-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Replacing a Siemens variable frequency drive is rarely just a part-number swap. In most facilities I work with, a Siemens drive sits at the center of a motor system that ties together production quotas, comfort in occupied spaces, and sometimes regulatory compliance. When that drive becomes hard to source, costly to maintain, or misaligned with your current strategy, the replacement decision has serious operational and financial consequences.

Electric motor systems account for a large share of industrial and building electricity use, and analyses cited by organizations such as the United Nations Industrial Development Organization and Fortune Business Insights put industrial motor power at well over half of total industrial consumption. That is why the choice of drive that controls those motors has an outsized impact on energy costs, uptime, and long-term risk.

This article walks through practical Siemens VFD replacement paths, grounded in what recent industry guidance and real projects show works in the field. The focus is on industrial and commercial applications: HVAC, pumping, materials handling, and process equipment. Along the way, I will also highlight situations where conventional VFDs are no longer the best technology and alternatives like brushless motor systems or electroŌĆæmechanical variable speed gearboxes deliver better lifecycle value.

A variable frequency drive, also known as an AC drive, adjustable speed drive, or simply inverter, is an electronic controller that adjusts an AC motorŌĆÖs speed and torque by varying the frequency and voltage it delivers to the motor. As described by engineering sources such as ETech Group and Avoca, a typical VFD has three internal stages.

The rectifier converts incoming AC power from the utility into DC. This may be a simple diode bridge in basic drives or an active front end in more sophisticated systems. The DC bus then smooths and stores this energy using capacitors and sometimes inductors, stabilizing the DC voltage. The inverter finally reconstructs AC with insulated-gate bipolar transistors or similar semiconductors, using pulse-width modulation to create a new AC waveform at the desired frequency and voltage.

By ramping frequency and voltage up and down gradually, the drive soft-starts the motor, limiting inrush current and mechanical shock. That is why VFD-driven pumps, fans, and conveyors typically last longer and demand less maintenance than their across-the-line counterparts. ETech Group points out that regenerative variants can even feed braking energy back to the DC bus or grid in cyclic processes, instead of wasting it as heat.

From a control standpoint, several strategies matter when selecting a replacement for a Siemens drive. Open-loop scalar control (constant volts-per-hertz) is common in basic pump and fan uses but typically delivers only on the order of a few percent speed regulation and no guarantee of torque under changing load, as Oriental Motor notes. Vector control, also called field-oriented control, separates torque and flux components of motor current and delivers tighter control under dynamics, and direct torque control focuses on very fast and accurate torque response, which Emotron recommends for highly dynamic applications like cranes, hoists, and test benches.

When you replace a Siemens VFD, you are really replacing an entire control philosophy and interface to your motor, so understanding these fundamentals is the first step to choosing an equivalent or better alternative.

Siemens sits comfortably among the top global VFD brands. Sources like Hars and several market analyses note Siemens for its engineering innovation, advanced control algorithms, and flexibility across industrial, HVAC, and renewable energy applications. In other words, there is nothing inherently wrong with staying on Siemens.

