-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Schneider Altistart soft starters do an essential job: they tame motor inrush and torque shock so your process starts smoothly and your power system stays steady. When they trip, production feels it. As a power system specialist who has commissioned and troubleshot ATS22 and ATS48 starters alongside UPSs, inverters, and sensitive plant distribution, IŌĆÖve learned that decoding a fault fast is as valuable as fixing it. This guide translates Schneider soft starter error codes into practical actions, with proven field techniques to get you from red lights back to green startsŌĆösafely and reliably.

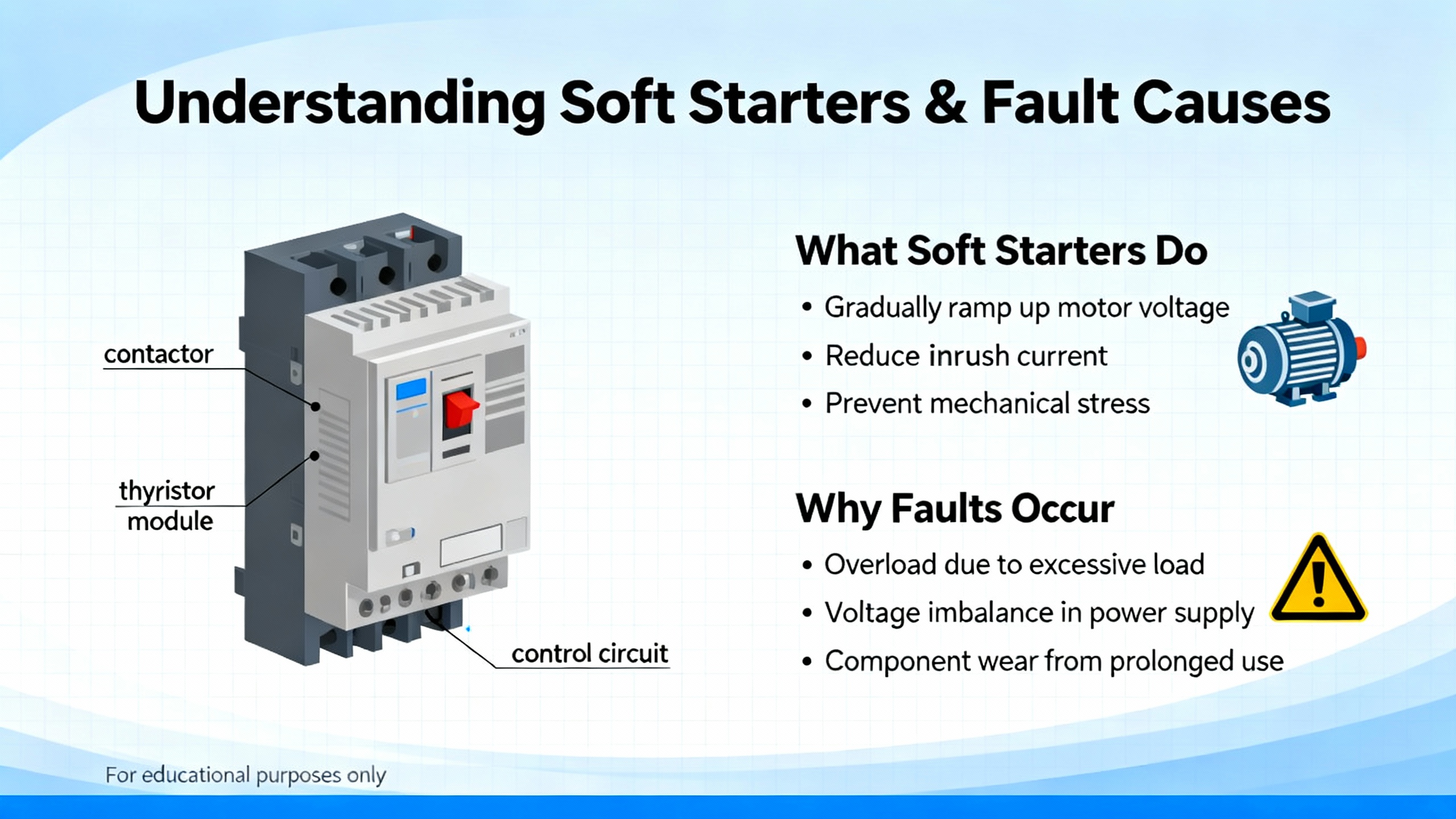

A soft starter is a solidŌĆæstate controller that ramps voltage through SCRs (thyristors) to limit starting current and torque. That simple idea prevents the 6ŌĆō8├Ś fullŌĆæload amperes typical of acrossŌĆætheŌĆæline starts and reduces mechanical strain on gearboxes, belts, and couplings. With appropriate settings, a soft starter typically holds inrush near 2ŌĆō4├Ś FLA while still achieving a confident runŌĆæup, depending on load and tuning. Those ballpark figures come from widely accepted industry guidance and are echoed by DigiŌĆæKeyŌĆÖs selection notes. Hoyer MotorsŌĆÖ application guidance reinforces the operational benefits as well: controlled starts and soft stops improve process stability and cut hydraulic hammer in pump systems.

