-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ââ.

Variable frequency drives from Schneider Electric and Square D have been the backbone of countless pump rooms, air handlers, and production lines. Many of those Altivar drives are now at end of life, discontinued, or operating in systems that have changed dramatically since the original design. When a Schneider VFD fails or becomes obsolete, you are not just shopping for a box with the same horsepower rating. You are making a decision that affects energy use, power quality, process stability, and longâterm maintainability.

From a reliability advisorâs point of view, the key question is not âWhich model replaces my old part number?â The question is âWhat drive solution now makes the most sense for this motor, this load, and this facility?â In some cases that will be a modern Schneider Altivar. In others, a different VFD brand, a brushless motor package, an eddy current drive, or even a mechanical modification will deliver better lifecycle value.

This article walks through the main options available when you are looking at Schneider VFD replacements, grounding each choice in real data and fieldâproven technologies referenced by sources such as ConsultingâSpecifying Engineer, Industrial Automation Co., Plant Engineering, and Empowering Pumps & Equipment.

Electric motor systems account for more than a third of total U.S. electricity demand and around 43â46% globally, with roughly 68% of motor power going into motors between 1 and 500 hp according to analysis published in ConsultingâSpecifying Engineer. That is the same horsepower band where Schneider drives dominate building and industrial applications.

Because energy costs across a motorâs life typically dwarf the purchase price of the motor and drive, a Schneider VFD replacement is a significant energy decision. At the same time, legacy drives and servo amplifiers eventually reach end of life. Industrial Automation Co. emphasizes that you cannot treat these devices as simple commodities: the wrong replacement can break communication with your PLC, mis-handle the torque profile, or cause nuisance trips that undermine system reliability.

It is also important to recognize where energy savings really come from. A technical discussion hosted on a motor engineering forum points out that improving the standalone efficiency of an induction motor often yields marginal savings. Real reductions come from running pumps, fans, and compressors at lower speeds when full flow is not needed. Whether you stay with Schneider or move to an alternative solution, your replacement decision should be driven by how well the new drive controls the system, not just by its own nameplate efficiency.

Before comparing Schneider and nonâSchneider options, it helps to frame three foundational questions.

Industrial Automation Co. summarizes drive selection around the torque profile.

For variableâtorque loads such as most fans and centrifugal pumps, torque rises roughly with the square of speed and power with the cube of speed. That is why Plant Engineering notes that slowing a centrifugal fan or pump to about 80% of rated speed can cut energy use by roughly half. Drives aimed at these applications, including Schneiderâs HVACâoriented Altivar products and Siemens SINAMICS G120X, focus on efficient operation across a wide speed range and optimized PID control.

Constantâtorque loads such as conveyors, mixers, and extruders have very different requirements. They demand full torque down to low speed and can punish drives that are optimized only for variableâtorque behavior. Here, Industrial Automation Co. points to drives with sensorless or closedâloop vector control as better suited, citing families like Mitsubishi FRâA800 as examples. Within the Schneider ecosystem, generalâpurpose Altivar drives with vector modes fill this role.

Servo and positioning systems are another category altogether. They need highâresolution feedback and rapid settling times. In that space, classic VFDs, Schneider or otherwise, may not be the right replacement at all; servo amplifiers or highâperformance brushless systems are usually more appropriate.

The same Industrial Automation Co. guidance stresses that you must match more than horsepower. The replacement drive must align with:

Input voltage, typically in bands like 230 V, 400â480 V, or 600 V. Motor fullâload amps and required overload capability. Output current must meet or exceed these values with adequate margin.

Enclosure and cooling, ranging from open IP20 or NEMA 1 units in clean electrical rooms to higherâprotection ratings for dusty or damp plant floors.

Heat dissipation and clearances, because upsizing by even one frame can force panel redesign.

On mediumâvoltage projects in the 2,300â4,160 V range, the choice is even more consequential. Articles from Empowering Pumps & Equipment and SET Solutions show that large mediumâvoltage VFDs can demand new transformers, electrical rooms, and dedicated air conditioning, whereas alternative technologies such as refurbished eddy current drives or variable speed gearboxes sometimes reuse the existing main motor and require far less infrastructure.

Modern drives are nodes on a network, not isolated components. Industrial Automation Co. underlines the importance of confirming:

The control mode, whether it is basic V/Hz, vector control, or torque control.

