-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Automotive manufacturing is under pressure from every direction: electric vehicle programs compress launch timelines, model variants multiply, and customers expect flawless quality at competitive prices. On the shop floor, that pressure lands squarely on the automation and power infrastructure behind body shops, paint shops, and final assembly. As a power system specialist and reliability advisor, I see the same questions repeatedly: can our existing PLC-based control keep up, should we move toward virtualized Siemens PLC architectures, and how do we tie automation to energy and power reliability without putting vehicle throughput at risk.

This article looks at those decisions through the lens of Siemens PLC technology in automotive production lines, focusing on SIMATIC controllers, software-defined automation, and the supporting HMI, SCADA, and power systems. Drawing on SiemensŌĆÖ own automotive and software-defined automation resources, an academic case study on energy management using Siemens S7-1500 and WinCC, and real-world assembly line expansion projects, the goal is to translate buzzwords into concrete guidance you can act on.

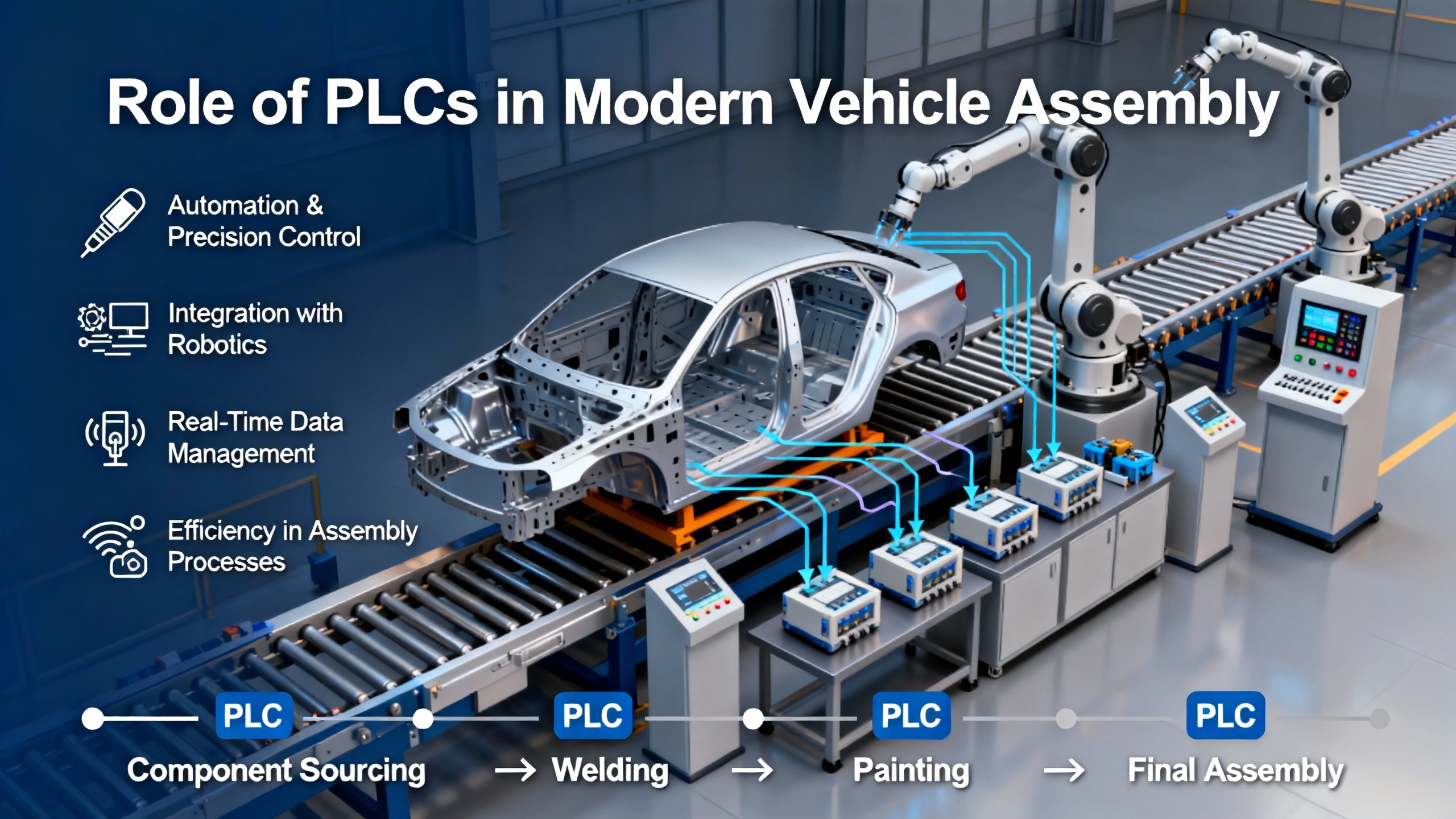

At the core of every modern vehicle assembly line is a programmable logic controller, or PLC. A PLC is a rugged industrial controller that executes deterministic logic to coordinate sensors, actuators, robots, drives, and safety interlocks in real time. SiemensŌĆÖ SIMATIC PLC family, especially the S7-1200 and S7-1500 ranges, is widely used as the ŌĆ£brainŌĆØ of automation across industries, including automotive, according to Siemens automation partners such as Naksh Technology.

In a typical automotive plant, compact Siemens S7-1200 PLCs often handle stand-alone machines or auxiliary systems, while S7-1500 controllers coordinate complex processes such as body shop welding cells, paint booths, and final assembly stations. The controllers interact with SINAMICS drives for precise speed and torque control on conveyors, pumps, and fans, and they expose process data to operators through SIMATIC HMI panels and WinCC SCADA systems. SiemensŌĆÖ Totally Integrated Automation Portal (TIA Portal) ties this stack together as a unified engineering environment for configuration, programming, and diagnostics, which reduces engineering time and simplifies changes.