Faults arise when supply conditions, wiring, thermal environment, load dynamics, or parameterization diverge from what the soft starter expects. Unlike a breaker trip that only reports overcurrent, a modern soft starterŌĆÖs diagnostic codes point to specific symptomsŌĆöphase loss, thermal issues, overcurrent at start, abnormal current paths, or network communication faultsŌĆöso you can aim your effort precisely.

SchneiderŌĆÖs Altistart lineup has several families; in industry, ATS22 and ATS48 are the most common. ATS22 is a compact, generalŌĆæpurpose soft starter that integrates well in fixedŌĆæspeed applications with fundamental protections and straightforward parameterization. ATS48 is a more advanced platform designed for heavier duty and more demanding environments, with features like a Torque Control System that reduces drivetrain wear, plus native communications for supervisory integration. Power ranges span from low tens to several hundred horsepower depending on line voltage; MRO ElectricŌĆÖs application notes outline representative ATS48 ranges and emphasize the integrated diagnostics that drive troubleshooting efficiency. While code names may differ slightly across firmware or regional labels, the underlying fault categories are consistent.

Lockout/tagout, discharge stored energy, and verify absence of voltage before touching conductors or power electronics. Start every response by capturing the code, the process state, and what changed upstream or downstreamŌĆönew contactor, retorqued lugs, adjusted PLC interlock, filter cleaning, seasonal temperature shift. Then perform the nonŌĆæintrusive checks: visual inspection, panel temperature, fans running, airflow paths unobstructed, and indicator states on any upstream protective devices. With that context, the code becomes a map rather than a mystery.

The following table summarizes Schneider soft starter faults explicitly documented in Schneider Electric sources or widely referenced service guidance, along with fieldŌĆæproven checks. Treat it as a practical crosswalk, then consult the specific user manual for modelŌĆæexact details and safety notices.

| Code | Model | Meaning (per source) | Likely Causes | First Checks | Source |

|---|---|---|---|---|---|

| PHF | ATS48 | Phase fault detection; phase loss upstream or downstream of the starter | Open fuse, loose/incorrect wiring, motor lead issue, line contactor sequencing | Verify threeŌĆæphase voltage at L1ŌĆōL3 and through to motor; inspect terminals; confirm line contactor timing relative to Start | Schneider Electric Community |

| PHL | ATS22/ATS48 | Phase loss/imbalance classification in Schneider repair notes | Supply imbalance, singleŌĆæphasing, bad connection | Measure phaseŌĆætoŌĆæphase voltages; tighten and retorque power lugs; inspect motor leads | Synchronics Electronics |

| SSCr | ATS22 | Abnormal current: no current at run command or excessive current through the starter | Open circuit to motor, welded internal contactor, leaky/shorted SCR | Confirm motor connected and any disconnects closed; measure resistance L1ŌĆōT1, L2ŌĆōT2, L3ŌĆōT3 both polarities; each should read at least 50 k╬®; nearŌĆæzero suggests welded contact, subŌĆæ50 k╬® suggests SCR issue | Schneider Electric FAQ |

| OCF | ATS22/ATS48 | Overcurrent during start | TooŌĆælow current limit, too short accel time, heavy or jammed load, undersized unit | Increase current limit and/or acceleration time, check for binding, validate motor FLA and sizing | Synchronics Electronics |

| OLF | ATS22/ATS48 | Overload per thermal model | Prolonged high current, incorrect motor nameplate settings | Set IL1 to motor nameplate, reduce mechanical load, verify ramp profile | Synchronics Electronics |

| THF / OHF | ATS22/ATS48 | Thermal overtemperature fault | Blocked airflow, failed fan, high ambient, continuous SCR conduction | Clean heatsinks, confirm fan operation, ensure bypass engaged at speed, improve ventilation | Synchronics Electronics |

| USF | ATS22/ATS48 | Unstable/underŌĆævoltage supply condition | Sagging feeder, undersized transformer, high impedance source | Measure upstream voltage stability, review starts per hour, coordinate with facility power team | Synchronics Electronics |

| SCF | ATS22/ATS48 | ShortŌĆæcircuit/shorted device path | Shorted SCR, wiring short, faulted motor | Insulation tests offline; diodeŌĆæmode SCR checks; inspect cabling | Synchronics Electronics; JustAnswer |

| CF | ATS48 | Communication fault on networked units | Broken cable, misconfigured node, noisy bus | Validate network settings, grounding, and cabling; isolate to local control to test | Synchronics Electronics |

| tLS timeout | ATS22 | Maximum start time exceeded | Ramp too short, current limit too low, heavy load | Increase tLS and ACC; verify ILt; example practice: with ACC at 10 s, set tLS at or above 20 s | JustAnswer |

