-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

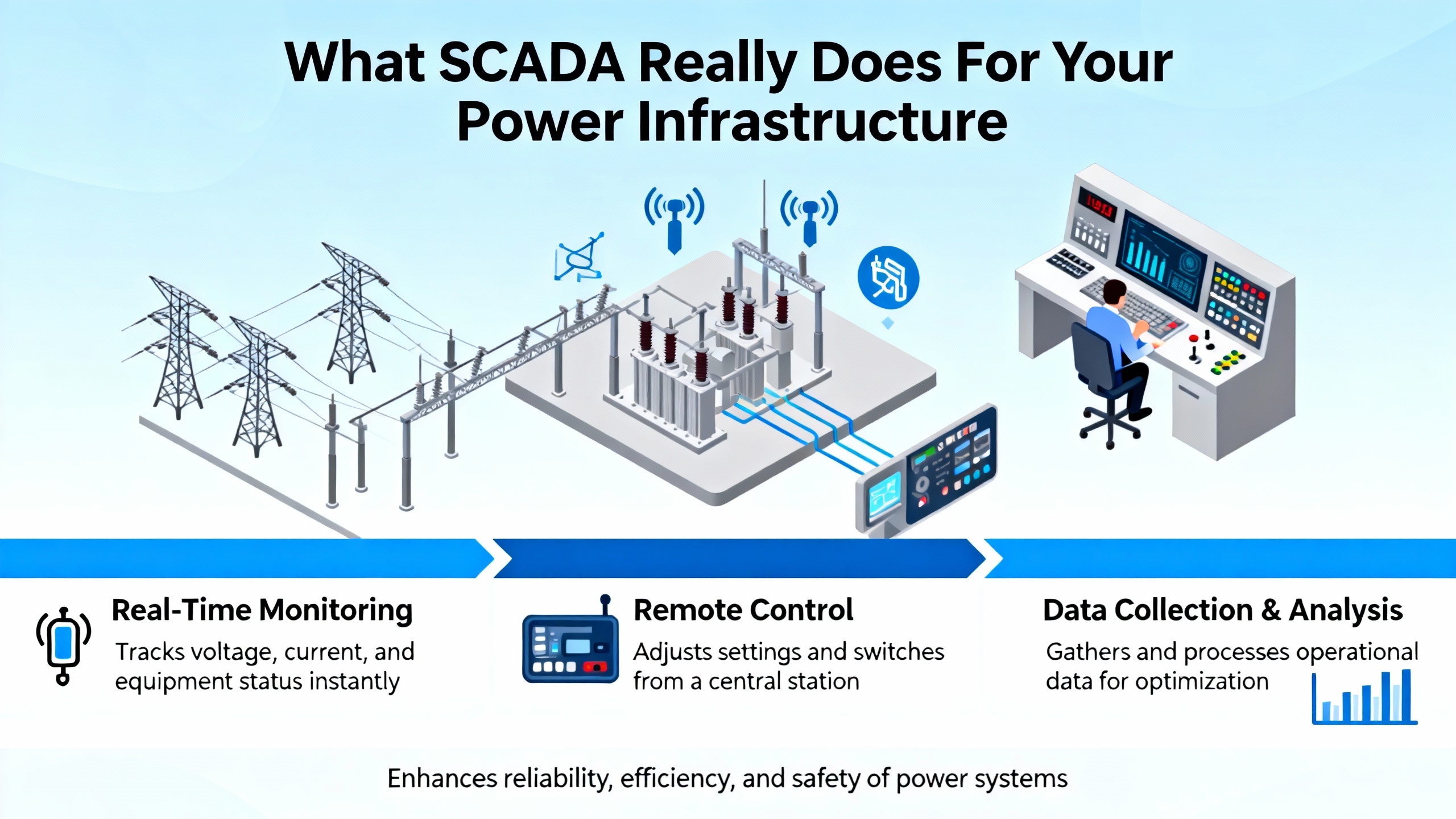

Modern industrial and commercial facilities live or die on power quality. Critical loads such as data centers, process lines, hospital theaters, and logistics hubs depend on uninterruptible power supplies (UPS), inverters, and power protection gear to ride through disturbances that the grid cannot absorb. Yet the true resilience of that power chain is no stronger than its ability to see problems early and react fast. That is where supervisory control and data acquisition (SCADA) and the parts that make it up become just as important as the switchgear.

