-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Reliable power is no longer just a facilities problem. In industrial plants, data centers, hospitals, and commercial buildings, unplanned outages now directly hit revenue, safety, and reputation. Schneider Electric PLC platforms sit in the middle of that risk: they orchestrate UPS systems, inverters, switchgear, and power protection equipment. When those controllers or their compatible modules are aging, misconfigured, or poorly integrated, the entire power chain becomes fragile.

From the field, I see the same pattern repeatedly. Legacy PLCs run critical UPS and inverter sequences, operators are nervous about touching them, and integration with modern SCADA or energy analytics is an afterthought. Schneider ElectricŌĆÖs own modernization work has shown that aging PLCs drive unplanned shutdowns, higher maintenance costs, and safety risk, while upgrades to modern PLCs and Ethernet-enabled process automation controllers sharply reduce downtime and improve profitability. The good news is that SchneiderŌĆÖs ecosystem of PLC-compatible modules, modernization kits, and integration tools makes it possible to modernize without tearing out everything you already own.

This guide walks through how to think about Schneider PLC-compatible modules in a power environment, how to integrate them cleanly, and how to approach upgrades with minimal risk.

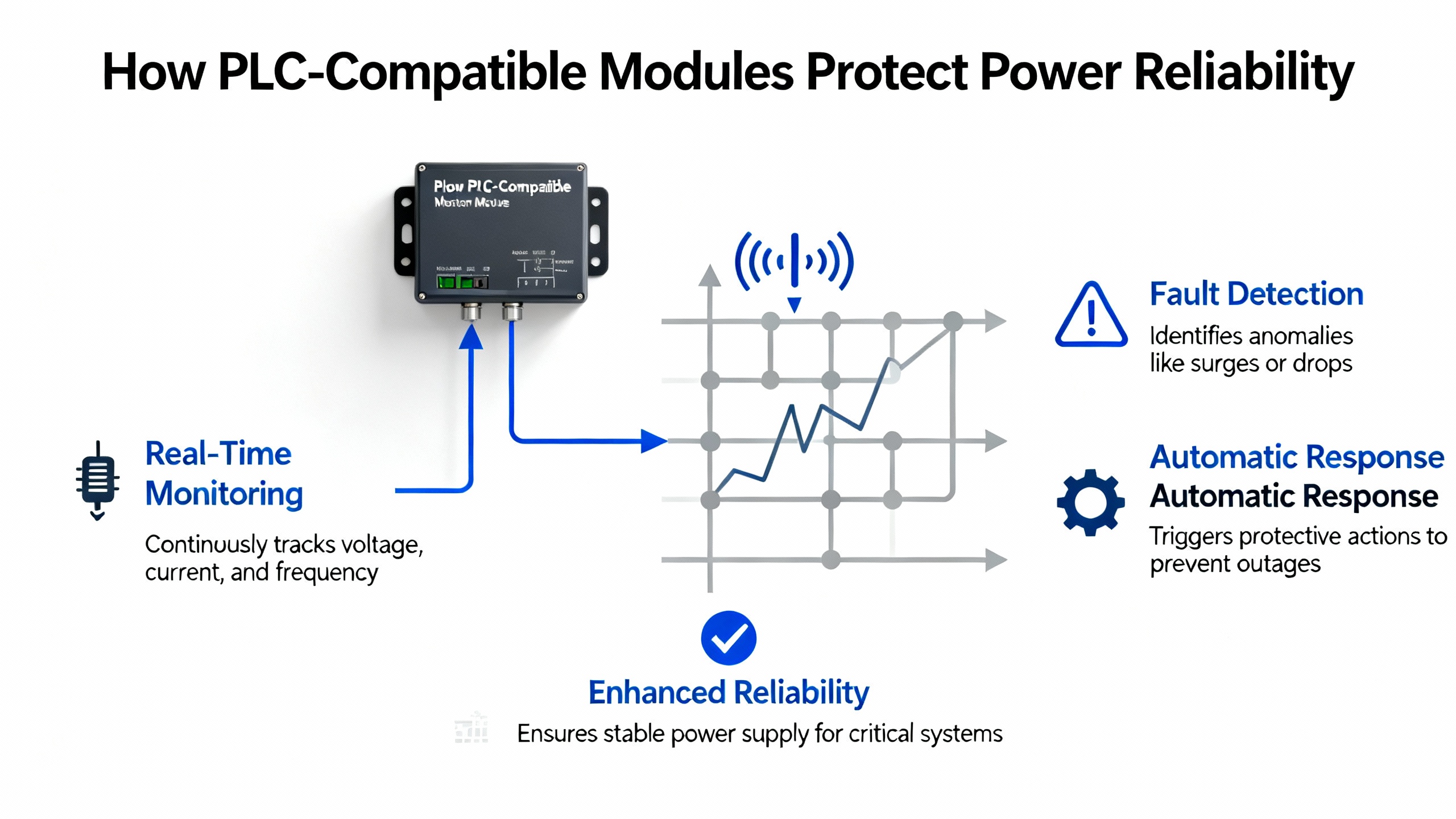

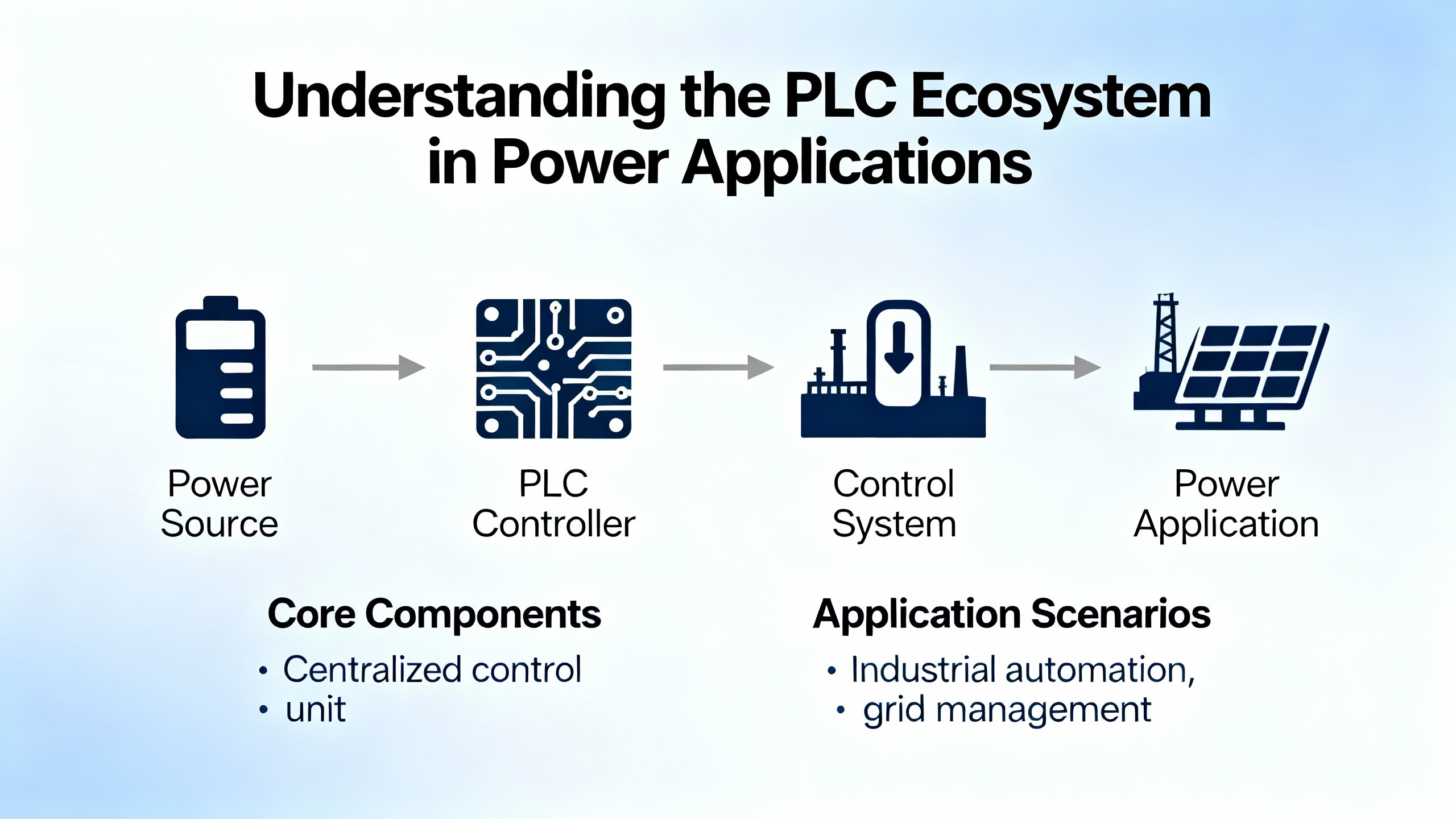

A programmable logic controller is a hardened industrial computer that reads inputs, executes control logic, and drives outputs in real time. In power systems, those inputs may be breaker positions, bus voltages, UPS status contacts, temperature sensors, or energy meters. Outputs might be breaker close commands, transfer switch signals, start commands to generator sets, or control words to inverters.

Schneider Electric is a global automation supplier, and its PLCs, HMIs, drives, and SCADA platforms are widely used to optimize operations and reduce cost. When you deploy Schneider PLCs with compatible modules in a power room, you are essentially assembling a modular control system that should meet three goals at once: availability of power, safety of personnel and equipment, and maintainability of the control solution over its lifetime.

Modern PLC and ePAC platforms add capabilities far beyond simple on/off control. Schneider Electric has documented how upgrades to newer platforms deliver faster processing, reduced cycle times, higher output, and improved cybersecurity, particularly where cloud connectivity and advanced data processing are involved. In the power context, that translates to tighter protection and interlocking logic, better disturbance analysis, and the ability to link switching decisions to real-time profitability or energy efficiency metrics.

If you treat PLC-compatible modules as just interchangeable boxes on a rail, you will miss these system-level benefits. The rest of this article frames them as building blocks in a deliberate architecture rather than isolated components.