From a reliability perspective, that integration is not just an engineering convenience. When logic, drives, and visualization live in a coherent ecosystem, it is easier to standardize code objects, enforce consistent safety strategies, and apply the same diagnostics patterns from the first robot cell to the last end-of-line (EOL) test stand. That coherence becomes even more valuable as EV powertrain content grows and stations become more tightly interlocked through energy-intensive equipment such as curing ovens, fluid fill systems, and battery module handling.

Consider a battery pack fastening station in final assembly. A Siemens S7-1500 monitors torque tools, manages the sequence for several dozen bolts, logs every fastening result to WinCC SCADA, and exchanges status with an upstream AGC or conveyor system. If every fastening cycle takes 10 seconds and the station runs around the clock, you are looking at well over 250,000 fastening operations in a single day. Without deterministic PLC control and reliable logging, proving that every critical bolt was tightened within specification becomes almost impossible. With a standardized Siemens PLC and HMI design, that proof is automatic, and any recurring fault at the power or tool level becomes visible in your SCADA dashboards and energy reports.

This kind of deterministic, audit-ready control is the starting point. The next question is whether the hardware PLC model that has served the industry for decades is still the best way to engineer and maintain an entire vehicle plant.

Many automotive body shops still rely on hundreds of physical PLCs distributed across welding cells and conveyor sections. A Siemens Xcelerator use case on virtualization of automation describes a common reality: PLC programs are updated manually, hardware and software are tightly coupled, and simulation, testing, and live operation sit on separate platforms. Every model change or process improvement means patching code controller by controller. That is slow, labor-intensive, and error-prone.

In practice, it is not unusual for a body shop to have several hundred PLCs in service. If an engineering change affects even ten percent of them, you may be asking an already stretched team to touch several dozen controllers, often over a compressed shutdown window. Each separate engineering environment and hardware-specific quirk is a chance for misalignment between the simulated and the live system.

SiemensŌĆÖ answer to this complexity is software-defined automation (SDA). A Siemens industrial blog on SDA explains that SDA shifts automation from hardware-centric controllers toward software-defined functions that combine IT flexibility with OT reliability and real-time performance. The centerpiece for PLC control is the SIMATIC S7-1500V virtual PLC.