Drawing on field experience with industrial power systems and the body of work from vendors and practitioners such as Schneider Electric, Inductive Automation, Maple Systems, Cedalo, Pacific Blue Engineering, and others, this article walks through what SCADA really does for your power infrastructure, how the main components fit together, and what to look for when you select a SCADA system parts distributor and supervisory control solution.

Industry sources consistently define SCADA as a combined hardware and software architecture that provides supervisory control and real-time monitoring of industrial processes and critical infrastructure. Schneider Electric describes it as a centralized system that connects and monitors machinery across an industrial site, while Inductive Automation frames it as a combination of software and hardware that controls processes, monitors and processes real-time data, interacts with field devices, and logs events for later analysis. Cedalo and eLynx emphasize the same loop: data acquisition, communication, processing, visualization, and control.

In practical power terms, think of SCADA as the nervous system that sits above your electrical gear. Sensors and intelligent devices measure parameters such as feeder currents, bus voltages, breaker positions, transformer oil temperatures, UPS battery strings, inverter outputs, generator status, and room environmental conditions. Remote terminal units (RTUs) or programmable logic controllers (PLCs) near the switchboard or UPS room aggregate that data, enforce local protection or interlocking logic, and talk to a supervisory computer over an industrial network. SCADA software on that supervisory node processes the data, stores it in historians, and presents it to operators via a humanŌĆōmachine interface (HMI). Operators and automated routines then use that view to make decisions: transferring loads, starting backup systems, isolating faults, or scheduling maintenance.

Several sources highlight that many time-critical safety functions stay local. Cedalo points out that RTUs and PLCs frequently execute the fastest protective actions at the field level to avoid network latency. For a power-protection engineer, this means your breaker tripping curves, generator protection, and UPS internal protections still belong on relay and controller hardware, while SCADA orchestrates the bigger picture: which feeder to reroute, which load to shed, and which maintenance crew to dispatch.

A simple example illustrates this layered approach. Imagine a facility with two UPS systems feeding critical panels and a third static transfer switch for redundancy. Current sensors on each feeder measure load, and the UPS controllers enforce overload and battery protections. A PLC in the electrical room reads those values, along with room temperature from a sensor above the UPS lineup. SCADA software in the control room logs the data, triggers alarms if one UPS consistently runs above a defined load threshold, and presents a trend showing that load imbalance has been growing for weeks. The operator can then plan a rebalancing outage, instead of discovering the problem when one UPS trips on overload during a storm.

The key takeaway is that SCADA turns raw electrical measurements into situational awareness and coordinated action. It does not replace protective relays or UPS firmware; it supervises and connects them.

Across multiple references, the same building blocks appear. Cedalo, Fidelis Security, Pacific Blue Engineering, Pro Electric, SolisPLC, and Maple Systems describe a common set of parts that any SCADA-focused distributor will work with every day.

Sensors and actuators are the systemŌĆÖs eyes and hands. Sensors measure temperature, pressure, flow, level, speed, or electrical quantities, and actuators operate valves, motors, switches, or breakers. In a power room, these could be current transformers, voltage transducers, temperature probes on transformers or UPS cabinets, motorized breakers, motor-operated disconnects, and motorized tap changers.

Field controllers, typically PLCs or RTUs, aggregate sensor data and drive actuators. Cedalo notes that RTUs excel at remote, harsh sites where communications are the primary function, while PLCs shine in richer control scenarios with high I/O counts, such as a factory floor or a large switchgear lineup. Pacific Blue Engineering and Pro Electric point out that both RTUs and PLCs convert raw signals into digital information, execute programmed logic, and relay data to the master terminal unit or SCADA server.

