-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

When you design industrial or commercial power systems, you rarely get the luxury of a “pure” power project. Your UPS, inverters, automatic transfer switches, and switchboards all need a control layer that is compact, dependable, and easy to service. That is where Siemens’ SIMATIC S7-1200 family fits: a compact PLC line that has enough I/O, communication, and safety options to supervise serious power infrastructure without dragging you into high-end DCS complexity.

From a power system specialist’s point of view, the S7-1200 is best understood as Siemens’ small-to-medium controller family within the broader S7 portfolio described by PLCHMIS and Siemens product overviews. The S7-1200 serves compact and cost-sensitive applications, the S7-1500 serves higher-performance, medium-to-large systems, and the S7-400 targets very demanding and large-scale plants. RealPars’ introductory material on S7-1200 reinforces this positioning: S7-1200 CPUs are compact, with integrated I/O and built-in PROFINET communication, suited to tasks like stand-alone machines and building HVAC systems.

For power engineers, that translates directly into systems like small switchboards, building-level UPS and generator control, PV or battery inverters, and compact utility interface panels. You get enough capability to implement robust sequencing, monitoring, and alarming, without jumping to more expensive high-end controllers until you truly need them.

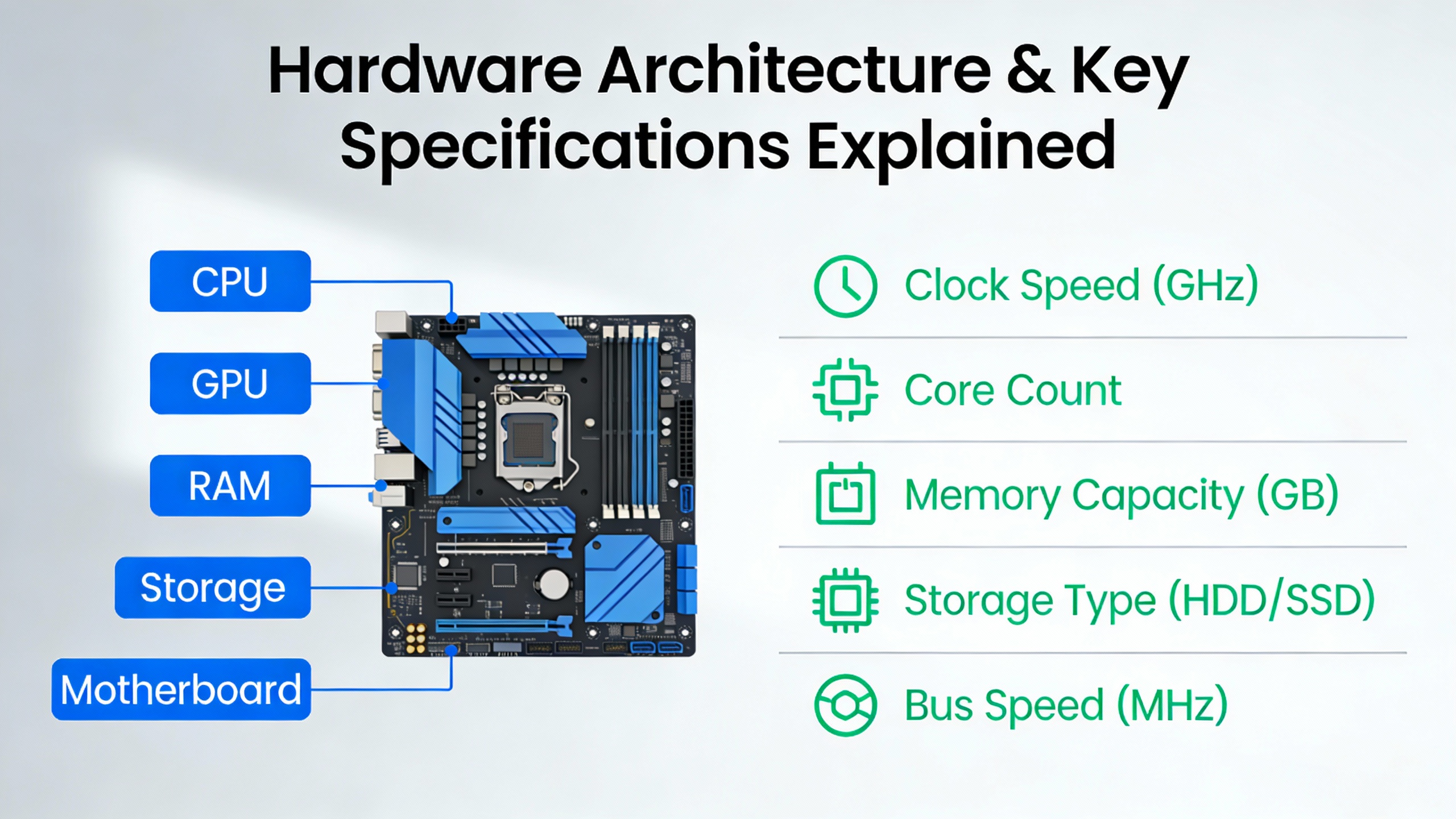

The S7-1200 family is built around several compact CPU types that share a common hardware concept described in RealPars and PLCHMIS sources. All these CPUs integrate a power supply, a central processing unit, built-in digital and often analog I/O, and a PROFINET Ethernet port, with the option to add more I/O and communication modules as needed.

RealPars breaks down the CPU models in terms of application scale and capability. CPU 1211C is described as a starter model with less memory and fewer communication options, suitable for small and medium projects, such as stand-alone machines or building HVAC systems. CPU 1212C has more inputs and outputs and supports PID control, making it appropriate for medium-sized applications like industrial furnaces, where temperature and pressure must be regulated precisely. CPU 1214C steps up to more