-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

When you design or upgrade a power-critical facility, the Allen-Bradley 1756 ControlLogix platform often sits at the center of the control and protection architecture. These controllers and communication modules orchestrate switchgear, UPS systems, static transfer switches, inverters, and protective relays while maintaining the deterministic behavior that keeps lights on and breakers closed. From a power system specialistŌĆÖs perspective, understanding the concrete specifications behind the 1756 family is not an academic exercise; it directly shapes reliability, network resilience, and how gracefully your plant rides through disturbances and utility events.

This overview walks through the key 1756 controller and communication modules using documented specifications from Industrial Automation Co., Do Supply, SolisPLC, Power Gear X, and community best-practice discussions. The focus is on how these specs translate into real decisions for industrial and commercial power systems.

ControlLogix processors are Rockwell AutomationŌĆÖs flagship programmable automation controllers for complex automation, as summarized by Power Gear X. They combine traditional PLC-style deterministic control with advanced networking, modular I/O, and support for integrated motion and safety. In power generation, water and wastewater, and manufacturing plants that depend on stable power, this means a single controller platform can manage feeder automation, generator controls, load shedding, and critical process interlocks.

In practice, the engineering questions are straightforward but unforgiving. You need to know whether a given controller can handle the I/O count of a substation plus plant loads, whether an Ethernet module can support all SCADA, HMI, and drive connections with margin, how much heat each module adds to a crowded panel, and how lifecycle status might affect long-term spares planning. The following sections break these issues down around actual catalog numbers: legacy processors such as 1756-L1 and high-performance models such as 1756-L61, together with Ethernet modules like 1756-EN2TR and the ENBT/EN2T/EN3T family.

At the platform level, Power Gear X describes ControlLogix processors as modular, chassis-based PACs in Rockwell AutomationŌĆÖs Logix family. A typical system includes a chassis, one or more controllers, communication modules, and I/O modules, all linked over a backplane. Controllers execute IEC 61131 style languages such as Ladder Diagram, Function Block Diagram, Sequential Function Chart, and Statement List, as highlighted by Do Supply for the 1756-L1. Communication modules bridge this backplane to EtherNet/IP, ControlNet, DeviceNet, and older networks, while I/O modules interface to field devices.

Do Supply notes that a 1756-L1 installs in a single slot of chassis such as the 1756-A4, 1756-A7, 1756-A10, 1756-A13, and 1756-A17. That range of chassis part numbers reflects a spectrum from compact to large backplanes. Community guidance summarized from PLCTalk discussions reinforces that designers often choose from chassis that roughly range from four to seventeen slots, grouping controllers, communication modules, and I/O logically by function. In power system work, this usually translates to a local chassis near switchgear with the main controller, Ethernet interfaces, and the highest-priority hardwired I/O, complemented by remote I/O racks closer to distributed loads.

The Allen-Bradley 1756-L1 is a ControlLogix 5550 processor aimed at medium-scale control applications, according to Do Supply. It is very much a legacy platform today, but it still appears in older power plants, substations, and combined process-and-utility panels that you may be asked to maintain rather than fully replace.

From a capacity standpoint, the 1756-L1 provides 64 KB of user memory and supports up to 250 simultaneous connections. That connection limit is important when you aggregate HMIs, engineering workstations, SCADA masters, and distributed I/O adapters; in a typical power application with one SCADA master, a few HMIs, several Ethernet adapters, and remote I/O networks, it is possible to approach those limits faster than the memory size might suggest.

The memory is battery-backed RAM. Do Supply notes that the base controller does not include built-in non-volatile memory, so retentive storage beyond what the battery can maintain requires a dedicated non-volatile memory module. Only specific modulesŌĆö1756-M1, 1756-M2, and 1756-M3ŌĆöare compatible. Using the wrong memory module is not a benign mistake; it can cause controller failure. In a power-critical context, that is the difference between a clean restart and an unplanned outage, so part-number discipline in the panel and in the spares cabinet is essential.