Schneider ElectricŌĆÖs portfolio spans from compact controllers for simple automation to advanced platforms meant for complex process and power systems.

At the entry-to-mid range, families such as Zelio and Modicon M100 and M200 support modest I/O counts and basic networking, suited to local equipment like individual UPS panels or small generator controllers. The M100 line, for example, scales up to roughly a few dozen I/O points and includes serial Modbus and USB connectivity for straightforward integration. M200 can expand to well over a hundred I/O points with Ethernet plus serial interfaces and basic motion capability, making it suitable where you need more discrete and analog points across a power distribution board.

Stepping up, controllers like M221, M241, and M251 bring higher I/O densities and richer communications. M251 in particular is designed with high I/O and both wired Ethernet and wireless options to connect into manufacturing execution or business systems. In a power distribution setting, it can act as a central controller coordinating different switchboards or backup systems while remaining connected upstream to energy management tools.

For process-style and large power systems, Modicon M340 and M580 become more relevant. M340 is a modular PLC capable of handling up to roughly a thousand discrete and a few hundred analog points, with strong motion and process control plus a built-in web server. M580 is SchneiderŌĆÖs Ethernet-enabled process automation controller, used heavily in modernization projects because it combines high performance, native Ethernet, and strong cybersecurity features. Schneider Electric has described how standardized modernization kits based on M580 allowed a thermal power plant to replace obsolete controls, integrate DCS and PLC functions, and achieve a cyber-secure, future-ready platform.

Across this range, compatible modules include CPU modules, I/O modules for digital and analog signals, safety CPUs, communication adapters, gateways, and software tools. The key to a successful integration or upgrade is to treat these modules as parts of an overall architecture rather than catalog items selected in isolation.

When you bolt new PLC-compatible modules into a power system, the physical wiring is rarely the hard part. The real complexity lies in how data flows between UPS controllers, inverters, meters, PLCs, HMIs, and supervisory systems. Schneider Electric and partners such as Balaji Switchgears describe several integration patterns that show up again and again.

Point-to-point integration is the simplest pattern: one device talking directly to one other device. A typical example in a power room is a Schneider PLC communicating with a legacy UPS controller over Modbus or a dedicated Ethernet link just to exchange status, alarms, and a few commands. The advantage is simplicity; there is usually less risk of unexpected interactions, and troubleshooting is straightforward because only two nodes are involved.

The downside is scaling. If you later want to add energy monitoring, dispatch control, or a second PLC, you can find yourself multiplying links and custom data mappings. For one or two critical paths, point-to-point is fine. For a large UPS farm or a complex inverter array, it can become fragile and expensive to maintain.

Vertical integration connects layers in a stack: devices and sensors at the bottom, PLCs in the middle, and HMIs or SCADA at the top. Schneider Electric often illustrates a path from Modicon PLCs up through HMIs to SCADA and then into higher-level platforms such as EcoStruxure for analytics, predictive maintenance, or cybersecurity services.

In a power system, a vertical stack might start with breakers and meters feeding a Modicon M580 controller. That controller then feeds a local HMI for switching operations and a SCADA system for alarms, trending, and remote operations. Above that, a data center infrastructure or energy management suite may consume the SCADA data for reporting and optimization.

Vertical integration is attractive when you want clean separation of concerns: protection and interlocks close to the equipment, operations at the HMI layer, and analytics at the top. However, it requires careful definition of interface points and responsibilities to avoid duplicated logic or conflicting control authority.

Star integration extends point-to-point by allowing each subsystem to connect to several others. In a star-shaped power control system, each Schneider PLC might connect directly to multiple peers and a central SCADA server. For example, several PLCs controlling different switchboards and UPS groups could exchange status among themselves for load shedding logic, while all report independently to SCADA.

This architecture can provide high flexibility and direct communication where needed, but as the number of connections grows, the system becomes harder to reason about. The more one-off links you create, the more you depend on tribal knowledge rather than documented architecture. From a reliability perspective, star integration should be used selectively and documented thoroughly.

Horizontal integration uses a hub to connect many systems. In many plants, SCADA platforms or data historians play this role. Schneider Electric highlights architectures where PLCs, sensors, and even cameras all talk to a central hub rather than to each other directly. Other integrations rely on neutral data formats such as XML or JSON so that different systems can translate their native data into a common format.

For power systems, a hub architecture simplifies the introduction of new modules. When you add a new gateway, I/O rack, or optimization service, you only integrate it once to the hub, not to every existing device. SchneiderŌĆÖs own guidance for data center integration projects emphasizes defining connectors and supported formats early, identifying required ports, and validating that systems can exchange data cleanly before writing any business logic.

Common data formats also make it easier to tie OT data to IT systems, for example feeding PLC energy data to business intelligence tools. That said, neutral formats alone do not guarantee data quality. You must still define unit conversions, normalization rules, and validation policies so that kW, kVA, and alarm states mean the same thing everywhere.

In successful projects, module selection and wiring happen surprisingly late. Schneider ElectricŌĆÖs integration and data center teams repeatedly stress that the first steps are about clarity, not hardware.