Fieldbus protocols, especially in plants standardized on EtherNet/IP for AllenâBradley systems, PROFINET or PROFIBUS for Siemens, or Modbus RTU/TCP and CANopen/DeviceNet, which remain common in Schneider and multiâvendor environments.

Support for encoder feedback, I/O mapping, fault diagnostics, and features such as integrated web servers, which many current drives use for browserâbased commissioning and troubleshooting.

Replacing a legacy Schneider drive with a new Altivar or with an ABB ACS580 or AllenâBradley PowerFlex 525 is straightforward only if these communication layers are engineered correctly. Firmware versions, control words, and safety functions all need to line up with existing PLC logic.

For facilities already standardized on Schneider, the most direct path is usually a modern Altivar drive with appropriate voltage and application ratings.

Schneiderâs Altivar 212 line is designed specifically for threeâphase asynchronous motors in HVAC and fluid applications. It covers power ratings from about 0.75 kW to 75 kW, roughly 1 to 100 hp, over common voltage bands such as 200â240 V and 380â480 V. Schneider notes that Altivar 212 can deliver up to about 70% energy savings compared with traditional control methods in heating, ventilation, air conditioning, and pumping systems by varying fan and pump speed instead of relying on throttling.

Altivar 212 also illustrates what modern Schneider drives bring beyond simple speed control. Integrated EMC filters help meet electromagnetic compatibility requirements. Builtâin building management protocols, including Modbus, BACnet, and others widely used in building automation, simplify integration. Antiâharmonic features keep total harmonic distortion of current below about 30%, easing stress on upstream transformers and switchgear.

For more general industrial duty, Industrial Automation Co. highlights Schneiderâs ATV320 family. Compared to older Altivar lines such as ATV31, newer models like ATV320U75N4B offer torqueâboost algorithms, compact mechanical footprints, higher protection ratings, and improved thermal management. These features translate into better overload handling and easier panel design in real installations.

Staying with Schneider has several advantages. Controls engineers can keep a consistent parameter structure and programming tools. Maintenance staff deal with one spareâparts ecosystem. Existing PLC code that was written around Schneiderâspecific registers and diagnostic bits tends to be easier to adapt.

Industrial Automation Co. additionally recommends using obsolescenceâdriven replacements as an opportunity to standardize on a single drive family where possible. For example, replacing a mix of older Schneider models with a consistent Altivar generation can unify parameters across multiple panels and simplify operator training.

That said, a oneâforâone Schneider replacement has limits. If the original design oversized the motor or used a VFD where only a soft starter was really needed, a new Altivar will not fix that. If structural issues such as poor base grouting or shaft misalignment are causing vibration and bearing failures, simply swapping a drive may mask mechanical problems temporarily. In a wastewater plant case study reported by Dynamatic, refurbishment of a large eddy current drive uncovered installation faults like inadequate grouting and poor alignment; correcting those issues significantly reduced vibration and extended life, independent of the control technology.

In other words, a SchneiderâtoâSchneider swap is often the lowestârisk path, but it should still be backed by a quick system review rather than done blindly.

Sometimes the best replacement for a Schneider VFD is a drive from another major manufacturer, either because the plant has migrated to a new standard or because a particular product line better fits the application.

Industrial Automation Co. discusses mapping legacy drives, including Schneider ATV31 and others, to current families such as ABB ACS580, Siemens SINAMICS G120X, AllenâBradley PowerFlex, LS Electric S100, and Mitsubishi FRâA800. These modern drives can bring benefits such as builtâin DC chokes, higher enclosure ratings, improved thermal design, and advanced control modes that were not available in older Schneider units.

The global landscape reflects this dynamic. A 2024 ranking of VFD brands lists Siemens, ABB, Schneider, Emerson, Rockwell, Mitsubishi, Fuji, Inovance, Delta, and HARS among the leading players, with Siemens and ABB often treated as benchmarks for comprehensive automation offerings. For facilities already invested in those ecosystems, replacing a Schneider VFD with a drive that aligns with existing PLC templates and spareâpart strategies can be a smart move.

