-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

As a reliability advisor working around UPS systems, inverters, and industrial drives, I see the same pattern across plants and data centers: ABB variable frequency drives quietly run millions of motor starts without complaint, right up until a seemingly “random” trip takes down a critical line. Most of those failures are not random at all. They are the predictable result of heat, contamination, loose terminations, and aging components that were allowed to drift past their reliable operating window.

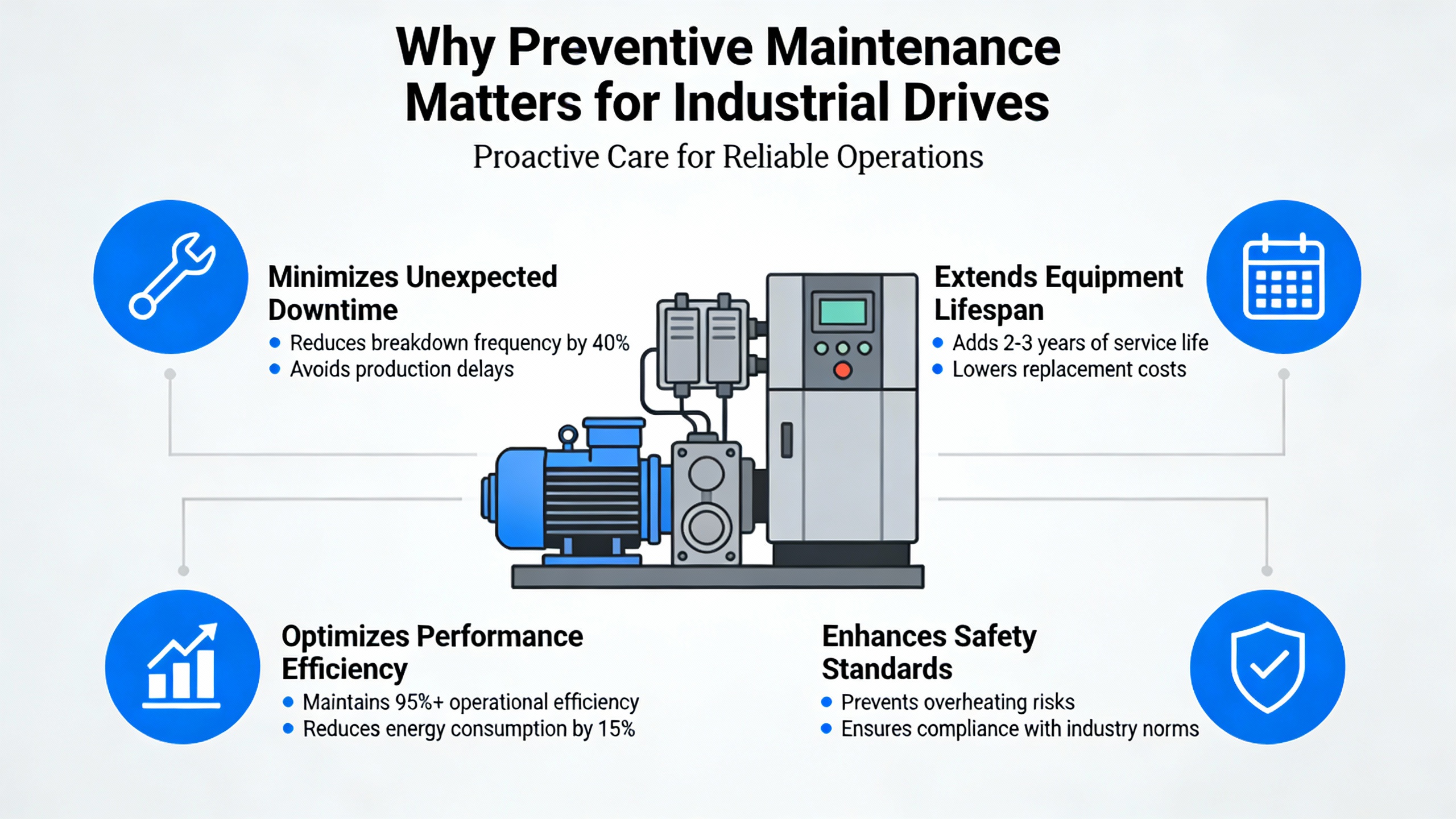

ABB Motion Services defines preventive maintenance as planned service while equipment is still running normally, with the goal of reducing unplanned failures and extending asset life. When you apply that philosophy to ABB drives, you are not just protecting a power-electronic box. You are protecting every motor, process, and power protection system that depends on that drive doing its job. In many plants, a single failed control component can stop an entire production line and cost thousands of dollars per hour in lost output, as described in reliability guidance on ABB control system spares.