You begin by defining what you want to achieve. In a power environment, that might be reducing unplanned transfer to backup, shortening recovery after faults, improving visibility of UPS loading, or enabling automated energy management. These goals should be documented along with non-functional requirements such as allowed downtime, cybersecurity expectations, and needed reporting retention.

Next comes understanding what is already in place. SchneiderŌĆÖs guidance on PLC migration calls out the need for a thorough site assessment. In practice, that means mapping out existing control panels, PLC types and firmware levels, communication networks, data flows, and known pain points. Involving operations and maintenance personnel is crucial; their day-to-day experience often reveals workarounds and failure modes that never make it into schematics.

Connectivity planning is the next foundation block. Schneider ElectricŌĆÖs data integration experts recommend identifying required network routes and firewall openings early, checking for available APIs or protocol connectors, and validating that protocols such as Modbus TCP or OPC can be supported end to end. Weaknesses here turn into late-stage surprises when a new module cannot talk to a legacy BMS or when a firewall silently drops SCADA polling traffic.

Data quality and validation policies should be defined before you write a single line of PLC logic. That includes deciding how energy values are scaled, how you detect sensor failures, how you handle missing or stale data from a UPS, and what conditions trigger alarms versus trends. SchneiderŌĆÖs own data integration work underscores that these rules affect not just engineering accuracy but system performance and maintainability.

Finally, you benefit from planning how you will test. Providing a realistic test system and sample data to developers shortens development, reduces risk, and prevents rework. In PLC projects, this can mean building a lab rack with a representative PLC and I/O modules, using simulation features in Schneider software, and planning how to stage the cutover so you can validate logic before it controls real breakers.

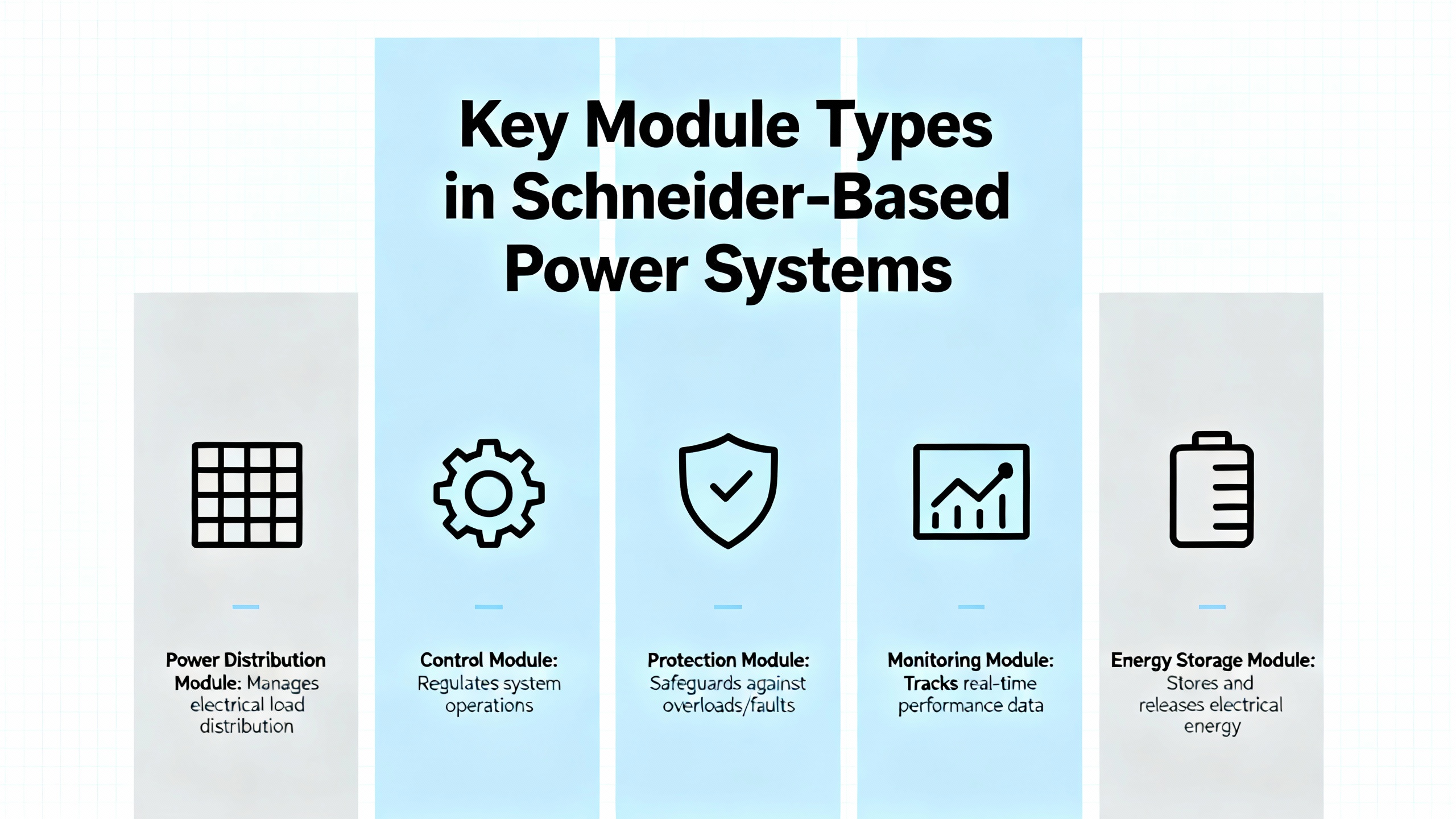

SchneiderŌĆÖs ecosystem is broad, but most power-focused architectures revolve around a few major module categories. Seeing how they fit together helps you pick the right upgrades and integration points.