If you see codes such as InF or trAP, treat them as internal or applicationŌĆætrap indicators and refer directly to the Schneider manual for your specific model. Some of these require cycling control power to clear, and clearing without root cause analysis risks repeat trips.

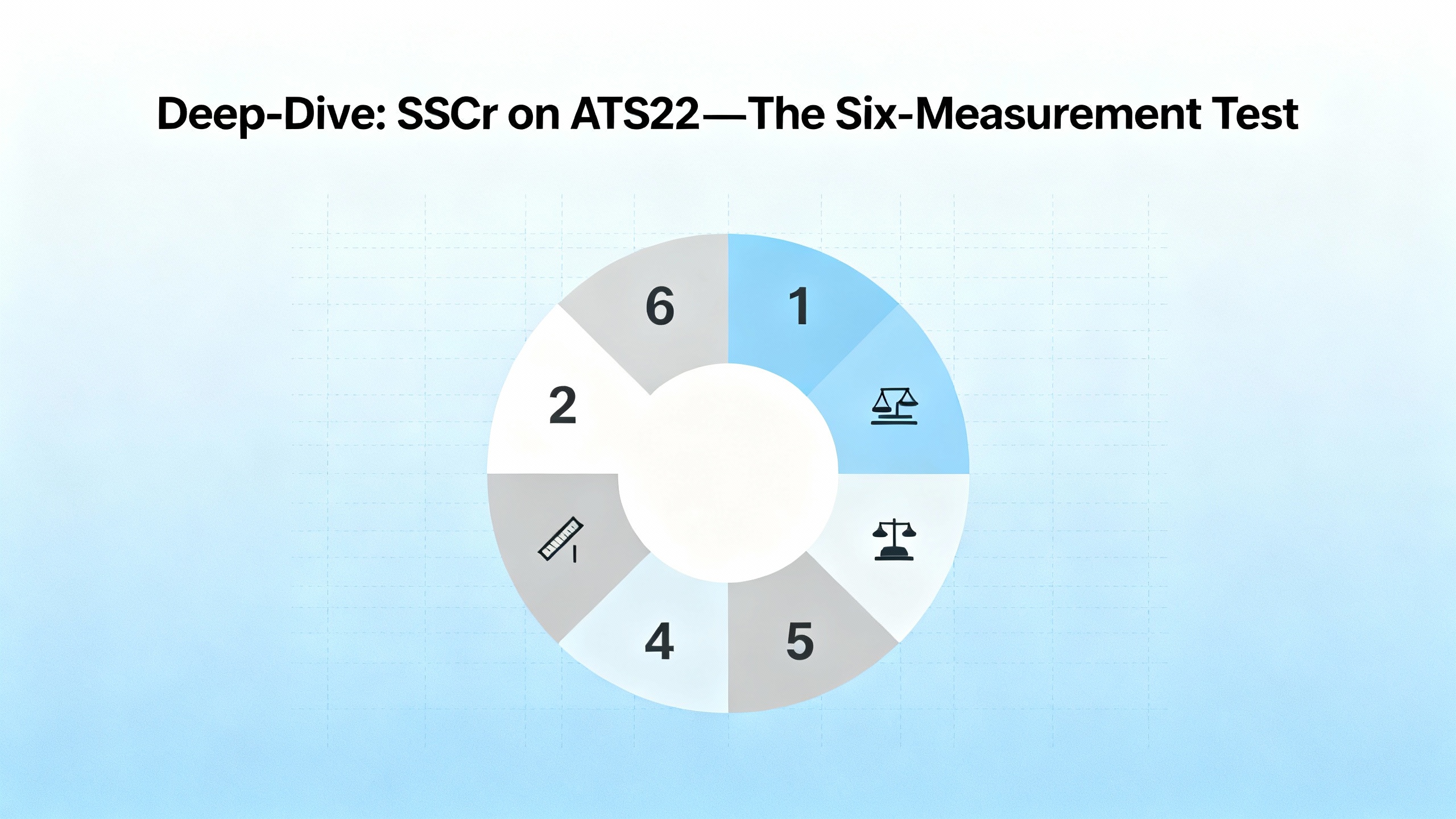

SSCr can be enigmatic until you apply a straightforward diagnostic taught by SchneiderŌĆÖs own FAQ. With the unit deŌĆæenergized and safe to test, measure resistance between L1ŌĆōT1, L2ŌĆōT2, and L3ŌĆōT3 with the meterŌĆÖs red lead on L and black on T. Record all three values. Reverse the leads and repeat. You should have six measurements in total and every one should be at least 50 k╬®. When a reading is near zero, it points to welded contacts in the internal shorting contactor. When a reading is above zero but below 50 k╬®, it suggests a leaking or shorted SCR. If all six are comfortably above 50 k╬® and your wiring is correct, refocus on the ŌĆ£no current at runŌĆØ scenario: open disconnects between starter and motor, a tripped overload downstream, a disconnected motor, or a miswired contactor path that bypasses the current sensors. This simple, disciplined test sequence prevents random partŌĆæswapping and gets you to the real failure mode efficiently.