advanced automation tasks such as material handling, pump control, or managing small processes, still with PID but with more advanced capabilities and capacity for larger systems. CPU 1215C targets large automation tasks that need high-speed processing and advanced communication, for example more complex process control, motion control, or large material handling systems, and it can be accessed over a web browser for remote interaction. CPU 1217C follows the same pattern as 1215C but provides more inputs and outputs and higher processing speed, which RealPars highlights as important for high-speed data acquisition, such as packaging lines where many data points must be captured quickly and used for real-time adjustments.

All these CPUs end with the letter “C,” which RealPars clarifies as indicating a compact design. Compact in this context means the CPU module itself is small and already includes integrated I/O, reducing panel space and wiring. If you need more points, you can add extra I/O modules or plug-in signal boards without abandoning the compact form factor. For power-system panels where every inch of DIN rail and every degree of enclosure temperature matters, that compactness is not cosmetic; it directly affects cabinet size, cooling, and layout.

The clearest published technical comparison in the notes is between the standard S7-1200 CPU 1212C and its second-generation G2 counterpart, as detailed in a Digi-Key learning example. Both versions retain a similar I/O mix: eight digital inputs at 24 V DC, six relay digital outputs rated at 2 A, and two analog inputs for 0–10 V DC. That onboard I/O set already fits many compact power applications, such as monitoring breaker auxiliary contacts and issuing trip or close commands while measuring a pair of analog signals, for example bus voltage and a load percentage signal from a meter.

Where the G2 version differentiates itself is in resource and efficiency improvements. The standard CPU 1212C has 100 kB of integrated work memory and 2 Mb of integrated load memory, with a power consumption of 9 W, and a height of about 90 mm, roughly 3.5 in. The CPU 1212C G2 increases work memory to 650 kB and load memory to 8 Mb, while reducing power consumption to 3 W and lowering the module height to about 70 mm, roughly 2.8 in. The G2 also operates from a 20.4–28.8 V DC supply range according to the same source.

