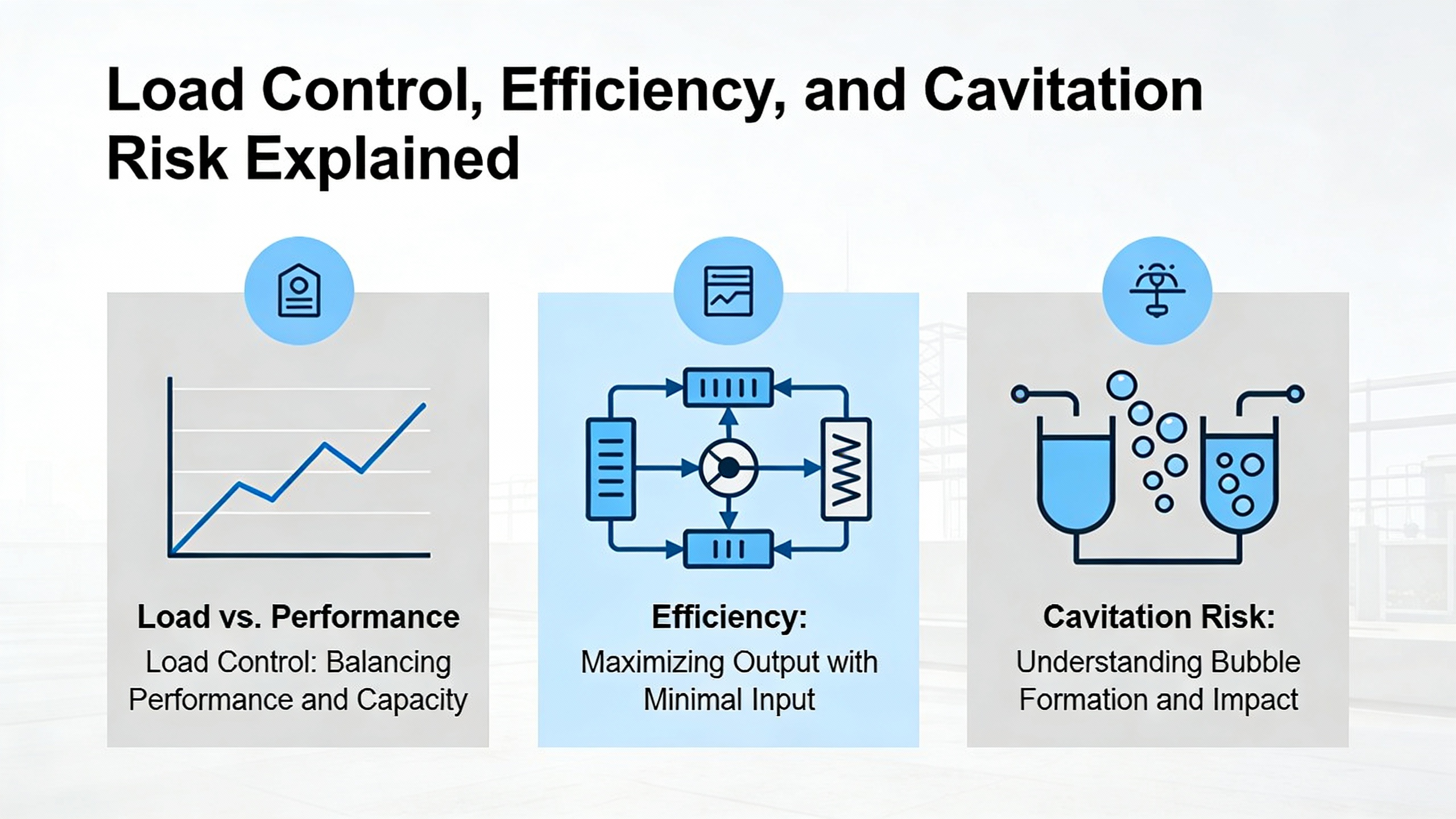

Hydro units are most valuable to the grid when they can modulate power quickly without sacrificing efficiency or damaging the plant. PetrotechŌĆÖs loadŌĆæcontrol analysis stresses that proper load distribution keeps turbines operating near their best efficiency point, typically around 85ŌĆō95% of rated capacity. Francis turbines, in particular, can exceed 90% efficiency and reach up to about 95% under optimal conditions.