With proper care, ABB drives commonly deliver 10 to 15 years or more of reliable operation, according to field experience reported by ABB-focused service providers. Without that care, dust, heat, and loose connections accelerate failures in fans, capacitors, and power devices. This article walks through how to design and execute a preventive maintenance strategy for ABB drives that is both technically sound and practical for real facilities, drawing on ABB’s own maintenance guidance together with proven practices from VFD and electrical maintenance experts.

The core decisions you must make are straightforward: how often to service ABB drives, which components to treat as wear items, how to use builtŌĆæin diagnostics for predictive maintenance, and how to handle spares and replacement parts without adding risk.

ABB frequency drives are essentially computers attached to power electronics. They take fixedŌĆæfrequency AC, convert it to DC, then build a new AC waveform to control motor speed and torque. In variableŌĆætorque applications such as pumps, fans, and many HVAC loads, that control can deliver roughly 20 to 50 percent energy savings compared with throttling methods, as described in ABB drive overviews. For facilities that also rely on UPS systems and power protection, those efficiency gains translate directly into lower loading on upstream supply and battery systems.

The flip side is that drives are sensitive electronic systems. Reliability guides for VFDs consistently highlight the same root causes of failure: contamination, overheating, poor power quality, and mechanical or electrical looseness. ABB’s own article on how to maintain a VFD, written around their HVAC drives, summarizes the philosophy in three phrases: keep it clean, keep it dry, and keep connections tight. Industrial Electrical Company’s VFD maintenance guide echoes that view, listing debris buildup, condensation, loose power connections, and corroded circuit boards as key failure drivers when preventive maintenance is neglected.

From a reliability standpoint, this is classic bathtubŌĆæcurve behavior. Early failures tend to be installation errors or environment issues. MidŌĆælife failures are usually driven by heat and contamination attacking wear components such as fans and electrolytic capacitors. LateŌĆælife failures show up as increased trips and intermittent faults as components approach end of life. ABB Motion Services positions preventive maintenance as a way to flatten that curve, reduce emergency repairs, and extend mean time between failures.

Consider a realŌĆæworld pattern I see repeatedly. A plant installs ABB drives in NEMA 1 vented enclosures on a dusty production floor. For the first few years everything looks fine. Then nuisance overcurrent or overtemperature trips start to appear. An ABB article on maintaining HVAC VFDs notes that dust in vented enclosures can block airflow and coat heat sinks, absorbing moisture and causing overheating or even insulation tracking on boards. When you finally open the cabinet, you often find an inch of dust on the drive and clogged fans. If the drive had been cleaned and inspected annually using vacuum tools, as recommended by multiple VFD maintenance sources, the same hardware could likely have run another decade instead of failing prematurely.

The cost comparison is stark. Electrical preventive maintenance guidance for facilities points out that breakdown repairs almost always cost more than addressing issues proactively, once you include emergency labor, rush shipping, and lost capacity. When a single ABB drive failure can halt an entire line and cost thousands per hour, a structured maintenance program that costs only a fraction of that per year is a straightforward reliability investment rather than a discretionary expense.

The first practical question is not “what can fail?” but “how often should we touch these drives, and how deep should we go?” The answer should balance OEM recommendations, environmental severity, and asset criticality.

Several ABBŌĆæfocused service providers describe a tiered schedule that has proven robust in the field. At the lightest level, they recommend monthly visual checks and alarm reviews. At the next level, quarterly cleaning and fan/airflow verification. Annually, deeper electrical inspections and cleaning. And roughly every five years, a more substantial component service including cooling fans and capacitors.

One ABB service firm that specializes in preventive maintenance for ABB drives proposes the following pattern. Every month, operators visually inspect drive enclosures for damage, check status lights, and review alarm or fault history on the keypad or via supervisory software. Every quarter, technicians verify fan operation, clean or replace air filters, clean surrounding areas to keep cooling paths clear, and review diagnostic logs for trends such as rising temperature or current. Once per year, they open the enclosure during a planned shutdown to inspect and tighten power and control connections as needed, vacuum dust, check for corrosion or discoloration on PCBs, and test capacitors. About every five years, they plan proactive replacement of cooling fans, detailed capacitor testing with replacement as needed, and inspection of solder joints and critical components.

Industrial Electrical Company supports this cadence by emphasizing that optimal intervals depend on drive make, model, age, and environment. They suggest that NEMA 1 vented drives in dirty environments require more frequent cleaning than NEMA 12 sealed units, and that older drives may justify shorter inspection intervals. ABB Motion Services similarly frames preventive maintenance as a set of service packages that can be aligned with known wear patterns and scheduled plant stops.

In practice, this means you treat ABB drive maintenance as a layered routine rather than a oneŌĆætime overhaul. You touch the drive lightly and often for inspections and log reviews, and less frequently but more intensively for component replacements.