The implications for a power system design are tangible. In terms of energy, moving from 9 W to 3 W on a typical 24 V DC control bus means the CPU’s current draw drops from about 0.38 A to about 0.13 A. For a modest DC UPS feeding several control loads, saving roughly a quarter of an ampere on the PLC alone helps extend ride-through time or leaves margin for future devices. On the thermal side, cutting CPU power dissipation by two-thirds reduces cabinet heating, which is especially helpful in densely packed switchgear or MCC sections. And the lower height opens room on the DIN rail for surge protective devices, small power supplies, or miniature Ethernet switches without growing the enclosure.

The memory increase is just as important from a reliability perspective. With work memory growing from 100 kB to 650 kB and load memory from 2 Mb to 8 Mb, you gain room for more structured logic, more detailed event logging, and more diagnostic blocks. In practice, this lets you keep richer histories of breaker operations, transfer events, and power quality alarms directly inside the PLC. Instead of trimming diagnostic detail to squeeze into a tight memory budget, you can maintain more tags, alarm texts, and extended states, which simplifies troubleshooting when something goes wrong at two in the morning.

These differences are summarized below.

| Parameter | CPU 1212C (standard) | CPU 1212C G2 | Source |

|---|---|---|---|

| Onboard digital inputs | 8 × 24 V DC | 8 × 24 V DC | Digi-Key example |

| Onboard relay outputs | 6 × 2 A | 6 × 2 A | Digi-Key example |

| Onboard analog inputs | 2 × 0–10 V DC | 2 × 0–10 V DC | Digi-Key example |

| Work memory | 100 kB | 650 kB | Digi-Key example |

| Load memory | 2 Mb | 8 Mb | Digi-Key example |

| Power consumption | 9 W | 3 W | Digi-Key example |

| Approximate module height | about 3.5 in (90 mm) | about 2.8 in (70 mm) | Digi-Key example |

| Supply voltage range | not specified in the notes | 20.4–28.8 V DC | Digi-Key example |

For new designs, the same Digi-Key source recommends shifting to G2 CPUs when available, particularly when panel space, energy efficiency, or cost are important and where you can take advantage of plug-in signal boards instead of larger expansion modules. For a power engineer, that is a straightforward reliability decision: lower heat, lower DC bus loading, and more memory for diagnostics, without changing the overall topology of your control system.

The S7-1200 platform is not limited to its onboard I/O. The same Digi-Key discussion highlights how G2 CPUs accept plug-in signal boards, such as the SB 1223, that attach directly to the CPU face. The SB 1223 adds four extra digital inputs and four high-speed transistor outputs, effectively extending I/O without needing a full-width expansion module. Compared with separate expansion modules like the SM 1223, signal boards use fewer materials, occupy less space, and generally cost less, while improving modularity and density.

Consider a small power distribution panel that must monitor twelve digital status points, such as breaker open/closed signals and protective relay trips, and must drive eight control outputs, such as breaker trip and close coils, UPS alarms, and fan contactors. A base CPU 1212C G2 provides eight digital inputs and six relay outputs. Adding one SB 1223 signal board raises this to twelve digital inputs and ten outputs (six relay plus four transistor), all within a very compact footprint. No extra DIN rail is required, wiring stays short and clean, and you still have room to add separate I/O modules later if the project grows. That is precisely the kind of incremental expansion that works well in power rooms, where new feeders and devices are routinely added over a facility’s life.

For larger expansions, PLCHMIS notes that the broader S7 family, including S7-1200, supports modular I/O structures, and RealPars reiterates that additional I/O modules can be attached to compact CPUs when more points are needed. In practice, that means you can start with a small S7-1200 CPU and then add discrete and analog modules as your power system evolves, without reworking the entire control architecture.

