-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Keeping GE FanucŌĆōbased systems running is not just about finding a replacement part number. It is about making sure that the part is genuine or properly refurbished, electrically compatible, configured correctly, and installed in a way that preserves the reliability of the entire cell or line. As someone who lives at the intersection of power quality, UPS-backed control systems, and automation reliability, I have seen more than one production line sit idle not because ŌĆ£no parts existed,ŌĆØ but because the maintenance team did not have a trusted supplier who could help them pick the right GE Fanuc module and get it onsite quickly.

The good news is that there are mature, specialized channels for GE Fanuc components that go far beyond anonymous eŌĆæcommerce listings. Several providers build their businesses around original OEM parts, dedicated Fanuc repair centers, and engineering teams that answer application questions instead of simply shipping boxes. When you match those capabilities to a disciplined spare-parts and power-protection strategy, you dramatically reduce the risk that a failed drive, encoder, or power supply will cascade into days of unplanned downtime.

This article walks through what makes GE Fanuc parts unique from a reliability standpoint, the main categories of suppliers that actually provide technical assistance, and how to choose the right partner for specific scenarios such as legacy CNC failures, planned upgrades, and strategic spare-parts stocking.

FANUC and GE Fanuc systems underpin high-precision CNC machines, industrial robots, and control systems in industries such as automotive and aerospace. The Lemhunter guide to finding quality FANUC parts notes that even though these systems are highly reliable, they still require periodic replacement of servo motors, amplifiers, power supply modules, control boards, operator panels, and robot assemblies. Each of these components is tightly integrated into the control architecture; swapping the wrong hardware can introduce subtle errors long before a full failure appears.

BinfireŌĆÖs discussion of why FANUC parts are a strong investment stresses that FANUC manufactures and inspects its components in-house, with certified technicians testing parts before they reach the market. Many suppliers offer both new and refurbished FANUC parts, and it is common to see one-year warranties that back up those quality claims. That combination of controlled manufacturing, rigorous testing, and warranty support is part of what makes OEM and carefully refurbished GE Fanuc parts so attractive when you are responsible for line availability.

Downtime risk is not abstract. The Binfire article explicitly calls out that even a single day of halted production can seriously damage a companyŌĆÖs bottom line. In my own work designing UPS and power protection for automation cells, I regularly see that a failed Fanuc power module or spindle drive is often the trigger that exposes weaknesses in spare parts strategy. When teams are forced into emergency sourcing from general marketplaces with minimal technical guidance, they may accept questionable substitutes, misinterpret part numbers, or overlook firmware and interface nuances that matter to long-term reliability.

The Lemhunter guide emphasizes that working with trusted, certified service partners or technicians is essential to getting the right part installed and calibrated correctly. That is exactly where technical assistance from a parts supplier becomes a strategic asset rather than a ŌĆ£nice to have.ŌĆØ It closes the gap between catalog specifications and the realities of your specific machine, field wiring, and power environment.

Before choosing where to buy, it helps to understand what you are actually buying. GE Fanuc and related FANUC systems rely on several core hardware families that each carry different risk and support implications.

Servo motors and amplifiers sit at the heart of motion control. Lemhunter highlights servo motors and amplifiers as among the most commonly replaced components because they are subject to mechanical load, thermal stress, and high switching currents. These devices translate controller commands into precise movement of axes and robot joints. Using genuine or high-quality compatible servo hardware preserves positioning accuracy and closed-loop stability and reduces the risk of nuisance alarms or drift that can quietly degrade product quality long before an outright failure.

Power supply modules and Fanuc power supplies form the backbone of every control and drive system. According to GE Fanuc SparesŌĆÖ overview of OEM CNC parts, Fanuc power supplies are a standard part of the catalog alongside encoders, servo motors, spindle drives, and PLCs. From a power-system perspective, these units are exposed to incoming sags, surges, and harmonics. If you replace them with questionable or poorly tested alternatives, you can end up masking deeper power-quality issues and actually increasing stress on UPSs, inverters, and downstream electronics. This is where a supplier that can talk about both electrical ratings and real application conditions is particularly valuable.