| Module category | Typical Schneider elements in the notes | Primary role in power systems |

|---|---|---|

| Controller and CPU modules | Modicon M100, M200, M221, M241, M251, M262, M340, M580 | Execute power control logic, sequencing, interlocks, and communication |

| Safety and redundancy modules | Modicon M580 Safety CPU, M580 Safe Hot-Standby | Maintain safe operation and high availability for critical power processes |

| I/O and energy monitoring modules | PLC-embedded energy monitoring using analog, fieldbus, Ethernet meters | Connect breakers, UPS, inverters, and meters to the PLC, calculate energy and power KPI values |

| Communication and gateway modules | Integration gateways, OPC interfaces, Modbus TCP, other fieldbuses | Bridge between PLCs, building automation systems, and external tools |

| HMI and SCADA integration | EcoStruxure HMIs, SCADA, PLCŌĆōHMI integration guidelines | Provide visualization, alarms, and operator control of power systems |

| Analytics and optimization layers | AI-based self-optimization and dynamic setpoints, historian analytics | Optimize efficiency, reduce energy cost, and tune control parameters in real time |

Controller modules are the brains of the system. In the Schneider world, Modicon PLCs and ePACs take this role. Mid-range controllers such as M100 and M200 provide enough I/O and networking for smaller switchboards or UPS systems. Advanced controllers like M251 allow high I/O counts and connectivity into business systems, providing a bridge between the electrical room and enterprise applications.

For larger power systems or plants, modular controllers like M340 and M580 matter. Schneider Electric documents how modern ePACs with real-time analytics can track variables such as vibration, temperature, pressure, and flow, linking them to financial indicators. While their example comes from mining and water treatment, the same pattern applies to power: you can monitor real-time profitability of power trains, calculate cost per unit of energy delivered or per ton of product, and justifiably prioritize modernization where it delivers the most financial impact.

When planning upgrades, it is common to preserve field wiring and replace legacy CPUs with M580-based modernization solutions that plug into existing racks using adaptors. Schneider reports a forest industry project where upgrading forty-five aging PLC systems and networks removed frequent PLC-caused outages that previously cost tens of thousands of dollars per hour, delivering a payback around a year and a half. For power reliability, similar economics often hold, even if the absolute numbers differ.

Critical power systems must both fail safe and remain available. SchneiderŌĆÖs Modicon M580 Safety CPU is built around a redundant processor architecture. In safety engineering, redundancy does not mean something unnecessary; it means an additional channel that ensures a safe outcome if one channel fails. If the secondary processor fails, the primary must still be able to bring the system to or keep it in a defined safe state, such as opening breakers to isolate a fault.

By contrast, standard hot-standby redundancy in control systems such as Modicon M580 Hot Standby has a different focus: if one CPU fails, another one takes over seamlessly so the process continues without interruption. This improves availability rather than safety integrity. To achieve both high safety integrity and high availability in a power system, SchneiderŌĆÖs experts recommend architectures such as M580 Safe Hot-Standby, which combine safety redundancy with bumpless process failover.

When planning module upgrades in a power protection environment, you need to decide what safety integrity level is required and whether the cost and complexity of safety CPUs and hot-standby pairs is justified. SchneiderŌĆÖs safety specialists also point out that simplified single-CPU safety options at lower integrity levels could be feasible technically, but not all such options exist in every product range. That is one more reason to align your risk analysis with the actual product catalog and not rely on assumptions.

Input and output modules connect field devices to the PLC. SchneiderŌĆÖs PLC-Easy concept for energy monitoring and management shows how much can be done when you treat energy as a native variable inside the PLC/SCADA application rather than a separate IT system.

In a PLC-Easy style architecture, existing instruments wired to the PLC, whether through analog signals, fieldbus devices, or Ethernet-connected meters, are used to calculate and display energy consumption. Energy values can be shown per control module, per equipment module, and up through units and process areas. For a UPS system, that might translate into per-feeder, per-UPS, and per-bus energy and demand views on the SCADA.

The benefit is twofold. Operators see both an overview of total energy use and a breakdown by area or device, which improves their ability to make informed decisions. At the same time, energy control schemes can be implemented within the PLC logic without introducing a separate stack of servers, databases, and integration points. This avoids many of the IT/OT convergence challenges and cybersecurity concerns that arise when energy monitoring is bolted on as a separate system.

