-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

In a modern process plant, your Emerson DeltaV distributed control system is not just another automation platform. It is the coordination layer that keeps reactors, distillation columns, boilers, and utilities running in a stable, safe, and predictable way. When DeltaV hardware fails and you do not have the right spare on the shelf, the risk is not limited to a few hours of lost production. You can face missed shipments, quality excursions, overtime charges, and sometimes long-term damage to customer confidence.

EmersonŌĆÖs own experts emphasize this in discussions on control-system reliability and spare parts. In a piece on the ŌĆ£5Ps of control system reliability and performance,ŌĆØ they point out that downtime cost includes far more than production loss. It also includes ongoing labor costs during outages, expedited shipping for emergency parts, and the reputational impact of delayed deliveries. That aligns with what I see in the field: a single day of unplanned downtime on a critical unit often outweighs years of incremental savings from holding a lean parts inventory.

As a power and reliability specialist, I view DeltaV just like high-criticality UPS-backed power infrastructure. You are not buying only controllers, I/O cards, and workstations. You are buying the assurance that, if something fails, the system can either ride through or be recovered within your acceptable mean time to repair. For that, you need both good design and dependable stock availability, at your site and within EmersonŌĆÖs ecosystem.

Before you can design a solid spares strategy, it helps to be clear about what you are protecting. EmersonŌĆÖs DeltaV platform is a full distributed control system that spans field I/O, controllers, HMI, batch and advanced control, historians, and integration to enterprise systems. According to DeltaV platform overviews and brochures, it scales from small skids and single units all the way to large multi-unit plants. Controllers, intelligent I/O (including CHARMs electronic marshalling), and operator workstations are pulled together in a single engineering and operations environment.

Emerson highlights high availability as a core value. Redundant controllers, power supplies, communication networks, and I/O paths are part of the standard architecture so that a single component failure does not cause loss of control. The DeltaV distributed design, combined with virtualization options and fit-for-purpose infrastructure, makes it possible to expand incrementally and to modernize without ripping out the entire system at once.

On the operations side, tools like DeltaV Live and high-performance HMI design services emphasize situational awareness, clear alarm presentation, and fast diagnosis. DeltaV History Analysis and related historian tools store long-term process data, alarms, and events, enabling engineers to understand how the system behaves and to troubleshoot subtle issues. DeltaV InSight adds loop-performance analytics, while DeltaV Advanced Control & Analytics brings model predictive control and inferential quality monitoring into the same environment.

This integration means that a single failed network switch or controller can affect far more than one loop. It can undermine advanced control applications, historian visibility, and safety margins that rely on stable regulatory control. That is why treating DeltaV hardware as an asset class deserving its own stock-availability strategy is critical.