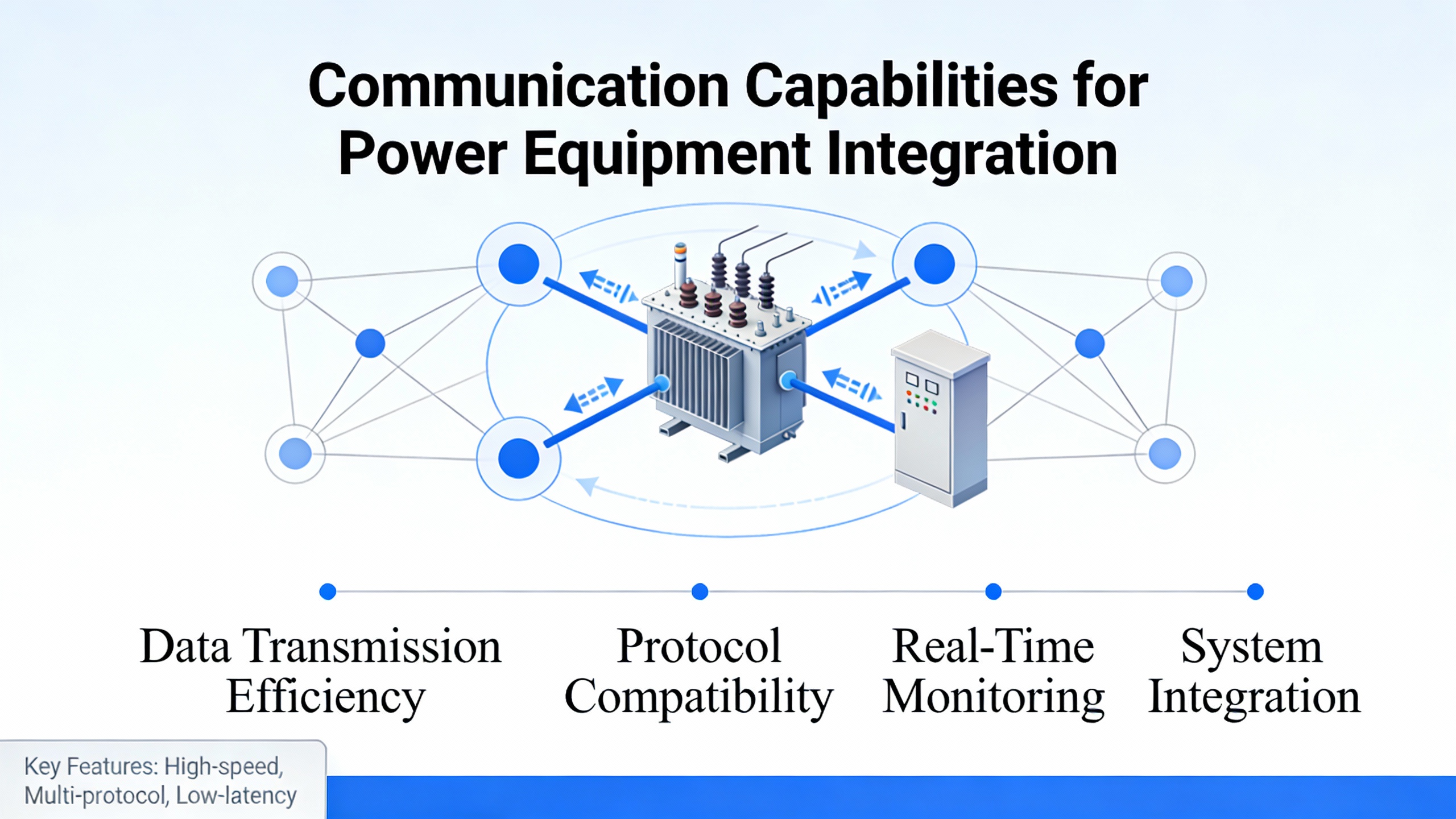

RealPars emphasizes that every S7-1200 CPU includes a PROFINET Ethernet port by default. For industrial and commercial power systems, that single fact is critical. One integrated Ethernet port lets you connect to HMI panels, supervisory systems, and Ethernet-enabled devices such as meters, drives, or remote I/O islands, while staying in a consistent Siemens engineering environment.