However, a hydropower unit is not a simple linear machine. The same source warns that running turbines persistently below roughly 60% of design capacity can lead to cavitation, pressure fluctuations, and mechanical damage. Cavitation not only erodes runners and draftŌĆætube surfaces but also introduces vibration that can propagate into the generator, bearings, and plant structure. A coordinated governor and plantŌĆælevel load control strategy therefore aims to keep units away from this lowŌĆæload regime except during transients.

A simple example illustrates the point. Consider a plant with three identical units rated at 50 MW each, and a demand of 75 MW. If all three units share the load equally, each runs at 25 MW, or 50% of rating, which is below the rough 60% threshold associated with cavitation risk. If instead the plant control system assigns the 75 MW to just two units, each runs at 37.5 MW, or 75% of rating, closer to the 85ŌĆō95% bestŌĆæefficiency band and above the cavitationŌĆærisk zone for extended operation. The governor and Automatic Load Control (ALC) must work together to implement this type of optimal unit commitment and loading in real time.

Broad turbineŌĆæefficiency guidance from Energy Sustainability Directory underlines how control contributes to this outcome. Turbine efficiency, defined as the ratio of useful electrical output to total hydraulic input energy, is highest near the design operating point. Efficiency falls when flow is constrained, when partŌĆæload operation is prolonged, and when startŌĆōstop cycling is frequent. Control systems, including governors and supervisory plant controls, are explicitly cited as major levers for keeping hydro units close to optimal efficiency by adjusting load sharing, setpoints, and operating modes in response to changing river conditions and grid demands.

Most existing hydro governors use proportionalŌĆæintegralŌĆæderivative (PID) controllers combined with droop characteristics to manage speed and power. Petrotech notes that overly aggressive PID tuning can cause continual hunting around setpoints, while overly conservative tuning leads to slow responses to frequency events. Hydro.org likewise emphasizes that droop and PID gains are optimized for specific combinations of unit size and load, and that settings appropriate for an infinitely stiff grid are not necessarily appropriate when a unit or small group of units must regulate an isolated system.

Despite these challenges, wellŌĆætuned PID governors remain workhorses in the industry. They are familiar to operators, relatively straightforward to commission, and adequate when grid conditions are stable, penstocks are short, and hydrology is reasonably predictable. However, as grids become more renewableŌĆæheavy and hydro plants are asked to provide faster and deeper balancing services, the limitations of classical PID control become more apparent.

Research published by Nature describes an improved internal model control (IMC) scheme for hydroŌĆæturbine governing systems that directly targets these limitations. The study focuses on a hydro generator unit connected to an infinite bus and observes that the system exhibits intrinsic oscillatory modes. A conventional singleŌĆædegreeŌĆæofŌĆæfreedom IMC performs well in steady tracking but fails to suppress highŌĆæfrequency oscillations under disturbance. To address this, the authors design a twoŌĆædegreeŌĆæofŌĆæfreedom IMC architecture and replace the standard model inverse with a generalized inverse solver (GIS), improving performance for nonŌĆæminimumŌĆæphase plants.

In stepŌĆæresponse simulations of an isolated hydroŌĆæturbine governing system, the IMC with GIS achieves an overshoot of 0%, undershoot of about 2.07%, and regulation time of roughly 14.32 seconds. These figures outperform traditional IMC and multiple PID tunings, including ZieglerŌĆōNichols, gain and phase margin based designs, particle swarm optimizationŌĆætuned PID, and adaptive PID. Importantly for practical implementation, the IMC with GIS and, to a lesser extent, conventional IMC and adaptive PID, produce smaller controlŌĆæoutput fluctuations, whereas several PID variants generate large initial control shocks that would be unacceptable in real hydro equipment.