Communication flexibility is one of the reasons older 1756-L1 systems remain in service. Do Supply explains that the controller supports DeviceNet, RS-232-C with DF1 or DH-485 protocols, ControlNet, DH+, and EtherNet/IP, with the integrated RS-232 port providing a direct interface for programming terminals, HMIs, and SCADA systems. The wide network support often allowed original designers to bridge older substations and switchgear into newer architectures without replacing all legacy devices at once.

Physically, the 1756-L1 is compact and lightweight, with a listed weight of about 0.28 kg, which corresponds to roughly 0.62 lb. It draws peak backplane currents of approximately 0.65 A at 5 V DC and 0.02 A at 24 V DC and dissipates about 3.3 W of power, which equates to around 11.3 BTU per hour of heat. Environmental ratings include an operating temperature from 32 to 140┬░F, a storage range from about ŌłÆ40 to 185┬░F, relative humidity from 5 to 95 percent non-condensing, shock tolerance of 30 G operating and 50 G in storage for short durations, and vibration resistance from 10 to 500 Hz up to 2 G. Those numbers are adequate for a well-ventilated control room or MCC lineup, but they should still be accounted for when you put several processors and Ethernet modules together in a tight enclosure.

One detail that power system engineers sometimes overlook is the battery specification. The 1756-L1 uses a 1756-BA1 lithium battery, with Do Supply noting a battery mass of about 0.59 g, roughly 0.02 oz. Using only the specified battery type is important not just for RAM retention but also to preserve the safety approvals that many critical facilities rely on for compliance.

A typical real-world scenario might involve a 1756-L1 supervising a medium-voltage substation with stand-alone I/O and a few networked protective relays. With 64 KB of memory and 250 connections, the controller can easily handle breaker control logic, basic load shedding, and SCADA communications. However, as the plant adds more networked meters, event recorders, and arc-flash detection devices, the connection count may creep toward the limit. At that point, knowing the 250-connection ceiling becomes the basis for a risk discussion: either offload tasks to a second controller or plan a migration to a newer processor family.

The Allen-Bradley 1756-L61 is a much more capable ControlLogix PAC and has been widely deployed in demanding industrial applications. Industrial Automation Co. describes it as a high-performance controller designed for complex, high-speed machinery and large networking applications, with extensive use in automotive, pharmaceutical, food and beverage, and general manufacturing. In many power plants and large commercial facilities, L61-class controllers have also been used to centralize both process and power system logic.

From a capacity standpoint, the difference from the 1756-L1 is stark. Industrial Automation Co. notes that the 1756-L61 supports up to 128,000 total I/O points and up to 4,000 analog I/O points. That scale allows a single controller to integrate extensive sensor and actuator networks, including numerous analog points for temperature, pressure, flow, and electrical measurements, without fragmenting the control strategy across multiple controllers unless you intentionally choose to for redundancy.

The memory architecture is also more generous. The 1756-L61 offers fixed controller memory options of 2, 4, or 8 MB, with 2 MB of user memory highlighted in the Industrial Automation Co. summary. Unlike the battery-only approach of the 1756-L1, non-volatile storage is handled using CompactFlash cards such as the 1784-CF128, so programs and critical data persist through power loss. That is particularly important in power system applications that expect full recovery after momentary utility outages or UPS transfers.

Performance-wise, the 1756-L61 offers very fast processing with a scan time around 0.08 ms, according to Industrial Automation Co. For protection and interlocking logic, this means you can reliably handle tight time constraints, such as sequencing interlocks between breakers, monitoring transformer differential or bus differential logic, and coordinating with fast digital I/O modules. As a simple illustration, if your protection routine runs in the primary continuous task, the controller can, in principle, evaluate protection logic thousands of times per second; that can be the difference between a nuisance trip and a properly discriminated response during a fault.

The tasking model is another strength. The same source notes that the 1756-L61 can handle up to 32 tasks, each supporting up to 100 programs. Practically, this allows you to dedicate separate tasks to power protection, normal process control, and auxiliary monitoring, each with appropriate priority and scan rates. In a combined power-and-process plant, you might run a high-priority task focused solely on bus and feeder interlocks while running slower tasks for utility reporting and historian integration.

