-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

An ABB breaker that keeps tripping in an industrial or commercial power system is more than an annoyance. In a critical environment feeding UPS systems, inverters, and sensitive loads, each trip is a protection event, a data point about how your system is actually behaving under stress. Data from industry sources such as BreakerHunters highlight that electrical failures contribute to tens of thousands of building fires every year in the United States, and breakers that fail to operate correctly are often part of the story. When an ABB breaker trips, especially on a critical bus, the goal is not to ŌĆ£defeat the nuisance,ŌĆØ but to understand exactly what hazard it is trying to protect you from and then correct that root cause.

As a power system specialist, I treat every repeated trip as a reliability investigation. The physics behind ABB molded-case, miniature, or air circuit breakers is the same as in residential breakers, and the causes of tripping are the same: overloads, short circuits, ground faults, arc faults, and sometimes a bad breaker. The stakes, however, are higher when those devices sit upstream of UPS input rectifiers, inverter outputs, or power distribution units feeding process control, data centers, or critical life-safety loads.

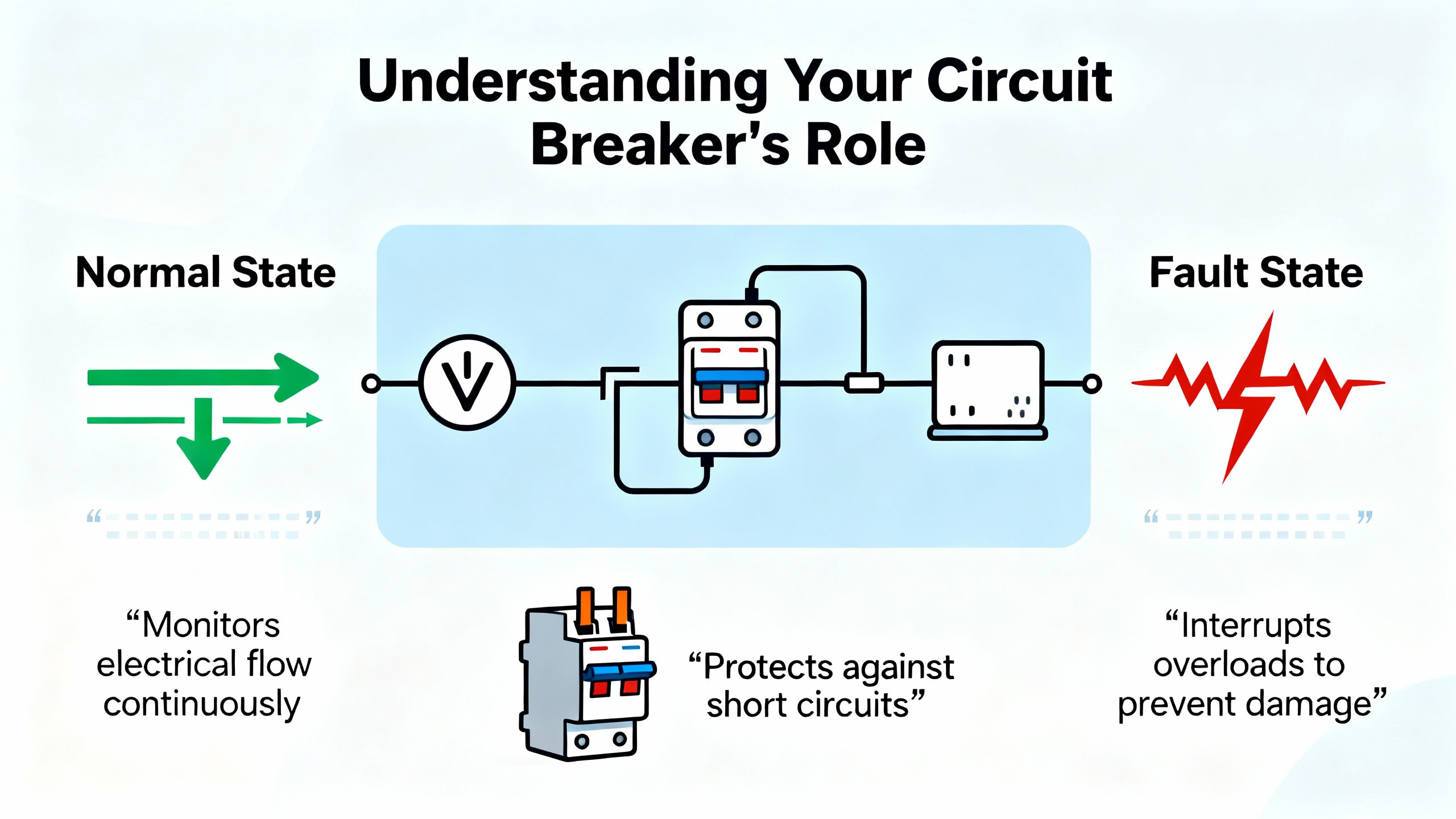

In simple terms, a circuit breaker is a resettable safety switch. Technical references such as Tameson and BreakerHunters describe it as a device that protects electrical systems from abnormal conditions like overcurrent, short circuits, and faults. Inside the ABB breaker you have three key elements: a trip unit that senses fault conditions, a mechanical mechanism that forces the contacts open, and an arc-quenching system that safely extinguishes the electrical arc when current is interrupted. Once the fault clears and the breaker is reset, power can be restored.