The supervisory computer and HMI form the human interface. Inductive Automation and Maple Systems describe this as the SCADA master or plant supervisory level, where servers run SCADA software, data historians, alarm engines, and HMI graphics that operators see in the control room or on engineering workstations. Fidelis Security adds that historians are specialized databases optimized for time-series data, supporting trend analysis and root-cause investigations.

A communication network ties everything together. Cedalo and Peakboard emphasize that modern SCADA increasingly uses open standards such as TCP/IP with Ethernet, radio, cellular, or other wide-area media, while Shoplogix underscores that performance and reliability of this backbone are critical for real-time monitoring across production lines.

For power-system engineers, this architecture maps naturally onto the electrical hierarchy. PLCs embedded in switchgear monitor and control breakers, contactors, and interlocking schemes. RTUs gather data from remote substations or generator yards several miles away. SCADA servers in a central control room host power dashboards, alarm lists, and reports. Operators use HMIs to see which feeders are energized, where faults occurred, what the UPS runtime margin looks like, and whether generator fuel levels are adequate.

To clarify how these pieces line up, the following table summarizes typical components and their roles in a power-protection context.

| Component | Typical role in power and UPS systems | Notes from industry sources |

|---|---|---|

| Sensors and actuators | Measure electrical and environmental variables; operate breakers, valves, and motors | Described as the ŌĆ£eyes and handsŌĆØ of SCADA by Pacific Blue Engineering and Pro Electric |

| PLCs and RTUs | Execute interlocks and control schemes; aggregate data near gear | Cedalo and SolisPLC distinguish PLCs for rich control and RTUs for remote telemetry |

| Supervisory computer | Runs SCADA software, alarm engine, and logic above field controllers | Inductive Automation and Maple Systems place this at the plant supervisory level |

| HMI | Provides diagrams of one-line diagrams, alarms, trends, and control commands | Fidelis Security, Eleks, and eLynx all stress HMIŌĆÖs central role in safe human supervision |

| Historian and analytics | Store time-series data and support performance and root-cause analysis | Fidelis Security and Shoplogix highlight historians and analytics in troubleshooting and OEE |

| Communication network | Connects field devices and control center across the plant or wide areas | Cedalo and Peakboard focus on Ethernet, cellular, radio, and secure IP-based designs |

A SCADA parts distributor focused on supervisory control solutions will typically stock or source many of these components: PLCs, industrial HMIs, industrial PCs, IIoT gateways, industrial Ethernet switches, and sensor families. Maple Systems, for example, positions its PLCs, HMIs, and industrial panel PCs as building blocks for SCADA frameworks, while vendors like Inductive Automation offer software platforms such as Ignition that sit on top of that hardware.

When you work in power quality and UPS integration, the key is not to view these parts as standalone products. Instead, you should evaluate them as an ecosystem that must tolerate electrical noise, environmental extremes, and high availability demands.

SCADA has evolved through multiple architectural generations. Inductive Automation describes monolithic, distributed, and networked eras, while Cedalo adds a fourth wave that embraces IoT and cloud integration. Maple Systems complements this with a five-level functional model from field devices up to enterprise planning.

Monolithic SCADA appeared in the early decades, built around mainframes or large centralized computers with direct connections to field devices. Cedalo and Inductive Automation both note that these systems were highly proprietary, hard to scale, and difficult to maintain. In power terms, a monolithic system might have been a single control room computer hard-wired to numerous relays and meters in a plant, with little flexibility and minimal integration outside the plant walls.

Distributed SCADA introduced local processing nodes on local area networks. Cedalo mentions that these systems became common over short ranges of a few hundred meters, using RTUs and PLCs as intermediaries. For a power engineer, this meant local PLCs in each substation or switchroom connected over a site LAN to a control room SCADA, simplifying wiring and enhancing resilience.

Networked and IoT-integrated SCADA are what most facilities are deploying today. Cedalo and Inductive Automation describe networked SCADA as built on open standards such as Ethernet and TCP/IP, enabling multi-vendor interoperability and wide-area networks, while modern IoT and cloud-enabled SCADA push data into cloud platforms for analytics and remote access, often using lightweight protocols such as MQTT.