The right maintenance plan for an ABB drive feeding a critical UPSŌĆæbacked cooling pump in a data center is not the same as for a small conveyor in a packaging line. Facility maintenance guidance recommends starting with an asset list and ranking equipment by criticality and replacement cost. You then align maintenance frequency with that criticality, equipment age, and run hours.

Electric motor maintenance experts note that in a plant that runs around the clock, essential machines are often checked every three months, with even shorter intervals for older units. Drives feeding those motors should follow the same rhythm, especially when they sit in the same harsh environment. At the other extreme, an ABB HVAC drive in a clean mechanical room might only need deep cleaning and electrical inspections annually, with quarterly log reviews handled by building automation staff.

Environmental conditions drive another adjustment. The ABB HVAC drive maintenance article highlights that NEMA 1 drives in dusty air require more frequent cleaning because their side vents let in fine particles. Industrial Electrical Company explains that sealed NEMA 12 enclosures reduce dust ingress but may still suffer from condensation if temperature swings are large. ABB recommends thermostatically controlled space heaters in environments that drop below freezing so that drives do not cycle through condensation when they cool while idle.

A simple way to convert environment and criticality into actions is to consider both together, as in the following table.

| Drive context | Typical risk factors | Suggested maintenance emphasis |

|---|---|---|

| Critical process drive in dusty area | Dust, vibration, heat, power quality issues | Quarterly cleaning and log review; annual deep inspection |

| Critical HVAC drive in clean room | Moderate heat, moderate dust | Quarterly log review; annual cleaning and connection checks |

| NonŌĆæcritical drive in harsh process | Heavy dust, moisture, corrosive atmosphere | Frequent cleaning; shorter fan and capacitor replacement span |

| NonŌĆæcritical drive in clean environment | Light dust, stable temperature | Annual inspection; fiveŌĆæyear component review |

This is not a replacement for ABB’s specific instructions, but it translates general guidance from ABB Motion Services and industrial VFD maintenance sources into a plantŌĆæfriendly view.

A case study around the ABB ACS550 F0002 overvoltage fault illustrates how configuration and preventive checks intersect. An analysis of that fault code explains that F0002 indicates DC bus overvoltage, typically caused by power line surges, deceleration times set too short, braking resistors that are undersized or damaged, or mechanically driven loads such as downŌĆæslope conveyors regenerating energy into the drive.

When maintenance is purely reactive, operators see “F0002 OVERVOLTAGE” trips, reset the fault, and try again. If the deceleration ramp remains too aggressive or the braking resistor is not sized for the load, regenerated energy pushes the DC bus past its safe threshold, the drive trips repeatedly, and eventually power components or fuses may fail.

A preventive approach, grounded in the same guidance, looks different. When the first overvoltage event appears, maintenance staff verify utility voltage levels at the ABB drive terminals, then review drive parameters and extend the deceleration time from a short value such as 5 seconds to a longer value such as 10 seconds to reduce regenerative stress. For highŌĆæinertia or hoisting applications, they confirm that braking resistor ratings match ABB specifications and inspect the resistor for damage. As part of periodic inspections, they check for DC bus alarms or trends in the drive logs. Instead of waiting for a hard failure, they use one nuisance trip as an opportunity to correct both configuration and hardware.

The next key decision is which parts of an ABB drive you treat as consumables versus “fit and forget.” Field experience from ABB service providers and VFD maintenance specialists is very clear: cooling fans, electrolytic capacitors, air filters, and electrical terminations should be on your preventive replacement and inspection list.

Cooling fans are one of the most critical wear components in ABB drives. An ABB drive maintenance article cited by a major ABB service partner notes that fan life is typically around 50,000 hours of operation. With continuous duty, that translates to something on the order of five to seven years of service under normal conditions. The same source recommends proactively replacing cooling fans every five to seven years rather than waiting for a bearing seizure or a thermal trip.

Overheating is a primary lifeŌĆæshortening stress for both motors and drives. Electric motor maintenance research points out that roughly an 18°F increase above a motor’s design operating temperature can cut its life about in half. While that figure comes from motor insulation studies, electrolytic capacitors and semiconductor devices in drives show similar sensitivity to temperature. DustŌĆæclogged filters, failed fans, or blocked cabinet airflow raise internal temperatures and shorten component life.

Industrial Electrical Company advises regular cleaning of cooling paths, verification that all fans spin freely, and confirmation that any liquidŌĆæcooling components are operating correctly. ABB’s own HVAC drive guidance stresses the difference between vented and sealed enclosures: vented NEMA 1 housings demand more frequent cleaning because dust can bridge fins and absorb moisture, while sealed NEMA 12 units reduce but do not eliminate contamination risks.