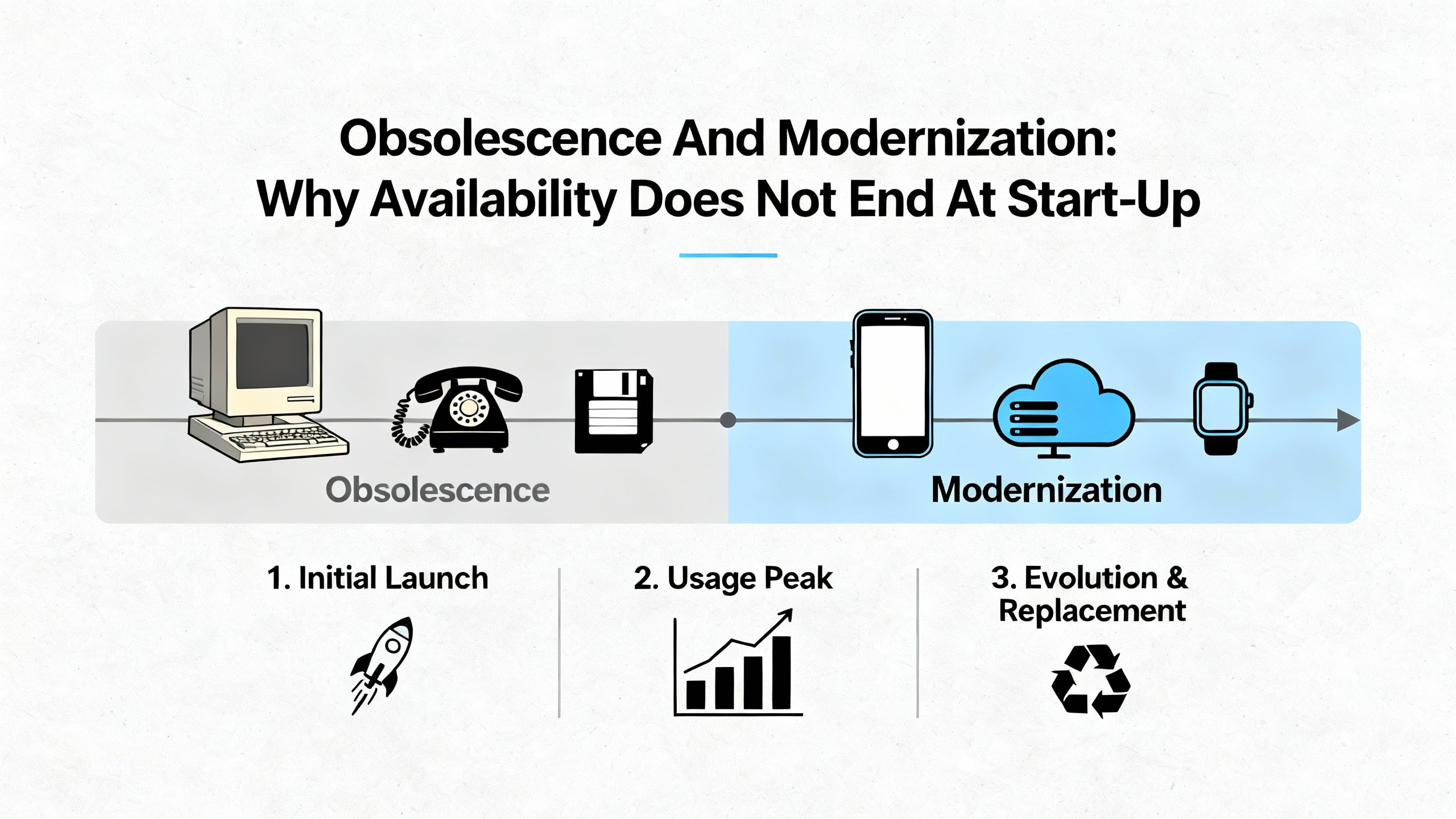

In many industries, especially in pulp and paper, plants are still running automation systems that are 15 to 30 years old. A Laurentide article on DeltaV modernization notes that some mills continue to operate control systems that predate the year 2000. The result is a combination of cybersecurity risk, hardware and software obsolescence, and a shrinking pool of experienced personnel willing and able to support these legacy systems.

The same article points out a key tension. Facilities often operate multiple obsolete DCS and PLC platforms at once. Managing even one outdated system is demanding; maintaining several quickly becomes unsustainable. Obsolescence is not just about whether spare parts exist somewhere in a global warehouse. It is about whether you can bring new I/O into the system, support plant expansions, or troubleshoot failures when parts, tools, and expertise are all aging out together.

Modernizing to a current-generation DeltaV system is framed as more than an obsolescence fix. It is a foundation for digital initiatives such as data analytics, artificial intelligence, machine learning, and advanced simulation-based operator training. However, modernization itself only pays off if you treat the new DeltaV system as a living asset with a clear lifecycle and stock strategy. That means thinking ahead about how quickly you can recover from a failed PK controller, I/O carrier, or workstation ten years down the road, not just during the first year after commissioning.

Electronic Marshalling is a good example. Laurentide highlights EmersonŌĆÖs Electronic Marshalling technology as a best-in-class option for ŌĆ£rip and replaceŌĆØ projects because it offers channel-level flexibility, a wide range of input types, and strong scalability. From a stock-availability standpoint, this can simplify your spare inventory by consolidating diverse I/O types into fewer, more flexible modules. It also raises the stakes: if many signals in a critical area depend on a single Electronic Marshalling base and CHARMs, the availability of those specific parts becomes even more important.