The following table summarizes how several drive families discussed in the research align with common load types and priorities.

| Drive or approach | Bestâfit applications | Noted strengths from published sources | Typical considerations |

|---|---|---|---|

| Schneider Altivar 212 | Building HVAC fans and pumps | Designed for threeâphase motors in fluid management; up to about 70% energy savings vs traditional controls; integrated EMC filters and BMS protocols; harmonic current limited below roughly 30% | Optimized for variableâtorque building loads; not intended as a universal constantâtorque solution |

| Schneider ATV320 | Generalâpurpose industrial loads | Torqueâboost algorithms, compact form factor, higher protection ratings, improved thermal management vs older ATV lines | Requires checking vector control modes and communication options against existing PLC requirements |

| ABB ACS580 | Generalâpurpose fans, pumps, conveyors | Integrated EMC filters and DC chokes; supports Modbus; modern diagnostics and energyâsaving modes | When used as a Schneider replacement, PLC control words and I/O mappings must be verified carefully |

| Siemens SINAMICS G120X | Variableâtorque fans and pumps | Energyâsaving modes and optimized PID for quadratic torque loads; oriented to HVAC and water/wastewater | Focused on fan and pump duty; protocol choices should align with the siteâs Siemens or mixedâvendor networks |

| AllenâBradley PowerFlex 525 | Packaged machines and skids | Tight integration with Logix controllers; common use of EtherNet/IP; parameter tools that aid migration from older PowerFlex models | A strong choice when Rockwell is the plant standard; may complicate life in Schneiderâcentric architectures |

The core message is that any crossâbrand replacement must be engineered. Key items from Industrial Automation Co. include verifying firmware compatibility, confirming controlâword and I/O mapping, and documenting existing motor tuning data so that startâup and reâtuning do not cause extended downtime.

For lowâ to mediumâpower machines, brushless DC (BLDC) motor systems can be a compelling alternative to an induction motor plus Schneider VFD.

A brushless motor system uses permanent magnets in the rotor and electronic commutation in the stator. A dedicated driver monitors rotor position using Hallâeffect sensors spaced 120 degrees apart or an encoder. By adjusting the commutation rate, the driver keeps the rotor synchronous with the commanded speed, rather than relying on line frequency and slip as in an induction motor.

An Oriental Motor analysis contrasts BLDC systems with VFDâdriven induction motors. Typical VFD systems for threeâphase induction motors operate in open loop and offer only moderate speed regulation, often drifting between about minus 3% and minus 15% as load changes. By comparison, BLDC systems with Hall feedback can hold speed within roughly plus or minus 0.2â0.5%, and with encoder feedback they can reach about plus or minus 0.05%.

Because the rotor carries magnets rather than induced currents, BLDC motors are usually more efficient, particularly at low speeds where induction motors suffer additional losses. They tend to run cooler, with less heat impacting bearings and insulation, and offer higher power density, which means more power from a smaller frame.

Brushless systems shine where compact size, tight speed control, and dynamic performance matter more than raw horsepower. Oriental Motor points to highâperformance factory automation and mobile platforms such as automated guided vehicles as prime candidates. Many of those applications are naturally DCâpowered, making BLDC drivers a clean fit.

In the context of Schneider VFD replacement, BLDC can be a good alternative when a legacy Altivar is driving a small induction motor on a critical, precisionâspeed machine and space is tight. Replacing both motor and drive with a BLDC package can eliminate the need for a panelâmounted VFD, improve speed regulation, and reduce noise.

The tradeoff is economic. BLDC drivers have higher initial cost and more complex electronics. The price gap is small in lower horsepower ranges, but at higher power levels VFDs remain more costâeffective and robust. For large pumps and fans in the tens or hundreds of horsepower, AC induction motors with VFDs, Schneider or otherwise, remain the standard choice.