When your power system requires other fieldbuses, RealPars notes that S7-1200 CPUs can be expanded with communication modules for networks like Profibus-DP, IO-Link, or AS-i. That is especially relevant when you are tying into older substations, MCCs, or packaged equipment where vendors have standardized on non-Ethernet protocols. Instead of redesigning or replacing field devices, you can add the appropriate S7-1200 communication module and maintain a single PLC platform as the control “hub.”

From a reliability standpoint, having all of that engineered in TIA Portal pays off. You configure your PROFINET topology, IP addressing, and device names within a single project, and Siemens’ TIA Portal Information System provides context-sensitive help for hardware objects and network configuration. That documentation is the authoritative place to confirm which modules, addresses, and parameters are valid for your specific CPU firmware version, which is far safer than relying on scattered web searches.

A simple example underscores the value. Imagine a power distribution panel where the S7-1200 must talk to a panel HMI over Ethernet, a variable-frequency drive over PROFINET, and a smart I/O block in a remote junction box over AS-i. With the base PROFINET port and an AS-i communication module, you can configure all three in TIA Portal, keeping addressing, device naming, and diagnostic handling in one engineering project. When a drive trips or the remote I/O block loses power, the PLC’s diagnostics can be surfaced consistently to the HMI, and fault-finding stays predictable for electricians and technicians.

Take a typical commercial UPS and main switchboard combination. You might need to monitor breaker positions, UPS status contacts, a battery voltage or load analog signal, and drive a few relays for alarms or contactor control. A CPU 1212C G2 can handle eight digital inputs for UPS and breaker statuses, six relay outputs for alarms and control, and two analog inputs for UPS or bus measurements. The integrated PROFINET port lets you connect an HMI panel in the same cabinet so operators can see transfer sequences, remaining DC bus autonomy, and alarm histories.

If the UPS or switchboard includes a small remote I/O block via IO-Link or an older Profibus-based metering module, you can add the corresponding S7-1200 communication module as described by RealPars. The result is a single compact controller supervising both local and remote signals. You avoid stitching together multiple small controllers or proprietary gateways, which tends to improve reliability and reduce spare-part complexity in the long term.

Industrial power systems often share characteristics with the high-risk environments highlighted in RealPars’ discussion of S7-1200 fail-safe CPUs. RealPars explains that certain S7-1200 models, notably fail-safe variants of CPU 1212C, 1214C, and 1215C (such as 1212FC), are safety-certified controllers designed not only to control machines but also to keep people safe. These fail-safe CPUs, easily recognized by their yellow color, include safety-related functions that can detect dangerous conditions and trigger emergency responses.

RealPars offers examples in elevators and the oil and gas industry. In an elevator application, a fail-safe 1212FC can detect abnormal conditions, such as power loss or component failure, and activate emergency braking to keep passengers safe. In oil and gas, fail-safe PLCs can respond to gas leaks by shutting down equipment, starting ventilation, and warning workers.

For power engineers, the same pattern applies directly to critical power systems. Where personnel safety and continuity of supply intersect, such as in hospitals, data centers, or large industrial plants, fail-safe S7-1200 CPUs can be used for functions like generator emergency shutdown, arc-flash mitigation tripping schemes, or safe disconnection of feeders during maintenance modes. Using a fail-safe CPU instead of a standard one allows you to implement safety logic and standard control in one integrated device, while still maintaining the required separation and redundancy at the logic level.

In addition, PLCHMIS and Siemens documents highlight that other S7 families, such as S7-1500 and S7-400, also have safety-certified versions when your system grows beyond what an S7-1200 can handle. The important design step is to decide early whether safety functions will live inside the PLC and to select a fail-safe CPU if they will. Retrofitting safety into an existing standard CPU application later tends to be significantly more complex.