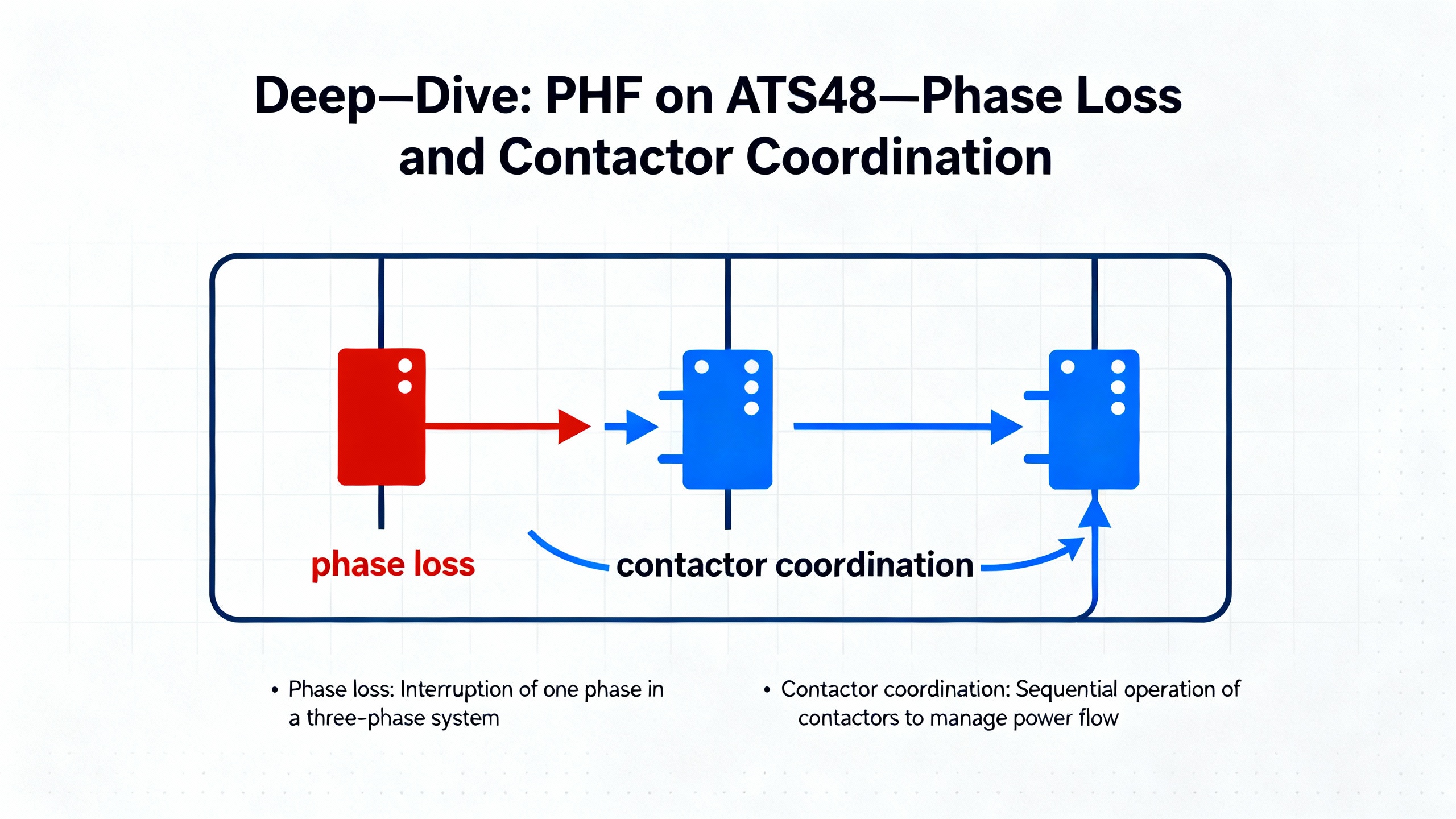

PHF indicates a phase anomaly on either side of an ATS48. From the field, the top three causes are wiring defects, intermittent upstream supply hardware, and misŌĆæsequenced control logic. One subtle but common pattern occurs when a line contactor closes at the exact moment the ATS48 receives its Start command. That transient can make the starter believe it has lost a phase and it trips PHF. The fix is not expensive: delay the Start signal slightly so the contactor closes, the bus settles, and