Maple Systems organizes SCADA into five levels. Level 0 contains field sensors and actuators, Level 1 is the direct control level with PLCs and RTUs, and Level 2 is the plant supervisory level where SCADA software and HMIs live. Levels 3 and 4 extend into manufacturing execution systems (MES) and enterprise resource planning (ERP), which coordinate production, material flows, and business metrics.

For electrical power and UPS integration, you can map this structure directly. Field current transformers, voltage transducers, breaker auxiliary contacts, and UPS dry-contact outputs sit at Level 0. Switchgear PLCs and generator controllers belong at Level 1. The central power monitoring and control system, where you see one-line diagrams, trend UPS runtimes, and issue transfer commands, is Level 2. If your plant uses MES or ERP, those higher levels can consume SCADA data to correlate outages with production losses or schedule maintenance around order backlogs.

Consider a concrete scenario. A campus has three main substations and multiple buildings with UPS-backed critical loads. Each substation has PLCs that handle transformer tap changer logic and breaker interlocks, plus gateways to legacy protective relays. Each buildingŌĆÖs electrical room has a UPS with SNMP or Modbus connectivity, connected to a local PLC that reads battery status, internal alarms, and breaker positions. A site-wide SCADA server in the main control room collects data over a redundant Ethernet network, displays the entire campus one-line, and logs events into a historian. For future flexibility, the organization adds a lightweight MQTT broker and selectively publishes non-sensitive metrics to a cloud analytics platform that focuses on energy optimization.

This architecture sits squarely in the ŌĆ£networked plus IoT integrationŌĆØ category described by Cedalo and Inductive Automation. It also respects Maple SystemsŌĆÖ levels by keeping core protection logic in Level 1 and using Level 2 for supervision and coordination. A good SCADA parts distributor will help you match PLC, HMI, gateway, and network switch choices to that architecture so that you do not inadvertently lock yourself into obsolete or mismatched technologies.

As soon as a SCADA system touches critical power infrastructure, cybersecurity becomes a reliability concern, not just an IT issue. Fortinet and Fidelis Security both frame SCADA as integral to utilities and other essential services, and they highlight how SCADA networks are highly valuable yet vulnerable targets. The vulnerability review published through ScienceDirect and the SCADA security overviews summarized in ResearchGate materials reinforce that many legacy SCADA protocols and devices were designed for reliability rather than security.

Many widely used industrial protocols, such as Modbus or early variants of DNP3 and proprietary fieldbuses, originally lacked encryption and strong authentication. The ScienceDirect review notes that they were designed for real-time performance and deterministic behavior, not for operating across hostile networks. As SCADA architectures evolved from isolated plants to interconnected networks and, in some cases, cloud-connected systems, the attack surface expanded dramatically.

UnmudlŌĆÖs overview of SCADA systems also recalls the Stuxnet incident as a turning point. That attack targeted SCADA and PLC systems and underscored that cyber compromise can cause physical damage and downtime.

In a power-system context, an unprotected SCADA network can become a single point of failure. If an attacker gains control of the supervisory layer or can inject false data, operators might misdiagnose faults, misoperate breakers, or fail to start backup generators when needed. The result can be simultaneous outages across multiple feeders, damage to transformers or UPS systems, or loss of visibility during a crisis.

Industry guidance converges on several themes. ScienceDirect and Fortinet stress network segmentation and defense in depth, separating the control network from the corporate IT network and using demilitarized zones to manage data exchange. Fidelis Security advocates understanding each SCADA componentŌĆÖs role and data flow as a prerequisite to designing appropriate network security controls. Research reviews emphasize stronger authentication, encryption where practical, and careful patch management tailored to high-availability environments.

In practice, that means treating your SCADA for power as critical infrastructure. Field PLCs and RTUs should sit on well-defined control VLANs or dedicated networks with tightly controlled access. Remote access for vendors or technicians should pass through secure gateways, such as VPNs with multi-factor authentication, rather than unrestricted internet exposure. Where devices are capable of encrypted protocols such as secure variants of DNP3 or embedded TLS, you should enable and test them during commissioning.