Control and circuit boards, PLCs, and I/O units are another major category. GE Fanuc Spares lists PLCs, PCB boards, and CNC control components as part of its OEM portfolio, and Tri Star CNC Services focuses on control board repairs using genuine FANUC control parts. These boards handle logic execution, position calculations, safety interlocks, and communications. They are also where field bus systems like FANUC I/O Link, EtherNet/IP, PROFIBUS DP, DeviceNet, and AS-i converge, as Tri Star describes. A seemingly minor mismatch in board revision, firmware, or field bus option can prevent a retrofit board from communicating correctly, which is why direct access to people who understand these details matters.

Operator interfaces, teach pendants, and robot wrist assemblies round out the ecosystem. Lemhunter notes that teach pendants and operator panels are routine replacement items because they are handled constantly, while robot wrist assemblies and cables see repetitive motion and often live in aggressive environments. These components are where human factors, cable management, and mechanical robustness intersect with control electronics and power wiring. An experienced parts supplier can help you choose variants and accessories that extend service life instead of simply duplicating the failure modes you already have.

When you view GE Fanuc parts through this system lens, you can see why buying from a catalog alone is risky. Each component sits in a web of electrical, mechanical, and network dependencies. The more complex your CNC or robot line, the more you benefit from a supplier that can answer ŌĆ£how will this behave in my environment?ŌĆØ instead of just confirming a part number.

There is no single best channel for every situation. Instead, you have a small set of supplier types that each bring different strengths. The key is to align your choice with the age of your equipment, the criticality of the failure, and the depth of support you need.

In the United States, Lemhunter identifies FANUC America and authorized distributors as primary sources for authentic FANUC and GE FANUC parts. These channels typically offer factory-backed warranties and access to technical support across different equipment generations. For plants running newer systems or those that must adhere strictly to OEM-only policies, this route provides the highest degree of assurance that parts are current, correctly rated, and fully supported.

The tradeoff is that OEM channels may not always be the fastest or most flexible route for older or obsolete GE Fanuc product lines. Lead times can be longer, and the range of officially supported refurbishment options may be limited. However, when you need unambiguous compatibility and the ability to escalate complex issues back through the manufacturer, OEM and authorized distributors are often the right place to start, especially when you integrate their guidance into your overall power and protection strategy.

Dedicated GE Fanuc specialists fill an important gap, particularly for older systems. GE Fanuc Spares positions itself as a supplier of original OEM GE Fanuc CNC parts, offering new, used, service-exchange, and refurbished components. All parts sold carry a warranty and are functionally tested in-house before shipment, supported by a dedicated Fanuc repair center equipped with test rigs to fully function-test items they repair or sell. That testing discipline is crucial when you are replacing boards in safety-critical or high-precision machines.

On the exchange side, GE Fanuc Spares operates an OEM FANUC Core Exchange Program. Customers receive an original FANUC spare part in exchange for sending in a repairable faulty identical part. Replacement units are repaired, fully tested, and serviced before being supplied, so you receive a ready-to-use module off the shelf instead of waiting for your own part to be repaired. The company highlights that all OEM exchange parts include a warranty and are tested before shipment, with ex-stock approved FANUC CNC machine parts held in a central UK parts center for immediate dispatch. They note next-day shipment to most of the UK and Europe and parts of the USA, subject to stock and courier reach.

From a reliability advisorŌĆÖs perspective, this kind of exchange program can be a powerful tool. It keeps legacy GE Fanuc hardware in service longer by recycling repairable cores and maintaining an active spares pool. At the same time, it gives you access to specialists who can help identify the correct part, discuss whether service-exchange or new/refurbished purchase makes more sense, and quote quickly when a line is down.