The same Nature study goes further and assesses robustness. It varies key nonlinear system parameters, such as the servoŌĆæhydraulic time constant, the water inertia time constant, and transfer coefficients, by about ┬▒10% around nominal values in 500 Monte Carlo trials. Across these variations, the IMC with GIS consistently yields lower average overshoot and settling time and favorable integrated time absolute error compared with conventional IMC and PID. Under different parameter changes, the advanced controller maintains smaller overshoot and undershoot and competitive or better settling times.

The authors also simulate severe grid disturbances, including temporary transmissionŌĆæline tripping, threeŌĆæphase short circuits at the generator terminal, and short circuits in the middle of the transmission line, each applied for about 0.1 seconds. Across all these scenarios, the IMC with GIS exhibits smaller overshoot and faster response than standard IMC and PID, effectively stabilizing turbineŌĆægenerator speed under conditions that would challenge conventional governors. This combination of tighter transient control, robustness to parameter drift, and improved disturbance rejection makes IMC with GIS a compelling option for hydro units required to support aggressive grid balancing or operate with significant model uncertainty.

A Nature Portfolio overview of hydropower systems and control strategies highlights broader research trends beyond IMC. One notable approach is a stateŌĆæfeedback robust slidingŌĆæmode controller designed specifically for hydraulic turbine governing systems with parameter uncertainties and external disturbances. TimeŌĆædomain simulations in that work show that slidingŌĆæmode controllers can achieve a practical tradeŌĆæoff between robustness and optimality, maintaining stability under changing conditions.

The same overview notes growing interest in fractionalŌĆæorder PID controllers, which generalize standard PID by using nonŌĆæinteger derivative and integral orders, and in metaŌĆæheuristic optimization of control parameters. Algorithms based on Hopf bifurcation theory and modern optimization have been applied to tune hydraulic turbine regulation systems more precisely in the face of nonlinear dynamics. These techniques allow more flexible shaping of the control response, potentially improving damping and response speed over a wider operating range than is feasible with classic integerŌĆæorder PID tuning alone.

For plant owners, the main message from the Nature and Nature Portfolio work is not that every hydro unit must immediately adopt a cuttingŌĆæedge controller. Rather, it is that there is now a proven set of advanced options with documented performance gains and robustness characteristics. For large plants providing primary frequency control, or for units in hydrological or system conditions where oscillations, long penstocks, or parameter uncertainty are problematic, it is worth evaluating whether an IMCŌĆætype or robust slidingŌĆæmode governor design would reduce wear, improve frequency performance, or both.

MDPI research on the El Hierro windŌĆōhydro power plant in the Canary Islands shows how hydro governors must evolve in hybrid renewable systems. Pumped hydroelectric energy storage (PHES) is described as the most mature largeŌĆæscale storage technology, with practical roundŌĆætrip efficiencies typically in the 70ŌĆō80% range, and as particularly suitable for small autonomous island systems. In this context, hydropowerŌĆÖs storage flexibility and frequencyŌĆæcontrol capability are central to integrating intermittent wind generation.

The El Hierro study points out that traditional turbine governors based on classical PI or PID control struggle with complex dynamics such as long penstocks and pressure waves and may not regulate frequency well when wind power fluctuates sharply. The authors propose a novel governor algorithm for impulse turbines that adds an innerŌĆæloop pressure stabilization circuit. This design specifically damps pressure waves associated with needle position changes, reducing their impact on frequency regulation. Importantly, the new strategy is implemented and validated on the actual windŌĆōPHES plant under real conditions where the thermal plant is offline and the windŌĆōhydro system alone is responsible for frequency control. The results demonstrate reduced load shedding and frequency deviations, offering a practical, experimentally validated pathway for similar isolated or weak systems that rely heavily on wind and hydro.