then the ATS48 ramps. Add verifiable timing in the PLC logic or offload it to a small onŌĆædelay timer. Validate with a single trial start and confirm stable current on all three phases.

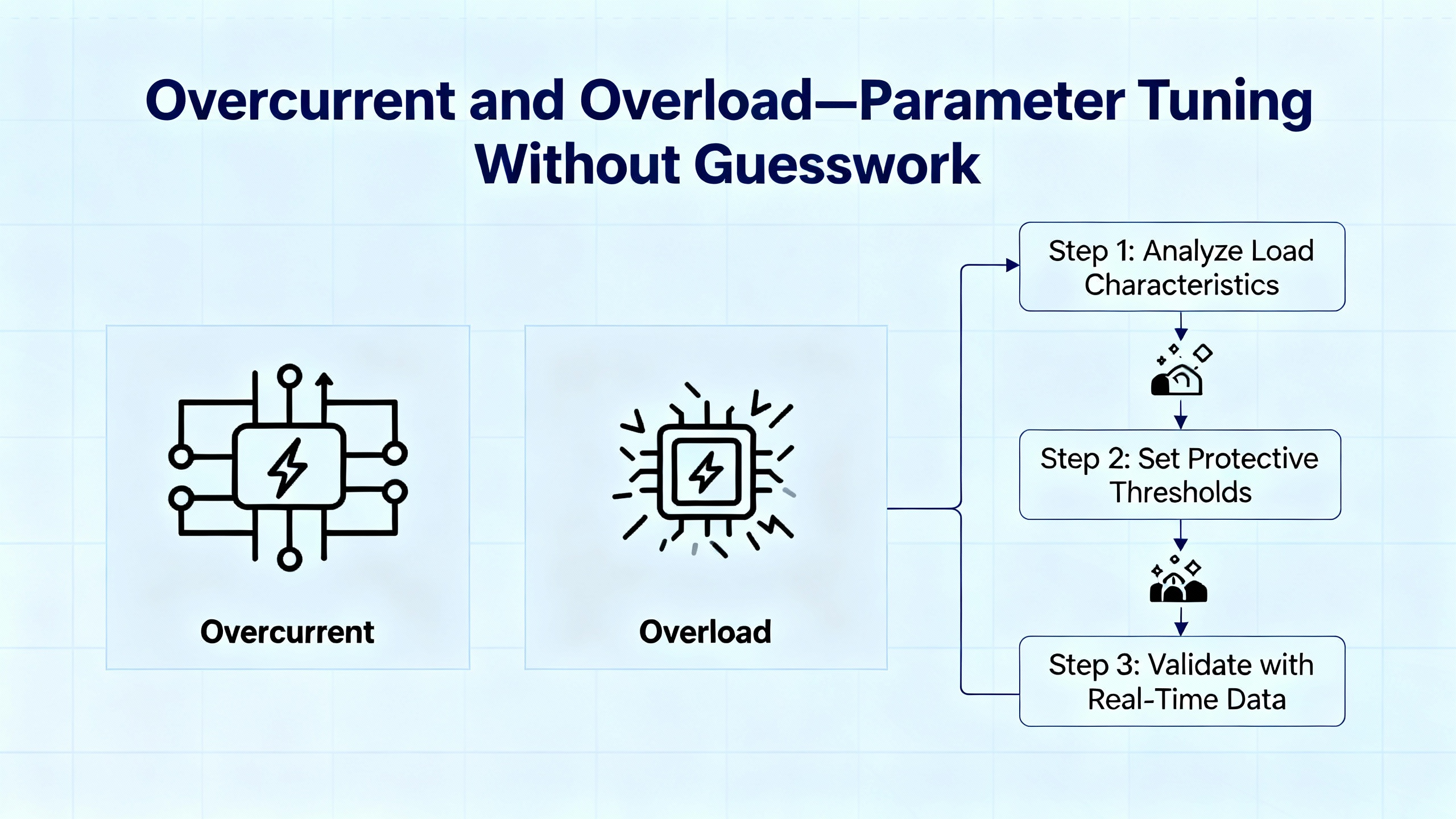

An overcurrent fault (OCF) during acceleration usually means your current limit is below what the load really needs to break away and accelerate, or your ramp time is too aggressive. A thermal overload (OLF) confirms the thermal model has accumulated more heat than allowed. The corrective approach is systematic.

