-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Replacing a Schneider Electric PLC is not just an automation decision. In industrial and commercial power systems, the PLC often sits in the middle of generators, UPS systems, inverters, transfer switches, and power protection relays. When that controller becomes obsolete or unreliable, your ability to keep power stable, clean, and available is at risk.

From a reliability advisor’s perspective, the right “Schneider alternative” is less about brand loyalty and more about matching control technology to your electrical risks, staffing, and budget. Based on published guidance from Schneider Electric and several independent integrators and vendors, this article walks through realistic replacement paths and how they play out in power and powerŌĆæadjacent applications.

A programmable logic controller, or PLC, is a rugged industrial computer that continuously reads inputs, executes a control program, and drives outputs to automate processes. Multiple sources, including DPS Telecom and Panelmatic, emphasize that PLCs were designed specifically for harsh environments and deterministic, realŌĆætime control. Schneider Electric’s Modicon families are a prominent example, widely deployed in manufacturing, energy, and infrastructure.

However, several converging pressures are making many Schneider PLC owners reconsider their position.

Panelmatic notes that organizations should look hard at PLC modernization when hardware is obsolete, vendor support is limited, or software is no longer supported by current operating systems. E&C Engineering’s description of a Quantum to X80 M580 upgrade fits this pattern: the project is framed around moving away from a legacy platform to a modern Modicon M580 controller that offers better connectivity and longŌĆæterm support.

The CMM Group highlights the direct business impact. As they point out, a failed PLC can cost several days or even weeks of lost production while you scramble for obsolete parts and workarounds. That observation aligns with what many plant teams see in power and utilities: one controller failure during a utility disturbance or a generator start can cascade into extended outage, manual workarounds, and a long postŌĆæevent cleanup.

Telecom and wideŌĆæarea operators are facing similar issues. DPS Telecom describes how aging PLCs in distributed networks require substantial inŌĆæhouse programming skill, are not always rugged enough for remote sites, and are awkward to integrate with modern communications. Their recommendation is to think seriously about alternatives when your control footprint is geographically dispersed, your expert PLC programmers are retiring, and you need remote visibility and control with fewer people.

Put simply, Schneider Electric PLC replacement climbs the priority list when any of the following is true: you cannot get parts, the software platform is frozen in time, unplanned downtime is increasing, modern networking and cybersecurity requirements are not met, or you need more data than a legacy controller can reasonably provide.

Before you choose an alternative, you have to be honest about what the existing Schneider PLC is actually doing.

Across the sources, the role of a PLC is consistently framed the same way. DPS Telecom describes it as the “nerves and muscles” in a SCADA architecture: the PLC watches discrete and analog inputs, executes logic, and energizes outputs to run equipment. IndustrialAutomationCo and multiple brand comparison articles reinforce the same picture: PLCs in energy and infrastructure constantly read sensors, switches, and transducers, then drive contactors, relays, and control signals.

In power applications, that typically translates into several responsibilities, even if they are not listed explicitly in the sources. The PLC coordinates breaker and contactor sequences, supervises permissives and interlocks for generators and other sources, enforces time delays for transfers, and exchanges alarms and status with SCADA or building management systems. Schneider’s M580 platform, for example, is described as optimized for energy management and infrastructure, with strong realŌĆætime data processing and IoT connectivity.

This matters because any viable alternative has to match more than I/O counts. It must replicate deterministic scan behavior, failŌĆæsafe states, and interactions with supervisory systems. ControlByWeb’s notes on replacing old PLCs with IoT controllers stress the need to fully map existing I/O, protocols such as Modbus, and timing behavior before migration, and to validate that the replacement behaves correctly in all safetyŌĆærelated scenarios.

In practice, Schneider PLC owners considering an “alternative” usually fall into one of four paths: modernize inside the Schneider ecosystem, migrate to another major PLC brand, redesign the architecture around RTUs or IoT controllers, or use microcontrollerŌĆæbased solutions in narrowly defined cases. Each path has its place if you select it for the right reasons.

For many sites, the most conservative “alternative” to a legacy Schneider PLC is a modern Schneider PLC.