Beyond pure Fanuc specialists, several industrial automation distributors combine broad product portfolios with specific Fanuc knowledge and strong technical support.

Industrial Automation Co. is a U.S.-based, veteran-owned global distributor specializing in industrial electronics and automation components. The company focuses on supplying industrial automation products and replacement parts worldwide, with brand positioning centered on industry-leading customer support that emphasizes speed and precision in handling orders and inquiries. Their FANUC spare parts portfolio includes servos, sensors, operator interfaces, PLCs, AC drives, and I/O units, along with other brands such as Mitsubishi and Reliance Electric. Industrial Automation Co. highlights the importance of proactive maintenance and encourages customers to stock spare parts before CNC machines fail, which aligns well with the preventive strategies described by Lemhunter.

Where speed is concerned, Industrial Automation Co. states that all FANUC spare parts under 20 lb qualify for two-day shipping within the continental United States, and that emergency expedited shipping can be arranged via same-day courier on request. They aim to provide price and availability quotes in ten minutes or less during business hours, with orders accepted by phone or email. For a maintenance team facing a disruptive failure, this combination of quick technical response, rapid quoting, and fast shipping is often more decisive than a marginal difference in part cost.

MRO Electric offers another example of a third-party distributor with Fanuc expertise. Their overview of FANUC parts positions these components as high-precision, reliable, and innovative hardware for modern manufacturing. MRO Electric emphasizes that they supply a wide range of FANUC products, including servo motors, robotics components, and CNC control systems, and that they focus on application-driven solutions rather than just catalog sales. Expert support is described as a core service, with staff guiding customers through part selection to ensure that components match specific operational requirements. A comprehensive inventory and fast shipping are stressed as mechanisms to support high uptime.

NRwell similarly focuses on GE Fanuc industrial automation equipment, including CNC controllers, robotic arms, and related components. They specialize in new, refurbished, and obsolete GE Fanuc parts, each sold with a warranty. NRwell emphasizes working closely with clients to deliver solutions tailored to specific operational requirements and frames their inventory as a single-source option for new, refurbished, and obsolete GE Fanuc parts. For operators balancing cost and reliability, refurbished parts from suppliers like NRwell can provide access to proven hardware at lower capital cost while still maintaining performance.

Some situations demand a more hands-on sourcing approach. DO Supply positions itself as a specialist resource for rare GE, Fanuc, and Emerson automation parts. The company focuses on helping customers struggling to find specific or obsolete components and offers a concierge-style service where a team member assists in locating the exact part required. They emphasize access to an expert team with knowledge of part numbers, compatibility, and sourcing channels, and their branding highlights ŌĆ£Buy, Sell & RepairŌĆØ as part of the lifecycle they support.

The value of this model becomes clear when you are dealing with parts that no longer appear in mainstream catalogs, or when the same function block exists under multiple revisions and cross-references. Instead of burning hours searching distributor sites, maintenance teams can bring part numbers, photos, and context to a DO Supply specialist and let them handle the hunt. When combined with robust power protection that prevents repeat failures, this approach can turn a near-obsolete system into a manageable asset rather than a chronic risk.

There are times when repair is the most reliable or cost-effective path, especially for complex control boards. Tri Star CNC Services describes itself as a leading CNC control repair provider in the U.S. Midwest, with a focus on FANUC-based control systems. Their specialization in CNC control board repairs and related services is aimed at keeping machines operating at high capability and efficiency. Tri Star stresses that they use genuine FANUC control parts for repairs and replacements, emphasizing reliability and compatibility over third-party alternatives.

Tri Star also underscores the breadth of FANUCŌĆÖs hardware offering, including motors, amplifiers, input modules, and control boards designed for relatively easy installation into existing CNC machines. They highlight versatile field bus systems such as FANUC I/O Link, EtherNet/IP, PROFIBUS DP, DeviceNet, and AS-i. For a plant facing intermittent faults or field bus communication issues rather than outright component failures, a repair partner like this can help diagnose root causes, recommend targeted part replacements, and coordinate with your power and grounding strategy to eliminate recurring problems.