Start by confirming IL1 matches the motor nameplate FLA. Then set ILt, your current limit, with a clamp meter in hand. For most pumps, fans, and conveyors, a soft starter can hold starts near 2ŌĆō4├Ś FLA with a ramp that is long enough to reduce torque shock but short enough to avoid lingering in the highŌĆæslip, highŌĆæloss zone. If you consistently hit OCF at the start, increase ILt modestly and extend ACC by a few seconds, observing current and speed rise. For OLF that trips after multiple starts or long accelerations, either reduce mechanical load, lengthen stops to avoid repeated heating, or verify that the programmed motor current actually reflects the nameplate and application. If your load is genuinely high torqueŌĆöcrushers, mixers with cold viscous products, high inertia drum startsŌĆöacknowledge that with settings and duty cycle. When highŌĆætorque, frequent starts are part of normal operations, a VFDŌĆÖs torque and speed control is often the right answer; DigiŌĆæKeyŌĆÖs guidance outlines this selection boundary clearly.

THF and OHF often point to panel thermal issues more than electronic failure. Check airflow path first. Replace clogged filters, ensure vents are not blocked by wire bundles, and confirm fans run at speed. Keep at least about 6 in of unobstructed space around ventilation paths, and do not treat cabinet roofs as storage shelves that smother convection. SynchronicsŌĆÖ experience suggests a 4 in clearance target as a practical minimum in tight spaces, with more margin preferred in hot rooms. For cleaning, keep liquids out and use dry methods; light compressed air around 87 psi is typically sufficient to remove dust without abuse, and a vacuum with a brush works well on fins. If the starter does not engage its internal or external bypass after the motor reaches speed, the SCRs remain in the power path and burn heat continuously; that can push you into thermal trips despite light mechanical load. Verify bypass engagement in diagnostics and correct any wiring or control interlock that prevents it.

USF and other supply abnormalities correlate with poor starts in weak networks where multiple large loads share the same feeder. Even though soft starters reduce starting current relative to acrossŌĆætheŌĆæline methods, they do not fix a feeder that already drops voltage too far under concurrent starts. Monitor line voltage during start; if sags are significant, adjust start sequencing, stagger loads, or request upstream capacity adjustments. In some facilities I support, a simple interlock that delays a pump start until a compressor is at speed keeps both machines online and faultŌĆæfree. Where harmonics or flicker are concern, note that soft starters impose very little distortion compared with VFDs, but power quality is still a system property; active filtering and feeder stiffening remain valid solutions when needed.

ATS48 units with industrial networks sometimes report CF when cabling is compromised, terminations are incorrect, or grounding is noisy. Isolate whether the starter itself is healthy by switching to local control or simple hardŌĆæwire mode and attempting a start. If it starts fine, pursue the network stack: correct addressing, proper shield terminations, intact twisted pairs, and reliable switch or gateway configurations. Keep communications independent from essential interlocks so that a network hiccup cannot block a safe local stop.

A thoughtful parameter set prevents a year of nuisance trips. The interplay between ACC (rampŌĆæup time), ILt (current limit), and tLS (maximum start duration) deserves attention. tLS should exceed ACC by a safe margin to avoid timing out a legitimate but heavy acceleration; a common practice is to set tLS at roughly twice ACC. If ACC is 10 seconds, a 20ŌĆæsecond tLS is a reasonable starting point in many plants. This does not relax protection; it recognizes that some loads need a beat to climb out of static friction and viscosity. Keep a record of parameter sets and annotate the process state when tunedŌĆöcold day, full reservoir, cleaned filterŌĆöso your next change is informed. When in doubt, log motor current during a test start and match what you see to the protectionŌĆÖs expectations rather than guessing.

Soft starters are forgiving, but dirt and heat are relentless. Clean cabinets routinely with a dry cloth, vacuum, or carefully controlled compressed air; avoid solvents and moisture. Inspect for discoloration, burned odor, loose lugs, and frayed control wires. Torque terminals to manufacturer specification. Validate fan operation and clear airflow; verify that any filters are clean and sized to the installation. Maintain environmental integrity: temperature within rating, humidity controlled, corrosive dust excluded by appropriate enclosure ratings and gasketing. Back up configuration snapshots after commissioning and after significant changes. Schedule periodic inspections, more frequent in dusty or hot areas, and complete a deeper cleaning and retorque at least annually. Gozyun and Riqno both emphasize the practical side of these routines; the result is fewer thermal and wiringŌĆærelated trips and longer asset life.