Cleaning methods matter. UPS maintenance guidance from a major AC drive and UPS manufacturer recommends cleaning internal areas with a vacuum and nonŌĆæconductive attachments at least once per year, avoiding blowers or standard compressed air that can drive contaminants deeper into electronics. ABB’s VFD article similarly recommends nonŌĆæstatic compressed air or a reverseŌĆæoperated ESD vacuum, warning that plant compressed air may contain oil or water and can create electrostatic discharge if not controlled. Soft brushes are recommended around delicate connectors, with all work performed deŌĆæenergized and following appropriate PPE requirements.

A simple calculation demonstrates how fan life planning works in practice. Suppose an ABB process drive operates about 20 hours per day, 6 days per week. That is roughly 6,240 hours per year. At 50,000 hours of expected fan life, you are looking at around eight years of operation under ideal conditions. However, if the drive runs in a warm, dusty environment, a fiveŌĆæyear replacement interval is prudent. Designing your maintenance plan around that interval lets you replace fans during planned outages before they become a root cause of thermal trips or derated operation.

ABB’s own preventive maintenance manuals for ACS800ŌĆæseries drives describe fan replacement as a straightforward procedure during planned service: remove the top cover, release fan retaining clips, disconnect the fan cable, and install the new fan in reverse order, ensuring airflow direction is correct. That reinforces the idea that fan replacement is routine, not an exotic repair.

Electrolytic capacitors in the DC link are the other major wear component in ABB drives. Preventive maintenance specialists focused on ABB drives report typical capacitor lifespans in the fiveŌĆæ to tenŌĆæyear range, heavily dependent on temperature and loading. As capacitors age, their internal resistance rises and capacitance falls, leading to higher DC bus ripple, degraded performance, and increased risk of drive trips or fuse failures.

ABB’s preventive maintenance guide for ACS800ŌĆæseries drives explains that the intermediate circuit uses several electrolytic capacitors and defines capacitor life as the time these components remain reliable in operation. The guide notes that it is not possible to predict the exact moment of capacitor failure, but when a failure occurs, it often coincides with mains fuse operation or a drive fault trip. The same document instructs users to contact ABB if capacitor failure is suspected and explicitly warns against using spare parts other than ABBŌĆæspecified capacitors.

Drive maintenance articles from Industrial Automation Co. highlight that modern ABB and other VFDs actually estimate capacitor aging internally, exposing “capacitor remaining life” indicators and related alarms. As capacitors age, drives may show increasing internal temperature at the same ambient and load, more frequent DC bus or undervoltage alarms, or specific capacitorŌĆæaging warnings. That makes it possible to combine timeŌĆæbased and conditionŌĆæbased approaches: you plan a midŌĆælife capacitor service around year seven for a critical ABB drive fleet and refine which units to prioritize based on their own diagnostics.

For spares, both ABB and independent reliability experts emphasize one often overlooked step: reforming electrolytic capacitors. ABB’s ACS800 maintenance materials include a dedicated publication on reforming converter modules with electrolytic capacitors and state that unused spare capacitors should be reformed about once per year so they remain in good condition. A separate ABBŌĆæauthored VFD maintenance article advises powering up spare drives about every six months to keep DC bus capacitors healthy, comparing them to batteries that degrade if stored indefinitely without voltage.

Surplus parts analysis focused on ABB systems adds another layer. It recommends that, for surplus ABB VFDs, you verify that capacitor banks still retain at least about 80 percent of their rated capacitance, and perform load tests around three quarters of rated output for several hours before trusting them as critical spares. That guidance aligns well with ABB’s own emphasis on using specified components and maintaining capacitors proactively.

In practical terms, if you expect an ABB drive to remain in service for 15 years in a demanding environment, planning at least one capacitor service between year five and year ten is prudent. For the most critical drives, that service may include full replacement with ABBŌĆæapproved capacitors; for less critical units, comprehensive testing and continued monitoring may be enough.

Loose or corroded electrical connections are a silent but frequent cause of drive failures. ABB’s HVAC drive maintenance article warns that loose input connections can lead to overvoltage faults, blown fuses, or damage to protective components, while loose output or control wiring can cause overcurrent faults, erratic starting, speed fluctuations, or safety hazards. Electrical preventive maintenance checklists for facilities similarly flag loose or frayed wiring and damaged bonding as key risks that must be corrected during routine inspections.

There is, however, nuance in how you maintain terminations. ABB’s VFD article cautions against indiscriminate reŌĆætorquing of screws during every visit, because repeated tightening can permanently reduce clamping force and degrade lock washers by around half their holding ability. Instead, they recommend a combination of methods: with equipment deŌĆæenergized, performing a “tug test” on conductors to detect loose connections, and using an infrared thermometer or thermal imaging to identify hot spots. If a particular terminal repeatedly loosens, their advice is to replace the screw or connector rather than repeatedly tightening it.