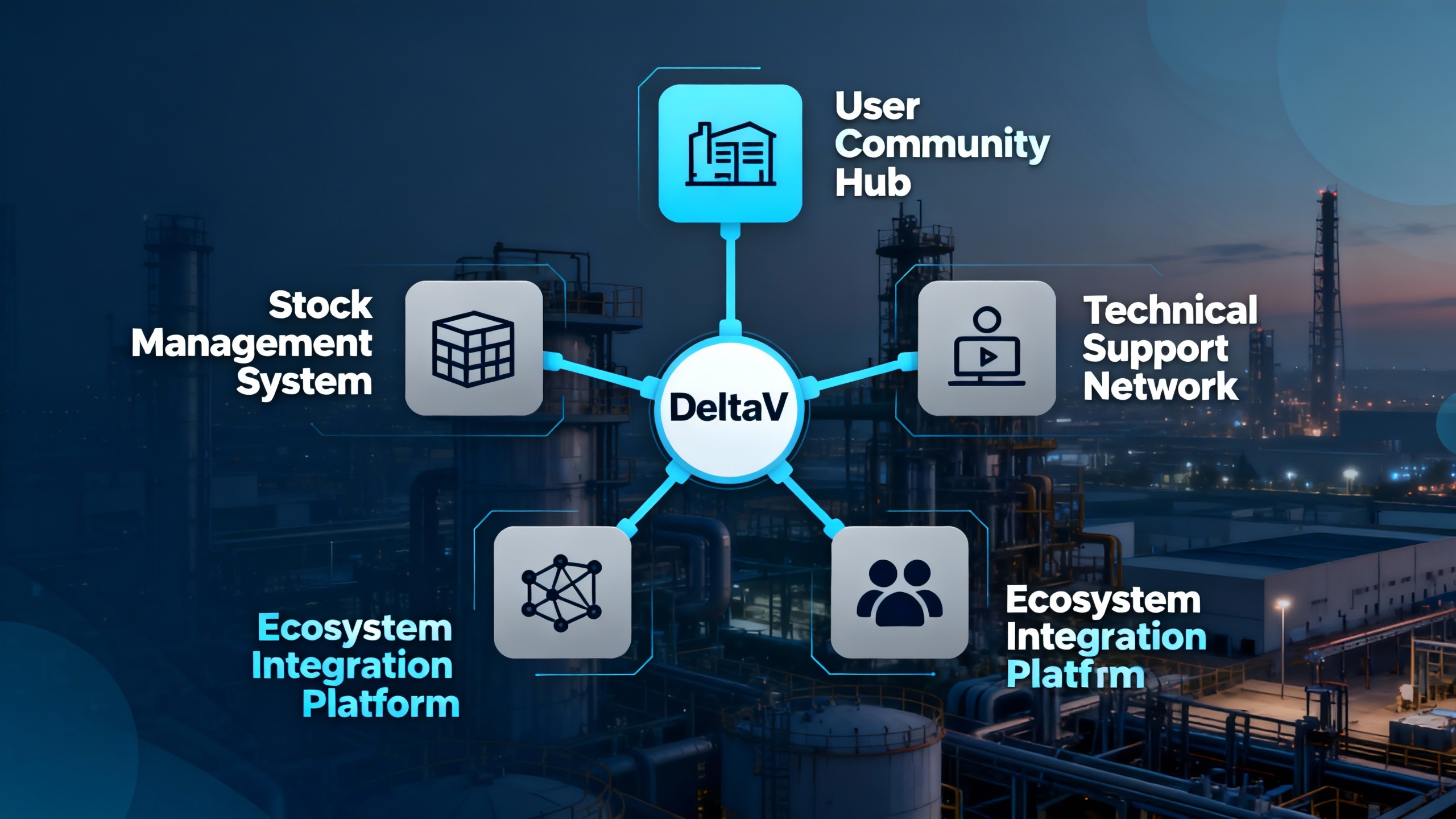

Stock availability is not just about what sits in your storeroom. It is also about the strength of the vendor ecosystem behind you. The 5Ps article on control system reliability and related Emerson service literature describe several layers of support and logistics designed to keep DeltaV assets available over their life.

Spare parts management is the first layer. Emerson emphasizes that onsite DCS spares for controllers, I/O cards, workstations, and networking devices are a proactive strategy that reduces time to repair, minimizes rush orders, and lowers the risk of extended downtime. Mean Time To Repair (MTTR) is a central concept: by holding critical spares locally, plants can restore service much more quickly than if they rely solely on external warehouses.