Mechanically, the 1756-L61 remains compact, with a listed mass of about 0.32 kg, or roughly 0.71 lb. Environmental ratings match what you expect from the platform: operation from about 32 to 140┬░F, relative humidity from 5 to 95 percent, and vibration tolerance from 10 to 500 Hz. An integrated RS-232 serial port supports programming, monitoring, and networking, and the controller interfaces cleanly with the wider ControlLogix communication ecosystem and the Studio 5000 or RSLogix 5000 software suite.

One important caveat is lifecycle status. Industrial Automation Co. notes that the 1756-L61 was discontinued with its lifecycle ending June 1, 2017, even though many systems remain in service. For a power-critical facility, that means new greenfield designs are better served by newer controller families, but the 1756-L61 remains entirely appropriate for sustaining and expanding existing ControlLogix installations, provided you plan spares carefully and confirm environmental and I/O needs against the 128,000-point and 4,000-analog limits.

A practical example comes from a high-speed production line backed by a central utility substation. A 1756-L61 can manage line control, drive coordination, and motion control while also coordinating breaker control and load shedding through fast digital I/O and analog monitoring of bus voltages and currents. The combination of large I/O capacity, sub-millisecond scan times, and multi-tasking means you can integrate power and process functions in one controller while still giving the most critical protective logic top priority.

For quick reference, the following table aligns some of the most relevant specifications of the 1756-L1 and 1756-L61 based on Do Supply and Industrial Automation Co. summaries.

| Specification | 1756-L1 ControlLogix 5550 | 1756-L61 ControlLogix PAC |

|---|---|---|

| User memory | 64 KB | 2, 4, or 8 MB (2 MB user memory highlighted) |

| Max total I/O points | Not specified in Do Supply summary | Up to 128,000 total I/O points |

| Max analog I/O points | Not specified | Up to 4,000 analog I/O points |

| Max simultaneous connections | Up to 250 | Not specified in Industrial Automation Co. summary |

| Scan performance | Not specified | Approximate scan time 0.08 ms |

| Non-volatile storage | Optional memory module (1756-M1/M2/M3 only) | CompactFlash card (e.g., 1784-CF128) |

| Communication interfaces | RS-232; supports DeviceNet, ControlNet, etc. | RS-232; integrates with broader ControlLogix ecosystem |

| Typical power dissipation | About 3.3 W (Ōēł11.3 BTU/hr) | Not specified |

| Approximate module weight | About 0.62 lb | About 0.71 lb |

| Operating temperature | 32 to 140┬░F | 32 to 140┬░F |

| Lifecycle status | Legacy, still in service | Discontinued June 1, 2017, still widely installed |

From a power system reliability viewpoint, the table illustrates the main decisions. The 1756-L1 is suitable when you inherit a legacy panel with moderate I/O counts and need basic integration. The 1756-L61 is better suited to large plants where a single controller must handle tens of thousands of I/O points and execute high-speed protection and coordination logic. Lifecycle status and future expan┬Łsion often drive whether you maintain and harden what you have or plan a phased migration to newer Logix families.