A SCADA parts distributor with a focus on supervisory control solutions can add real value here. Distributors who work closely with security-oriented vendors and integrators will understand which PLCs, industrial PCs, and networking devices support modern security features and how to configure them without jeopardizing deterministic control. Combining their catalog knowledge with security recommendations from Fortinet, ScienceDirect, and similar sources helps you avoid buying hardware that becomes a permanent weak link.

Several sources, including Pacific Blue Engineering, Pro Electric, Shoplogix, NexGen, Maple Systems, and Inductive Automation, emphasize that SCADA success depends not just on software selection, but on hardware quality, system architecture, and the people who design and support it. For power and UPS-focused applications, your SCADA parts distributor sits right in the middle of that equation.

From a practical standpoint, you should look for three broad capabilities.

First, the distributor should understand the SCADA component stack. Pacific Blue Engineering and Pro Electric both describe architectures that combine sensors, actuators, RTUs, PLCs, master terminal units, communication infrastructure, HMIs, historians, and security layers. A distributor who regularly supports this full stack can advise whether, for example, a rugged RTU is better suited than a high-end PLC for a remote substation several miles away, or whether a panel PC from a vendor like Maple Systems is more appropriate than a basic HMI when you need to run SCADA software in a harsh electrical room.

Second, the distributor should be comfortable with integration across layers and vendors. Eleks and Interlake Mecalux highlight how SCADA increasingly integrates with MES, ERP, and warehouse systems, while Shoplogix and Peakboard discuss blending SCADA data with analytics and other business systems. In power environments, that integration often means combining power quality meters, protective relays, UPS network cards, and generator controllers from different manufacturers into one supervisory view. A distributor with broad protocol and brand familiarity can recommend the right mix of gateways and SCADA software (for example, an open platform like Ignition) so you do not become dependent on a proprietary single-vendor ecosystem.

Third, the distributor should align with best practices for reliability and security. Shoplogix recommends assessing current infrastructure, selecting scalable SCADA solutions, integrating tightly with existing systems, and maintaining regular updates and training. NexGen suggests a stepwise approach to SCADA deployment, starting with clear monitoring requirements, proofs of concept, and thoughtful architecture design. Security-focused sources such as Fortinet and the ScienceDirect review add the need for robust security practices. A good distributor will reflect these ideas in their pre-sales discussions: asking whether you plan for redundancy in SCADA servers, what your uptime and failover expectations are, and how your control network is segmented.

Real-world examples underline the importance of that partnership. Maple Systems describes projects ranging from the Seattle Space Needle to the Golden Gate Bridge, where SCADA-based solutions support safe operations and future growth. Interlake Mecalux notes that SCADA supervises automated warehouse systems at large food producers such as Nestl├®ŌĆÖs Dolce Gusto plant and Congelados de Navarra. In all these cases, a combination of suitable SCADA parts, solid architecture, and knowledgeable integration is what keeps complex systems running safely.

When you engage a SCADA parts distributor as a power-system specialist, it helps to bring a clear picture of your loads, protection schemes, and reliability expectations. That way the distributor can map their catalog to your real constraints, whether that means redundant server hardware in the control room, matched sets of PLCs and I/O modules across substations, or hardened industrial PCs with extended temperature ratings for outdoor electrical enclosures.

To make these ideas concrete, consider a mid-size manufacturing facility with the following characteristics: one main incoming utility service, a standby generator plant, a central UPS feeding critical production lines and control systems, and several secondary distribution panels throughout the building.

At the field level, current transformers on main feeders and bus sections measure load. Voltage transducers capture line-to-line voltages, while auxiliary contacts on breakers indicate open or closed status. The UPS exposes data points such as output load percentage, battery state of charge, and internal alarms through an industrial protocol. Temperature sensors monitor the switchgear room and UPS battery area to ensure environmental limits are respected.

At the direct control level, a PLC in the main switchgear line-up collects these signals. Its logic enforces interlocks for generator start and transfer, ensures that backfeed conditions do not occur, and coordinates load shedding during blackouts. Additional smaller PLCs or remote I/O modules gather data from secondary panels where full control logic is not needed.