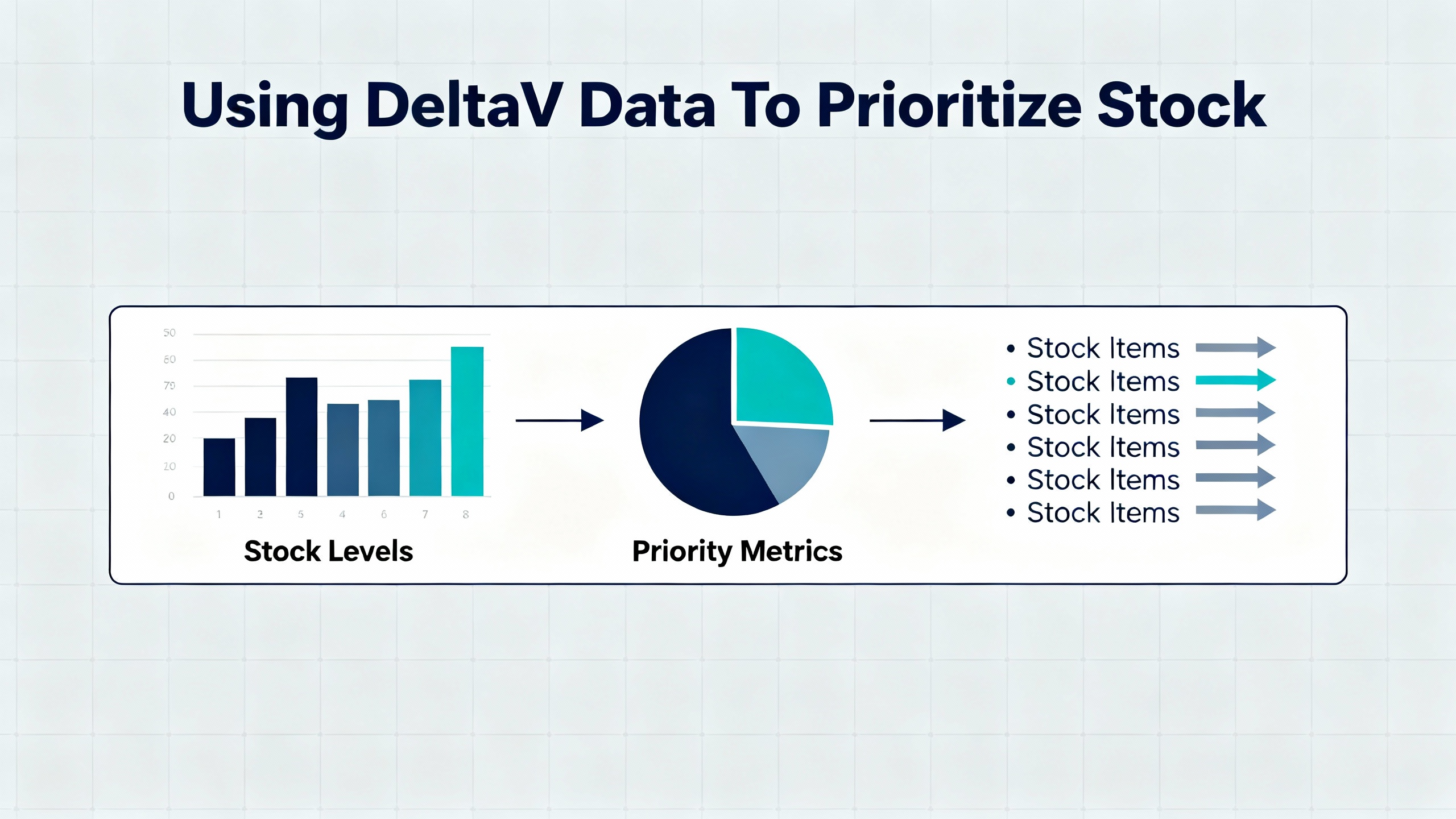

To help calibrate how much to stock, Emerson references reliability intelligence such as Mean Time Between Failures (MTBF) and field experience. Lower MTBF components justify higher stocking levels, while higher MTBF devices may require fewer spares. This is not guesswork. The Emerson Spare Parts Calculator App draws on reliability data, product lifecycle information, field failure rates, and even country-specific transit times to recommend onsite spares and calculate an ŌĆ£in-stock probability percentageŌĆØ for parts availability.

Above onsite inventory sit expedited logistics programs. QuickShip Emergency is a 24/7 service aimed at identifying and shipping critical parts rapidly, while QuickShip Expedite focuses on sourcing DeltaV DCS and safety-system parts from the nearest distribution center within a few business days. These programs help bridge gaps where onsite stock is insufficient or where unusual failures exceed what you planned for.

The DeltaV Extended Hardware Warranty Service adds another layer. For enrolled DeltaV DCS, SIS, or PK controller systems, Emerson offers replacement assemblies, new or factory-repaired, at no additional cost within the warranty structure. Each replacement carries its own warranty period, and parts are dispatched from central depots within a business day after material return processing. That effectively turns some of your ŌĆ£virtual sparesŌĆØ into guaranteed availability from EmersonŌĆÖs network rather than inventory you pay to stock on the plant floor.

Taken together, these elements represent a multi-layer availability strategy: onsite spares to minimize MTTR, data-driven stocking recommendations to avoid over- or under-stocking, expedited logistics for exceptions, and extended warranty programs to guarantee supply for covered hardware families.

Stock availability is only useful if you know the true health of your system and can act before a failure becomes a crisis. EmersonŌĆÖs lifecycle service literature for DeltaV systems makes this point by positioning services as a continuous thread from design through operation, optimization, and modernization.

Lifecycle services commonly cover front-end consulting, project implementation, commissioning, and then long-term support such as patch management, backup and recovery, remote diagnostics, and modernization planning. A central message is to move from reactive, break-fix maintenance toward proactive, risk-based strategies guided by condition monitoring and OEM insight. Guardian Support for DeltaV, as described in partner data sheets, is a subscription-based service that brings together technical support, software and firmware updates, and often remote health diagnostics into a structured program.