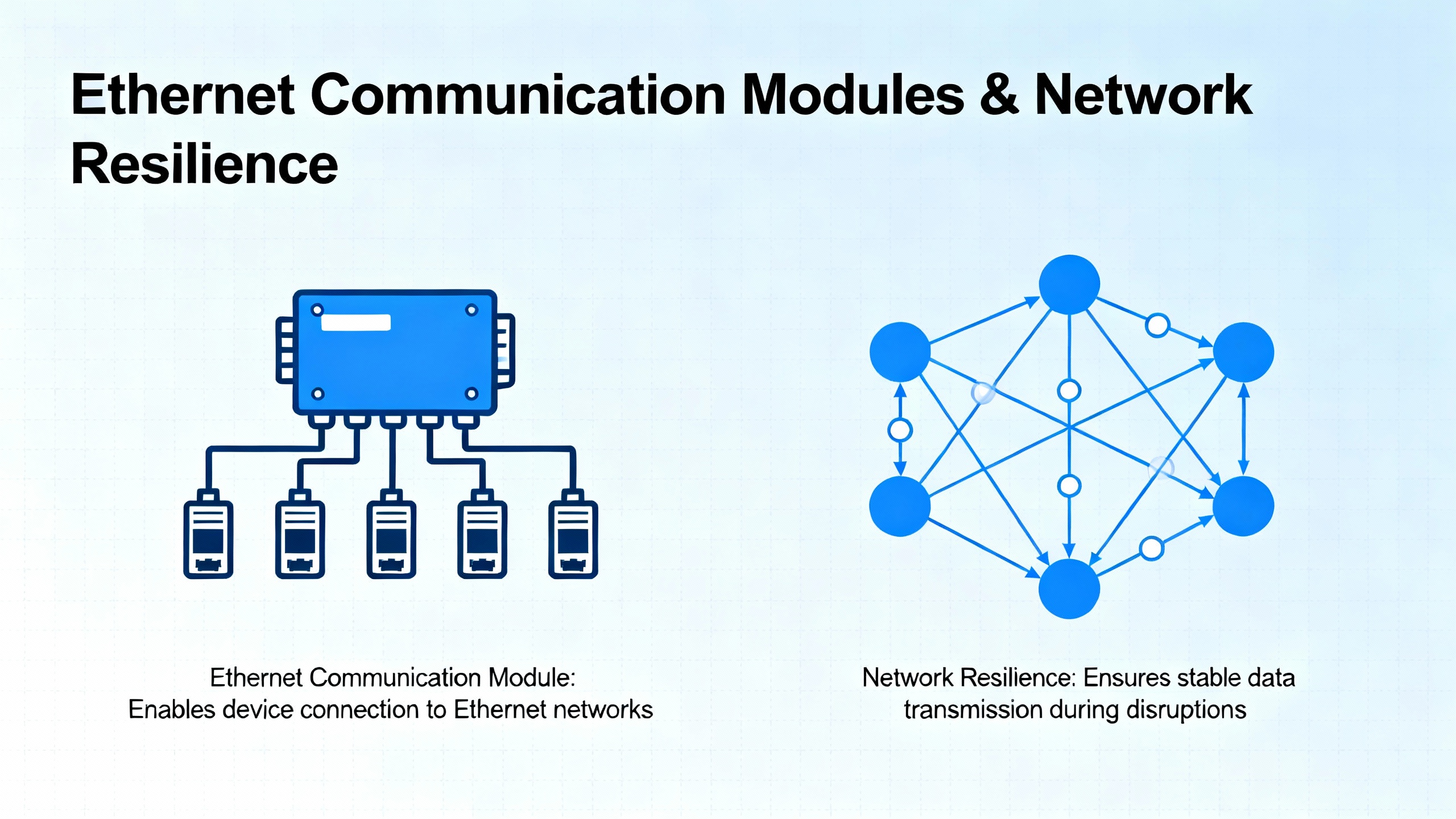

The Allen-Bradley 1756-EN2TR is a chassis-mounted EtherNet/IP communication module designed to bridge controllers, I/O, and Ethernet networks, as detailed by Industrial Automation Co. It occupies a single slot in the ControlLogix chassis and provides two copper RJ45 ports with an embedded switch. In power-critical applications, this module often forms the backbone of communication between the main controller, intelligent electronic devices, and SCADA systems.

A key attribute of the 1756-EN2TR is its compliance with CIP Safety standards. Industrial Automation Co. notes that it can simultaneously handle safety data, standard control traffic, and diagnostic information. This makes it suitable for safety-critical automation systems where power system protection and machine safety interact, such as generator switchgear with safety-rated interlocks.

From a networking standpoint, the module supports dual-port EtherNet/IP at speeds of 10 or 100 Mbps, can handle 128 TCP/IP connections and 256 total connections, and supports up to eight motion axes. It also supports ring and star topologies and high-availability features such as Device Level Ring (DLR) networks and compatibility with Parallel Redundancy Protocol (PRP). For power system engineers, DLR and PRP capabilities are especially important because they provide network paths that remain available even if a segment fails or a switch loses power during a disturbance.