E&C Engineering’s Quantum to X80 M580 project illustrates this. While the article body is limited, the context is clear: upgrading from a legacy Quantum platform to a modern Modicon M580 and X80 I/O is positioned as a costŌĆæeffective, seamless upgrade. Best practice in such projects, as described in industry summaries, is to reuse field wiring and as much I/O infrastructure as practical. That reduces installation time and material cost, and keeps downtime short compared with ripping everything out.

Schneider Electric’s own modernization services, marketed under the EcoFit brand, are built around the same idea. The notes describe EcoFit PLC modernization as preserving as much of the existing investment as possible, including wiring, field devices, and even application logic, while swapping out obsolete hardware. The result is a system with enhanced connectivity, stronger cybersecurity, and support for analytics and digital tools, but without the disruption of a complete rearchitecture.

Other independent sources reinforce that this kind of “migration” has clear pros and cons. Panelmatic explains that migration, where you keep the I/O and field wiring and replace the CPU and software platform, reduces material cost, shortens downtime, and keeps system behavior familiar to operators and technicians. However, it can limit longŌĆæterm flexibility, especially if you retain an older wiring and panel architecture that makes future networking or safety improvements harder.

For power and powerŌĆæprotection systems, staying with Schneider typically makes sense when you have a large installed base of Modicon hardware, your team already understands the Schneider software ecosystem, and your main goal is to eliminate obsolescence risk while gaining better networking and diagnostics. It is particularly attractive if your power control panels are physically difficult to modify, such as in tight switchgear lineups or critical data center rooms where downtime windows are short.

Sometimes the real “alternative to Schneider” is another topŌĆætier PLC platform. That decision is usually driven by standardization across plants, the skill set of your engineers and integrators, or regional support.

Multiple brand comparison articles from Industrial Automation Co., PLC Department, Vista Projects, and PEKO Precision highlight the strengths of the major players. They consistently describe Siemens and AllenŌĆæBradley (Rockwell Automation) as premium options for complex, dataŌĆæintensive plants, with Mitsubishi, Omron, ABB, Schneider, and a few others rounding out the field for different niches.

According to one Industrial Automation Co. comparison, AllenŌĆæBradley is known for highŌĆæperformance PLCs, particularly in North America, with integrated Logix platforms and the Studio 5000 development environment. It is positioned as a premium choice, with CompactLogix PLCs roughly around $1,000 to $3,500 and highŌĆæend ControlLogix systems exceeding $5,000, plus software and training. Schneider, in the same comparison, is noted for a wider and generally more costŌĆæaccessible range, with Modicon M221 entry models around $400 and advanced M580 systems above $2,000, leveraging energyŌĆæefficient designs that can reduce longŌĆæterm operating cost.

Siemens, as profiled by PLC Department and others, leads industrial automation revenue globally and targets complex, largeŌĆæscale automation. Its SIMATIC S7ŌĆæ1200 and S7ŌĆæ1500 families, supported by the TIA Portal engineering suite, are credited with highŌĆæspeed processing and strong global support. Case studies in the same sources mention reductions in downtime and better quality control when Siemens PLCs are deployed in demanding applications such as automotive manufacturing.

ABB’s AC500, Mitsubishi’s MELSEC lines, and Omron’s CP, CJ, and CS series are all described as credible alternatives with different strengths. ABB focuses on harsh, heavyŌĆæindustry environments such as mining and oil and gas. Mitsubishi positions itself as affordable to midŌĆærange, with highŌĆæspeed control and compact designs. Omron is characterized as durable and accurate, with strong integration to robotics and vision systems and relatively low entry pricing.

A concise way to think about the crossŌĆægrade options, strictly using the published descriptions, is summarized here.

| Option | Positioning in the sources | Typical strengths for powerŌĆæadjacent work | Main watchŌĆæouts compared with Schneider |

|---|---|---|---|

| Schneider Modicon (M221–M580) | Energy management and infrastructure, IoTŌĆæready, midŌĆærange cost | Strong connectivity including Ethernet and Modbus, EcoStruxure integration, focus on energy efficiency | Staying in the same ecosystem may limit leverage in commercial negotiations |

| AllenŌĆæBradley Logix | Premium, highŌĆæperformance, dominant in North America | Tight integration with drives and plant software, strong for complex manufacturing and process plants | Higher upfront hardware and software costs |

| Siemens SIMATIC | Global leader, suited to complex, largeŌĆæscale automation | Advanced engineering tools, global support, proven in highŌĆæend applications | MidŌĆætoŌĆæhigh pricing, learning curve for teams without Siemens experience |