Scallon ControlsŌĆÖ description of DeltaV System Health Monitoring adds further detail. Their service continuously scans the health of the integrated DeltaV control system, from controllers and servers down to switches and network components. The solution runs around the clock, automatically diagnosing health warnings and generating alerts when issues are detected. That means you can detect abnormal conditions or early signs of degradation long before they cause outright failures.

When you combine continuous health monitoring with Guardian Support and structured lifecycle services, you gain the ability to align your spare parts strategy with real field behavior rather than static assumptions. Assets that show repeated warnings or borderline performance can be flagged for additional spares. Components that remain stable and are backed by strong MTBF data may justify leaner stocking. In practice, this reduces the chance of missing a high-impact failure and lowers the total cost of carrying inventory you rarely use.

From a reliability-engineering standpoint, an effective onsite spares strategy for DeltaV needs to be structured, defensible, and closely tied to your plantŌĆÖs risk appetite. EmersonŌĆÖs guidance on spare parts and extended warranty programs provides the foundation, but the actual stocking levels must reflect your particular configuration, processes, and consequences of failure.

A practical way to approach this is to classify DeltaV components by criticality and recoverability. Controllers running high-hazard or high-value units, backbone network switches, and key I/O subsystems that feed safety logic or advanced control applications typically fall into the highest criticality tier. For those assets, the target MTTR should be extremely low, so you plan to hold at least one fully compatible spare onsite. For less critical assets, such as engineering workstations that can be temporarily replaced with another node, ŌĆ£virtual stockŌĆØ through warranty and QuickShip may suffice.

The 5Ps article highlights that MTTR and MTBF should guide stocking decisions. You cannot directly control MTBF once you select a technology, but you can dramatically influence MTTR with the right spare parts on the shelf and proven replacement procedures. At the same time, inventory costs are real. Controllers and I/O cards are high-value items, and they often require climate-controlled, secure storage and periodic inspection to ensure they remain usable. Obsolescence risk also grows over time: if you hold spares for hardware that becomes unsupported, your stock can lose value quickly.

This is where EmersonŌĆÖs Spare Parts Calculator becomes useful. By capturing MTBF, lifecycle stage, and logistics, it outputs recommended spares and an in-stock probability percentage. In my experience, this type of calculation can be used as an initial proposal which you then adjust based on process risk. For a unit whose failure might ruin a batch, damage equipment, or create an environmental incident, you may choose to target a higher in-stock probability than for a noncritical utility area.