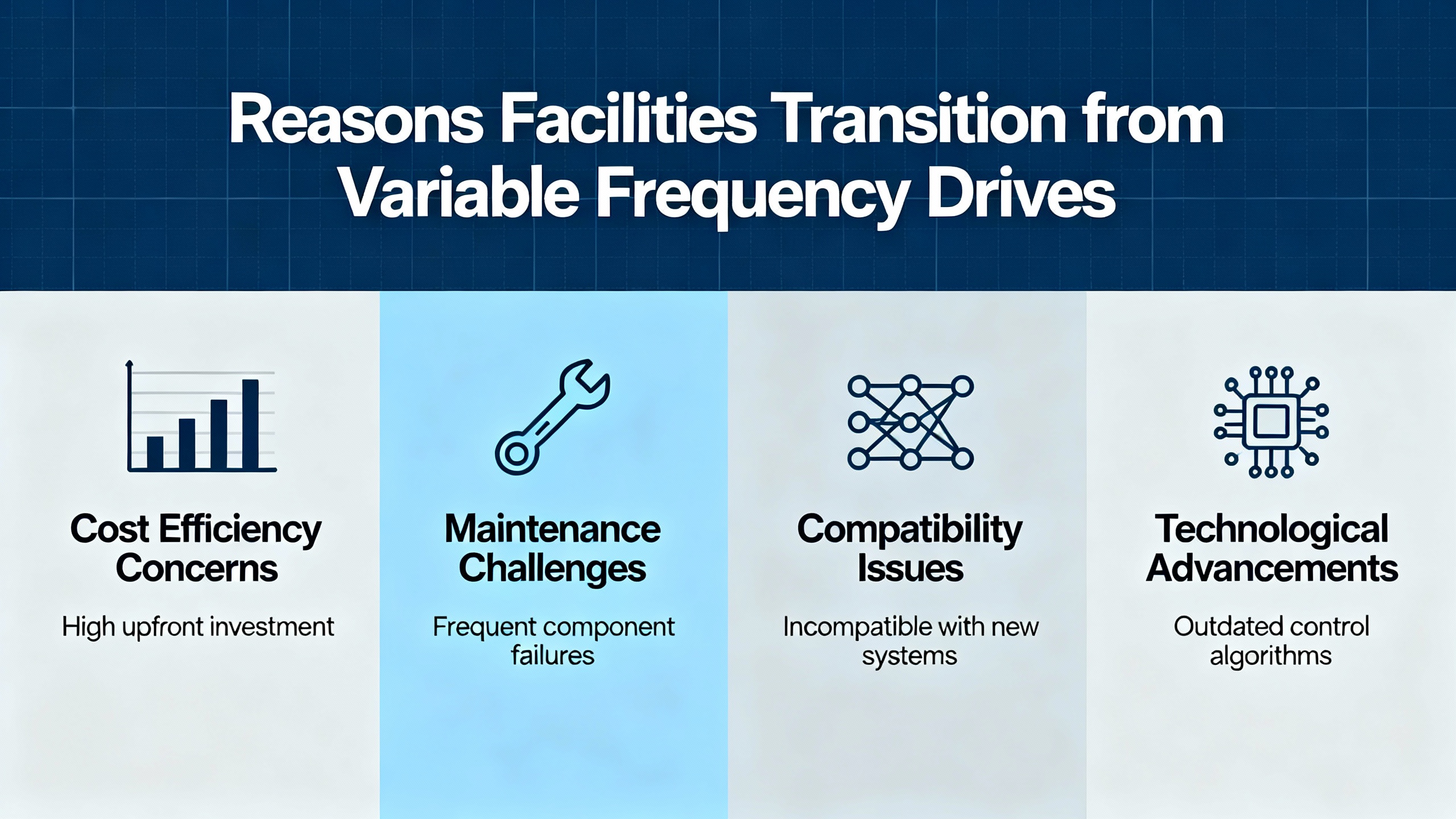

Yet in real facilities, I see several recurring drivers that push teams to look at alternatives.

One trigger is cost and availability. CanroonŌĆÖs 2025 price comparison work points out that, for example, a Siemens 7.5 kW drive in one comparison sells around $1,800, while a generic alternative might be closer to $1,200 for the same power. For large fleets or big horsepower drives, that premium is significant. The same analyses mention that ABB drives can be 20 to 30 percent less costly than some Rockwell units for similar functionality; Siemens often sits in that same premium tier where the tradeoff between cost and brand ecosystem must be carefully examined.

Another trigger is standardization. Many facilities operate mixed fleets: legacy Siemens on some lines, Rockwell or ABB on others, and lower-cost options in utility spaces. Articles on industrial reliability from Canroon and guidance from TSL Group emphasize that standardizing on a smaller set of brands simplifies technician training, spares, and troubleshooting. When a plant decides to consolidate around a non-Siemens vendor, Siemens drives naturally become candidates for replacement as failures or expansions occur.

Lead times, support structure, and integration can also push change. While Siemens is broadly supported, some regions have stronger service networks from ABB, Danfoss, Rockwell, or Yaskawa. If your automation platform is tightly tied to another vendorŌĆÖs ecosystem, integrating new Siemens drives into that environment may not be as simple as staying with the control vendorŌĆÖs preferred family.