The main supplier types described above are not interchangeable; each is stronger in certain use cases. The following table summarizes their typical roles and technical assistance strengths based on the research sources.

| Supplier type | Example providers | Technical assistance focus | When it fits best |

|---|---|---|---|

| OEM and authorized distributors | FANUC America and authorized distributors (per Lemhunter) | Factory-backed compatibility guidance, warranties across equipment generations | Newer or strategic systems where strict OEM policies and long-term support are priorities |

| Specialist GE Fanuc spares and exchange | GE Fanuc Spares (OEM GE Fanuc CNC parts and core exchange) | Identifying correct OEM parts for legacy CNC controls, advising on service-exchange vs new or refurbished, providing fully tested units | Legacy and hard-to-find parts, urgent replacements where next-day shipment and exchange programs minimize downtime |

| Multi-brand distributors with Fanuc expertise | Industrial Automation Co., MRO Electric, NRwell | Application-focused support, rapid quoting and shipping, guidance on servo, drive, and controller selection | Plants needing fast turnaround, mix of Fanuc and other brands, and practical advice on balancing cost vs reliability |

| Concierge sourcing for rare parts | DO Supply | Hands-on search for rare or obsolete GE Fanuc and Emerson components, leveraging expert knowledge of part numbers and compatibility | Obsolete parts, unclear part number histories, or situations where internal procurement has hit a dead end |

| Repair and control-board specialists | Tri Star CNC Services | Diagnosis and repair of FANUC control boards using genuine parts, expertise in field bus and control architecture | Persistent faults, intermittent issues, or cases where repairing complex boards is more practical than replacing them outright |

When you map your situation onto this landscape, patterns emerge. A plant with modern FANUC robots under a strict corporate standard might lean toward OEM channels for key axes and controllers, while relying on a specialist like GE Fanuc Spares for legacy CNCs and on Industrial Automation Co. or MRO Electric for common spare motors and drives that need fast shipment. DO SupplyŌĆÖs concierge model becomes valuable when documentation is thin and you are chasing obscure GE Fanuc part numbers. Repair-focused partners such as Tri Star CNC Services are especially useful where failure modes are complex and a simple module swap is unlikely to solve the underlying issue.