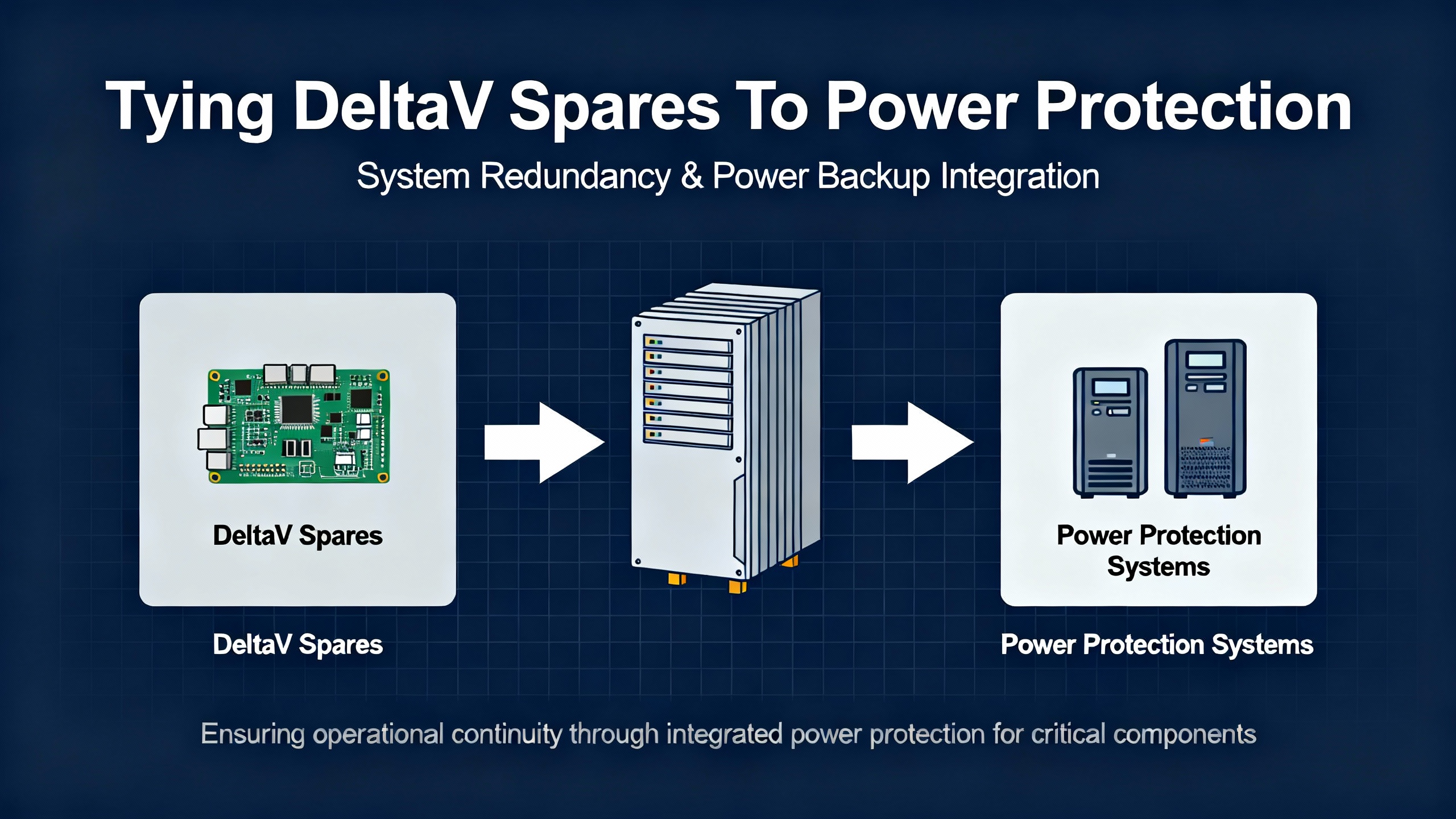

While the provided sources focus on control hardware and services, power reliability sits under all of this. In the field, I routinely see DeltaV systems protected by layered power architectures that include redundant feeds, industrial UPS systems, and well-sized inverters to ensure clean, uninterrupted power. Even with excellent spare parts strategies, repeated power disturbances will erode controller and I/O reliability, stress storage media, and trigger nuisance trips.

From a stock-availability perspective, this means your spares plan cannot be isolated from your power protection plan. If your UPS runtime is marginal, or your power distribution exposes parts of the control system to frequent sag or transient events, your effective MTBF for those components will be lower than generic data suggests. In that case, you either improve the power design or accept higher stocking levels for affected parts.

Conversely, if you invest in robust power conditioning and regular battery maintenance, you can rely more confidently on published MTBF figures and design a leaner spare inventory. This is also where DeltaV System Health Monitoring, combined with power quality monitoring, can highlight whether power-related events are driving control hardware faults. When you see patterns of controller resets or network anomalies that correlate with power disturbances, you have hard evidence to justify both power-system upgrades and adjustments to your spares approach.

EmersonŌĆÖs tools for data analysis and performance monitoring can do more than support process optimization. They can directly inform stock decisions.

DeltaV History Analysis provides trending and investigation across long time periods. Engineers commonly use it to diagnose upsets, validate control strategy changes, and examine batch variability. However, the same tool can reveal patterns of instrument and valve behavior that hint at degrading hardware. Frequent bad-quality periods, repeated manual interventions on certain loops, or recurring alarm floods from a specific I/O card can all indicate where additional spares or targeted maintenance would provide the biggest risk reduction.

The article on extracting history collection configuration from DeltaV Explorer shows how to export lists of historized points into tools like Excel or Access. While that workflow is aimed at auditing historized parameters, it also provides a way to enumerate which control modules and signals your team cares about most. These are typically tied to critical loops, key performance indicators, or safety constraints. By mapping those historized points back to specific controllers and I/O channels, you effectively identify the hardware that supports your most important measurements and control actions. That hardware deserves priority in your spare parts strategy.

DeltaV InSight, although not described in detail in the notes, is generally positioned by Emerson as an intelligent process control module that continuously evaluates loop performance and flags poorly performing loops and suspect valves. Using InSightŌĆÖs diagnostics, you can identify troublesome loops that may be affected by valve problems, tuning issues, or hardware limitations. When particular hardware segments repeatedly generate performance concerns, that is a signal to review both their condition and your stock coverage.

Continuous engineering, as described by Proconex, takes this idea even further. Instead of treating control-system improvements as rare, large projects, continuous engineering calls for ongoing system reviews, tuning, backup verification, and patch testing. By institutionalizing these activities, you gather a steady stream of data about which nodes are stressed, which networks are near capacity, and which loops behave on the edge of acceptable performance. Spares decisions based on this real-time engineering insight are far more effective than static, once-per-decade stocking studies.