The important point is that replacement rarely comes from dissatisfaction with Siemens performance as such. It is usually a strategic move to align costs, support, and integration with where the organization is heading.

Transitioning away from a mature platform like Siemens only makes sense when the technical and lifecycle boxes are ticked. Engineering guidance from sources like TSL Group, CSE Magazine, and multiple VFD reliability reviews align on several criteria that should drive your replacement choice.

Motor and load matching sits at the top. The alternative drive must match your motorŌĆÖs voltage, frequency, and full-load current, and it must be suitable for the motor type. TSL Group stresses that poor matching leads directly to overheating, erratic behavior, or outright failures. You also need a clear understanding of load type. Constant-torque loads such as conveyors and mixers require strong starting torque and robust overload capability. Variable-torque loads such as fans and pumps offer more opportunity for energy savings but still require adequate reserve for transient events.

Environment and enclosure rating are next. CanroonŌĆÖs reliability comparisons and field experience show that dust, moisture, heat, and vibration are often the silent killers of drives. A dusty mechanical room or pump gallery will treat a NEMA 1 or open IP20 chassis very differently than a clean MCC space. For harsh environments, high IP ratings or fully enclosed NEMA 4 housings, as used in some HVAC and industrial drives, can yield dramatically longer lifetimes.

Control and communication requirements come closely behind. TSL Group emphasizes the need to examine your automation architecture: which protocols your PLCs and building management systems use, how much data you want from the drive, and whether onboard logic is important. Modern drives from ABB, Siemens, Rockwell, and others frequently support Modbus, Ethernet-based protocols, and drive-level diagnostics. If your Siemens drive currently serves as a local ŌĆ£smart node,ŌĆØ any replacement must offer equivalent capabilities or be paired with external control.

Safety and compliance cannot be an afterthought. Built-in overload, short-circuit, and ground-fault protection are standard in reputable drives, but certifications like UL, CE, and CSA, and features such as Safe Torque Off, matter for code compliance and safe maintenance. TSL Group recommends explicitly verifying these elements before finalizing a selection.

Finally, you should evaluate lifecycle economics rather than purchase price alone. CSE Magazine points out that in the context of federal U.S. energy standards, any efficiency measure with roughly a three-year payback on added first cost is considered economically justified. Given that energy costs over a motorŌĆÖs life far exceed the purchase price, the total cost of ownershipŌĆöenergy, maintenance, downtime risk, and support agreementsŌĆöshould be the basis for comparing Siemens against alternatives.

When Siemens replacement is on the table, the obvious question is which drive families can sit confidently in its place. Market and technical reviews from Fortune Business Insights, Canroon, Hars, Industrial Automation Co., and others consistently highlight a set of leading brands.

The table below summarizes several of these, along with attributes noted in the research that are especially relevant when you are used to SiemensŌĆÖ performance and breadth.

| Brand / Family | Noted strengths in the research | Relevance when replacing Siemens |

|---|---|---|

| ABB (ACH series, general) | Energy-efficient HVAC and industrial drives; broad portfolio; often priced below some Rockwell equivalents | Strong candidate where cost reduction and energy optimization are priorities while staying tier-one |

| Danfoss (VLT HVAC, others) | Focus on HVAC and process efficiency; wide power range; strong sustainability positioning | Good fit for fans, pumps, compressors in HVAC and process cooling |

| Rockwell / Allen-Bradley | PowerFlex drives with close integration to Rockwell PLC platforms; robust industrial features | Natural option if your automation is Rockwell-centric |

| Yaskawa | Recognized for exceptional quality and reliability; Deming Prize winner; strong in continuous uptime applications | Attractive for critical lines where downtime costs are very high |

| Schneider Electric (Altivar) | Integration into Schneider automation ecosystem; connectivity and monitoring for smart automation | Compelling if your switchgear and PLC base is Schneider |

| Fuji Electric | High ambient capability, long uptime; three-year warranties; strong showing in harsh environments | Useful in hot, dirty, or remote sites where derating is a concern |

| Mitsubishi Electric | Long-life designs (for example, FR-E700 series target 10+ year service life); suitable for heavy duty and HVAC | Interesting in heavy-duty but space-constrained applications |