On the electrical side, the 1756-EN2TR draws about 1 A at 5 V and roughly 3 mA at 24 V from the backplane, with a current draw around 1.2 A overall. Power consumption is listed at about 5.1 W, and thermal dissipation is around 17 to 21 BTU per hour. Operating temperature covers approximately 32 to 140┬░F, and the module carries a continuous insulation voltage rating of 30 V. For a practical calculation, if you have two EN2TR modules and one 1756-L1 in a chassis, the L1 dissipates about 11.3 BTU per hour and the two EN2TR modules together add roughly 34 to 42 BTU per hour, yielding on the order of 45 to just over 50 BTU per hour total. If this chassis is in a sealed compartment near a transformer room, that heat load must be factored into panel ventilation or HVAC sizing.

Industrial Automation Co. notes that integration and compatibility are broad. The 1756-EN2TR works within ControlLogix systems and with remote devices like CompactLogix controllers, FLEX I/O, and POINT I/O, and it also interoperates with other Allen-Bradley controllers such as PLC-5, MicroLogix, and SLC 500 via EtherNet/IP gateways. It is equally at home with third-party devices, SCADA systems, HMIs, converters, and gateways, which is exactly what you want when tying together protective relays, metering systems, and utility interfaces that may not all come from the same vendor.

Initial IP addressing can be handled with the Allen-Bradley BOOTP-DHCP tool by mapping the moduleŌĆÖs MAC address to an IP address, followed by configuration in RSLogix 5000 or Studio 5000 Logix Designer. Security features like electronic keying and explicitly secured mode help ensure only authorized hardware and firmware combinations join your system, an important layer in modern power system cybersecurity frameworks.

A concrete example is a medium-voltage switchgear line-up with two 1756-EN2TR modules forming dual rings: one ring for protection and breaker control I/O, and a second for metering and non-critical diagnostics. With 128 TCP/IP connections and 256 total connections, you can allocate connections to protective relays, breaker control modules, UPS status interfaces, and plant SCADA, while still retaining margin for future devices. The DLR and PRP features help ensure that even if a switch fails or a UPS transfer glitches a network segment, communication continuity is maintained.

The broader EtherNet/IP module family also matters when you maintain or upgrade existing ControlLogix systems. SolisPLC provides a detailed tutorial on configuring EtherNet/IP communication to a ControlLogix PLC using modules like the 1756-ENBT. Within that family, the article describes the general order from newest to oldest modules as 1756-EN3T(R), 1756-EN2T(R), 1756-ENET, and 1756-ENBT, while noting that newer 1756-L8x CPUs now incorporate built-in Ethernet ports.

The 1756-ENBT is an older EtherNet/IP adapter that has since been discontinued. SolisPLC cites Rockwell AutomationŌĆÖs notice that the 1756-ENBT was officially discontinued on December 31, 2021, with the 1756-EN2T recommended as its replacement. Both ENBT and EN2T support network speeds from 10 to 100 Mbps, and the ENBT supports up to 128 CIP connections according to its official specification, as summarized by SolisPLC. The EN2T remains a single-slot EtherNet/IP adapter with one RJ45 port, while the EN2TR variant adds a second port plus redundancy and larger-topology features, as Industrial Automation Co. describes for the EN2TR.

From a migration standpoint, this means that when you encounter an older panel with 1756-ENBT modules, you should plan for replacement with EN2T or EN2TR modules when you expand or refurbish the system. The connection and throughput specs are similar, but the EN2T and EN2TR give you a more current platform and better long-term support. For example, if your existing power management system uses an ENBT card near its 128 CIP connection limit due to SCADA masters, HMIs, drives, and I/O adapters, a direct swap to EN2T maintains capacity while giving you a platform that remains in active support.