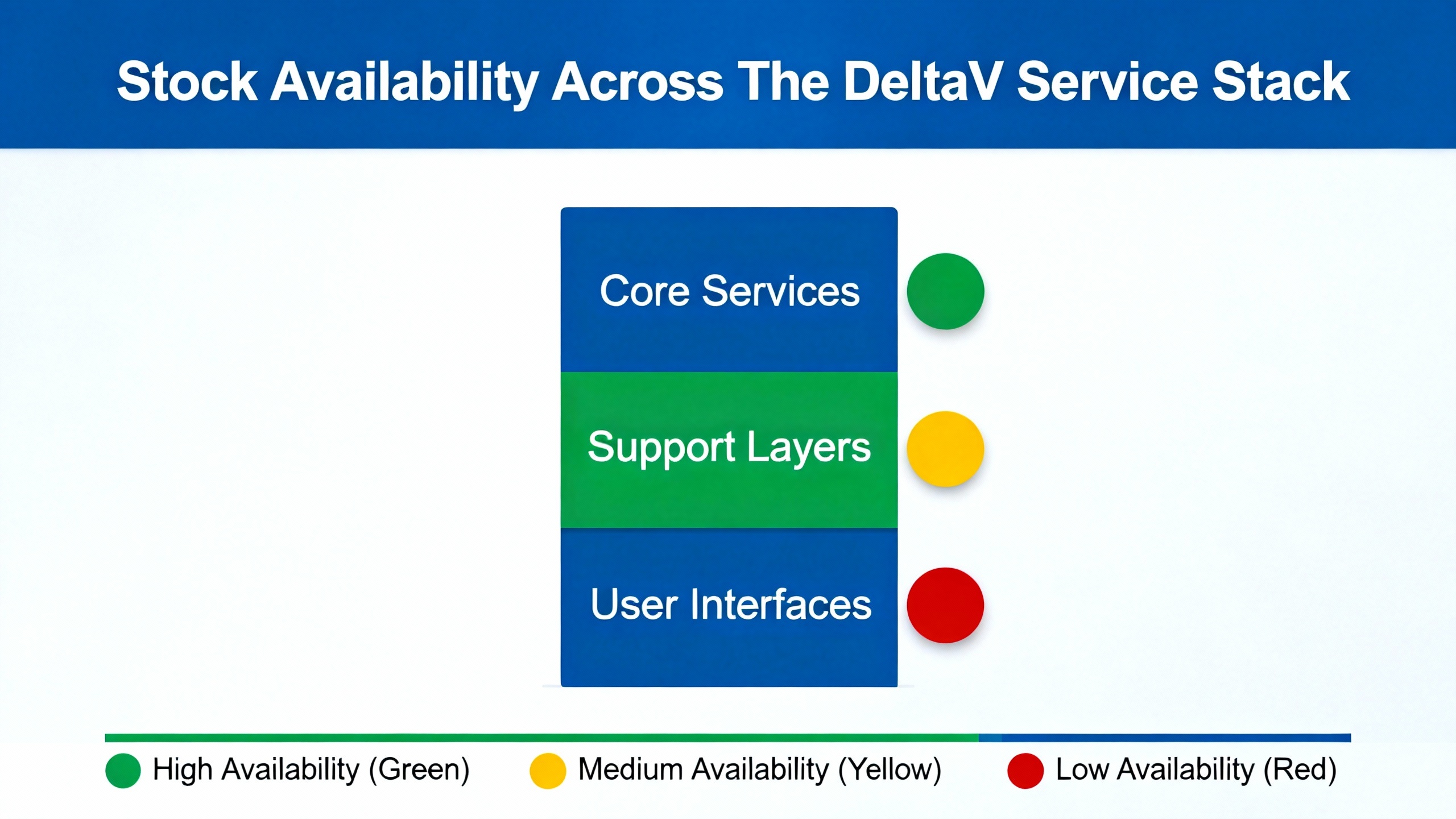

Seen from a plant perspective, stock availability for DeltaV is not just about a box of cards labeled ŌĆ£DCS spares.ŌĆØ It spans their entire service stack. The table below summarizes how different Emerson offerings and related services support availability and uptime.

| Element | Primary Role In Availability |

|---|---|

| Onsite spares and Spare Parts Calculator App | Minimizes MTTR by ensuring critical DeltaV components are physically available at the plant when needed. |

| QuickShip Emergency and QuickShip Expedite | Provides expedited shipment of parts from EmersonŌĆÖs network when onsite stock is insufficient or missing. |

| DeltaV Extended Hardware Warranty Service | Guarantees access to replacement assemblies for enrolled hardware families with defined response times. |

| Guardian Support and lifecycle services | Coordinates technical support, patch management, and modernization planning to prevent availability gaps. |

| DeltaV System Health Monitoring | Continuously scans controllers, servers, switches, and networks to detect issues early and trigger action. |

| DeltaV History Analysis and InSight | Uses historical data and loop diagnostics to expose patterns that inform maintenance and stocking priorities. |

| Continuous engineering programs | Keeps configurations, backups, and performance tuning aligned with current operations to avoid latent risks. |

A robust DeltaV stock strategy acknowledges all of these layers. You hold spares locally for high-impact failures, leverage quick logistics and warranty programs for the rest, use health and performance data to adjust your stocking over time, and rely on lifecycle services to avoid being trapped on obsolete, unsupported hardware.