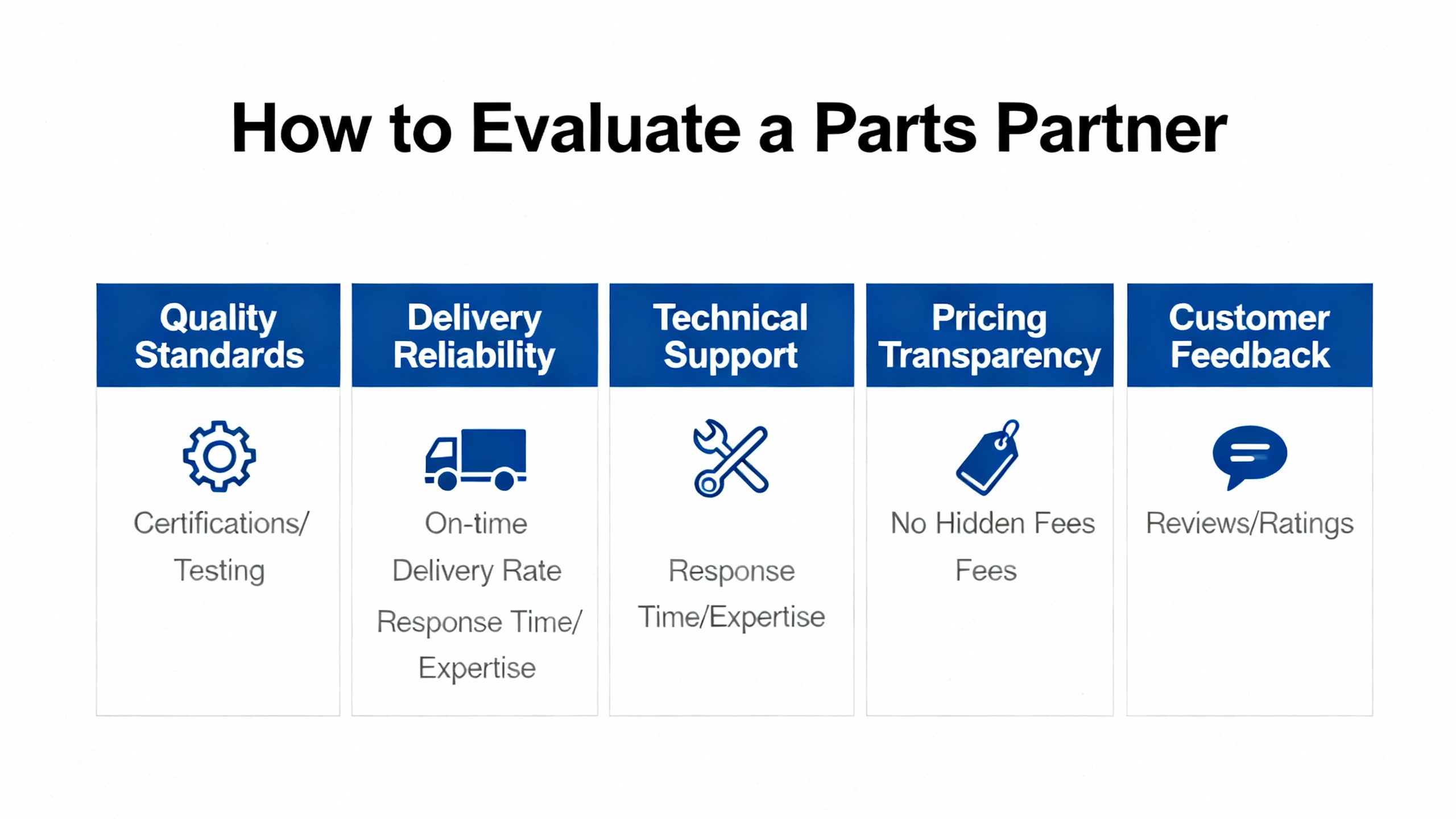

From a reliability and power-systems standpoint, evaluating a GE Fanuc parts supplier is about more than price. The GE Fanuc Spares overview explicitly recommends prioritizing suppliers that provide fully tested OEM parts with a warranty, in-house repair capability, and next-day shipping where possible. That combination reduces the risk that a replacement introduces new faults and ensures that logistics do not become the bottleneck when a key CNC or robot cell is down.

Quality and testing should be front and center in your evaluation. GE Fanuc Spares emphasizes that all GE Fanuc parts sold are functionally tested in-house before shipment, and that service-exchange items are repaired and fully function-tested on dedicated rigs. Lemhunter notes that high-quality FANUC replacement parts are tested to strict standards to ensure seamless integration and compatibility with existing control systems and hardware. When you speak with a potential supplier, ask explicitly how they test parts, whether they can document those tests, and what conditions void the warranty. A supplier that can answer these questions concretely is usually better equipped to support you when something goes wrong.

The breadth of lifecycle services also matters. DO Supply highlights ŌĆ£Buy, Sell & RepairŌĆØ capabilities, while GE Fanuc Spares combines new, used, service-exchange, and refurbishment. NRwell emphasizes support for new, refurbished, and obsolete GE Fanuc components, and MRO Electric focuses on application-driven guidance throughout the selection process. Having access to both new and refurbished options, as well as repair paths, allows you to optimize cost, risk, and lead time on a case-by-case basis rather than being locked into a single approach.