Hydropower units usually operate connected to the Bulk Electric System, but Hydro.org warns that they can become islanded under abnormal conditions. The behavior of the governor in these scenarios is critical. The same generator that is tuned to provide strong primary frequency response on a large, stiff grid can become a source of instability when asked to regulate a small island.

Hydro.org explains that governor droop control automatically adjusts speed reference in response to frequency deviations, while compensating controllers such as PID or temporary droop determine the speed of response. Gains and settings are typically optimized for specific combinations of unit size and load. For example, a 120 MW unit operating at 10 MW requires different tuning than the same unit operating at 100 MW or multiple units sharing a smaller load. These settings also differ between an infinitely stiff grid and isolated operation.

When islanded, best practice according to Hydro.org is for governors to operate in traditional speed droop with gate feedback, using speed or frequency control or gateŌĆæposition control, and to disable fastŌĆæload features such as feedforward and aggressive undamped loading functions that may have been tuned for BESŌĆæconnected operation. The reason is that features which are benign or beneficial on a stiff grid can amplify oscillations when inertia is limited.

System stability in islanded operation depends strongly on inertia. Units with larger inertia constants and neighboring units in spinning reserve, motoring, or condensing mode act as flywheels, providing damping as their speed changes. Hydro.org identifies Mechanical Starting Time, defined as the time required to accelerate rotating elements from standstill to synchronous speed at rated power, and Water Starting Time, defined as the time required to accelerate water in the penstock to rated velocity at rated head, as key parameters. Lower Water Starting Time improves stability. A striking example from the same guidance is that a unit at about 10% of rated load can have roughly ten times the Water Starting Time and therefore significantly less stability than the same unit at 100% load.

Penstock design also matters. Hydro.org notes that penstock length is ideally kept below about five times the turbine head to limit pressure rises and servo timing constraints and that multiple units on a single penstock can interact adversely in frequency control. These physical constraints directly influence how aggressively governors can be tuned and whether advanced control strategies are needed to maintain stability.

Unit isolation scenarios are categorized by Hydro.org as planned separation with known load, unplanned separation with known load, planned separation with unknown load, and unplanned separation with unknown load. Each requires different governor settings and transition strategies. Transitions between BESŌĆæconnected and islanded configurations can be managed manually by trained operators, via definite detection based on breaker status in simple topologies, or via inferred detection using frequency behavior, which is most common but more challenging. The stakes increased with the implementation of NERC standard BALŌĆæ001ŌĆæTREŌĆæ1 in ERCOT, which mandates strong primary frequency response and requires governors to be in service and responsive whenever units are online. Higher droop gains suitable for BES operation further increase the need for reliable detection of isolation and automatic retuning to islandŌĆæappropriate settings.

For industrial and commercial customers, these dynamics matter because hydro units often back the very grids that feed their facilities. A governor that is not configured for island scenarios may attempt to respond to frequency deviations with large gate movements, triggering oscillations that lead to voltage dips or frequency swings. Ensuring that hydro plants identify likely isolation scenarios in advance, model them, and tune governors and advanced controllers accordingly is a direct investment in downstream power quality and equipment protection.

Modern hydropower optimization is explicitly multiŌĆælayered. An Energy Sustainability Directory overview on Hydroelectric Optimization Strategies frames optimization as enhancing efficiency, reliability, and sustainability by making each component and process perform at its best. It identifies water resource management, turbine efficiency enhancement, generator performance, and operational optimization as fundamental areas, and emphasizes that optimization is increasingly about smarter management rather than simply building larger dams.