The more advanced your control strategies become, the more important stock availability is. EmersonŌĆÖs DeltaV advanced control and analytics materials emphasize model predictive control, advanced regulatory control, and inferential quality calculations. These strategies operate near constraints, coordinating multiple loops and assets to reduce variability and energy use.

In practical terms, this means that a single controller or I/O subsystem often hosts both basic regulatory loops and the variables that feed advanced control and optimization. An outage on this hardware can cause a step backward in process stability and operating margins, not just a simple mode change. The same is true for batch operations and recipe management in DeltaV. When key batch units rely on complex sequences and S88-aligned recipes, losing the relevant controllers can disrupt an entire campaign.

Stock strategies therefore need to recognize that some hardware is ŌĆ£leverage equipmentŌĆØ for advanced control. For those nodes, you may choose to hold additional spares or to enroll them in more comprehensive warranty and support programs. That way, if a controller that hosts a critical model predictive controller fails, you can replace it quickly and restore your intended operating envelope, rather than reverting indefinitely to a less efficient mode.

Digital transformation initiatives also interact with stock. As Laurentide points out, modern DeltaV systems are the enabler for projects ranging from real-time optimization and predictive maintenance to energy management and simulation-based operator training. These digital projects often rely on continuous, high-quality data from specific nodes and networks. The failure of those nodes does not just break control; it breaks analytics, training workflows, and corporate key performance indicators. That broader impact should be reflected in how you classify and stock those assets.

A: There is no universal number, because stocking levels should be driven by MTBF, MTTR targets, logistics, and process risk. Emerson addresses this by providing the Spare Parts Calculator App, which uses reliability and lifecycle data plus transit times to recommend onsite inventory and quantify the probability that you will have a given part in stock. In practice, engineers typically start with these recommendations and then adjust for high-consequence units where failures have disproportionate safety or economic impact.

A: QuickShip Emergency and QuickShip Expedite significantly reduce lead time compared with conventional ordering, and extended hardware warranty ensures access to replacements for enrolled hardware. However, even a short shipping delay can be too long for some units. When the cost of an hour of downtime exceeds the carrying cost of a spare, local inventory is still justified. Onsite spares are about driving MTTR toward the minimum that your safety, contractual, and business requirements demand.

A: Continuous health monitoring, as described by Scallon Controls, reveals which parts of your DeltaV infrastructure are experiencing repeated warnings, borderline conditions, or intermittent faults. When a controller, server, or switch is repeatedly involved in health alerts, that is a strong signal to both plan proactive maintenance and verify that you have compatible spares available. Conversely, assets that show consistently clean health histories, combined with strong MTBF data, might allow leaner stocking.

A: Modernization to a current DeltaV platform solves many obsolescence problems and opens the door to new support and warranty programs, but it does not automatically create a good spares strategy. LaurentideŌĆÖs modernization guidance emphasizes breaking projects into manageable phases and designing a roadmap. A complete roadmap should include explicit decisions about which DeltaV components will have onsite spares, which will rely on expedited logistics and warranty support, and how your stocking plan will be updated as the system evolves.

A: While the Emerson notes focus on control hardware, field experience shows that power disturbances are a major driver of control-system failures. If your DeltaV system is not backed by robust UPS and power conditioning, actual MTBF for controllers and servers may be lower than generic data suggests. In that case, your spares plan should either assume higher failure rates or, preferably, you should improve the power infrastructure and then review stocking levels. Aligning power reliability and stock strategy is one of the most effective ways to reduce both downtime and inventory cost.

When you look at DeltaV through a power and reliability lens, stock availability stops being a purchasing detail and becomes a core design variable. EmersonŌĆÖs ecosystem of spares, logistics, monitoring, and lifecycle services provides strong building blocks, but the real resilience comes from how you combine them with your own onsite inventory, power protection, and continuous engineering practices. If you treat your DeltaV platform with the same discipline you apply to high-criticality power systems and UPS-backed infrastructure, you can turn spare parts from a reactive expense into a strategic tool for long-term process stability and business continuity.

Leave Your Comment