| Delta Electronics | Cost-effective general-purpose drives; MS300 and ME300 noted as versatile with broad HVAC applicability | Case where budget pressure is high but you still need brand support |

| Canroon | Value-focused with high-performance vector control; good priceŌĆōperformance for demanding but cost-sensitive uses | Practical alternative in smaller facilities or non-critical loads |

| Invertek (Optidrive Eco) | HVAC-oriented, including outdoor-rated IP55/IP66 models; integrated disconnects and energy-optimized fan/pump control | Strong for rooftop fans, cooling towers, and outdoor equipment |

| Johnson Controls, Honeywell, DiversiTech | Drives positioned for building systems; designed for BMS integration and energy savings | Logical choice in large campuses where controls are from these vendors |

| Eaton (PowerXL, H-Max) | HVAC and industrial drives, including compact units for 200ŌĆō240 V; attention to power quality and configurability | Option where Eaton gear and support already dominate the site |

This table is not exhaustive, but it shows that Siemens-class performance is available from many vendors. The right alternative depends less on raw drive capability and more on how well the brand aligns with your motor fleet, automation stack, and service ecosystem.

Budget drives are often dismissed out of hand in discussions about Siemens replacements. That is a mistake. The research from Canroon on price comparison and budget HVAC drives paints a more nuanced picture.

On the smaller end of the power range, Canroon and DeltaŌĆÖs MS300 and ME300 series cover a wide band of HVAC and light industrial applications at significantly lower price points. DeltaŌĆÖs ME300 models span from about 10,024 rupees up to 46,480 rupees in the research sample, and MS300 models from around $100 up to $4,000, with list examples in the low hundreds of dollars. For facilities upgrading many fractional and low-horsepower motors, these prices can free up budget for better sensors, isolation valves, or controls.

Industrial case studies also show that the energy savings potential is not limited to premium brands. One distribution center that installed a 40 horsepower drive on a fan load cut monthly energy use from about 28,000 kWh down to 11,600 kWh, a savings of roughly 58 percent and around $18,000 per year at typical tariffs. This was achieved by slowing the fan during off-peak conditions; slowing fans or pumps by about 20 percent speed can deliver on the order of 50 percent power reduction because of the cubic relationship between speed and power on centrifugal loads.

The caveat, documented in these budget-drive comparisons, is reliability and support. Premium vendors such as ABB and Siemens typically rate as high on both reliability and after-sales service. Midpriced brands like Delta, Canroon, and Automation Direct rank as medium. Cheaper drives around $1,200 in some examples may fail sooner under heavy use, eroding the apparent saving. That is why the research repeatedly emphasizes total cost of ownership: combining purchase cost, expected energy savings, maintenance, warranty coverage, and available technical support.

If your Siemens drive is running a critical production line where downtime costs thousands per hour, cutting corners to save a few hundred dollars on the replacement drive makes little sense. Conversely, for secondary air handlers, small pumps, or comfort-only loads, a well-supported budget VFD from a reputable second-tier brand can be a sensible, defensible step down from Siemens without unacceptable risk.

There are situations where the smartest Siemens ŌĆ£VFD replacementŌĆØ is not another VFD at all, but a different motor or speed-control technology.

For smaller pumps and fans, especially in OEM equipment, brushless motors with dedicated electronic drivers are a serious alternative to the conventional three-phase induction motor plus VFD architecture that Siemens and similar brands serve.

Oriental MotorŌĆÖs analysis of variable speed pump applications is a good illustration. In many basic pump and fan systems, open-loop scalar V/f VFD control gives only about plus or minus a few percent speed regulation and cannot guarantee how the motor responds to load changes. If the fluid type or viscosity changes, the AC induction motor can slow down, and the transferred volume becomes inconsistent.

Brushless motor systems integrate Hall-effect sensor feedback and closed-loop style drivers, yielding much tighter speed regulation without a separate encoder and VFD. Figures from Oriental MotorŌĆÖs brushless systems show maximum speed regulation around plus or minus 0.2 percent in some series, and down to plus or minus 0.05 percent with encoder feedback at rated speed. That is an order of magnitude tighter than typical open-loop VFD control.