The S7-1500V encapsulates the software stack of a SIMATIC S7-1500 controller as an Industrial Edge application. Instead of living on a dedicated piece of PLC hardware, the control logic runs as a virtual PLC instance on an edge server or industrial PC. Siemens emphasizes several specific characteristics.

First, deployment is flexible and scalable. Because the S7-1500V runs as an Industrial Edge app, you can deploy multiple PLC instances on the same physical edge server or across several servers and virtual machines. When you introduce a new robot cell or assembly station, you can spin up additional virtual PLC instances from a central orchestration environment rather than procuring and wiring new hardware PLCs.

Second, performance remains suitable for factory automation. Siemens notes that the virtual S7-1500V supports PROFINET communication with cycle times down to 1 millisecond, meeting hard real-time needs in many automotive applications. It is not a lab experiment; it is designed to run shop floor operations with the same deterministic behavior expected from a hardware PLC.

Third, existing engineering work is preserved. Because the virtual PLC reuses the S7-1500 software stack and is integrated into TIA Portal, you can largely reuse existing S7-1500 projects. For a plant that already standardized on Siemens hardware PLCs, this dramatically lowers the barrier to virtualization. You are not rewriting the line; you are rehosting and modernizing it.

Fourth, visualization and HMI follow a similar pattern. SIMATIC WinCC Unified for Industrial Edge packages the core visualization capabilities of WinCC Unified into an Industrial Edge app, allowing you to build HMIs and SCADA dashboards that run on industrial edge devices while operators access them from any HTML5-capable browser. According to Siemens, these browser-based HMIs can be built with minimal custom coding, and they integrate naturally with other Edge applications for analytics and data access.

In the automotive context, Siemens presents virtual PLCs as a way to rethink how a factory and its infrastructure are designed and organized. A Siemens automotive production line optimization overview even calls the virtual PLC a revolution in automation engineering, suggesting that decoupling software from hardware opens the door to more radical redesigns of body and assembly lines.

AudiŌĆÖs early adoption reinforces that this is not only theory. Siemens reports that Audi has been rolling out SIMATIC S7-1500V in selected applications since July 2023, managing virtual PLCs centrally and treating this shift as a revolution in how shop floor automation is deployed and maintained.

The contrast between traditional hardware PLCs and virtualized Siemens PLCs can be summarized along a few practical dimensions.

| Aspect | Traditional hardware PLCs | Siemens virtual PLC / SDA |

|---|---|---|

| Controller location | Dedicated PLC hardware in each panel or cell | PLC instances as software on shared edge servers |

| Change management | Manual updates controller by controller | Central deployment and version management across many instances |

| Coupling of hardware and software | Strong; logic tied to specific PLC devices | Looser; logic targeted to virtual instances hosted on generic compute |

| Simulation and testing | Often on separate tools and test racks | Potential to use the same virtual PLC instances for simulation and runtime |

| Scalability and rebalancing | New PLC hardware for new capacity, limited reuse of compute resources | Spin up or reassign virtual PLC instances on existing edge infrastructure |

| Brownfield integration | Physical retrofits often required | Edge devices and virtual PLCs can overlay existing control where suitable |

For an automotive plant, the value of virtual PLCs shows up most clearly when engineering changes are frequent and model variation is high. If the line is relatively stable and safety certification requirements are strict, a conventional hardware PLC architecture may still be the conservative choice for now. Siemens itself notes that SDA is best suited where scalability and flexibility demands exceed what traditional hardware-centric OT can economically deliver, and where IT/OT infrastructure and skill sets are already maturing.

From a reliability and power perspective, virtual PLCs introduce new considerations. You are consolidating control workloads onto fewer, more powerful edge servers, which means those servers and their upstream power supply, including UPS and distribution, become more critical. At the same time, centralization can simplify how you design redundancy, power protection, and failover schemes, because you are now protecting a smaller number of key nodes instead of hundreds of scattered PLC panels.

Imagine a body shop with two hundred PLC-controlled cells. A traditional architecture might scatter those controllers across the shop, each with its own panel, power feed, and engineering file. A model change affecting weld sequence or clamp logic could force your team to touch a significant fraction of those PLCs during a shutdown, with all the associated power isolation, lockout, downloads, testing, and documentation.