| ABB AC500 | Designed for harsh, heavyŌĆæindustry environments | Robust hardware, advanced diagnostics, interoperability with thirdŌĆæparty systems | Pricing in the midŌĆætoŌĆæhigh range |

| Mitsubishi MELSEC | Affordable to midŌĆærange, strong in highŌĆæspeed manufacturing | Compact, modular designs, attractive to small and midŌĆæsize enterprises | Less dominant in some regions, so local support may vary |

| Omron PLC families | Reliable, easy to use, strong in robotics and vision integration | Good fit for compact machines and production lines where integrated sensing and control are important | Ecosystem may be less familiar to teams standardized on Schneider or AB |

Infinity Industrial and other sources consistently recommend evaluating total cost of ownership when making these moves. That includes not only hardware and software but also training, spare parts, and the degree of vendor lockŌĆæin you are comfortable accepting. If you operate multiple facilities, standardizing on one or two brands simplifies maintenance and training, but you give up some purchasing leverage and diversity of supply chain.

For a power and UPSŌĆæcentric site, crossŌĆægrading is most compelling when the rest of your automation landscape is already standardized on another brand, or when your preferred integrator has deep expertise in that ecosystem. It is less attractive if the Schneider PLCs you want to replace are tightly coupled with SchneiderŌĆæspecific hardware and software that would require extensive rework.

Schneider Electric PLCs often sit in a broader SCADA landscape, especially in utilities and telecomŌĆæstyle networks. In such cases, a remote telemetry unit, or RTU, can be a very realistic alternative.

DPS Telecom’s articles on PLC alternatives and PLC replacement lay out the distinctions. They describe PLCs as highly customizable and well suited to manufacturing, but note that they often require significant inŌĆæhouse programming skill and may not be rugged or communicative enough for remote telecomŌĆælike applications. RTUs, by contrast, are presented as costŌĆæeffective and more rugged, with builtŌĆæin wideŌĆæarea communications.

In their description, RTUs like the NetGuardian line monitor many discrete and analog sensors, control relays, and speak networkŌĆæfriendly protocols such as SNMP and ASCII. They highlight features such as detailed alarm notifications with diagnostic data, web interfaces accessible from any browser, redundant communication paths, and redundant power inputs with battery backup. Another DPS guidance piece emphasizes that RTUs can be preŌĆæprogrammed by the manufacturer, reducing dependence on inŌĆæhouse PLC specialists, while remaining expandable for future needs.

A separate DPS article comparing PLCs and RTUs notes that RTUs are generally more rugged and have higher monitoring and control capacity, making them preferable at sites with many points to monitor and control, such as server rooms and IT infrastructure. PLCs, in their framing, remain preferable when there are many locations with only a few points each, and when highly customized process logic is needed.

If you are using a Schneider Electric PLC primarily for monitoring breakers, power system environmental conditions, and a handful of control relays across multiple remote sites, the RTU path may be more attractive than moving to another brand of PLC. You gain builtŌĆæin remote access, alarm processing, and redundancy features tailored to wideŌĆæarea networks. The tradeŌĆæoff is reduced flexibility in custom control logic, since RTUs are typically configured rather than extensively programmed.

The most aggressive alternatives move away from traditional PLCs entirely and lean on IoT controllers or microcontroller platforms.

ControlByWeb’s blog on replacing old PLCs with IoT controllers is not directly accessible in the captured research, but the summarized notes give a clear picture. An IoT controller is described as a networkŌĆæconnected industrial controller that exposes I/O and logic through standard IP networking, web interfaces, and APIs, such as HTTP, MQTT, Modbus/TCP, or OPC UA. Typical motivations for replacing aging PLCs with IoT controllers include hardware obsolescence, the desire for easier remote access, better data visibility, and vendorŌĆæagnostic integration.

However, the same notes underscore the engineering discipline required. They recommend a detailed audit of devices, safety interlocks, failŌĆæsafe states, and required scan times to ensure that the IoT controller can meet determinism and reliability requirements. They also advocate starting with a pilot on a single machine or subsystem, running in parallel with the existing PLC where possible, and implementing rollback and manual override procedures so operators can stay safe if the new controller, network link, or cloud service fails. Cybersecurity, including network segmentation, encrypted communications, and strong authentication, is flagged as a central concern because IoT controllers broaden the attack surface.