When diagnostics point to a failed SCR or a welded internal bypass contactor, a repair with the right parts and techniques is effective. Testing SCRs with a meterŌĆÖs diode mode, replacing faulty modules with genuine Schneider parts, applying fresh thermal compound, and validating gate trigger circuits are straightforward for trained technicians. Reputable service organizations emphasize proper parts and loadŌĆæsimulation testing; Synchronics reports that professional repair can save up to 70% compared with replacement, preserve system compatibility, reduce eŌĆæwaste, and extend useful life by 3ŌĆō5 years. Those numbers are credible because in many cases only one power device or fan assembly has failed, and the control logic is intact. When boards are obsolete, verify availability of compatible spares before you commit; if you are facing frequent highŌĆætorque starts or harsh duty that strains a soft starterŌĆÖs envelope, a VFD upgrade may be the smarter longŌĆæterm play.

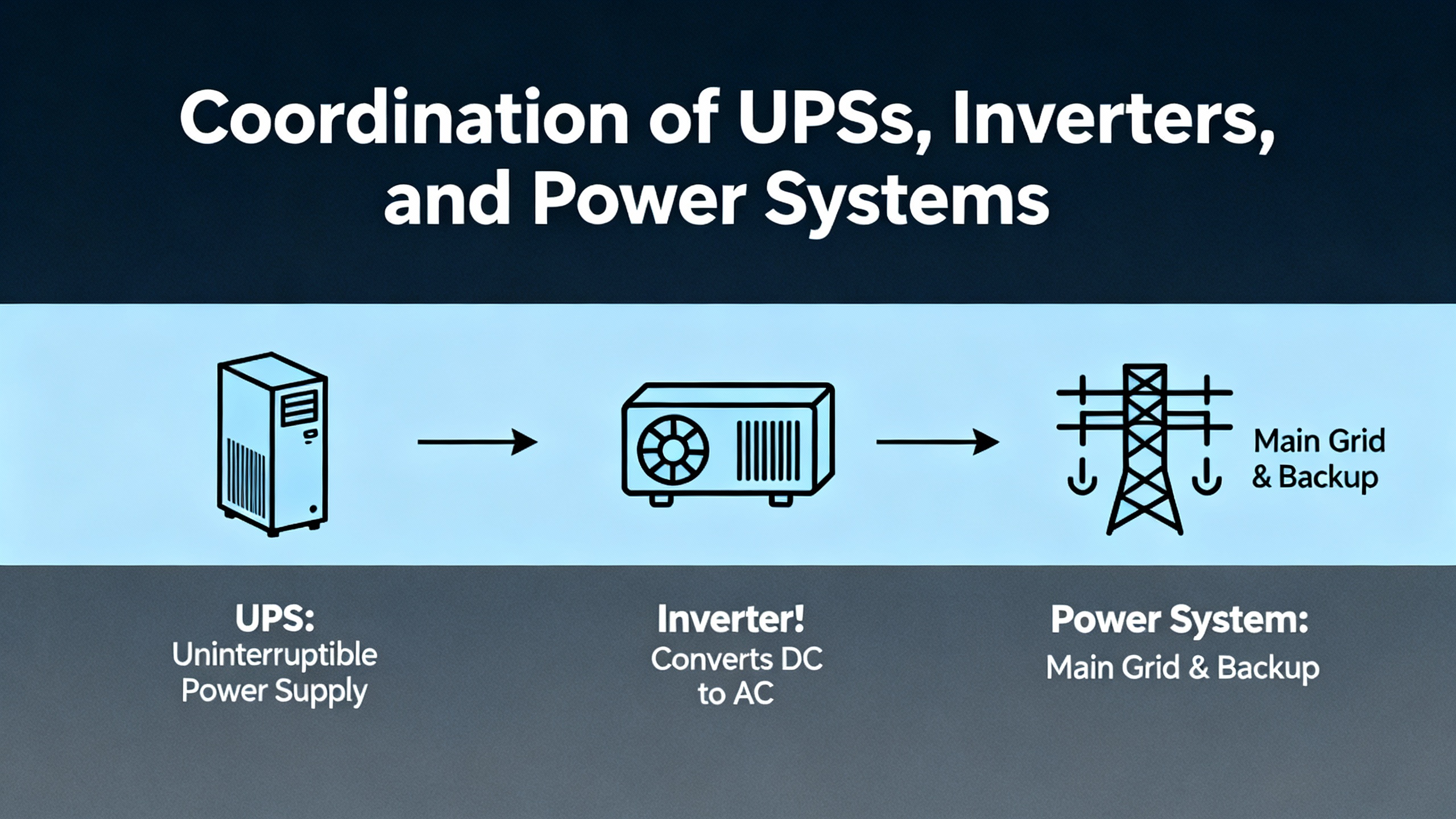

In facilities where UPSs, inverters, and sensitive process controls share upstream feeders with motor loads, soft starters are part of the powerŌĆæquality plan. Even though they curtail inrush compared with acrossŌĆætheŌĆæline starts, they still draw multiples of FLA during acceleration, and SCCR coordination with upstream fuses or breakers remains mandatory. Many soft starters require semiconductor fuses to protect SCRs during faults; this is not optionalŌĆömisŌĆæcoordinated protection can sacrifice the starter during a shortŌĆæcircuit event. Ensure bypass contactor wiring and control voltage references are aligned with UPS transfer behavior so that a rideŌĆæthrough event does not confuse the starterŌĆÖs state. Careful review of the IEEE 519 context for harmonic limits and the IEC 60947ŌĆæ4ŌĆæ2 standard for AC semiconductor motor controllers keeps procurement aligned with compliance.

A soft starter shines in fixedŌĆæspeed applications where gentle starts and stops are the principal need and lower cost, lower heat, and simpler integration are benefits. A VFD is the right tool when you need variable speed, precise torque control, frequent heavyŌĆæduty starts, positionŌĆæsensitive ramps, or advanced diagnostics. The Altistart families can run for years when set up well, and in many plants I support they coexist with VFDs: soft starters on pumps and fans that simply need kinder starts, VFDs on conveyors and mixers that benefit from speed scheduling and torque limits. Choosing the right tool reduces nuisance trips because you are no longer trying to force one device to behave like the other.