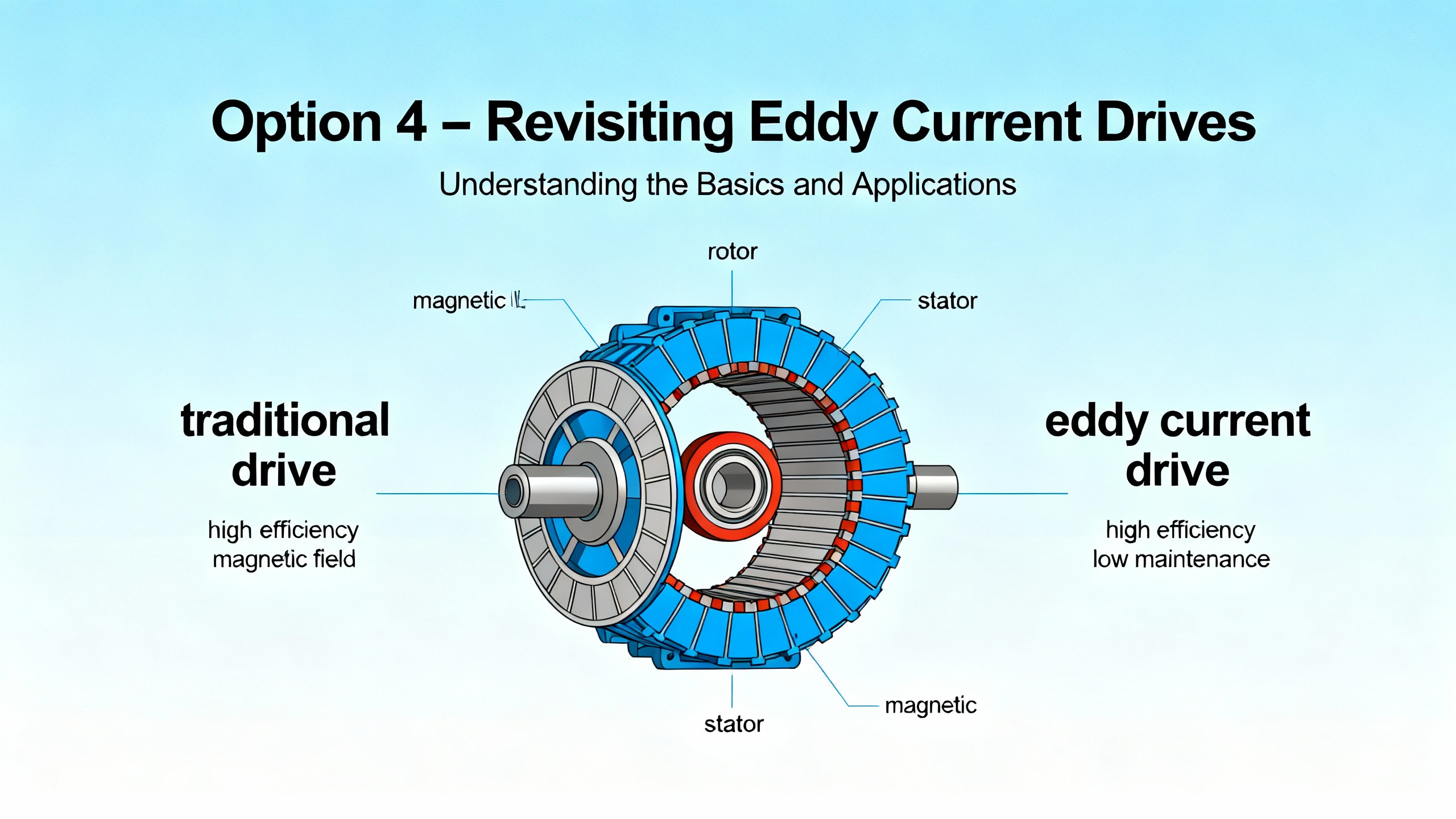

Eddy current variable speed drives are an older technology that preâdates modern power electronics but still has a place as an alternative to new VFDs, especially for large, mediumâvoltage machines.

An eddy current drive uses a constantâspeed motor to spin a magnetic rotor inside a steel drum. A DC excitation coil energizes the rotor. By increasing or decreasing this excitation, the system controls the torque transmitted across the air gap and thus the output speed.

Empowering Pumps & Equipment describes these drives as mechanically simple rotating machines made of steel castings, bearings, and windingsâcomponents that most maintenance technicians can understand and service without specialist electronics training. The technology has been in use since the 1930s and was widely applied to variableâspeed pumps and fans in the 1960s and 1970s. Many units are still in service 30 to 50 years later.

One wastewater pump installation featured a threeâstoryâhigh, 1,650 hp eddy current clutch. Scheduled maintenance, combined with an upgrade to a modern digital controller, uncovered a damaged drum and improperly rewound rotor poles. Correcting those issues avoided a catastrophic failure and cost far less than replacing the system with new motors and mediumâvoltage VFDs, which would have required millions of dollars and additional building space.