When the breaker trips, it is doing its job. A breaker that does not trip during a serious fault is far more dangerous than one that ŌĆ£seems too sensitive.ŌĆØ Many commercial articles, from Electricians Service Team to Exquisite Electric, emphasize this point: the breaker is not the enemy, it is the messenger.

In critical power systems, ABB breakers often protect feeders to UPS inputs, to inverter outputs, to static transfer switches, or to key distribution panels. A trip at any of these points can drop your critical bus. That makes it tempting to blame the breaker itself. In practice, most recurring trips trace to issues in loads, wiring, or settings, not a defective ABB mechanism.

Every authoritative source in the research notes, including BreakerHunters, Rella Electric, and utility guidance from Edison, stresses safety before troubleshooting. In industrial and commercial switchboards, the available fault current and arc energy can be many times higher than in a home. That changes the risk profile dramatically.

Before anyone opens a panel or switchboard, the work should follow OSHA and NFPA 70E style practices: proper PPE, clear procedures, and only qualified personnel working on or near exposed live conductors. That means insulated gloves rated for the system voltage, safety glasses, and arc-rated clothing matched to the available incident energy. The Lockout/Tagout concept highlighted in industrial guidance is essential when you de-energize upstream disconnects to test or replace a breaker.

Several sources recommend a basic division of labor. Facility staff who are not electrically qualified can safely do visual checks from the outside and operate breaker handles with the panel closed. Only licensed electricians or trained in-house technicians should remove covers, perform live testing, or disturb terminations. Mistakes inside a live ABB breaker compartment can be fatal; the risk is simply not worth casual ŌĆ£DIYŌĆØ inside a commercial panel.

Even though many of the articles summarized in the research focus on homes, the underlying trip causes are the same in industrial systems. Understanding those causes is the foundation of ABB breaker troubleshooting.