SolisPLC also emphasizes practical configuration details. Rotary switches on the top of a 1756-ENBT allow quick IP assignment: a value from 1 to 254 forces the moduleŌĆÖs IP to 192.168.1.xxx, where xxx matches the switch value. Setting the switches to 888 and cycling power performs a factory reset, re-enabling BOOTP. This is particularly useful in a maintenance scenario where you need to replace a failed card and restore its IP settings without deep access to engineering tools, but you must follow the recommended power-down and power-up sequence.

The mechanics of assigning IP addresses and securing network modules are not glamorous, but they are essential for reliable power control. SolisPLC describes how, with BOOTP enabled, a 1756-ENBT waits for an IP address from a BOOTP utility. The user connects via Ethernet, launches BOOTP, identifies the module by its MAC address, and assigns the desired IP. Best practices include setting the PCŌĆÖs Ethernet adapter to use a dynamic IP for more reliable device discovery, connecting to only one BOOTP-capable device at a time to avoid mis-assignments, and carefully matching the deviceŌĆÖs MAC address with its physical label.

Once the IP is set, RSLinx is used to create an EtherNet/IP driver, ensuring the PC is on the same subnet as the module. Newer EtherNet/IP modules that include a USB port allow users to bypass BOOTP entirely by connecting directly over USB, installing the RSLinx USB driver, and setting network parameters directly from the device properties. Industrial Automation Co. confirms that the 1756-EN2TR has a USB 1.1 port, which supports this more streamlined approach.

Security overlays these technical steps. Industrial Automation Co. notes that modules like the EN2TR support electronic keying and a secured mode to enforce correct firmware and hardware combinations. From a power reliability standpoint, that protects you from accidental mis-matches during maintenance. From a cybersecurity standpoint, it reduces the chances that an unapproved device or firmware variant participates in critical control networks.

In a typical modernization project, you might replace multiple ENBT modules with EN2TRs in a ring connected to protective relays and smart switchgear. You would use BOOTP for initial addressing, verify communication in RSLinx and Studio 5000, and then enable electronic keying and secured mode once the system is stable. Throughout, you would track CIP and TCP/IP connection usage to ensure the new configuration remains comfortably within each moduleŌĆÖs spec, especially when adding additional HMIs or historian links for power-quality analytics.

While-controller and network module specifications define what your system can do logically, environmental and power specs determine whether it can do so reliably under real-world conditions.

Across the controllers and modules discussed here, operating temperature ranges typically span 32 to 140┬░F. The 1756-L1 and 1756-L61 both fall in that range, and the 1756-EN2TR shares the same operating span. Relative humidity specifications commonly specify 5 to 95 percent non-condensing for controllers like the 1756-L1 and L61. Shock and vibration ratings, such as the 30 G operating shock and vibration from 10 to 500 Hz up to 2 G for the 1756-L1, are adequate for most switchgear rooms and control centers, provided the panels are mounted according to Rockwell AutomationŌĆÖs guidelines.

Power and thermal characteristics require a bit more attention in dense panels. The 1756-L1 dissipates about 3.3 W, corresponding to roughly 11.3 BTU per hour, while the 1756-EN2TR dissipates about 5.1 W or 17 to 21 BTU per hour. When you place several communication modules and high-density I/O cards in a single chassis, the total BTU per hour can add up quickly. For example, three EN2TR modules and one L61 could easily exceed 70 BTU per hour of heat, and that is before you account for I/O modules and power supplies. Even though the absolute numbers are not huge, in sealed cabinets or enclosed UPS rooms they can push internal temperatures toward the upper end of the 140┬░F limit unless proper ventilation or cooling is provided.

Backplane current consumption drives power supply sizing. Industrial Automation Co. lists backplane requirements for the 1756-EN2TR at about 1 A at 5 V and 3 mA at 24 V. Do Supply lists 0.65 A at 5 V and 0.02 A at 24 V for the 1756-L1. Summing these values across all modules in a chassis provides a first-pass estimate of the required power supply rating. The installation guidance from Industrial Automation Co.ŌĆÖs step-by-step ControlLogix controller article emphasizes the importance of installing a power supply rated for the total load of all modules and grounding it according to RockwellŌĆÖs wiring and grounding guidelines. In practice, this means you should calculate both steady-state and worst-case load, include a margin, and verify that the selected 1756 power supply can deliver the required current without excessive derating at the ambient temperature your panel will see.