In a virtual PLC scenario, many of those logic instances run on a redundant pair of edge servers in a protected room. An engineering change still needs to be carefully managed, but deployment is now a central operation, and you can pre-validate many changes on the same virtual PLC instances used in production. The physical power work may be limited to the stations that actually receive new field devices, while logic and diagnostics remain centrally controlled.

No matter where you land on the hardware versus virtual PLC debate, you still need a robust overall architecture for control, visualization, and supervision. SiemensŌĆÖ automation portfolio and industry examples give clear patterns for building a reliable stack.

Naksh Technology describes Siemens PLCs as the heart of automation, complemented by SIMATIC HMI Comfort Panels and WinCC SCADA. In automotive applications, TIA Portal is the common denominator. It allows engineers to configure PLCs, HMIs, and drives in a single environment, which is vital when you are enforcing standards across dozens of lines and hundreds of stations.

From a reliability standpoint, TIA PortalŌĆÖs value is in repeatability and diagnostics. Standardized function blocks for conveyor control, robot cell handshakes, and safety zones can be deployed across many stations. When an issue occurs, engineers can rely on the same faceplates, alarm structures, and trend views everywhere. This is similar in spirit to what SkyIO achieved in a non-Siemens SCADA environment by reorganizing a Wonderware System Platform installation into a modular, hierarchical ŌĆ£galaxyŌĆØ with reusable objects and dashboards. The lesson is that modularity and reusability are key, regardless of vendor, and SiemensŌĆÖ environment is designed explicitly to support that.

At the operator level, SIMATIC HMI panels give clear visualization of process data at each station. Multi-touch, high-resolution panels provide context-aware views of production status, interlocks, and alarm causes. In an automotive assembly line, that can be the difference between an operator waiting several minutes for maintenance after a fault and an operator seeing immediately that a simple light curtain is blocked or a torque tool is out of tolerance.

SiemensŌĆÖ WinCC SCADA solutions scale that visibility to the plant level. WinCC provides supervisory monitoring, historical data, and analytics that help identify bottlenecks, chronic faults, and quality issues. When combined with SIMATIC PLCs, it enables centralized monitoring of distributed processes, from body shop to paint shop to general assembly.

WinCC Unified Runtime for Industrial Edge takes this further by turning SCADA and HMI functionality into Edge applications. Operators can monitor and control machines from any HTML5-capable device, while configuration remains in TIA Portal. Siemens emphasizes that this approach is particularly valuable in brownfield scenarios. Instead of risky, high-cost upgrades of legacy machines, especially in regulated environments, you can add Edge devices to bridge older equipment into a unified visualization layer without invasive changes.

Automotive plants often resemble those regulated environments more than many realize, because every major change can trigger new validation for safety and quality. Edge-based visualization provides a way to modernize data access and user interfaces while limiting the need to recertify existing PLC programs and safety systems.

The benefits of a well-architected control, visualization, and supervisory stack show up clearly in capacity expansion projects. A SkyIO case study describes an assembly line where the customer needed to expand capacity by fifty percent while keeping the existing line running. The project added two new assembly lines, doubled the size of the post-assembly area for test, repair, and shipping, and tied old and new areas into a single integrated production system.

SkyIO acted as the automation project manager, coordinating AGC controls, Andon systems, and SCADA. The Andon system required substantial PLC code rewrites and careful integration with new AGC pathways. The SCADA system was reorganized from a collection of one-off applications into a modular, hierarchical model with dashboards and scoreboards for both existing and new lines. The result was not only the targeted capacity increase but also a more scalable, maintainable automation environment.

Although that project used a different SCADA platform, the principles align closely with how Siemens recommends using TIA Portal, WinCC, and standardized PLC code. If your plant is planning a similar expansion with Siemens PLCs at the core, the message is that you should treat the control and SCADA architecture as a strategic platform, not a set of project-specific point solutions.