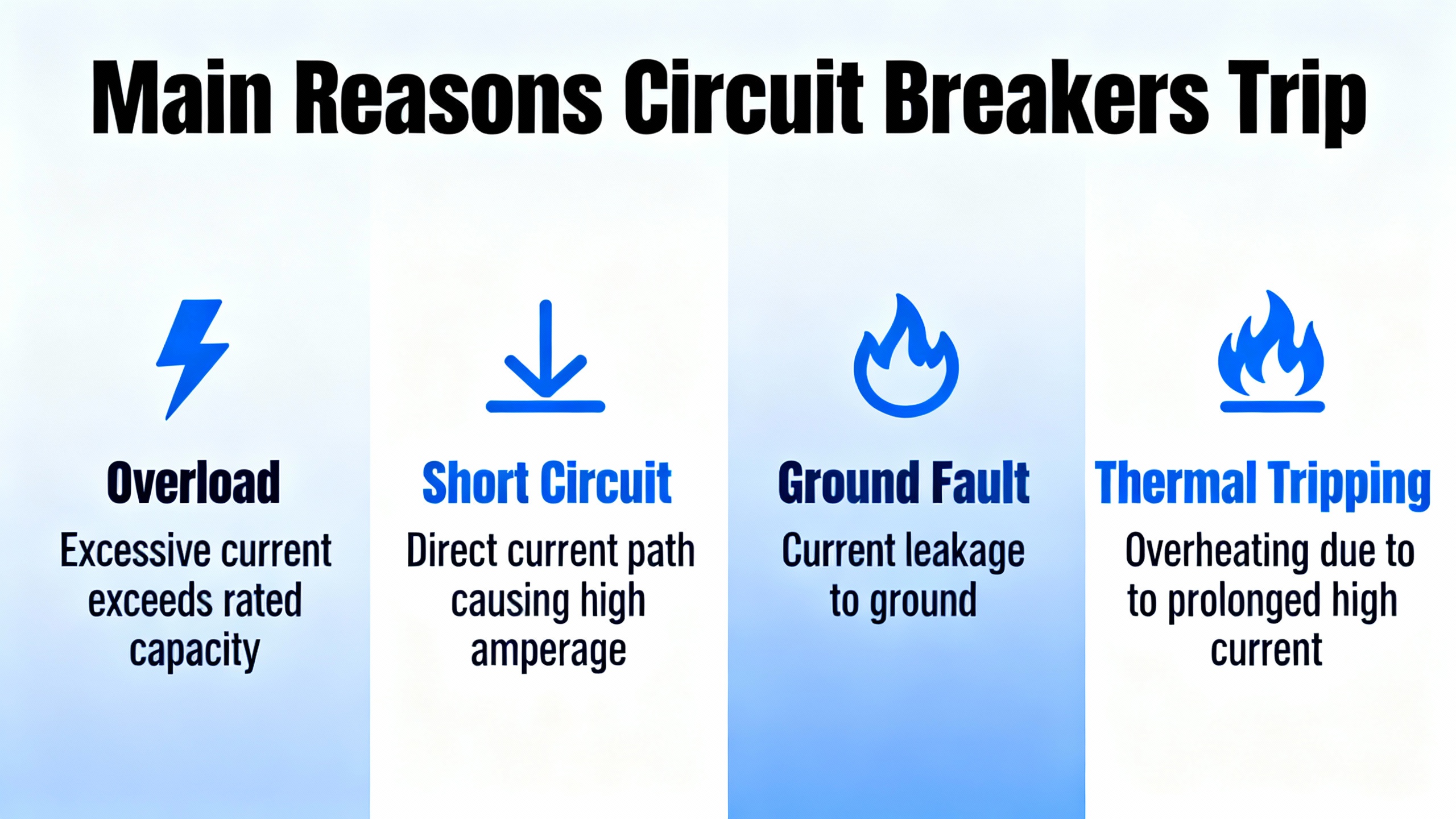

Overload is the most common reason for tripping, according to Florida Academy, Tameson, Team Austin, and multiple residential and commercial guides. An overload occurs when the total current drawn on a circuit exceeds the breakerŌĆÖs continuous rating. In a plant or data hall this might be a feeder that now supplies more server racks than it was originally designed for, a production area where new process equipment was added, or a panel feeding multiple large HVAC units.

Symptoms of overload are often gradual. Magnify Electric and other sources describe warning signs such as flickering or dimming lights when large equipment starts, warm outlets or panels, and breakers that trip only after some time under heavy load rather than instantly. In a UPS environment, overload may appear when the critical load grows and ŌĆ£temporaryŌĆØ loads become permanent, pushing UPS outputs or downstream ABB breakers beyond their intended utilization.

Every breaker has a timeŌĆōcurrent characteristic curve. As one Quora-based explanation notes, a fifteen amp device does not trip instantly at fifteen amps. It trips quickly at very high currents and allows a short period of modest overload, for example during motor inrush, to avoid nuisance trips. That same principle applies to ABB breakers. Repeated trips under similar load conditions usually indicate that your real operating current is too close to the breakerŌĆÖs long-time pickup setting or thermal capacity.

Short circuits occur when a live conductor makes unintended contact with neutral, ground, or another phase in a way that creates a very low-resistance path. Electricians Service Team, This Old House, and HomeElectrical all emphasize that this leads to a sudden current spike and immediate tripping. In industrial systems, short circuits may occur inside equipment, in cable joints, in bus duct, or in aging junction boxes.