On the microcontroller side, Dojo Five’s discussion of using Arduino OPTA as a PLC replacement highlights similar tradeŌĆæoffs. Arduino OPTA is presented as an industrialŌĆæfocused, openŌĆæsource platform with modularity, costŌĆæeffectiveness, and an easyŌĆætoŌĆæuse programming environment, supported by a large community and rich library ecosystem. It is well suited for rapid prototyping and scaling from small setups to larger production lines.

At the same time, the article and related community discussion caution that traditional PLCs have a long track record of reliability in harsh industrial environments, while microcontrollerŌĆæbased solutions must be thoroughly tested in the specific application. Integration with legacy proprietary protocols can require extra engineering, and longevity must be considered so you do not end up on a dead platform.

An ArduinoŌĆæfocused forum thread summarized in the research notes adds another nuance. It points out that PLC ladder logic is highly standardized, so almost any PLC programmer can understand, adjust, or fix ladder programs written years ago. Arduino and similar platforms, by contrast, allow the same simple task to be implemented in many different ways in CŌĆæstyle code, some of which are hard to read or maintain. That flexibility is valuable but can become a longŌĆæterm risk if only the original author understands the design.

Those notes also describe a deployment strategy where custom boards use pluggable I/O, and failures in the field are handled by quick board swaps rather than onŌĆæsite debugging. The operators tolerate up to a week of downtime, indicating that the processes under control are not missionŌĆæcritical.

Taken together, IoT controllers and microcontroller platforms are attractive Schneider alternatives in very specific situations: where the control problem is modest, downtime tolerance is relatively high, and you place outsized value on open platforms and deep customization. For critical power supply and protection systems, they may still play a role at the periphery, but the bar for adoption is much higher.

Choosing a Schneider alternative is one thing. Engineering it into a power system that behaves correctly during every disturbance is another. Several themes show up repeatedly across the research and are particularly important in power and UPSŌĆærelated work.

Reliability and determinism come first. All of the PLC brand overviews, from Industrial Automation Co. to Vista Projects, rate performance and reliability as a primary evaluation criterion. For Schneider’s Modicon range and its peers, that means predictable scan times, robust hardware, and proven behavior in harsh conditions. When you step outside the Schneider ecosystem to another PLC, an RTU, or an IoT controller, you must verify that the replacement can meet your worstŌĆæcase timing requirements and failŌĆæsafe states, especially for source transfer, load shedding, and protection signaling.