In another metropolitan wastewater plant, refurbishing a remaining 2,250 hp eddy current drive and its 12,400 V synchronous motor cost well under $200,000. The same utility had previously spent nearly $2 million to replace three similar units with new motors and VFDs. The remanufacturing work also exposed installation faults such as poorly supported bases and inadequate grouting, and fixing those shortcomings reduced vibration and extended equipment life.

These examples illustrate a key point for Schneider users: if you already have an eddy current drive on a large pump or fan, tearing it out for a brand new mediumâvoltage Schneider VFD and motor package may not be the most economical or reliable choice. Evaluating preventive maintenance, mechanical corrections, and control upgrades on the existing eddy current system should be part of any serious retrofit study.

The main strengths of eddy current drives are simplicity, ruggedness, and ease of maintenance with inâhouse skills. For largeâhorsepower, mediumâvoltage applications where a mediumâvoltage VFD would otherwise demand new electrical rooms and dedicated cooling, remanufacturing a legacy eddy current drive can be more spaceâ and costâefficient.

On the downside, eddy current systems generally cannot match the best modern VFDs in energy efficiency, especially at low speed or light load where slip losses are more pronounced. For projects driven primarily by aggressive energy targets and where space and MV infrastructure are not constraints, a new VFD and motor solution may still win. The Empowering Pumps & Equipment guidance is clear: always investigate maintenance and remanufacturing potential before committing to a wholesale VFD conversion.

For very large drives, such as boiler feed pumps, a mechanicalâelectrical hybrid approach can rival or outperform classic mediumâvoltage VFDs.

SET Solutions describes a variable speed gearbox concept called SETCON. Instead of a large mediumâvoltage VFD feeding a main motor, SETCON uses a variable speed gearbox driven partly by a downsized main motor and partly by lowâvoltage servo motors powered through standardized lowâvoltage frequency converters.

Only about 20% of the total driven power flows through the lowâvoltage converters. The rest passes mechanically through a highâefficiency planetary gear stage. In a boiler feed pump example of about 6,000 kW, roughly 8,000 hp, running around 8,500 hours per year, SETCON was estimated to save about 1,400 MWh annually compared with a mediumâvoltage VFD plus gearbox.

Efficiency numbers from the manufacturer indicate gearbox efficiencies up to about 97%, aided by the fact that the servos can operate as generators at partial load and feed some power back into the grid. Because power electronics handle only a fraction of the total power, cooling demand and electrical room space are significantly reduced.

From a maintenance standpoint, SETCONâs lowâvoltage architecture allows most routine work to be handled by inâhouse teams after basic training. The system uses standardized lowâvoltage drives and servo motors, improving spareâparts availability and reducing reliance on specialist highâvoltage technicians.

For sites considering large Schneider mediumâvoltage VFDs as replacements for aging control systems on big pumps, a variable speed gearbox solution like this is a legitimate alternative to examine.

Not every Schneider VFD should be replaced with another VFD at all. In some duties the VFD is being used almost exclusively for soft starting, and in others a mechanical adjustment may yield the same or better results.

PanelShop.com contrasts soft starters with VFDs. Soft starters are used only during startup, reducing applied voltage to limit inrush current and mechanical shock. Once the motor reaches full speed, a bypass contactor takes over, and the motor runs across the line. Soft starters are compact and inexpensive compared with VFDs.

VFDs, by contrast, control both voltage and frequency at all times. They grant fullâcycle speed control, smooth acceleration and deceleration, and the ability to match speed to process demand. That is why applications like elevators and variableâflow pumps are better served by VFDs.

If your Schneider drive is only controlling rampâup current on a motor that always runs at fixed speed, replacing it with a soft starter in the same frame size might reduce cost and complexity without sacrificing performance. Conversely, if the process genuinely needs variable speed, a soft starter is not a suitable substitute and should only be considered for nonâcritical loads where fixedâspeed operation is acceptable.

An engineering note on limitations and alternatives to VFDs provides useful cautions. A VFDâcontrolled pump, for example, cannot replace the safety and shutoff functions of a control valve at zero flow. If throttling valves are removed in favor of VFD control, designers may need auxiliary valves to handle noâflow and backâflow situations safely. Some processes, such as those requiring instantaneous response to setpoint changes, may be better served by fastâacting control valves than by variable speed alone.