Typical signs include a breaker that trips instantly when you reset it and re-energize a specific feeder, sometimes accompanied by visible sparks, a popping sound, or a sharp burning odor at the fault location. Several sources warn that char marks, melted insulation, or discolored devices near the affected circuit are strong indicators of a short that needs professional investigation.

Short circuits are high-energy events; ABB breakers are designed to interrupt them within their listed interrupting rating. However, the breaker should not be expected to tolerate repeated short-circuit events. If a breaker trips instantaneously each time a certain load or feeder is energized, it is a strong sign of a wiring or equipment fault, not of a ŌĆ£weakŌĆØ breaker.

A ground fault happens when a live conductor contacts a grounded surface or conductor such as a metallic enclosure, conduit, or equipment frame. Florida Academy, Electricians Service Team, and several safety guides note that ground faults are especially dangerous near water and in damp or corrosive industrial areas.

In many modern installations, GFCI devices or ground fault protective breakers monitor the balance between hot and neutral currents and trip if they detect current leaking to ground. Magnify Electric points out that issues concentrated in wet locations, or circuits that trip only when equipment near water is used, often trace to ground faults.

In commercial facilities, ground faults can occur on long cable runs through wet trenches, in outdoor gear exposed to the weather, or anywhere insulation has deteriorated. They can also be intermittent, appearing only with vibration or moisture. ABB breakers with ground-fault protection will trip rapidly when that leakage exceeds their pickup setting, often before a conventional overcurrent element operates.

Arc faults are another category of dangerous abnormal condition. Exquisite Electric and Quora-based explanations describe them as intermittent sparking events caused by loose connections, damaged insulation, or degraded wiring. The current may not be high enough to trip a standard thermal-magnetic breaker, but the arcing can still generate intense localized heating and ignite surrounding material.

Modern arc-fault circuit interrupters (AFCI breakers) recognize the signature of these arcs and trip to prevent fires. In industrial settings, arc faults might arise in aging panelboards, cable terminations, or equipment subject to vibration. Random, hard-to-reproduce trips on an ABB breaker equipped with arc-fault or sensitive electronic trip functions can indicate issues of this type rather than pure overload.

Several sources warn strongly against repeatedly resetting breakers that seem to trip ŌĆ£for no reason.ŌĆØ Those nuisance trips may be your only early warning of an insulation failure that will become a serious event if ignored.

There are cases where the ABB breaker itself is at fault. Team Austin and BreakerHunters cite typical breaker life in the range of a few decades under normal use, and note that repeated high-fault interruptions, chronic near-overload operation, water damage, and frequent manual switching all shorten that useful life.

Signs of a bad breaker include tripping with minimal load, a handle that will not stay in the ON position, severe discoloration, melted or charred housing, a strong burning smell, or a buzzing or sizzling sound that grows louder with load. Tameson notes that a breaker should not exceed about 140┬░F at its surface; if you cannot comfortably touch the plastic, overheating is likely. In that case you must investigate the cause, which could be loose terminations, continuous near-trip current, or internal damage.

Most sources agree that once a breaker shows physical damage, significant heat, or persistent erratic behavior, replacement is the only responsible choice. Any replacement must match the original type and rating. BreakerHunters specifically highlight the risk of incorrect application or low interrupting ratings and warn about defective or poorly sourced refurbished breakers. In a critical ABB installation, that translates directly into verifying that replacement units meet the original manufacturer and system specifications.

Before you can fix repeated ABB breaker tripping, you need to classify what you are dealing with. Different trip behaviors point toward different root causes. The research sources describe consistent patterns that apply equally in commercial switchgear.

The first pattern involves trips that occur only when many loads run together on the same circuit. For example, the breaker holds when only a few devices are on, but trips after some time when all process lines, comfort cooling, and ancillary loads are running. Magnify Electric and Florida Academy classify this as classic overload. The breaker is responding to too much total load rather than a specific fault.

The second pattern involves immediate trips when a particular load is energized. Rella Electric, AAA Electrical Services, and others describe scenarios where a breaker resets, but the moment a certain motor, heater, or section of lighting is turned on, the breaker trips instantly again. That behavior strongly suggests a short circuit or severe internal fault in that specific load or its wiring.