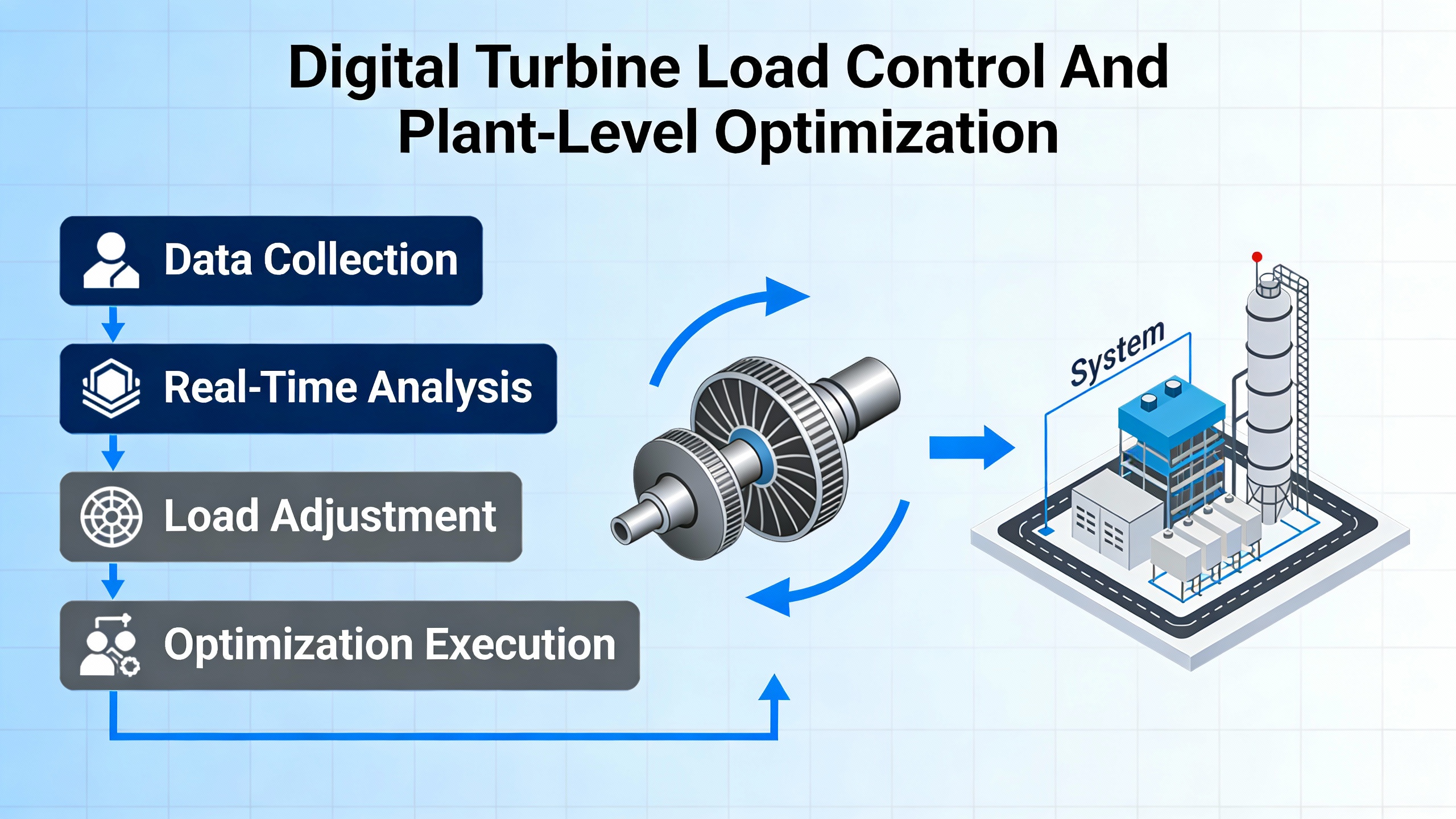

At the plant level, PetrotechŌĆÖs Hydro_TR case study is a concrete example of how digital turbine load control ties these layers together. In a runŌĆæofŌĆæriver hydropower plant, the Hydro_TR system used continuous monitoring of head, flow, turbine speed, and gate position combined with advanced algorithms to regulate water flow and maintain reservoir levels within licensing limits. It improved load distribution across units, enhanced frequency stability via optimized speedŌĆædroop control, and reduced mechanical wear through smoother start and stop sequences and integrated protections.