Finally, consider how the supplier will work with you over time. Lemhunter recommends regular inspections, scheduled preventive maintenance, and keeping an on-site inventory of critical and frequently replaced FANUC parts. Suppliers such as Industrial Automation Co., which encourage customers to stock up on spare parts before CNC machines break down, are naturally aligned with this strategy. A strong partner will help you identify high-risk components, estimate realistic lead times, and design a spare-parts cabinet that complements your UPS and power-protection design so that transient events and component wear do not translate directly into long outages.

It is often easier to choose the right supplier when you think in terms of specific scenarios rather than abstract criteria. Three situations come up repeatedly in plants that rely on GE Fanuc hardware.

Imagine that a legacy GE Fanuc CNC control goes down during a peak production run, taking a high-value machining center offline. The failed module is an older spindle drive that no longer appears in mainstream catalogs. In this case, specialist providers such as GE Fanuc Spares or DO Supply are often the most effective starting point. GE Fanuc Spares can check whether the part exists as an OEM exchange item, provide a fully tested replacement from their ex-stock inventory, and arrange next-day shipment where logistics allow. DO SupplyŌĆÖs concierge-style service can help track down rare or obsolete part numbers using their network.

Technical assistance is critical here. You want a specialist to confirm that the proposed replacement is truly identical or that any revision differences are compatible with your controller, field bus, and power infrastructure. If repeated failures point to underlying power quality or thermal issues, coordinating with your power-systems team to verify UPS sizing, grounding, and surge protection will prevent the replacement from suffering the same fate.

In a second scenario, you might be planning a controller or robot upgrade rather than reacting to a failure. Perhaps you are migrating an older GE Fanuc robot cell to a newer model while keeping some legacy axes or peripherals. Lemhunter stresses that the correct FANUC spare parts are vital for maintaining safety, production quality, and efficiency, and that specialized third-party suppliers can provide refurbished and tested components for older systems that are no longer in regular production.

Here, a combination of OEM or authorized distributors and multi-brand distributors such as NRwell, MRO Electric, or Industrial Automation Co. can be effective. OEM channels can supply the latest controllers, motors, and safety-related modules, while third-party distributors provide refurbished or obsolete components needed to bridge old and new. The technical assistance you want in this scenario involves compatibility guidance, advice on what should be upgraded vs left in place, and help planning a spare-parts strategy that covers both generations without unnecessary duplication.

The third scenario is less dramatic but arguably more important: building or refining a strategic spares cabinet so that the next failure is far less disruptive. Lemhunter recommends keeping an on-site inventory of critical and frequently replaced FANUC parts and pairing that with regular inspections and scheduled preventive replacement. Industrial Automation Co. echoes this by encouraging customers to stock FANUC spare parts before CNC machines break down. Industrial Automation Co., MRO Electric, NRwell, and GE Fanuc Spares are all positioned to help identify which servos, amplifiers, power modules, boards, and operator interfaces fail most often in systems like yours.

In my own practice, I like to align that spare-parts list with the power and protection design. If you know a particular power supply or servo amplifier is sensitive to voltage sags or transients, it may be a candidate both for local surge protection and for higher stocking levels. A distributor that can talk through failure histories, recommend a mix of new and refurbished units, and help you prioritize against a limited budget becomes a long-term reliability partner rather than just another vendor.

Although GE Fanuc part sourcing and power protection are often managed by different teams, they are tightly coupled in practice. Power supply modules, servo amplifiers, and control boards are among the first components to suffer when there are repeated voltage dips, transient overvoltages, or grounding issues. If you are continually replacing the same GE Fanuc power supplies or drives, the problem is rarely ŌĆ£bad partsŌĆØ in isolation.