A third pattern is tripping that occurs primarily when equipment near water or in damp locations operates. For example, an ABB breaker feeding outdoor receptacles or wash-down areas trips only when hoses are in use. That points toward ground faults, especially when associated GFCI devices are also tripping.

A fourth pattern is random, hard-to-reproduce tripping without a clear link to load level or specific devices. Quora-based guidance notes that this can be a sign of intermittent shorts, arc faults, ground faults, or a failing breaker. In industrial environments, vibration, temperature cycling, or moisture can modulate these intermittent issues.

The last pattern is no trip at all but noticeable heat, buzzing, or flickering downstream power. Tameson distinguishes between a soft hum under load, which can be normal, and louder buzzing or sizzling, which often reflects loose connections or overloaded breakers. A breaker that feels hot to the touch without tripping may be operating just below its trip threshold continuously, raising long-term fire risk.

The table below summarizes these patterns in a way that is practical for ABB applications around UPS and inverter systems.

| Trip pattern or symptom | Most likely cause | Typical signs mentioned in sources | Immediate focus |

|---|---|---|---|

| Trips after some time under heavy combined load | Overload | Dimming lights, warm outlets or panel, normal operation at lighter loads | Measure or estimate load, redistribute or reduce, consider new circuits |

| Instant trip when a particular load starts | Short circuit or severe equipment fault | Sparks, popping sound, burning smell, visible charring at device or box | Isolate that load, inspect wiring and internals, do not keep resetting |

| Trips mostly in damp or wet areas | Ground fault | Tripping when using tools near water, GFCI outlets tripping | Inspect for moisture and damage, test and repair, ensure GFCI protection |

| Random trips, no obvious pattern | Arc fault, intermittent wiring issue, or bad breaker | Occasional buzzing, old or damaged wiring, no single offending load | Detailed inspection, possible breaker and wiring testing, call specialist |

| Breaker hot or buzzing without tripping | Loose connections or continuous near-overload | Panel warm or hot, breaker hums more loudly under load | Check terminations and loading, de-rate or replace components as needed |