Automatic Load Control, as described by Petrotech, automates realŌĆætime load adjustments across turbines. It reduces operator workload, distributes loads to keep units near their best efficiency point, handles sudden demand or waterŌĆæflow changes, prioritizes critical loads, and sheds nonŌĆæessential loads when necessary. When combined with predictive algorithms and condition monitoring, ALC can also support remote, multiŌĆæsite operation. These capabilities are especially valuable in drought conditions or under tighter grid code requirements for frequency, voltage, and cybersecurity, all of which Petrotech lists as key challenges in modern turbine load management.

The Energy Sustainability Directory overview also reminds us that true optimization must consider climate change, hydrological variability, and socioŌĆæpolitical factors. Optimization models that rely solely on historical hydrological data may no longer be valid as precipitation patterns and snowmelt dynamics shift. Academic treatments now emphasize robust and scenarioŌĆæbased approaches to reservoir operation and hydropower dispatch, prioritizing resilience and adaptability rather than static optimality. On the socioŌĆæpolitical side, advanced control and optimization must be paired with stakeholder engagement, environmental safeguards, and policies that reflect the true value of water and ecosystem services.

Research synthesized by Nature Portfolio shows that pumped storage hydropower is a central piece of this puzzle. Transient process optimization in pumped storage plants is used to balance peakŌĆæload demands against equipment safety and to support variable renewable sources while preserving grid stability. MultiŌĆædomain modeling frameworks that couple hydraulic, mechanical, and electrical subsystems help quantify the efficiency losses and regulation mileage associated with hydropower providing shortŌĆæterm balancing. These frameworks reveal the economic and wearŌĆæandŌĆætear costs of flexibility, reinforcing why wellŌĆædesigned and robust governor systems are essential to minimize unnecessary regulation mileage while meeting grid needs.

From a reliability advisorŌĆÖs perspective, this means that digital governors and plantŌĆælevel control systems should be evaluated not only on immediate transient performance but also on their impact on longŌĆæterm efficiency, cavitation risk, wear, and regulatory compliance. An integrated strategy that combines modern governor algorithms, ALC, and systemŌĆæwide optimization delivers better outcomes than piecemeal tuning.

For utilities, independent power producers, and large industrial offŌĆætakers who depend on hydropowerŌĆædominated grids, several practical decisions around turbine governors determine longŌĆæterm performance and resilience.

Plant owners should start by understanding where their units operate relative to best efficiency and cavitation thresholds. Historical operating data can reveal whether units are spending significant time below roughly 60% of rated capacity or cycling frequently around lowŌĆæload conditions, as flagged by Petrotech. If so, the governor and ALC strategy likely need adjustment to change unit commitment and load sharing, using fewer units at higher loading whenever water and transmission constraints permit.

Next, owners should review governor tuning and modes across BESŌĆæconnected and islanded scenarios. Hydro.orgŌĆÖs guidance makes it clear that a single set of droop and PID gains is rarely optimal for all conditions. Where standards such as NERC BALŌĆæ001ŌĆæTREŌĆæ1 apply, governors must provide stronger primary frequency response, which may require different gains in BES operation than in islanded operation to avoid instability. Modeling and timeŌĆædomain simulation, using realistic mechanical and water starting times and penstock characteristics, is essential to validate these settings before field deployment.

On the technology side, operators of units involved in frequent frequency regulation, in longŌĆæpenstock schemes, or in hybrid windŌĆōhydro systems should seriously consider advanced controller options. NatureŌĆÖs IMC with GIS study and Nature PortfolioŌĆÖs slidingŌĆæmode controller work show that robust, modelŌĆæbased controllers can deliver lower overshoot, shorter settling times, and better disturbance rejection than tuned PID in many scenarios, including severe faults. The MDPI El Hierro case demonstrates that specialized algorithms addressing pressure dynamics can materially improve frequency regulation in real plants. A staged approach that pilots advanced controllers on one or two units, validated against both simulations and measured performance, is often an effective path.