When you select I/O and energy monitoring modules, the focus should be on input types, accuracy requirements, and integration. Schneider ElectricŌĆÖs PLC software tools allow you to configure module types, physical addresses, signal scaling, and communication parameters. Misconfiguration at this layer can create dangerous situations, because the PLC will interpret incorrect values or drive the wrong output points. That is why configuration should be treated with the same rigor as protection settings in relays.

In any mixed-vendor power system, communication modules and gateways determine whether your Schneider PLCs can coexist peacefully with other devices. SchneiderŌĆÖs integration guides for building automation systems highlight the use of protocols such as Modbus, as well as OPC interfaces and dedicated integration gateways. Those concepts transfer cleanly to power systems.

Gateways can translate between proprietary protocols on UPS controllers and standard protocols on PLCs, or they can unify data from Schneider building automation platforms with power control PLCs. SchneiderŌĆÖs Integration Methods guide emphasizes that gateways and OPC layers are central to linking heterogeneous systems, and that each major platform, whether Andover Continuum, TAC Vista, or TAC I/Net, has its own set of supported protocols and gateway options.

In practice, when introducing new PLC-compatible communication modules, you should verify that each link in the chain supports the same protocol version and options, check that required ports are open in firewalls, and confirm that any common data format agreements are documented. SchneiderŌĆÖs data center integration team stresses the importance of defining logging and audit requirements at design time, so that you can prove later which modules exchanged what data, and when.

HumanŌĆōmachine interfaces and SCADA platforms are not usually thought of as modules, but in Schneider architectures they function as closely coupled companions to PLCs. EcoStruxure HMIs and SCADA systems rely on PLC tags for visualization and control. Effective integration allows operators to see breaker positions, UPS status, and alarms in real time, issue control commands, and review historical trends.

Schneider Electric and independent experts show that good program structure on the PLC side helps HMI integration. They recommend separating input processing, main control logic, output handling, and error management, then exposing a clean set of tags to the HMI for visualization and override control. In material handling examples, this has been used to orchestrate multiple sensors and actuators through EcoStruxure Machine Expert. The same principles apply in power systems for tasks such as route selection, load transfer, and alarm acknowledgement.

Alarm management and historical logging depend heavily on how PLC events are mapped to HMI and SCADA objects. Careful design here reduces nuisance alarms and ensures that real problems stand out. As power systems grow more complex and interconnected, the HMI and SCADA layer also becomes a frontline for cybersecurity, with access controls and authentication required to protect PLCs from unauthorized commands.

Finally, there is a growing category of modules that are not physical at all: analytics and optimization layers built on top of PLC data. Schneider Electric notes that modern PLC platforms, combined with cloud-based historians, allow real-time accounting and advanced analytics. Plants can compute cost per unit of production, benchmark similar lines, and calculate profitability indices that justify modernization investments.

Third-party solutions such as Oxmaint go further by integrating AI with Schneider PLC data. In such architectures, an AI module continuously adjusts PLC control parameters based on live operational data. It may manage dynamic setpoints for loads, adjust control loop tuning, or modify energy management strategies to reduce waste and handle varying conditions. The AI layer focuses on keeping the process near optimal operating points rather than relying on fixed settings chosen during commissioning.

From a reliability advisorŌĆÖs point of view, these layers should be introduced carefully. They can deliver significant efficiency and profitability gains, but they add new dependencies and failure modes. The right approach is to treat them as modular additions that can be isolated or bypassed if needed, with clear roles and responsibilities defined between PLC logic and optimization algorithms.