Mechanical robustness also matters. The relatively low weights of controllers like the 1756-L1 at around 0.62 lb and the 1756-L61 near 0.71 lb make them easy to handle, but you still need to respect ESD precautions during installation. Industrial Automation Co.ŌĆÖs guidance on installing ControlLogix controllers calls for securely mounting the chassis in the cabinet to protect against vibration and environmental damage, installing the power supply first, and then inserting the controller carefully, typically in slot zero, until it clicks firmly into place. In power system projects where cabinets may see more vibration due to proximity to transformers or large motors, these seemingly routine steps form the foundation for long-term reliability.

Specifications for memory, scan time, and network connections only pay off if your data access patterns between controllers and SCADA or HMI systems are efficient. This is where community best practices, such as those captured in an Ignition and Logix discussion on the Inductive Automation forum, become highly relevant.

The forum thread explains that directly reading many members from a PIDE (PID Enhanced) instruction data block in Logix is usually inefficient for Ignition, because each PIDE element becomes its own read operation. In contrast, when you expose critical values via a structured tag or user-defined type, the SCADA system can perform optimized block reads. For day-to-day operation, the most critical values tend to be the process variable, setpoint, and output, which are often already exposed as separate tags outside the PIDE instruction.

The recommendation from that discussion is to configure Ignition to read and write external PV, SP, and output tags instead of binding directly to PIDE members wherever possible. This approach improves communication efficiency and keeps PLC logic simpler for future maintainers. Less frequently used configuration parameters, such as gains and deadband values, do not need fast continuous updates and can be placed in leased tag groups so they are read slowly when no HMI screens are open and faster only when a related view is active.

There are caveats. The forum notes that leased tag groups can take up to about eight seconds to switch scan rates, and if many such tags live on a single device connection, the transition can cause noticeable delays when an operator opens a configuration screen. One mitigation is to enable ŌĆ£read after writeŌĆØ on the tag group so that changed configuration values are read back immediately, though this adds additional traffic. A more structured solution is to create a dedicated add-on instruction or parameterized subroutine in the PLC that bridges between Ignition and each PIDE. In this pattern, you define a compact user-defined type in Ignition with only the required fields, and a subroutine copies data between that structure and the PIDE elements. Ignition then reads and writes the UDT instance only, gaining the benefits of block-optimized reads while encapsulating the PIDE implementation.

In a power system context, imagine you manage multiple PIDE loops for bus voltage regulation or generator excitation through a 1756-L61. If your SCADA system naively polls dozens of individual PIDE members at high speed over a 1756-EN2TR, you could quickly consume connection bandwidth and introduce latency just when you need deterministic behavior during disturbances. By exposing only PV, SP, and output tags for continuous polling and placing less critical parameters in leased tag groups or bridge UDTs, you preserve bandwidth and reduce the risk of communication bottlenecks. These practices do not change the underlying specs of the 1756 hardware, but they allow you to exploit those specs more effectively.