Finally, industrial and commercial users with substantial UPS, inverterŌĆæbased systems, and critical loads should ensure that their powerŌĆæquality and protection strategies account for the behavior of upstream hydro governors. While they cannot control the plantŌĆÖs tuning directly, understanding whether their supply comes from a hydro system with modern digital governors and ALC, or from aging analog or mechanical controls facing the challenges listed by Petrotech and Hydro.org, informs decisions about rideŌĆæthrough settings, reserve capacity, and onŌĆæsite power protection schemes.

Industry experience summarized by Petrotech indicates that droop settings around 4% provide a relatively rapid and strong response, corresponding to about a 25% change in turbine power for each 1% change in frequency, while 5% droop provides a somewhat steadier response, with around a 20% power change per 1% frequency change. In practice, the choice and exact tuning should be driven by system studies that consider unit size, penstock dynamics, expected load ranges, and whether the unit will ever operate in islanded mode, as emphasized by Hydro.org. Higher gains suitable for BES operation may need to be reduced or reshaped for islanded operation to maintain stability.

If a plant operates with long penstocks, exhibits oscillatory behavior that is difficult to damp with PID tuning, must provide aggressive balancing for high shares of wind or solar, or faces large parameter uncertainties, advanced controllers are worth serious consideration. The Nature IMC with GIS study shows that a carefully designed IMCŌĆæbased governor can achieve zero overshoot, small undershoot, acceptable regulation times, and strong robustness across parameter variations and grid faults. Nature PortfolioŌĆÖs slidingŌĆæmode work and the MDPI El Hierro case also show improved performance in complex conditions. For smaller units in stable systems, a wellŌĆætuned PID governor may be sufficient, but for critical balancing resources, the additional design effort of advanced controllers can pay off in reduced wear and better grid performance.

Hydroelectric Optimization Strategies from Energy Sustainability Directory and Nature PortfolioŌĆÖs hydropower research both argue that optimization must be multiŌĆædimensional, integrating efficiency, environmental integrity, social equity, and climate resilience. Governors are the realŌĆætime execution mechanism for many of these objectives: they determine how water releases translate into power, how flexibly a plant can respond to variable renewables, and how much mechanical stress is imposed on equipment. When paired with advanced plantŌĆælevel controls and robust reservoir and dispatch optimization, modern governors help hydropower deliver more value from each gallon of water while supporting ecological flows and longŌĆæterm asset health.

WellŌĆædesigned and tuned hydro turbine governors turn a hydropower station from a simple energy producer into a highŌĆævalue reliability resource, capable of stabilizing grids, protecting equipment, and supporting deeper renewable penetration. For operators and industrial users who depend on stable power, investing in modern governor strategies, from careful droop tuning to advanced IMC and robust control, is one of the most direct ways to improve both system resilience and longŌĆæterm asset performance.

| Source or publisher | Topic or contribution |

|---|---|

| Petrotech | Turbine load control, coordinated setpoint distribution, speedŌĆædroop tuning, cavitation risk below roughly 60% loading |

| Hydro.org Powerhouse | Governor behavior in BESŌĆæconnected versus islanded hydro units, inertia and penstock impacts, isolation scenarios |

| Nature | Improved internal model control with generalized inverse solver for hydroŌĆæturbine governing systems |

| Nature Portfolio | Overview of hydropower systems and control strategies, robust slidingŌĆæmode controllers, pumped storage optimization |

| MDPI | WindŌĆōhydro power plant on El Hierro with novel governor algorithm and innerŌĆæloop pressure stabilization |

| Energy Sustainability Directory | Hydroelectric optimization strategies and turbine efficiency fundamentals, including control as a key optimization lever |

| Case Western Reserve University | Systems and control engineering as a foundation for optimizing renewable energy systems |

Leave Your Comment