The Siemens global S7-1200 G2 product page includes a general but important reminder: protecting plants, systems, machines, and networks against cyber threats requires a holistic and continuously maintained industrial security concept. Siemens explicitly states that its products and solutions form only one element of such a concept.

In other words, dropping an S7-1200 into a power panel does not, by itself, make the system secure. You also need network segregation, hardened remote access, disciplined user management, and procedures for maintaining firmware and TIA Portal project versions. This aligns with Siemens Support guidance on industrial security more broadly, which treats cyber risk as an ongoing, evolving concern rather than a one-time checklist.

From a reliability advisor’s perspective, the practical takeaway is straightforward. Use the PLC’s features as part of a larger security design, not a replacement for it. Run dedicated engineering networks rather than mixing control and office traffic, restrict who can connect to the S7-1200 over PROFINET, and treat TIA Portal project files as controlled configuration items. When you combine that with Siemens’ technical measures and an organizational security program, you reduce the likelihood that a cyber incident compromises your critical power infrastructure.

Siemens’ programming guidelines and styleguide for SIMATIC S7-1200 and S7-1500, published via Siemens Support, are not about individual voltages or currents; they describe how to structure your TIA Portal projects so that systems are maintainable and reusable. The styleguide recommends a clear project structure, symbolic and meaningful tag names, and separating reusable library blocks from process-specific logic. It encourages designers to avoid monolithic logic in the main organizational block and instead split functionality into functions and function blocks with well-defined interfaces, making heavy use of user-defined data types and structured tags.

For power systems, this maps naturally to structuring code around physical equipment. One function block per breaker, per feeder, per UPS, or per generator aligns closely with the StackOverflow community advice that PLC best practices must reflect the physical process, with code organized so technicians can quickly relate logic to field devices. In smaller or lower-risk systems, you might accept some shortcuts or less-than-perfect tag hygiene, but in high-risk contexts like large industrial power systems or pharmaceutical plants, StackOverflow contributors stress zero tolerance for unused tags, warnings, or overly generic subroutines.

Siemens’ styleguide and the TIA Portal Information System together support that discipline. For example, you can define a structured data type that encapsulates all signals for a feeder, including breaker status, trip cause, and energy counters, and then reuse that block for all feeders in the switchboard. The TIA Portal Information System provides detailed reference information on system functions and OB types so you can choose appropriate cyclic, time-driven, or event tasks for each part of your power logic. This approach reduces commissioning time and makes it easier to onboard new engineers because the code base looks familiar across projects.

Returning to the CPU 1212C G2 memory increase, Siemens does not prescribe exactly how you must use that extra capacity, but from a reliability perspective, it is an opportunity to embed richer diagnostics. Suppose your standard 1212C-based design logs a minimal set of events for each transfer: just a timestamp and whether the transfer succeeded. With the G2’s expanded work and load memory, you can store more information per event, for example breaker statuses before and after transfer, measured bus voltages, and selected protection relay indications. Over many operations, that richer dataset makes it easier to distinguish between nuisance trips and genuine system issues.

Because both S7-1200 and higher-end S7-1500 controllers are engineered in TIA Portal, you also gain consistency when you eventually scale up. Blocks written in line with Siemens’ styleguide on S7-1200 often port more easily to S7-1500, as long as you respect any differences in instructions and system functions. This compatibility protects your investment in diagnostic and power automation logic as your facility grows.

PLCHMIS and RealPars both stress that selecting the right S7 family and CPU type hinges on understanding your application’s size and complexity, required I/O types and counts, processing performance, communication needs, and safety requirements. For power systems, that translates into a few concrete questions.

First, consider system scale. If you are automating a small switchboard, a single generator, or a local UPS with a limited number of feeders, an S7-1200, such as a CPU 1212C or 1214C, is usually appropriate. PLCHMIS notes that S7-400 and S7-1500 families are better suited to very large or complex systems, where many I/O points and advanced communication are required.