Other VFD maintenance guidance reinforces this approach. Industrial Electrical Company recommends tightening electrical connections per OEM torque values during annual inspections to prevent overheating and premature failure, while also suggesting advanced methods such as thermal imaging to detect problems early. In noisy or highŌĆævibration environments, ABBŌĆæfocused troubleshooting guides for motors and drives recommend routine alignment checks and prompt correction of any looseness to prevent vibrationŌĆædriven connector fatigue.

Circuit boards and I/O modules deserve similar attention. ABB service partners advise visually checking PCBs for corrosion, discoloration, or evidence of moisture during annual inspections. Smart Elemech’s ABB troubleshooting guide notes that dust and moisture on boards can lead to intermittent faults, especially where sensors or lowŌĆælevel signal circuits are involved, and recommends protective enclosures and regular calibration or inspection for devices that fail frequently.

Cleanliness is the foundation that supports every other preventive action. Even UPS maintenance guidance from major AC drive manufacturers starts with keeping equipment clean to reduce electrical failures. ABB’s HVAC VFD article makes the same point: in vented NEMA 1 enclosures, dust can accumulate quickly even in seemingly clean rooms, blocking airflow and creating conductive paths on circuit boards when mixed with moisture.

Industrial Electrical Company and other VFD experts recommend routine vacuum cleaning of control panels and vents, particularly on NEMA 1 drives, and stress that cleaning must be done with the equipment deŌĆæenergized using nonŌĆæstatic tools. UPS and motor maintenance articles warn against using standard compressed air that may contain oil and moisture, as it can push contaminants deeper into the unit and introduce electrostatic discharge risks. Soft brushes and lintŌĆæfree rags lightly dampened with fastŌĆædrying, nonflammable solvents are recommended for stubborn deposits around delicate components.

Moisture is the other environmental enemy. ABB’s HVAC drive article describes a case where water dripping from a dehumidifier above a drive caused severe circuit board corrosion within about six months. To mitigate condensation risks, ABB recommends NEMA 12 enclosures and thermostatically controlled space heaters in environments where temperatures fall below freezing or where drives remain idle for long periods and therefore do not selfŌĆæheat. VFD maintenance literature also suggests that outdoor or rooftop installations should avoid direct sun and extreme ambient temperatures, noting that, with proper environmental control and preventive maintenance, VFD mean time between failures can reach around 200,000 hours, which is roughly 23 years.

A typical example is a drive room in a water treatment plant. On paper, the room is “indoors,” but in reality it sees high humidity and periodic washdown. ABB drives mounted in NEMA 1 cabinets on an interior wall may experience condensation and dust accumulation, while those in NEMA 12 cabinets with small heaters stay much drier internally. Plants that retrofit sealed enclosures and add simple heaters often see a noticeable drop in unexplained drive trips and board replacements over subsequent years, reflecting exactly the risks and mitigations described in ABB’s maintenance guidance.