At the plant supervisory level, a SCADA server running on a rugged industrial PC connects to the PLCs and UPS via Ethernet. It logs feeder currents, voltages, breaker operations, UPS statistics, and ambient temperatures to a historian database. An HMI application presents a one-line diagram, trend charts for UPS load and battery runtime, and alarm lists showing abnormal conditions such as high temperatures, repeated breaker trips, or UPS on-battery events.

Now consider two operational questions in this example. First, how do you know whether your UPS is appropriately sized and loaded over time? By trending UPS load and runtime in SCADA, you can see, for instance, that the UPS has been operating at a comfortable margin for months, but a recent process change has steadily increased the load. If you project that trend forward, it might cross your design threshold within a few weeks. That information, visible in SCADA charts, informs whether you adjust load distribution or plan a UPS upgrade before the margin erodes.

Second, how do you quickly locate the root cause of nuisance breaker trips? SCADAŌĆÖs historian, as described by Fidelis Security and Pacific Blue Engineering, stores time-stamped data. When a breaker trips, you can go back to the moment of the trip and inspect current, voltage, UPS state, and environmental parameters. If the data shows a simultaneous voltage sag on the utility feeder and a heavy inrush on a downstream motor, you have a plausible explanation. If instead you find no unusual load and no external disturbance, you might suspect a faulty breaker or relay and schedule focused testing.

A SCADA parts distributor participates in this example at every stage. The distributor supplies the PLCs and I/O modules with enough channels and isolation ratings for your feeders, the industrial PC with sufficient computing power and environmental resilience to run SCADA software in the electrical room, HMIs with suitable ingress protection for local panels, and appropriate communication gear such as industrial Ethernet switches and protocol gateways for the UPS. Guided by lessons described by Maple Systems, NexGen, and Shoplogix, the distributor can help you standardize on one SCADA software platform and a coherent set of hardware to simplify long-term maintenance.

A few questions come up repeatedly when power engineers and facility managers start working with SCADA system parts distributors for UPS and protection projects.

One common question is whether SCADA is really necessary for smaller facilities that already have intelligent UPS and switchgear. Industry references from Eleks, eLynx, and NexGen emphasize that SCADAŌĆÖs value lies in centralizing control and turning scattered device data into actionable insight. Even if each UPS or breaker has its own display, you gain faster troubleshooting, better trend visibility, and improved maintenance planning when those data points are aggregated in one supervisory system. For any facility where downtime has a significant cost, that central view quickly justifies itself.

Another frequent question concerns the difference between PLCs and RTUs in power applications. Cedalo, SolisPLC, and Pacific Blue Engineering agree that PLCs are typically used in dense, local control scenarios with rich logic, such as factory floors or main switchgear rooms, while RTUs focus on reliable data gathering and basic control at remote sites. In practice, modern devices blur the line, and many products can perform either role. When you select parts through a distributor, think in terms of environment and function: use rugged RTUs with strong communication capabilities for remote yards several miles away, and PLC-based systems where you need complex interlocking and fast local decision-making.

A third question is how to future-proof SCADA investments as power systems become more digitized. Sources such as Cedalo, Inductive Automation, Shoplogix, Peakboard, and Unmudl all point toward open, standards-based architectures, integration with analytics and enterprise systems, and scalable licensing models. In concrete terms, that means favoring SCADA platforms that speak standard protocols, can integrate with SQL databases and web technologies, and can grow to accommodate additional sites or devices without exploding licensing costs. On the parts side, it means choosing controllers, HMIs, and industrial PCs with enough headroom in processing power and communications to handle additional tags and network traffic over the coming years.

Reliable power protection is not just about buying a bigger UPS or adding another generator. It is about visibility, coordination, and informed action. SCADA is the supervisory layer that delivers those capabilities, and the components that make it up are as critical as any transformer or breaker in your one-line. When you treat your SCADA system parts distributor as a technical partner, ground your architecture in proven patterns from the SCADA community, and align your choices with security and reliability best practices, you build a power infrastructure that not only stays online, but does so with confidence and control.

Leave Your Comment