These systems also offer a wider effective speed range than many VFD-driven induction motors used this way. Standard brushless motors in the cited examples cover about 80 to 4,000 rpm, compared with roughly 90 to 3,600 rpm for many VFD-driven induction motors in similar power classes. Because the rotor uses permanent magnets, efficiency increases; Oriental Motor cites roughly 27 percent lower power consumption compared with comparable induction motors. For a 200 W class motor, their brushless unit can be significantly shorter and lighter than the induction equivalent, which matters in compact equipment.

For facilities considering Siemens replacements on small packaged systems where size, hygiene, or consistent flow matter more than leveraging an existing induction motor, a brushless motor with an integrated driver can solve root-cause issues rather than simply refreshing the drive.

At the other end of the size spectrum, large pumps and compressors traditionally rely on medium-voltage VFDs. Siemens has strong offerings in that segment, but MV drives bring substantial complexity: large transformers, high-voltage safety regimes, heat rejection from high-power electronics, and strict maintenance needs.

SET Sustainable Energy Technologies describes a different path with its SETCON variable speed gearbox. Instead of feeding the entire motor load through a medium-voltage VFD, SETCON uses a combination of low-voltage frequency converters, servo machines, and a planetary gearbox to vary the speed of a constant-speed main motor.

Only about 20 percent of driven power passes through the low-voltage converters; the rest flows mechanically through the gearbox. This simplifies electrical infrastructure, cuts cabinet losses, and reduces cooling demand. In partial load operation, the servo machines act as generators, feeding excess energy back into the grid. SET reports overall efficiency up to about 97 percent in this configuration.

One of the most compelling retrofit aspects is mechanical compatibility. SETCON can often reuse an existing constant-speed main motor, adjusting the gearbox to match the operating conditions. That avoids some of the infrastructure modifications and insulation requirements that come with medium-voltage VFD retrofits. Maintenance also becomes more approachable, since the electronics are low-voltage; much of the routine work can be handled by in-house technicians after basic training rather than high-voltage specialists.

For plants evaluating Siemens MV-VFD replacements on large rotating equipment such as boiler feed pumps, a technology like SETCON is worth studying alongside conventional medium-voltage drives, particularly where electrical room space, cooling capacity, or high-voltage maintenance resources are limited.

In HVAC, a different class of alternatives is gaining ground: integrated electronically commutated motors, where the fan, motor, and onboard speed controller come as a single assembly. Plant Engineering notes that these ECM solutions have become common in fan arrays and air-handling units because they are more efficient than many older IE3 induction motor systems and promise simpler mechanical and electrical design.

However, these integrated assemblies come with tradeoffs. They often sit directly in the airstream, which can disturb airflow and limit how far designers can optimize fan geometry and duct layouts. More importantly for replacement strategy, ECM solutions tie you tightly to a single vendorŌĆÖs motor, fan, and control interface. Plant Engineering points out that most ECM assemblies are not serviceable; if a bearing or capacitor fails, you replace the entire unit, sending otherwise sound components to landfill and relying on the vendorŌĆÖs future support.

By contrast, a discrete Siemens-style architecture with separate VFD, motor, and fan allows you to choose the most efficient fan, switch motor technologies over time, and dual-source components. In an environment where supply chain resilience and lifecycle sustainability are now strategic concerns, that flexibility matters. If you are replacing Siemens drives in fan arrays, the decision between staying with discrete drives or shifting to ECM should be made at the system level, not just on price or advertised efficiency.