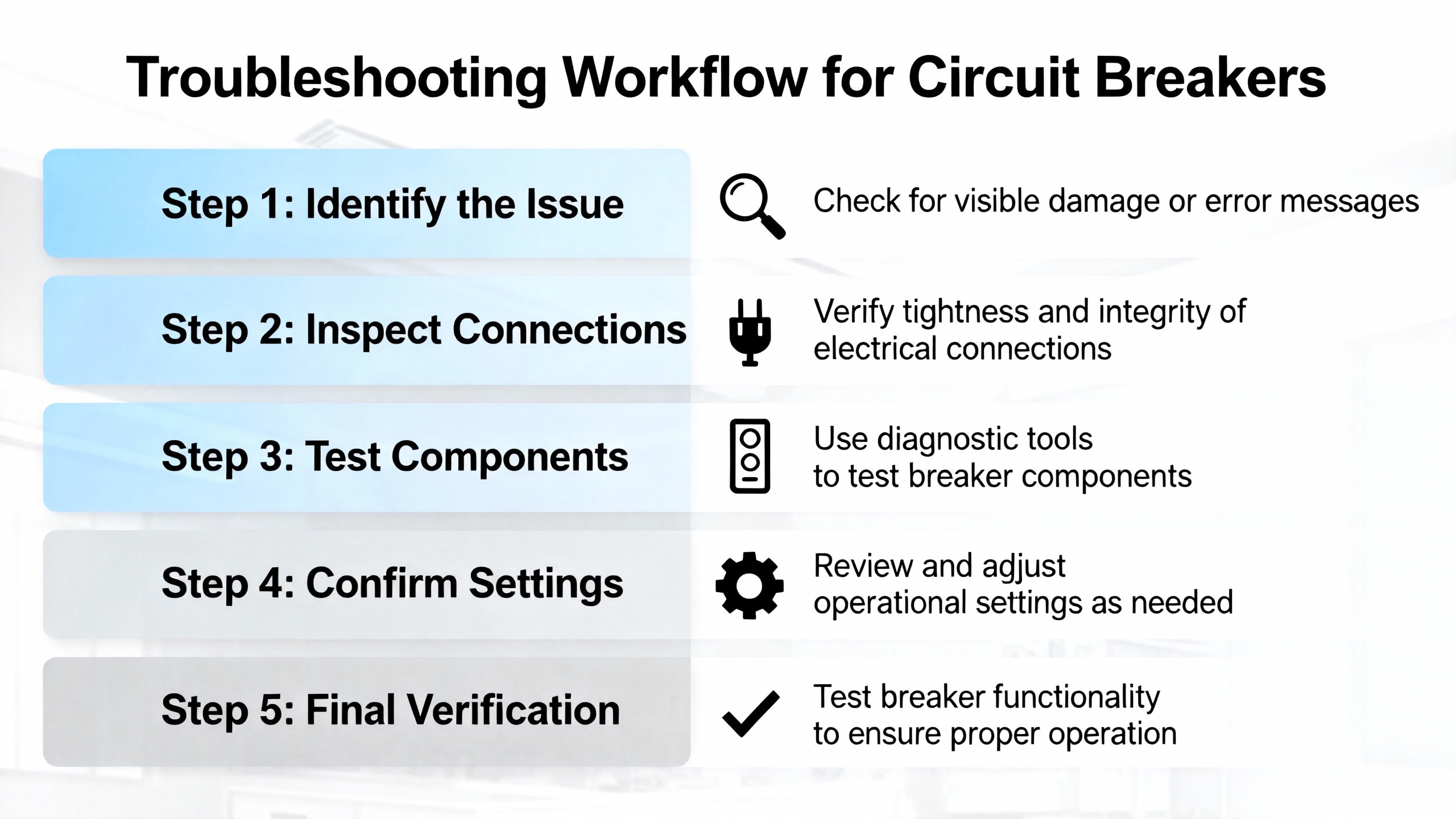

In industrial practice, you need a structured approach that respects safety, minimizes downtime, and protects high-value equipment such as UPS units and inverters. The following workflow consolidates practical steps from BreakerHunters, Tameson, Magnify Electric, AAA, Rella Electric, and other sources, adapted for ABB breakers in commercial settings.

Begin with safety. Verify whether the issue is localized to one ABB breaker or part of a wider outage. Check if other panels on the same bus or neighboring facilities have power, similar to the guidance from Tameson about checking nearby buildings. Confirm that no obvious emergency is in progress, such as smoke, arcing, or a strong burning smell. If any of those are present, treat it as a potential fire and follow your facilityŌĆÖs emergency procedures.

Gather basic information while systems are still in their tripped state. Note which breaker has tripped, what loads it feeds, whether it is an incoming feeder, UPS input, UPS output, or a downstream distribution breaker. If the panel is properly labeled, as multiple residential and commercial guides recommend, this step is faster and safer.

If it is safe to proceed, reset the breaker properly. Articles from Edison, AAA Electrical Services, Tameson, AHS, and Team Austin all stress that a tripped breaker often rests in a middle position, not fully OFF, and that it must be moved fully OFF before it can be turned ON again.

Stand to the side of the panel, keep your hands dry, and avoid leaning your body directly in front of the breaker in case of an arc event. Move the ABB breaker handle firmly to the OFF position until you feel or hear a definite click. Pause briefly, then move it decisively back to ON. If it immediately trips again while most loads remain connected, treat that as an indication of an underlying fault rather than trying over and over.

Guidance from utilities and electriciansŌĆÖ services repeatedly warns against multiple rapid resets. Repeatedly forcing a breaker that will not stay on can produce arcing inside equipment and raise fire risk.

If the first reset suggests overload or a load-related fault, the next step is to isolate loads. Magnify Electric, Rella Electric, Tameson, and several others all describe the same basic method: disconnect everything you can, then reintroduce loads systematically.

In an industrial context, that means shutting down nonessential equipment on that circuit or feeder. On a UPS output, switch off or disconnect downstream racks, PDUs, or subpanels where possible. On a feeder to process equipment, coordinate with operations to shut down machinery safely. Once the loads are off, reset the ABB breaker again.