Suppliers that invest in technical assistance can help you spot these patterns. When GE Fanuc Spares tests a returned module and sees consistent damage signatures, or when Tri Star CNC Services diagnoses recurring faults on repaired boards, their findings can inform how you size UPS systems, configure inverters, or deploy surge protection. Likewise, distributors such as MRO Electric and Industrial Automation Co., which position themselves as application-focused rather than purely transactional, are often willing to discuss whether repeated failures might be linked to environmental or electrical conditions rather than inherent part quality.

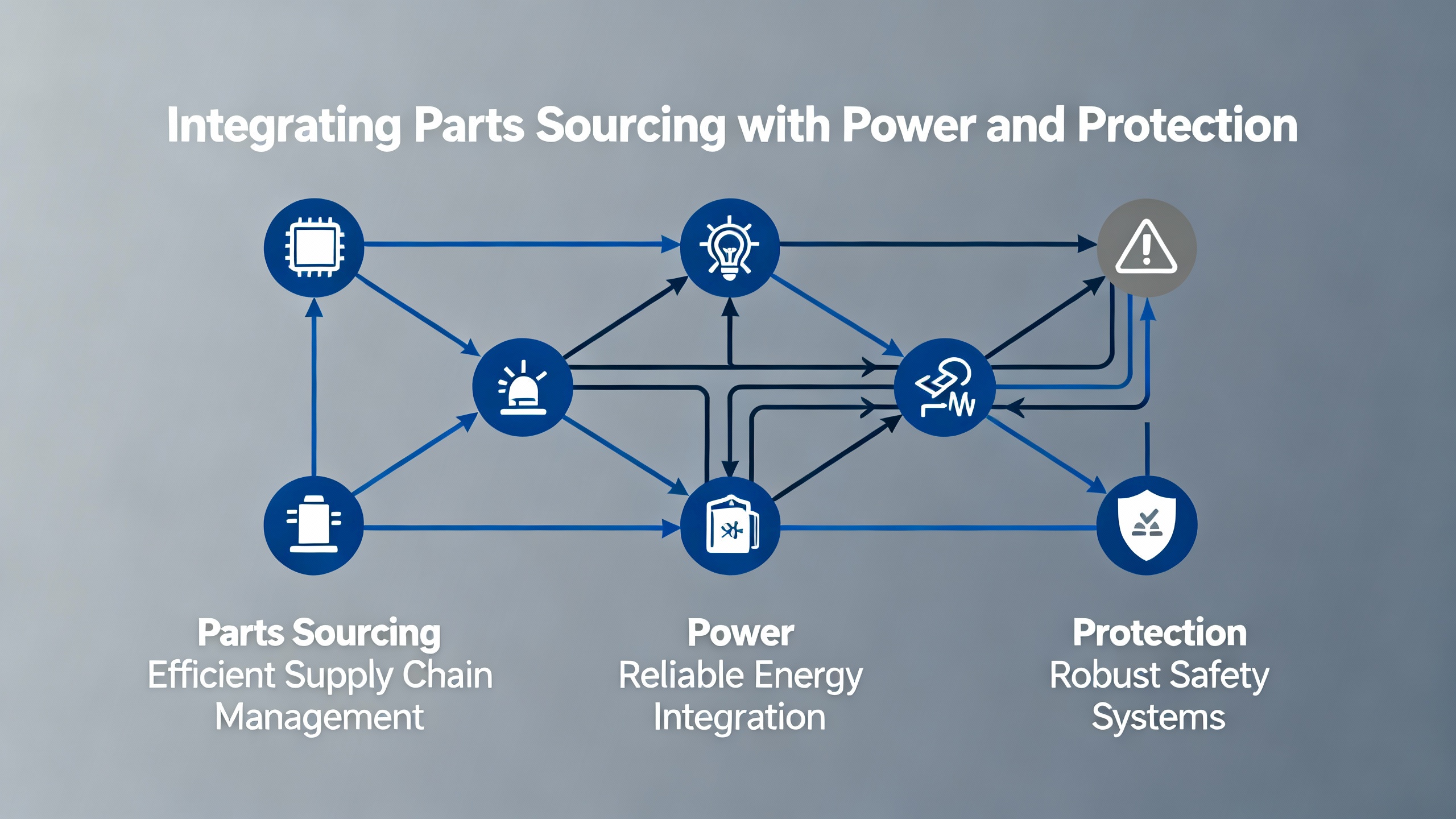

From the power-system side, integrating part failure data into your reliability models allows you to distinguish between expected wear (such as servos that reach end-of-life under heavy duty cycles) and preventable stress (such as power modules failing early due to poor harmonic conditions). When you treat GE Fanuc parts sourcing, repair, and power protection as a single reliability ecosystem, every failure becomes an opportunity to strengthen both your spare-parts strategy and your electrical infrastructure.

The research consistently shows that genuine OEM or high-quality refurbished GE Fanuc parts can both be appropriate, depending on context. Lemhunter emphasizes that using genuine or high-quality compatible FANUC parts extends machine life, protects accuracy, and reduces the risk of frequent breakdowns and long-term repair costs. GE Fanuc Spares and NRwell both offer refurbished or service-exchange components that are functionally tested in-house and backed by warranties. In practice, OEM new parts are often preferred for safety-critical functions or where corporate policies demand them, while refurbished parts from reputable suppliers are a cost-effective option for legacy systems and non-safety-critical roles, provided they are rigorously tested and warrantied.

Speed depends on geography, stock levels, and whether the part is current or obsolete. GE Fanuc Spares reports ex-stock approved FANUC CNC parts in a central UK parts center with next-day shipment to most of the UK and Europe and parts of the USA, and they also offer OEM core exchange to accelerate turnaround. Industrial Automation Co. highlights two-day shipping within the continental United States for FANUC spare parts under 20 lb and the possibility of same-day courier service in emergencies, coupled