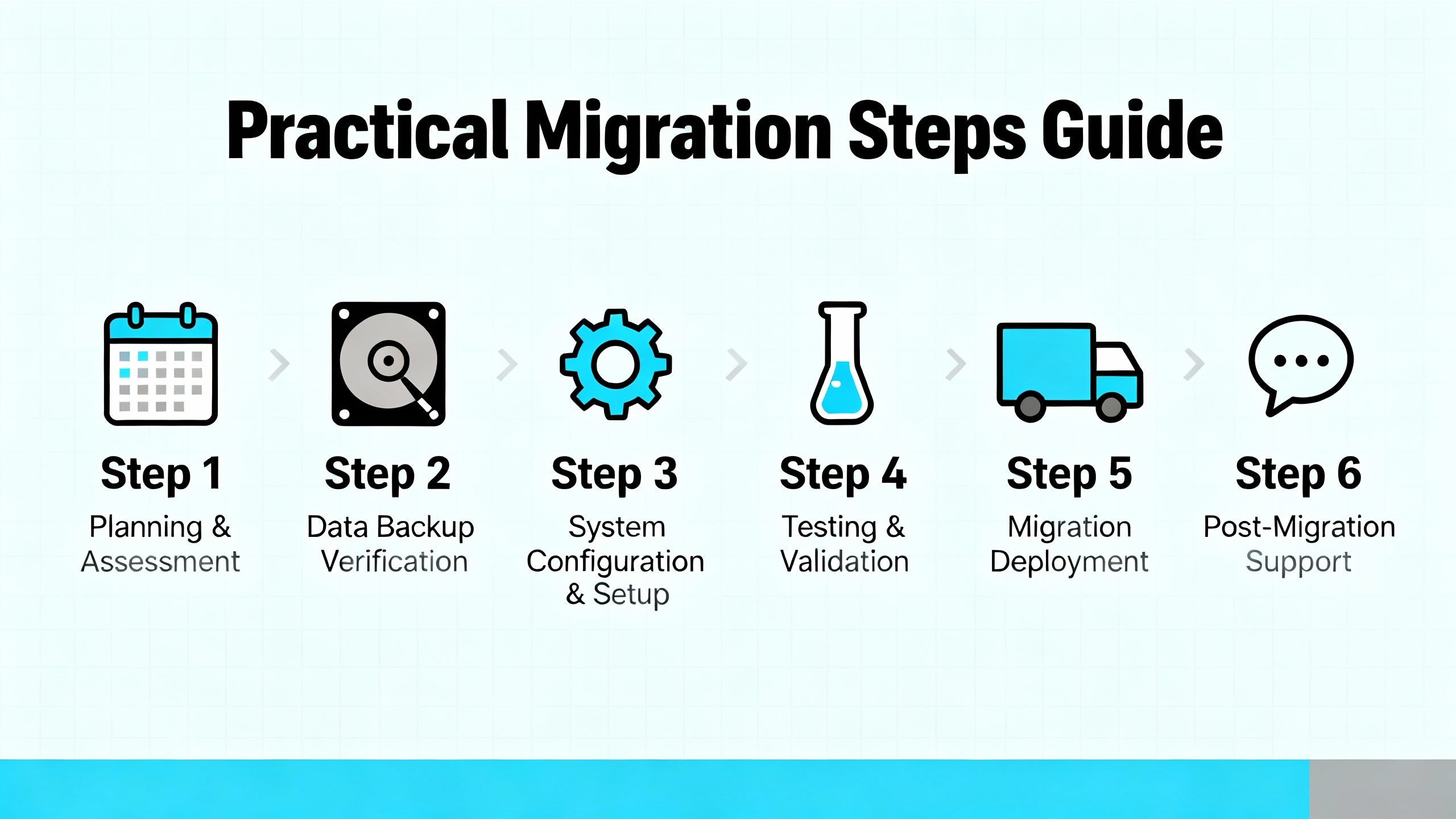

Once you have decided that a Siemens drive should be replaced with an alternative, the migration should be treated as an engineering project, not just a procurement event. Industry guidance from TSL Group, Precision ElectricŌĆÖs upgrade commentary, and others converges on several practical steps.

Start by documenting the existing motor and process. Capture motor nameplate data, wiring configuration, and any peculiarities like high starting-torque requirements or frequent braking cycles. Identify whether the load is constant torque or variable torque, and how often it runs at partial load. Sources like ETech Group remind us that motor energy use depends on both torque and speed, with efficiency typically peaking near rated speed, so understanding how the process actually runs is important.

Next, analyze the electrical environment. Confirm the available supply voltage, short-circuit rating, and whether you are feeding a low-voltage or medium-voltage motor. Articles on cost-effective VFD selection from Canroon highlight that enclosure type, harmonic limits, and ambient conditions strongly influence both cost and reliability. For harsh environments, specify appropriate ingress protection and cooling.