If the breaker now holds with minimal load, that points toward overload or a particular device. Energize loads one group at a time, watching the breaker. When it trips again as a particular group comes online, you have narrowed down the suspect area. Within that group, further subdivision or targeted inspection can often isolate a single faulty device or branch.

This progressive loading method is effective because it turns a complex system-level fault into a series of simple yesŌĆōno questions, using the breaker itself as a crude but reliable diagnostic, exactly as suggested by research from Tameson and Quora-based troubleshooting advice.

With suspect loads identified or with the breaker still tripping with everything off, visual inspection becomes essential. Multiple sources stress the importance of checking for burn marks, melted plastic, discoloration, and damaged insulation around outlets, junction boxes, and the panel itself.

On the load side, look at devices for charred connectors, frayed cables, or signs of moisture ingress. On the panel side, only qualified personnel should remove covers to inspect ABB breaker terminals and bus connections. Tameson and Mr. Mighty Electric both warn that loose connections increase electrical resistance, which in turn increases heat and can cause both overheating and noise.

If you find clear evidence of burning, charring, or melted components, do not re-energize that portion of the system until repairs are complete. These are situations where the breaker has likely prevented something worse, and continuing to try resets would be irresponsible.

When visual inspection is insufficient, electrical testing is the next step. BreakerHunters and Vdiagtool guidance converge on a similar procedure for testing breakers with a multimeter and, when appropriate, a clamp meter.

For qualified personnel, live voltage tests can confirm whether the ABB breaker is delivering the correct voltage when in the ON position and fully stopping voltage when OFF. Abnormal readings, such as full voltage on the line side but zero or unstable voltage on the load side despite the handle being ON, suggest internal breaker issues or poor connections.

After locking out and de-energizing the panel, the breaker can be isolated for continuity tests. With the load conductor removed and the breaker removed if necessary, a multimeter can check resistance across the terminals in ON and OFF positions. A good breaker should show low resistance when ON and no continuity when OFF. Deviations from this behavior, especially when confirmed on the bench rather than in-situ, support replacement.

A clamp meter can be used to measure actual current under normal operation and compare it to the breakerŌĆÖs rating. Several sources emphasize that persistent operation very close to the rating, even if technically within limits, will heat the breaker and may eventually trigger thermal trips. That is particularly important where load growth over time has pushed feeders close to their original design margins.

At this point you can typically classify the problem into one of three categories.

If testing shows currents clearly exceeding the breakerŌĆÖs rating when all intended loads are running and there is no evidence of faults, then your system is simply overloaded. The appropriate remedy, echoing the advice from Electricians Service Team, Florida Academy, and AustinŌĆÖs electrical service, is to reduce or redistribute loads, add new circuits, or increase capacity through proper design. Increasing the breaker rating without evaluating conductor sizes and code limits is not an acceptable solution. Quora-based safety guidance reminds us that breakers must never exceed the allowable ampacity of their smallest conductors; for example, common branch circuits use fifteen amp breakers with fourteen gauge wire and twenty amp breakers with twelve gauge wire.

If tests and inspection point toward a wiring fault or equipment fault, then the breaker is behaving appropriately and the focus must shift to repairs. That can include replacing damaged cables, repairing faulty junction boxes, or replacing failed equipment. Almost every source in the research notes stresses that repairs inside junction boxes, panels, and equipment should be performed by licensed electricians or properly trained technicians, not improvised in the field.

If both loads and wiring appear healthy but the breaker shows inconsistent voltage, erratic continuity, unusual noise, or heat, the breaker itself may be defective or worn out. In that case, replacement with a matching ABB unit is the right course, performed by qualified personnel with the circuit safely de-energized. Any time a breaker shows visible damage or a burning smell, replacement is not optional.

Although most general guides assume residential loads, the same trip mechanisms affect ABB breakers feeding UPS and inverter equipment. If a feeder breaker upstream of a UPS input is tripping, the underlying issues tend to fall into the same categories: overload from additional downstream loads, short circuits in the distribution, or faults within the UPS or its cabling. The diagnostic logic does not change just because the load is a UPS instead of a toaster.

When troubleshooting around critical power equipment, one additional consideration is sequence. Repeated trips during UPS recharge or during inverter transfer may coincide with specific operating modes. For example, if the breaker trips only when the UPS attempts to recharge after an outage, it is reasonable to suspect that the combined load of recharging and supplying the critical bus has pushed that feeder beyond its intended load profile. That is still an overload problem, but with a very specific operating scenario behind it.