The same source lists several alternatives that can complement or replace VFDs:

Sequential controllers that stage multiple parallel pumps or fans on and off according to demand. This approach lacks the fine granularity of continuous speed control but can still yield significant savings in systems with multiple units.

Mechanical speed changes such as adjusting pulley ratios or gearbox ratios. These are particularly attractive when a machine consistently runs at a lower speed than it was designed for. Payback periods of only a few months are possible when the modification cuts chronic overcapacity.

Equipment modifications such as trimming pump impellers or changing fan impellers to better match system demand.

A realâworld example from a pneumatic conveying line reinforces these ideas. A chemical engineer reported on an engineering forum that positive displacement blowers driven by 40â100 hp motors were providing too much air, causing product degradation and pipe wear. Bleeding off the excess air improved conveying but wasted energy. The blower manufacturer explicitly prohibited throttling the inlet or outlet with valves. In that scenario, the viable options boil down to reducing speed with VFDs or changing mechanical ratios, such as sheaves, on constantâflow lines, coupled with some form of variable control on lines with changing demand. The lesson is that mechanical and control strategies must be considered together rather than defaulting to VFDs in every case.

ConsultingâSpecifying Engineer traces todayâs focus on motor and drive efficiency back to federal legislation such as the Energy Policy and Conservation Act and the Energy Independence and Security Act. Those laws gave the Department of Energy authority to mandate efficiency standards, with a typical threshold that measures showing payback within about three years are strong candidates for adoption.

Motor efficiency requirements are well established in codes like the International Energy Conservation Code. VFD efficiency standards have lagged, and current codes usually frame requirements in terms of âvariable speed capabilityâ rather than mandating specific technologies. Nevertheless, Europeâs International Electrotechnical Commission has already published test standards for VFDâcontrolled motors and is moving toward efficiency classes for adjustableâspeed drive systems. IEEE and NEMA are working on harmonization, which signals that VFD system efficiency will be scrutinized more closely over time.

At the application level, the physics are compelling. ConsultingâSpecifying Engineer demonstrates that a 7.5 hp, 1,800 rpm motor running a centrifugal load at an average of 75% speed only needs about 3.16 hp on average. Plant Engineering adds the practical rule of thumb that dropping centrifugal fan or pump speed to around 80% can cut energy consumption by roughly 50%. These relationships explain why Schneiderâs Altivar 212 and other variableâtorque drives can claim energy savings up to around 70% compared with constantâspeed systems with throttling.

Power quality is the second constraint. Industrial Automation Co. recommends drives with integrated EMC filters and DC chokes, plus external line reactors where appropriate, to mitigate harmonics and voltage spikes. Schneiderâs own data for Altivar 212 shows current harmonics limited to below about 30%, which helps protect transformers and reduce nuisance trips. Where regeneration is expected, such as on highâinertia loads that brake frequently, options like brake resistors or regenerative front ends should be evaluated alongside plant powerâquality and cooling constraints.

Drive reliability is as much about the manufacturer and documentation as it is about any single spec point.

A VFD brand review notes that staying in the drive business requires robust products and effective support, which tends to weed out weaker manufacturers. At the same time, a Practical Machinist discussion warns against very cheap, noâname VFDs sold through online marketplaces under obscure or gimmicky labels. These units may have attractive prices but often lack meaningful warranty support, clear documentation, or longâterm availability. Some buyers justify the risk by viewing them as disposable, but the real cost is unplanned downtime and lost production.

On the other side, brands such as Teco win praise for clear Englishâlanguage manuals, sometimes written or adapted by local engineers, which makes commissioning more reliable. Hobbyist experiences with U.S.âmade VFDs reinforce the value of choosing one brand and sticking with it across several machines, both for familiarity with programming and the ability to cannibalize lessâcritical drives as temporary spares.

The 2024 VFD brand survey mentioned earlier places Schneider among global leaders like Siemens, ABB, Rockwell, Mitsubishi, Fuji, Delta, and fastâgrowing Chinese manufacturers such as Inovance and HARS. Many of these brands offer complete automation platforms that bundle drives, motors, gearboxes, controllers, and HMIs into coherent ecosystems. Plant Engineering highlights similar platform thinking from SEWâEURODRIVE and others, where fieldbusâcompatible drives, servos, and gear units are designed to work together seamlessly.