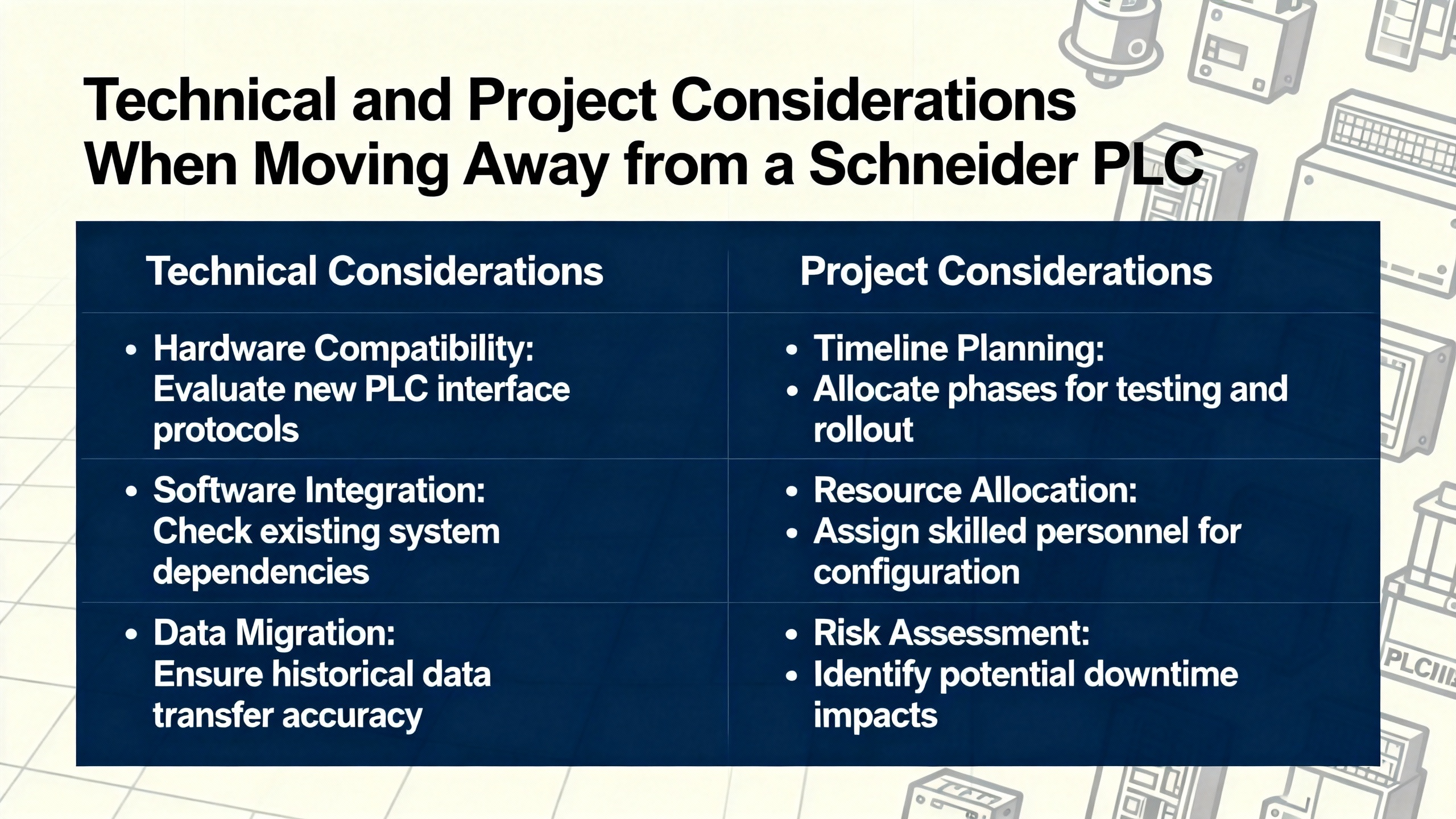

I/O mapping and wiring reuse are practical constraints. Panelmatic’s explanation of migration versus full replacement is particularly useful here. Migration, which keeps the existing field wiring and often much of the I/O, minimizes downtime and risk but can constrain your choice of alternative platforms. Full replacement, which swaps entire control panels and sometimes HMIs, opens up options but demands longer outages and more commissioning effort. E&C Engineering’s Quantum to M580 upgrade and Schneider’s EcoFit framework both reinforce that reusing wiring and I/O, when safe, is a major lever for costŌĆæeffective modernization.

Software tools, programming standards, and maintainability should not be underestimated. The brand comparison articles repeatedly highlight that ease of programming and software ecosystem maturity are key selection criteria. For Schneider, that means EcoStruxure tools and associated engineering suites. For Siemens it is TIA Portal; for AllenŌĆæBradley, Studio 5000. DPS Telecom’s critique of legacy PLCs emphasizes the risks of relying on a small group of experts who understand highly customized logic. Arduino community discussions push the point further: nonstandard code can become effectively unmaintainable. When you choose a Schneider alternative, you are also choosing how maintainable your control logic will be in ten years, when the next generation of technicians inherits your system.

Cybersecurity and remote access capabilities now influence nearly every control decision. Schneider’s M580 is specifically called out in PLC Department’s overview as having builtŌĆæin cybersecurity and EcoStruxure Plant integration, and ControlByWeb’s IoT controller guidance focuses heavily on network segmentation, encryption, and secure remote access. DPS Telecom’s RTU recommendations also emphasize web interfaces, strong alarm reporting, and redundant backup communication links. If your Schneider PLC is currently airŌĆægapped or minimally networked, any alternative that improves visibility must be scrutinized for how it will be protected.

Finally, total cost of ownership governs whether the project will be viewed as a success. Vista Projects, Industrial Automation Co., and the “Top PLC Brands” overviews all stress that buyers should look beyond list prices to include software licenses, accessories, training, and expected gains in uptime, quality, and energy efficiency. Schneider is frequently positioned in these comparisons as midŌĆærange in cost with strong energyŌĆæefficiency benefits. AllenŌĆæBradley and Siemens often sit at the premium end, while Mitsubishi and Omron occupy more costŌĆæsensitive segments. RTUs and IoT controllers may carry lower hardware costs but can introduce integration and training work that must be included in the business case.