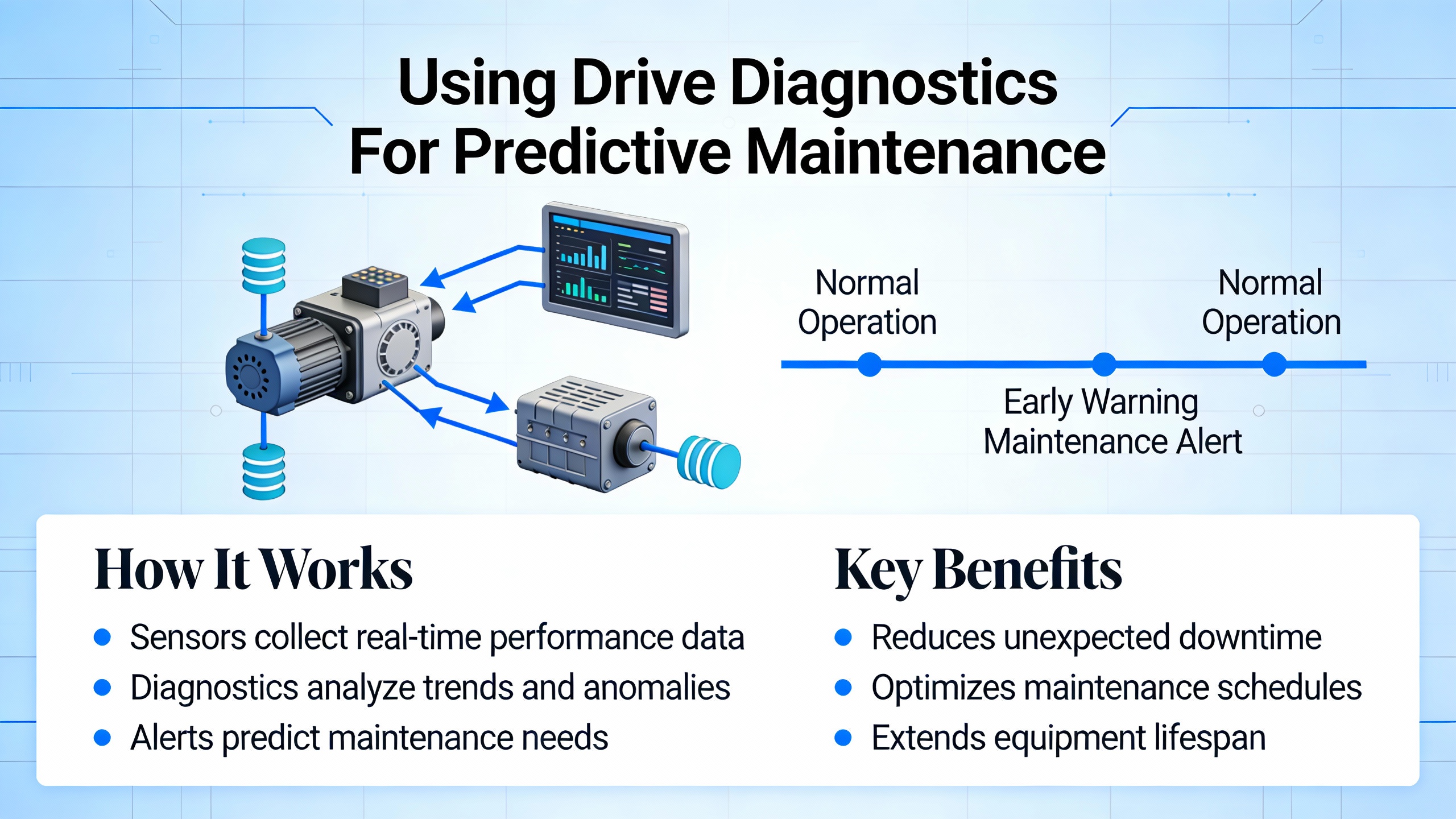

Modern ABB drives are not just power controllers; they are builtŌĆæin sensor suites for your motors and power system. Industrial Automation Co. emphasizes that VFDs continuously monitor motor current, torque demand, phase balance, line voltage, DC bus status, temperature, and even the aging of fans and capacitors. Many ABB models expose this information as detailed parameters for trending and as clear fault or warning codes.

The key mindset shift is to treat drive alarms and logs as earlyŌĆæwarning signals, not nuisances to be cleared. Predictive maintenance articles on drives note that intermittent or recurring faults are signs that operating conditions are drifting out of range. For example, trending motor current is highlighted as a simple but powerful diagnostic: a gradual rise in current at constant speed and throughput often points to worn or dry bearings, misaligned belts or gearboxes, clogged pumps or filters, or product buildup on conveyors. Acting on that trend before an overcurrent trip occurs turns a surprise outage into a scheduled mechanical repair.

Temperature is another leading indicator. Drive diagnostics often provide heat sink temperature and estimate motor thermal load. Industrial Automation Co. notes that a drive running just moderately hotter than normal can dramatically shorten the life of capacitors and fans. Motor maintenance research shows that roughly an 18°F rise above design temperature can halve life; while the exact number differs by component, the principle holds for power electronics as well. Combining that knowledge with ABB drive data allows you to set practical thresholds in your maintenance system: if a particular ABB drive’s internal temperature trend creeps above its historical baseline at the same load and ambient conditions, you schedule cleaning, airflow checks, and potentially derating long before thermal trips appear.

Drive diagnostics also see upstream electrical issues early. When multiple drives in a facility start showing DC bus overvoltage during deceleration or nuisance undervoltage trips during peak plant demand, predictive maintenance experts recommend investigating power quality. Smart Elemech’s ABB troubleshooting guide suggests checking for loose or damaged supply connections, failing breakers or fuses, overloaded transformers, or voltage distortion from large nonŌĆælinear loads. ABB’s overvoltage fault analysis for the ACS550 reinforces this view, pointing to line surges and regeneration as common contributors. Trend data from drives gives you a way to localize and quantify those issues before they produce largeŌĆæscale outages.

ABB and other drive vendors provide tools to make use of this data. ABB’s Drive Composer and similar software allow engineers to download fault histories, trend graphs of load and temperature, and parameter sets. Industrial Automation Co. notes that higherŌĆæend drives from several manufacturers now include onboard data logging and even integrated energy and process monitoring, enabling anomaly detection without additional sensors. Predictive maintenance platforms can ingest this data and, as ServiceChannel’s broader electrical maintenance guidance suggests, compare it against historical trends to predict when interventions are needed.