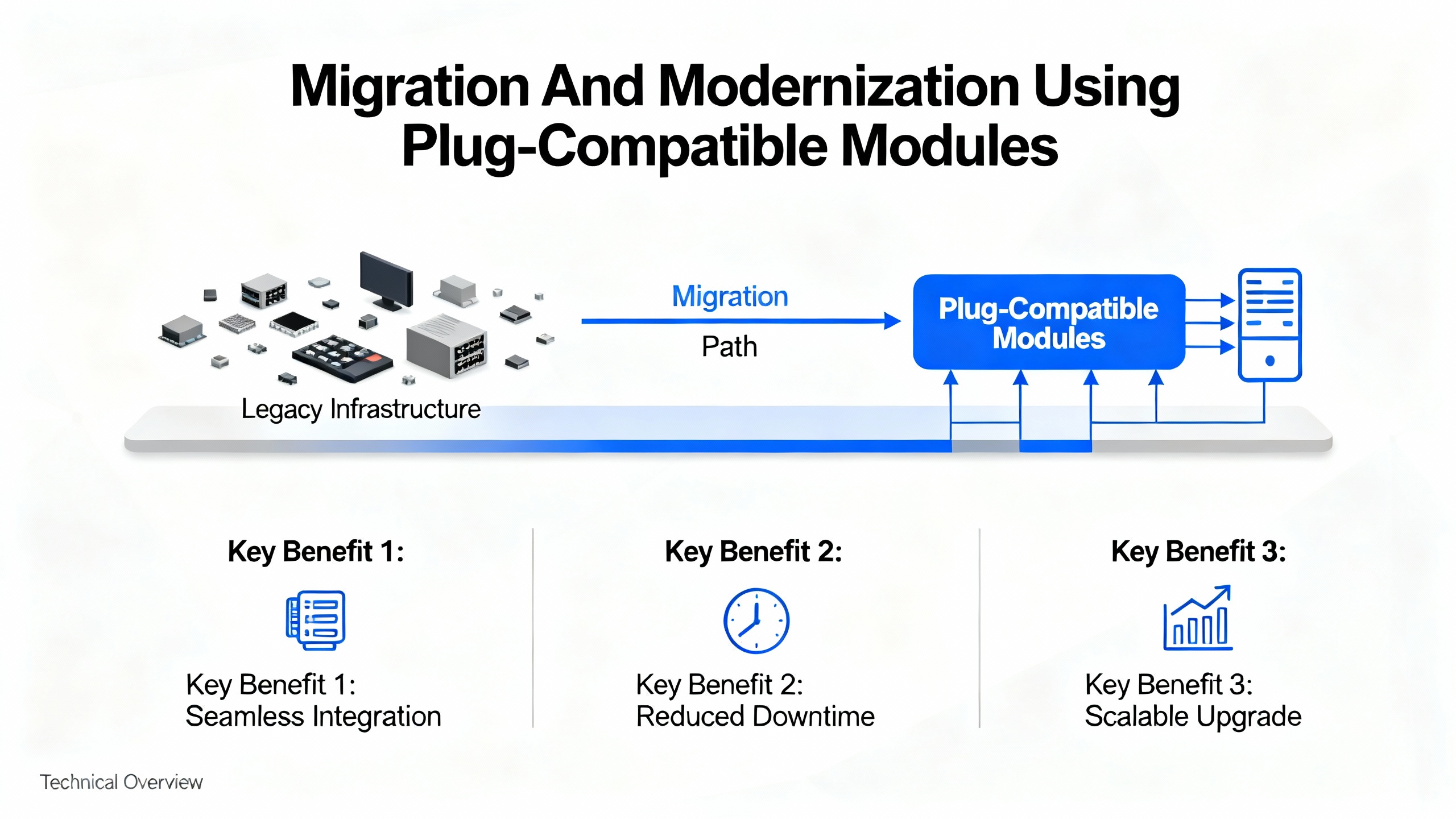

Migrating from legacy PLCs controlling critical power systems to modern Schneider platforms is a high-stakes project. Schneider ElectricŌĆÖs own experts describe PLC migration as complex but manageable, provided that you follow a structured approach.

A thorough site assessment is the first success factor. In practice, that means inventorying all PLCs and modules, documenting what each one controls, identifying obsolete components, and listing known operational issues. Schneider recommends that this assessment produce a detailed report to help maintenance managers prioritize projects and build realistic budgets. Involving maintenance and operations personnel is essential, as they bring an understanding of day-to-day workarounds and hidden failure modes.

The second factor is the use of appropriate tools and hardware. Schneider Electric offers software tools to convert PLC code from older platforms to newer ones, reducing technical risk and preserving proven logic where it still makes sense. Plug-and-play wiring adapters can map old I/O terminations to new I/O modules without rewiring hundreds of field cables. This approach preserves signal integrity, cuts cutover time, and reduces the probability of wiring errors, which can be particularly dangerous in power applications.

The third factor is building the right migration team. SchneiderŌĆÖs migration specialists emphasize that successful projects blend technology expertise with deep understanding of the process. In power systems, that means having people on site who know both the legacy PLC platform and the new one, as well as the power system behavior those PLCs are controlling. Experienced implementers can decide when legacy code should be preserved, when it should be adapted to new capabilities, and how to recover quickly from unexpected issues during cutover.

Modernization is not just a technical exercise; it is an economic decision. Schneider ElectricŌĆÖs PLC modernization case studies show that many customers initially struggle to justify upgrades because they focus narrowly on avoiding rare catastrophic failures. Once you quantify continuous benefits such as reduced downtime, higher production or availability, lower energy use, and better asset utilization, the business case often becomes compelling. In one reported project, upgrading dozens of PLC systems eliminated frequent outages and produced a payback of roughly a year and a half. For critical power systems, where outage costs can be extremely high, similar economics are common.

Translating all of this into a practical workflow, consider a facility with multiple UPS systems, inverters, and power distribution boards that already uses Schneider PLCs but needs better reliability and visibility.

You might start by clarifying objectives: for instance, reduce nuisance transfers to generator power, improve situational awareness for operators, and capture energy data by feeder and UPS to support energy management programs. With that agreed, you would perform a structured site assessment, cataloging existing PLCs, compatible modules, communication networks, and known nuisance issues. This is where you identify obsolete controllers, unsupported I/O modules, and any single points of failure in existing safety and redundancy schemes.

Armed with this understanding, you move into architecture and hardware selection. Using tools such as SchneiderŌĆÖs Modicon PLC Configurator, you can select candidate PLC and I/O configurations, compare options like M262 for IoT-ready applications versus M580 for high-availability and safety-oriented solutions, and generate a bill of materials. The configuratorŌĆÖs graphical editor helps you visualize islands of control, define which modules sit in each location, and add accessories such as communication cables and memory cards.