Inverter outputs feeding downstream ABB breakers can show overload symptoms when new IT racks or process lines are connected without updating the original load analysis. Combining the progressive load reconnection method with UPS event logs and inverter alarms often provides enough data to pinpoint exactly when and where overload or fault currents arise.

The key principle is that breaker settings and coordination with UPS and inverter protections must be engineered, not guessed. If recurring ABB breaker trips are tied to particular UPS events or transfer operations, that is a sign that protection coordination and load planning need to be reviewed by your power systems engineering team or by the manufacturerŌĆÖs technical support, rather than a sign that your breaker is ŌĆ£too sensitive.ŌĆØ

Once you have resolved the immediate cause and restored operation, the long-term reliability work begins. The research notes from Florida Academy, Rella Electric, This Old House, Mr. Mighty Electric, and others consistently highlight three recurring preventive themes that apply directly in industrial settings: proper load management, regular inspection, and using the right protection devices.

Good load management means understanding what each ABB breaker actually feeds and how those loads behave over time. Avoid letting ŌĆ£temporaryŌĆØ connections on UPS outputs or panelboard circuits become permanent without revisiting breaker sizing and feeder capacity. Distribute high-demand equipment across multiple breakers where possible, and consider dedicated feeders for large loads instead of stacking them on general-use circuits.

Routine inspection and maintenance of panels, breakers, and wiring are equally important. That includes checking for signs of heat and discoloration at breaker terminals, tightening terminations where appropriate, and inspecting outdoor or damp-area equipment for moisture ingress or corrosion. Several sources recommend periodic professional inspections for homes; in industrial facilities with ABB switchgear and critical power systems, such inspections are a baseline expectation rather than an optional extra.

Finally, ensure that protective devices match their environments. In wet or high-risk areas, that means appropriate use and testing of GFCI or similar ground-fault protection, as recommended by Florida Academy and Magnify Electric. In areas with aging wiring or high fire risk, arc-fault or equivalent protective features may be justified. In all cases, the trip features of ABB breakers and any supplementary protection should be coordinated so that the right device trips first, limiting both damage and downtime.

Guidance from Edison, Team Austin, and several electrical service firms is very consistent: it is only safe to reset a breaker promptly when you are confident that the cause is a simple overload, and even then it should be done carefully. If an ABB breaker trips again immediately, or trips repeatedly after short periods of operation, treat that as a warning sign of an underlying fault rather than forcing more resets. Continuing to reset in those conditions can create arcing, overheating, and increased fire risk.

Tameson notes that breakers should generally not exceed about 140┬░F at their surfaces, and that plastic parts should be touchable without burning your finger. A hot ABB breaker that has not tripped may be carrying current near its long-term limit, or may have loose connections at its terminals. Either situation warrants investigation, especially in a critical panel. Persistent warmth under normal load should trigger a load review and a check of terminations by qualified personnel.

Replacing an ABB breaker with a higher rating to ŌĆ£get rid of nuisance tripsŌĆØ is one of the most dangerous approaches you can take. Quora-based guidance and multiple service firms emphasize that breakers must never exceed the safe ampacity of the conductors they protect. In common branch circuits, that means fifteen amp breakers for fourteen gauge wire and twenty amp breakers for twelve gauge wire, and the same principle applies in industrial feeders according to their own design and code limits. If an appropriately sized breaker is tripping, the correct fix is to reduce or redistribute the load or upgrade both conductors and protective devices based on a proper engineering design, not to oversize the breaker alone.

Frequent ABB breaker trips are not just a maintenance nuisance; they are your protection system telling you exactly where your electrical infrastructure is under stress. When you treat those events as structured reliability data, investigate with discipline, and correct the underlying overloads, faults, or aging components, you not only stop the trips, you also harden your UPS, inverter, and power distribution systems against the kinds of failures that cause costly downtime and, in the worst cases, fires. As a power system specialist, I can say that the facilities with the fewest surprises are rarely the ones with zero breaker trips; they are the ones where every trip has been understood, learned from, and engineered out of the system.

Leave Your Comment