Second, examine your I/O needs. RealPars points out that CPUs like 1212C and 1214C are differentiated by their number of inputs and outputs, and that the 1217C is designed for more complex tasks due to higher I/O capacity and speed. In a power context, if you foresee many breaker statuses, protection signals, and analog measurements, it is prudent to choose a CPU model with headroom in both onboard I/O and expansion capability.

Third, assess performance and timing. High-speed applications such as transfer schemes with tight timing, fast load shedding, or high-rate data acquisition for power quality require more powerful CPUs. RealPars identifies CPU 1215C and 1217C as suited to large automation tasks and high-speed data acquisition. If your protective scheme demands rapid evaluation of many conditions, these higher-end S7-1200 CPUs are preferable within the family.

Fourth, define communication and safety needs. If your system uses only Ethernet-based communication and modest safety requirements, a standard S7-1200 with PROFINET and simple hardwired safety interlocks may be enough. If you must integrate older Profibus-based equipment or IO-Link and AS-i field devices, RealPars indicates that you will need the corresponding communication modules. If safety functions such as emergency shutdown, elevator safety, or hazardous gas shutdown must be integrated into the PLC, RealPars’ coverage of fail-safe CPUs makes it clear you should select a safety-certified S7-1200 variant like 1212FC, 1214FC, or 1215FC.

The notes also provide broader context on where S7-1200 stops being the right tool. PLCHMIS and other Siemens overviews describe S7-1500 as a high-performance PLC family for medium to large-scale applications, with advanced features such as motion control, safety, and security. Additional general context from community discussions suggests that S7-1500 CPUs typically provide more program and data memory, faster execution, and richer diagnostics than S7-1200, along with broader scalability and modularity.

In practical terms, an S7-1200 is usually sufficient when your power system is limited to a few switchboards, one or two generators or UPS systems, and a manageable number of field devices, and when your performance requirements are moderate. Once you are dealing with a large campus, many feeders, extensive communication with other PLCs and SCADA systems, or sophisticated control like coordinated motor control and complex protection schemes, S7-1500 begins to make more sense.

A useful rule of thumb is to use S7-1200 when a single compact controller can comfortably handle both present and foreseeable future needs, and to plan on S7-1500 when your design involves multiple layers of coordination, high data throughput, or demands for the most advanced diagnostics and security features. Because both are engineered in TIA Portal and covered by the same Siemens programming guidelines, the skills and architectural patterns you develop on S7-1200 carry forward when you scale up.

Based on the capabilities described by RealPars and PLCHMIS, the S7-1200 is well suited to small and medium automation tasks, including building HVAC and stand-alone machines, with integrated I/O and PROFINET communication. Those same capabilities map naturally to UPS and generator control in commercial buildings, as long as the I/O count and performance requirements fit within the chosen CPU and any expansion modules.

RealPars makes clear that fail-safe S7-1200 CPUs, such as the 1212FC, 1214FC, and 1215FC, are intended for safety-related functions where people and equipment must be protected from hazardous events. For purely monitoring or non-safety control tasks, a standard S7-1200 may be sufficient. If your power system logic must implement formal safety functions, such as emergency stops or automatic shutdowns in dangerous situations, then a fail-safe variant is the appropriate choice.

The notes emphasize that Siemens’ TIA Portal Information System and Siemens Support documentation are the authoritative sources for device-specific technical specifications, programming guidelines, and version details. For purchasing and product lifecycle information, Siemens’ integrated SiePortal platform combines product selection and online support. For engineering decisions that hinge on exact limits, such as maximum I/O counts or environmental ratings, it is best to consult those Siemens references directly.

In power reliability work, the S7-1200 family offers a compact but capable control platform. When you pair the verified specifications from Siemens and trusted training sources with disciplined engineering practices in TIA Portal, you get a PLC that supports dependable UPS, inverter, and switchgear control today while leaving room to evolve toward higher-end platforms as your plant grows.

Leave Your Comment