with quote turnaround in about ten minutes during business hours. For very rare or obsolete components, DO SupplyŌĆÖs concierge-style service may lengthen the sourcing phase but can still be faster than unmanaged searching. The main takeaway is that choosing suppliers who explicitly invest in fast logistics and support is at least as important as the initial unit price.

Based on how these suppliers describe their services, it helps to come prepared with precise part numbers, equipment model and generation, a description of the failure mode, and any recent changes in your process or power system. DO Supply emphasizes that their expert team assists in locating exact parts, which is far easier when part numbers and context are clear. GE Fanuc Spares and Tri Star CNC Services both rely on accurate identification to decide whether repair, service-exchange, or direct replacement is best. In my experience, providing photos of nameplates and control cabinets, along with notes on recent power disturbances or mechanical changes, allows technical teams at suppliers like MRO Electric, Industrial Automation Co., and NRwell to give more targeted advice and avoid misorders.

LemhunterŌĆÖs overall recommendation is to treat investment in reliable FANUC parts, proactive maintenance, and reputable suppliers as a direct investment in long-term operational stability, precision, and productivity. Binfire ties high-quality FANUC parts to avoidance of costly machine downtime and emphasizes that dependable parts also support operator satisfaction and workplace safety. When you complement that with suppliers such as GE Fanuc Spares, DO Supply, Industrial Automation Co., MRO Electric, NRwell, and Tri Star CNC Services, which all highlight various forms of technical support, fast response, and repair capabilities, you create a closed loop: failures are resolved quickly with appropriate hardware, lessons from those failures inform your spare-parts and power strategies, and your systems run closer to their designed reliability.

In the end, buying GE Fanuc parts with strong technical assistance is not just a procurement decision; it is a reliability strategy. When you align OEM and specialist suppliers, refurbishment and repair options, and robust power protection around the specific realities of your plant, you turn each replacement into an opportunity to harden your automation assets rather than simply getting back to where you were yesterday.

Leave Your Comment