On the software side, development environments like EcoStruxure Machine Expert and EcoStruxure Control Expert support multiple IEC 61131-3 languages and provide a unified workflow for configuration, programming, and debugging. Best practice in Schneider environments is to structure programs into reusable function blocks with clearly defined inputs and outputs, to use global variable lists for hardware-independent tags, and to leverage timers, counters, and structured text for complex sequences.

Before touching live equipment, simulation is your friend. SchneiderŌĆÖs PLC tools offer emulation modes where you can run control logic against simulated inputs, step through code, and examine variables. Independent training providers demonstrate motor-control examples built this way; in power projects the principle is the same, even if the stakes are higher. You validate that transfer sequences, interlocks, and alarm logic behave correctly in simulation before you apply them in the field.

Finally, you plan and execute the cutover. Modernization kits and plug-compatible modules allow you to swap controllers while preserving field wiring and much of the existing architecture. A well-planned cutover uses staged testing: first powering up the new hardware, then validating I/O mappings, then running dry tests, and only then energizing the system under careful monitoring. After commissioning, ongoing monitoring through SCADA and analytics helps you refine settings, detect emerging issues early, and quantify the reliability improvements that the upgrade delivered.

In real projects, the difference between a smooth integration and a painful one often comes down to avoidable mistakes rather than exotic technical issues.

One frequent pitfall is weak data compatibility planning. Teams bolt on new modules or gateways without a clear mapping strategy, leading to inconsistent units, misinterpreted status bits, or unreliable timestamps. SchneiderŌĆÖs data integration guidance stresses the need for defined normalization rules, unit conversions, and validation checks. In a power system, you should be explicit about how you represent breaker states, UPS modes, power flows, and alarm severities across all systems.

Another common issue is underestimating communication configuration. Schneider ElectricŌĆÖs PLC software documentation makes clear that misconfigured protocols can directly cause process failures. In electrical systems, a misconfigured Modbus TCP link can leave SCADA blind to a critical bus, or a wrong IP setting can isolate a safety PLC from its peer. Network and firewall checks should be part of the early design stages, not an afterthought.

Overlooking code quality is another risk. SchneiderŌĆÖs EcoStruxure Control Engineering team has published PLC coding guidelines and a verification tool that automatically checks compliance. Applying these guidelines in power projects improves readability and maintainability of control programs, which in turn simplifies troubleshooting and reduces downtime. Skipping such standards can leave you with fragile logic that only its original author understands.

Some teams also neglect workforce development. A broad review of electrical industrial automation highlights the need for skilled engineers and technicians who understand PLC programming, networking, cybersecurity, and increasingly AI and IoT technologies. When you introduce new PLC-compatible modules, you should plan how operators, technicians, and engineers will be trained to maintain and evolve the system.

Finally, there is the temptation to add optimization layers prematurely. AI-based self-optimization and dynamic setpoints, such as those offered by certain Schneider-integrated solutions, can deliver impressive efficiency improvements. However, if the underlying PLC logic, data quality, and communication infrastructure are not robust, these layers can amplify instability rather than reduce it. A disciplined approach is to first stabilize and modernize the core PLC modules and integration, then layer on optimization in a controlled manner.

In this context, a PLC-compatible module is any hardware or tightly coupled software component designed to work within a Schneider PLC ecosystem. That includes CPU modules such as Modicon M340 and M580, safety CPUs, I/O racks and cards, communication adapters, integration gateways, and certain analytics or optimization layers that interface directly with Schneider controllers. Compatibility is not just mechanical; it also means that configuration tools and integration patterns support consistent, reliable operation.

You should consider modernization when you see frequent PLC-related outages, difficulty sourcing spare parts, lack of vendor support, or an inability to meet new cybersecurity or data integration requirements. Schneider ElectricŌĆÖs modernization case studies show that avoiding these issues often yields strong financial returns, especially in environments where downtime is expensive. A formal site assessment is the right first step to quantify the risk and build a business case.

Safety CPUs and redundant controller pairs allow your system to both fail safe and remain available. Safety modules such as Modicon M580 Safety CPUs focus on ensuring that faults lead to or maintain a safe state, while hot-standby redundancy focuses on seamless continuation of control in the event of a failure. Architectures such as M580 Safe Hot-Standby combine both, which is particularly important in critical power systems where you cannot easily shut down but must still protect people and equipment.

AI-based optimization that tunes setpoints and control parameters in real time can unlock additional efficiency and responsiveness, especially in large or variable-load power systems. However, it is not a substitute for robust PLC design. As a reliability advisor, I recommend first establishing a modern, well-integrated PLC foundation with high-quality data, then selectively applying AI modules where they can deliver clear value without undermining stability or safety.

As power systems grow more complex and business expectations rise, Schneider Electric PLC-compatible modules offer a path to higher reliability, better visibility, and smarter operation. The facilities that succeed are the ones that treat integration and modernization as deliberate engineering efforts, grounded in sound assessment, disciplined design, and a clear link to operational and financial outcomes.

Leave Your Comment