Most nuisance trips yield to a handful of disciplined actions. Verify threeŌĆæphase voltage at the starter and at the motor; correct any phase loss or imbalance before chasing software. Inspect and retorque power and control connections; feel is not a torque wrench. Clean heatsinks and ensure that fans run; thermal trips are often airflow trips wearing a different coat. Check the line contactor and Start timing on ATS48; a small delay on Start eliminates a deceptive PHF. Validate motor nameplate current in the starter and tune ACC, ILt, and tLS with a clamp meter in hand rather than guessing. When SSCr appears on ATS22, use the sixŌĆæmeasurement test to distinguish a contactor weld, an SCR leak, or an open circuit. This isnŌĆÖt glamorous, but itŌĆÖs the fastest path back to reliable starts.

For planning and spares, it helps to know that ATS48 spans a broad horsepower range across common North American voltages, integrates the Torque Control System to reduce drivetrain wear, and supports supervisory integration for diagnostics and parameter management. MRO ElectricŌĆÖs application overview documents those capabilities and the practicality of using vendor tools for monitoring and configuration. For ATS22 installations, keep an eye on the supply conditions and duty cycle; the compact form factor is a strength, but it relies on accurate parameterization and healthy airflow to stay cool and predictable.

Not every code supports a remote reset. Some conditions, particularly internal or trapŌĆæstyle codes, require removing and reapplying control power. SchneiderŌĆÖs documentation notes that certain codes such as SCF and similar hard faults are not clearable via a simple reset command. Record the fault, correct the cause, and only then clear it.

OCF is about instantaneous overcurrent during start; OLF is about the accumulated thermal model exceeding limits. If you trip immediately as torque rises, you likely need more current limit or a longer rampŌĆöor a lighter load. If you trip after a longer acceleration or multiple starts, you likely need to reduce thermal stress, back off starts per hour, or improve cooling.

If your starts are frequent and heavy, if you need speed control or torque shaping to avoid process shocks, or if you want richer diagnostics and trending, a VFD is the right tool. If you only need gentle starts and stops at fixed speed, a soft starter remains the simpler, cooler, and more economical solution.

This guide draws on Schneider Electric Community discussions regarding ATS48 PHF behavior; a Schneider Electric FAQ detailing ATS22 SSCr diagnostics and acceptance criteria; Hoyer MotorsŌĆÖ primer on soft starter principles and application benefits; DigiŌĆæKeyŌĆÖs selection guidance and startingŌĆæcurrent expectations; Synchronics ElectronicsŌĆÖ repair and troubleshooting notes across ATS22/ATS48 fault categories and maintenance practices; MRO ElectricŌĆÖs ATS48 overview with power ranges and configuration tooling; and userŌĆæreported field experience collated from service resources including JustAnswer.

In reliability work, speed and rigor win together. If you want a second set of eyes on a stubborn code or a quick sanity check on parameter choices, IŌĆÖm happy to help you turn red lights into smooth, steady starts.

Leave Your Comment