In practical terms, a predictive strategy built around ABB drives might look like this. Vibration and temperature measurements on large motors are collected quarterly, as motor maintenance experts suggest, while drive diagnostics on current, torque, and DC bus status are polled weekly or daily through a building or plant automation system. When the system detects that a particular pump drive’s current at a specific speed has increased by a noticeable margin over several weeks, it flags an inspection of bearings, alignment, and filters. When capacitor aging indicators in an ABB HVAC drive approach limits, it generates a work order to schedule capacitor replacement during the next planned shutdown. The drive becomes the lead sensor for both motor health and its own internal condition.

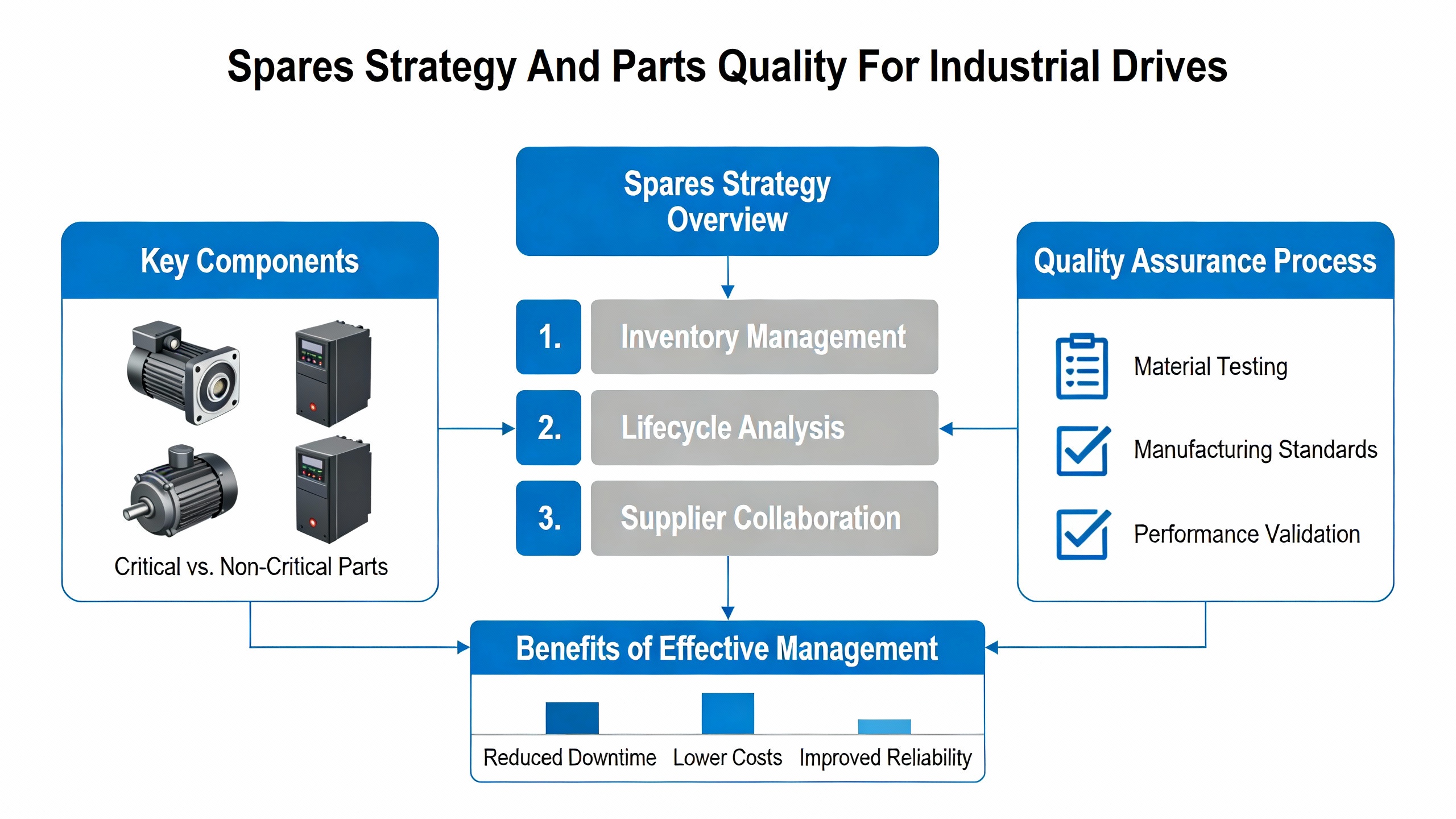

The last major decision area is how you handle spare ABB drives and components. Done well, a spares strategy turns predictive warnings into scheduled work. Done poorly, it introduces new failure modes through incompatible or degraded parts.