Once you have decided whether your Schneider alternative is a newer Modicon, another PLC brand, an RTU, or an IoTŌĆæstyle controller, the way you execute the project will largely determine its success.

Panelmatic outlines a structured PLC upgrade process that maps well onto Schneider replacements. It starts with a site evaluation, including an inventory of existing hardware, wiring, and I/O. Next comes system design and platform selection, followed by panel fabrication or rework, software development for the PLC and any HMIs, testing and factory acceptance testing, onŌĆæsite installation and commissioning, and then training and ongoing support. The CMM Group’s service description aligns with this flow, emphasizing that they can supply replacement PLCs, preassembled and preprogrammed racks, HMI and control modifications, or full programming as needed.

ControlByWeb’s IoT controller guidance and Dojo Five’s Arduino OPTA recommendations add additional safeguards that are especially important if you are moving away from a Schneider PLC to a new architecture. They stress fully documenting safety interlocks, emergencyŌĆæstop behavior, and failŌĆæsafe states before touching anything. They recommend running the new controller in parallel with the old one when possible, mapping inputs and outputs and validating behavior under different operating conditions, and designing a staged or parallel cutŌĆæover strategy that allows rollback.

DPS Telecom’s RTU replacement recommendations also highlight the organizational side. They encourage selecting systems that can be configured by a small core of experts but are easy for lessŌĆæexperienced staff to operate over a decade or more. They argue for vendors that can provide strong documentation and support, and for architectures that include backup communication and power so your visibility does not disappear during the very events your system is supposed to handle.

In dayŌĆætoŌĆæday project work, that translates into several habits. Treat every Schneider replacement as a safetyŌĆæcritical change, even if the PLC’s main job seems to be “just alarms.” Validate not only normal operation but also abnormal conditions such as utility dips, UPS transfers, generator failures, and protection operations. Build test harnesses and use simulation where possible, as Panelmatic recommends, to catch logic and communication issues before they reach the field. And keep your operators involved; as the CMM Group and others point out, HMI improvements are often one of the biggest practical benefits of an upgrade, but only if they reflect how operators actually work.

The research does not prescribe a single “safest” choice. Schneider’s own modernization services and projects like Quantum to M580 upgrades show that staying within the Schneider ecosystem can minimize risk by reusing wiring and retaining similar behavior, while adding modern connectivity and cybersecurity. However, independent comparisons from Industrial Automation Co. and PLC Department show that Siemens, AllenŌĆæBradley, ABB, Mitsubishi, and Omron also deliver highŌĆæreliability platforms. The safer path is the one where your team and partners have the deepest experience, the platform is well supported in your region, and the migration is engineered and tested thoroughly.

According to DPS Telecom, RTUs are particularly well suited to geographically dispersed sites with many points to monitor and control, such as telecom or IT facilities. They come with builtŌĆæin wideŌĆæarea communications, web interfaces, detailed alarm reporting, and redundant power and communication options. If your Schneider PLC is mainly acting as a remote alarm and control concentrator across multiple sites, an RTU can be a better fit than a generalŌĆæpurpose PLC. If it is running complex, tightly coupled process logic in a single plant, a PLC usually remains the better choice.

The sources are cautious on this. Dojo Five presents Arduino OPTA as a costŌĆæeffective, flexible alternative with a large community and rapid prototyping advantages, but they stress the need for thorough testing, reliability assessment, and longŌĆæterm support planning. ControlByWeb’s IoT controller guidance emphasizes detailed I/O and safety mapping, parallel testing, and robust cybersecurity. Community discussions add that nonstandard code and lack of ladderŌĆælogic standardization can hurt maintainability. For nonŌĆæcritical or auxiliary systems, these platforms may be viable, but for core powerŌĆæsupply and protection controls, traditional industrial PLCs and RTUs still have a clear edge in proven reliability and support.

In critical power and protection work, replacing a Schneider Electric PLC is ultimately about risk redistribution. You can keep that risk low by choosing alternatives whose strengths are well documented in the sources, matching them carefully to your power architecture, and executing the migration with the same rigor you apply to your protection schemes.

Leave Your Comment