From a power systems perspective, one of the most underused capabilities of PLC-based automation in automotive plants is energy management. A detailed academic study on smart energy management in manufacturing plants using PLC and SCADA, conducted in a mid-sized automotive parts facility, illustrates what is possible when Siemens S7-1500 PLCs and WinCC SCADA are used as an energy management platform.

In that study, Siemens S7-1500 PLCs were connected to WinCC SCADA, with real-time energy meters communicating over Modbus RTU. Custom optimization algorithms, written in structured text, coordinated plant-wide energy control. Over a twelve-month period covering 8,760 hourly measurements and analyzed with rigorous statistical methods, the plant achieved several significant improvements.

Total energy consumption dropped by 28 percent and peak demand decreased by the same percentage. The carbon footprint reduction was measured at 35.1 percent, while equipment efficiency improved by 24.1 percent. Operationally, unplanned downtime fell by 63 percent and equipment utilization improved by 42 percent, demonstrating that energy-focused automation also enhanced overall reliability and asset productivity.

Financially, the first-year return on investment was reported at 37.1 percent, with a cumulative ROI of 542.3 percent over five years. The authors noted that typical industrial energy-saving projects often achieve around 15 to 20 percent reduction, and that broader deployments of smart energy management systems can reach energy reductions in the 25 to 35 percent range. In other words, this PLC-SCADA implementation did not just match industry norms; it exceeded many of them.

A simple back-of-the-envelope example shows why this matters for automotive plants. If an assembly or components facility spends $2,000,000.00 per year on electricity, a 20 percent reduction, which sits comfortably within the range reported for smart energy management systems, would translate to about $400,000.00 in annual savings. A 28 percent reduction, similar to the case study, would be roughly $560,000.00. Those savings can fund UPS upgrades, redundant edge servers for virtual PLCs, and enhanced power quality monitoring without new capital coming from elsewhere.

Importantly, the study also highlights that integration with legacy systems was a key challenge, addressed through communication gateways, protocol converters, and carefully phased implementation. That is directly relevant for automotive plants integrating Siemens energy management into existing lines.

For a power system specialist, the most compelling aspect of Siemens PLC-based energy management is the way it can coexist with and enhance traditional power protection strategies. PLCs and SCADA do not replace UPS systems, inverters, or surge protection; they orchestrate load behavior and make power events visible and manageable.

In a vehicle assembly line, you typically have three layers to think about. The incoming utility supply and medium-voltage distribution are designed for capacity and protection. Downstream, low-voltage distribution and motor control centers feed drives, welders, robots, and auxiliaries. At the edge, PLCs, HMIs, and network gear depend on stable power with tight tolerance.

By integrating energy meters, drive feedback, and UPS or inverter status into Siemens PLC and WinCC systems, your line can respond gracefully to disturbances. For example, if your PLC-based energy management detects that peak demand is approaching a contracted threshold, it can coordinate a short, controlled pause in non-critical processes, guided by optimization algorithms similar to the Model Predictive Control and Demand Response strategies recommended in the smart energy management study. This avoids punitive demand charges without sudden, uncontrolled trips.

During a brief outage or sag, a properly sized UPS keeps critical PLCs, edge servers, and HMIs alive long enough for drives to coast to a stop and for the SCADA system to record the event. When power returns, restart logic in your Siemens PLCs can consider the state of the process, energy constraints, and equipment health rather than simply restarting everything at once. That approach reduces inrush, minimizes breakers tripping on reclose, and supports a smoother return to full throughput.

The key is to treat Siemens PLC and SCADA systems as part of your power reliability architecture, not as separate domains. When you align your control strategy with your UPS design, protective device coordination, and energy procurement, you get a plant that not only runs but also rides through disturbances without turning every blip into an unplanned downtime event.

Deciding how far to go with Siemens PLC modernization, virtual PLCs, and integrated energy management is ultimately a strategic question. Siemens materials and the external case studies described earlier suggest a practical sequence.