ABB’s own preventive maintenance materials are blunt about replacement components such as DC link capacitors: use ABBŌĆæspecified parts. Their ACS800 guide explicitly states that spare capacitors are available from ABB and warns against using nonŌĆæABB parts. This is not just about branding; it reflects matching voltage ratings, ripple current capacity, and lifetime characteristics tested for specific converter modules.

A detailed analysis of surplus ABB control system parts expands the risk picture. It distinguishes between surplus parts, which may be new old stock or refurbished, and obsolete parts, which are no longer manufactured but still required for legacy systems. The authors point out several pitfalls: unknown operating history, hidden wear such as capacitors losing capacitance or microfractures on PCBs, and the presence of counterfeit parts with fake labels and date codes. They also describe integration failures caused by firmware mismatches and communication protocol differences, including an example where a surplus VFD with a different fieldbus caused a multiŌĆæday shutdown.

To mitigate these risks, the same article recommends treating surplus ABB VFDs with caution. Before putting one into service, you visually inspect boards for heat damage or bulging capacitors, use ABB diagnostic tools to read operating hours and fault logs, and confirm firmware versions and communication settings match your installed base. They specifically suggest verifying that capacitor banks retain at least around 80 percent of rated capacitance and performing load tests at about three quarters of rated output for several hours in a staging environment. Drives that pass these tests can then be added to your critical spares roster.

Industrial Automation Co. reinforces the importance of a strategic spares plan for VFD fleets. They recommend keeping at least one spare drive for each key horsepower range or line, stocking spare cooling fans, filters, and humanŌĆæmachine interfaces where configurations depend on them, and maintaining parameter backups so a replacement drive can be dropped in quickly. Combined with ABB’s own advice to power up spare drives periodically to keep capacitors healthy and to reform unused capacitors annually, this points to an active spare management program rather than a passive “parts on a shelf” approach.

When you combine these insights, a practical ABB drive spares strategy emerges. For current models under OEM support, you prioritize ABBŌĆæapproved replacement parts and, where budgets allow, complete spare drives configured and powered periodically. For discontinued models, you carefully vet any surplus ABB drives using the testing and burnŌĆæin approaches described above and keep detailed records of firmware, configuration, and test results. Across both categories, you lean on drive diagnostics and preventive maintenance intervals to schedule replacements before catastrophic failures occur, rather than relying on lastŌĆæminute emergency purchases.

Bringing all of this together into a program means integrating ABB drive care into your wider electrical preventive maintenance and reliability strategy. Facility maintenance experts recommend starting with a structured asset list, ranking assets by criticality and repair or replacement cost, and then designing checklists and schedules accordingly. ABB drives that feed critical UPSŌĆæsupported loads, essential process pumps, or key HVAC systems will naturally land in the highest criticality tier.

For those assets, you establish a layered plan. Operators perform monthly visual checks and respond to drive alarms by creating maintenance notifications rather than habitual resets. Maintenance technicians carry out quarterly cleaning, fan checks, and log reviews, and annual deep inspections of connections, boards, and cooling systems. Reliability engineers analyze drive diagnostics and energy data to identify trends and feed predictive models, potentially alongside motor vibration and thermal imaging data as recommended by Industrial Electrical Company and motor maintenance experts.

Training and safety sit at the heart of this program. Both VFD maintenance guides and ABB troubleshooting resources stress the need for qualified staff, correct PPE, and established lockout procedures when working on energized or recently deŌĆæenergized equipment. Training operators to recognize early signs of trouble, such as abnormal noises, excess vibration, or frequent drive faults, helps ensure those issues are logged and investigated promptly. Maintenance personnel need specific familiarity with ABB parameter structures, diagnostics menus, and tools like Drive Composer so they can extract and act on data efficiently.

Finally, you close the loop with documentation and continuous improvement. Electrical preventive maintenance guidance emphasizes that every asset change and maintenance action should be recorded, ideally in a facility management or maintenance system that tracks history and helps forecast future needs. For ABB drives, that means capturing installation dates, fan and capacitor replacement dates, firmware versions, environmental changes such as enclosure upgrades, and any major fault events. Over time, you refine maintenance intervals based on real wear patterns in your environment, guided by ABB’s recommendations but tuned by your own data.

In industrial and commercial power systems, ABB drives are a critical bridge between the grid, your power protection equipment, and the mechanical loads that keep production and facilities running. Treating their preventive maintenance as a structured reliability program rather than an afterthought is one of the highestŌĆæleverage decisions you can make. When you keep ABB drives clean, cool, dry, electrically sound, and supported by dataŌĆædriven diagnostics and a disciplined spares strategy, you are not just extending drive life. You are buying back uptime, stabilizing your power system, and giving your operations team the breathing room to focus on higherŌĆævalue work instead of the next avoidable trip.

Leave Your Comment