For Schneider users facing widespread VFD obsolescence, this raises a strategic question: is now the time to double down on Schneider as the standard, or is it the right moment to align with another ecosystem that better fits your siteâs PLCs, networks, and longâterm support arrangements? There is no one right answer, but the decision should be deliberate rather than driven by the last part number you happened to use.

In practice, the most successful Schneider VFD replacement projects follow a structured path.

First, characterize the load and process. Determine whether it is variableâtorque, constantâtorque, or positioning. Review operating profiles to understand how often the system runs at partial load and whether rapid transients or safetyâcritical stops place special demands on the drive.

Next, audit the existing motor and power system. Record nameplate data, fullâload amps, service factor, and any restrictions the OEM places on reducedâspeed operation. Check shortâcircuit levels, grounding, and existing harmonic mitigation. For mediumâvoltage systems, involve specialists early to assess transformer and switchgear implications.

Then, choose the technology path. Decide whether a modern Schneider Altivar, a crossâbrand VFD, a BLDC motor system, an eddy current drive refurbishment, a variable speed gearbox, or a soft starter plus mechanical modification best aligns with the process, energy targets, and capital constraints. Use vendor data and case studies, such as SETCONâs boiler feed pump example or Dynamaticâs wastewater drive refurbishments, to quantify potential savings and risks.

After that, engineer power quality, safety, and integration details. Select drives with appropriate EMC filters, DC chokes, and braking or regenerative options. Confirm safety functions and whether they will be handled in the drive, the PLC, or both. Align protocols with plant standards, following recommendations from Plant Engineering and Industrial Automation Co. to use widely supported standards like EtherNet/IP, Modbus, or OPC UA, and to verify fieldbus mappings and diagnostics ahead of time.

Finally, plan commissioning and ongoing monitoring. Back up parameters from the existing Schneider drive where possible. Document motor tuning constants. Take advantage of modern diagnostics, web servers, and IIoT features that many new drives offer. SHCKELE and Plant Engineering both emphasize using drive dataâtemperatures, vibration, operating hoursâfor predictive maintenance and continuous improvement. Training operators and technicians to interpret this data is an essential part of realizing the full benefit of any replacement.

Not necessarily. Energy savings come primarily from running the driven equipment closer to its true demand profile, not from the incremental efficiency of the drive electronics themselves. A motor engineering analysis points out that adding a VFD to a lightly loaded motor that always runs at full speed can actually increase total losses because of the driveâs own inefficiency. Meaningful savings appear when speed is reducedâparticularly for centrifugal pumps and fans where power drops significantly with speedâas highlighted by ConsultingâSpecifying Engineer, Plant Engineering, and Schneiderâs own Altivar 212 data.

Eddy current drives and variable speed gearboxes such as SETCON become attractive on very large, mediumâvoltage machines where installing a mediumâvoltage VFD would require major infrastructure additions and ongoing dependence on specialist highâvoltage service. Empowering Pumps & Equipment documents cases where refurbishing existing eddy current drives, combined with mechanical corrections and control upgrades, cost a fraction of full MVâVFD conversions. SET Solutions shows that variable speed gearboxes using lowâvoltage drives for only a portion of the power can achieve high overall efficiency while reusing existing motors and simplifying cooling and maintenance.

No. Technical guidance on VFD limitations makes it clear that a VFDâcontrolled pump cannot perform the shutoff and backâflow prevention roles of a proper control valve at noâflow conditions. In processes requiring rapid, precise changes in flow, a highâperformance control valve may still be needed even when a VFD is present. Designers should treat variable speed and throttling devices as complementary tools and ensure that safety and process integrity are maintained under all operating states.

Schneider Electric VFD replacements are rarely a simple catalog exercise. The most reliable and efficient solutions come from stepping back, understanding the load and system, and then choosing among modern Schneider Altivar drives, crossâbrand VFDs, brushless packages, eddy current drive refurbishments, variable speed gearboxes, and in some cases soft starters and mechanical modifications. When you treat the drive as part of a complete motor system, not just a component, you can turn an endâofâlife Schneider VFD into an opportunity to improve resilience, cut energy waste, and simplify future maintenance.

Leave Your Comment