The first step is to choose your pilot scope carefully. For software-defined automation and virtual PLCs, automotive body shops are often an ideal candidate because they already struggle with manual updating of hundreds of PLCs and frequent model changes. A single body-in-white zone with clearly defined performance metrics and a mix of brownfield and greenfield equipment can provide a focused test bed. For energy management, the automotive case study shows that even a mid-sized plant can achieve substantial savings with S7-1500 and WinCC, so an area with energy-intensive equipment such as paint ovens or compressed air systems is a strong candidate.

The second step is to build an IT/OT and reliability foundation that can support SDA. Siemens emphasizes that software-defined automation requires appropriate IT infrastructure, such as server-based or cloud-like architectures, and engineers who are comfortable with IT tools and concepts. From a power perspective, consolidating controls onto edge servers means you need clear single-line diagrams, selective coordination, UPS strategies, and operating procedures that treat those servers as critical loads. You should involve both your automation engineers and your power engineers in the design of edge computing rooms, including cooling, redundancy, and maintenance plans.

The third step is to design your PLC, HMI, and SCADA standards with modularity and reuse in mind. The SkyIO assembly line expansion, the Siemens TIA Portal ecosystem, and the automotive energy management case all underline this point. Standardized function blocks, faceplates, and SCADA objects make it possible to expand capacity or replicate successful configurations quickly. PepsiCoŌĆÖs collaboration with the AI company Fractal in packaging lines, although outside automotive, reinforces this: they moved from manual tuning of more than three hundred parameters per line to AI-driven self-optimization that could be replicated across multiple sites once proven. Automotive plants can follow a similar pattern by designing Siemens PLC and SCADA templates that can be scaled and, eventually, enhanced with analytics or AI.

Finally, you need to measure, learn, and scale. The energy management study validated results with a year of data and proper statistical analysis, building a solid business case. A Siemens SDA pilot should be held to similar standards. Define what success looks like, whether that is faster changeover, reduced engineering hours, improved uptime, or energy savings, then collect the data to prove it. That empirical evidence is what will support investment to expand virtual PLCs, edge HMIs, and integrated energy management line-wide and plant-wide.

Siemens positions the SIMATIC S7-1500V virtual PLC as a production-ready controller, not a laboratory experiment. The company reports that it supports PROFINET communication with cycle times down to 1 millisecond and integrates with the existing S7-1500 ecosystem in TIA Portal. AudiŌĆÖs use of S7-1500V in selected applications since July 2023 is an early indicator that leading manufacturers see it as viable for real shop floor workloads. That said, safety-related functions and certifications still require careful evaluation. In many plants, a hybrid architecture, where virtual PLCs handle non-safety-critical logic and hardware safety PLCs handle safety functions, will be a pragmatic path.

In most cases, no. One of the key advantages Siemens highlights is that S7-1500V reuses the same software stack and TIA Portal engineering environment as hardware S7-1500 controllers. That means you can usually port existing projects with limited change, then deploy some logic to virtual PLCs while other parts remain on hardware PLCs. Over time, as you gain confidence and your IT/OT infrastructure matures, you can decide where virtual PLCs make the most sense, whether that is new zones in a body shop, test cells, or areas where rapid reconfiguration is a priority.

The automotive parts plant documented in the smart energy management study achieved a 28 percent reduction in total energy consumption, a similar reduction in peak demand, and a 37.1 percent first-year ROI, with a cumulative ROI above 500 percent over five years. Those results used Siemens S7-1500 PLCs, WinCC SCADA, and real-time metering, combined with tailored optimization algorithms. While every plant is different, this case and broader benchmarks showing 15 to 20 percent typical energy savings for smart energy projects suggest that integrating energy management into your Siemens PLC and SCADA environment can be one of the highest-yield automation investments you make, especially once rising energy prices and carbon regulations are considered.

When you look at Siemens PLCs in automotive production lines through a power and reliability lens, the message is clear. Deterministic control is still the foundation, but the real gains now come from how that control is engineered, virtualized, visualized, and linked to energy and power systems. Plants that embrace software-defined Siemens PLC architectures, modular HMI and SCADA standards, and PLC-based energy management, while designing the surrounding power infrastructure accordingly, will be the ones that can retool quickly, expand capacity with confidence, and ride through disturbances without sacrificing vehicle throughput or quality.

Leave Your Comment