Integration planning comes next. Map out how the existing Siemens drive communicates with upstream controllers and what local I/O it provides. If the replacement will come from a different vendor, verify protocol support and data mapping. Where industrial Ethernet or building automation protocols are used, note that survey results reported by Control Techniques show most machine users are already using or evaluating Ethernet, and many modern drives (including building-focused series from ABB and Johnson Controls) now embed Ethernet-based connectivity as standard.

Before bulk replacement, pilot the alternative drive. Precision ElectricŌĆÖs summary of upgrade best practices notes that lab testing a representative drive, validating parameter mappings, and vetting functional safety behavior are standard risk mitigation steps. Commission the pilot on a non-critical yet representative load and let it run through normal operating cycles, including any emergency stops or fault conditions.

Finally, treat the project as a long-term energy and reliability decision. CSE Magazine recommends designers mirror the U.S. Department of EnergyŌĆÖs framework for standards, which weighs life-cycle operating savings, aggregate energy conservation, product utility, competition, and broader environmental and employment factors. In practical terms, that means looking beyond the short-term capital budget: assessing expected energy savings, maintenance intervals, warranty terms, and service responsiveness of the chosen brand relative to Siemens.

If you are moving away from Siemens primarily for cost or standardization reasons, it is reassuring to see that correctly applied alternative drives can deliver meaningful improvements rather than merely holding the line.

AvocaŌĆÖs coverage of HVAC VFDs notes that, according to ABB, pump and fan applications with VFD control can see energy savings up to 70 percent in some cases. More broadly, many facilities see reductions of up to about 50 percent in motor energy usage when systems are converted from constant-speed to well-tuned variable-speed operation. These savings are compounded by reduced mechanical wear from soft-start and smooth control, which extends equipment life and reduces maintenance.

Pump-focused analysis from Zhejiang Chuanken (SHCKELE) gives additional context: advanced sensing, IoT-enabled VFDs, and high-efficiency motors deliver incremental efficiency gains on the order of 12 to 25 percent depending on the control strategy. Case evidence includes a wastewater treatment plant that achieved around a 30 percent reduction in energy use with a smart VFD that adjusts to flow in real time. In agriculture, solar-powered VFDs reduce dependence on grid power and operating cost.

On the industrial side, Emotron and CSE Magazine remind us that many alternative technologies, such as mechanical throttling or two-speed motors, can meet minimum code language but rarely match the efficiency of a well-selected VFD-controlled motor system. Even modest reductions in average speed yield substantial savings on centrifugal loads.

In other words, when you replace Siemens drives with modern alternatives, you are not only responding to procurement or support pressures. You have an opportunity to improve wire-to-work efficiency and reliability at the same time, so long as you choose and commission the replacements thoughtfully.

From a power-system perspective, running Siemens and non-Siemens drives on the same distribution system is routine, provided each drive meets relevant harmonic and protection requirements. The tradeoff is more about maintenance and integration. Reliability reviews from Canroon and others suggest that standardizing on a smaller set of brands simplifies programming, spares, and training. For many plants, a pragmatic approach is to standardize per area or per application rather than force a single brand across the entire site.

Budget VFDs from brands such as Delta, Canroon, and Automation Direct make sense on non-critical loads where failure consequences are modest and where energy savings are the primary justification. Research examples show strong energy savings even with lower-priced drives, but they also caution that cheaper units may not last as long in heavy-duty use. The key is to align drive tier with load criticality: keep premium brands for production-critical or safety-related systems, and use cost-effective alternatives for secondary HVAC or utility services.

Yes, in specific cases. For small OEM-style pumps and fans where precise speed regulation, compactness, or hygiene are paramount, brushless motor systems with dedicated drivers can outperform traditional induction motor plus VFD combinations, as Oriental MotorŌĆÖs data shows. For very large rotating equipment where medium-voltage VFDs add substantial complexity, electro-mechanical solutions such as SETŌĆÖs variable speed gearbox can deliver high efficiency with simpler low-voltage electronics and easier maintenance. These decisions should always be based on a study of your particular process, not on a general rule.

A Siemens VFD replacement is an opportunity to rethink how you control and protect your motors, not just a brand swap. If you ground the decision in your load profile, environment, integration needs, and lifecycle economics, you can use this transition to cut energy use, reduce complexity, and improve reliability for years to come.

Leave Your Comment