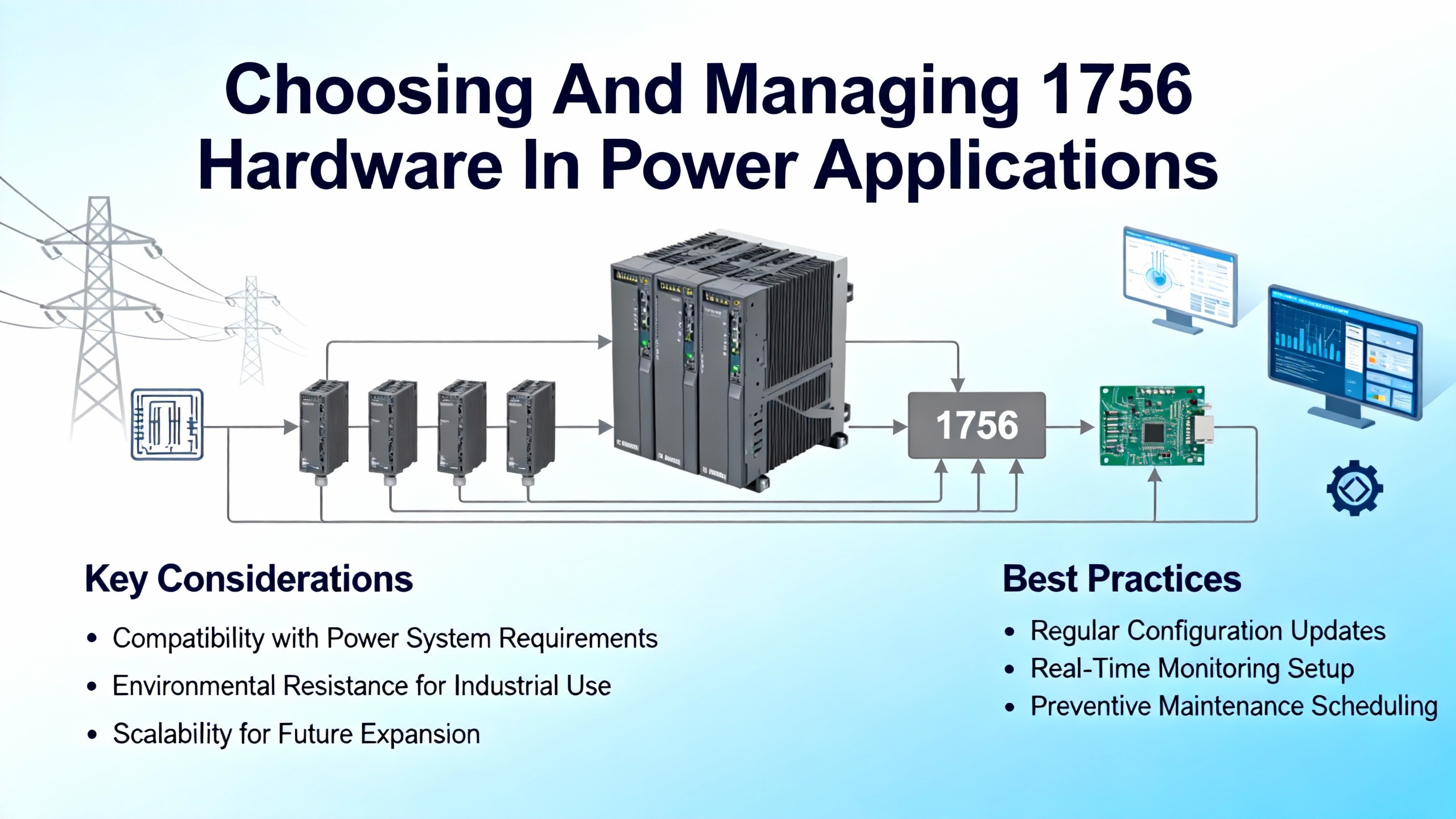

Bringing these specifications together, the selection and management of 1756 hardware in power applications becomes a set of practical trade-offs rather than abstract numbers.

Power Gear X encourages engineers to size ControlLogix processors based on CPU performance, available memory, required I/O capacity, network connections, and redundancy or safety requirements. For a new medium-size facility where power automation is important but not enormous, you might lean toward newer CompactLogix platforms, as SolisPLC notes that ControlLogix generally offers higher I/O capacity and cost, and that CompactLogix is often preferred unless high I/O counts, higher CPU performance, or many servo axes are required. However, if you are dealing with a large plantŌĆömultiple substations, extensive metering, integrated load shedding, and tight interaction with process controlsŌĆöthe I/O and tasking capacity of a 1756-L61-class or newer ControlLogix controller becomes compelling.

Lifecycle awareness is central. Industrial Automation Co. highlights that the 1756-L61 is discontinued, while SolisPLC notes that the 1756-ENBT network module has been discontinued with the 1756-EN2T recommended as a replacement. In a power-critical facility, that means you should avoid building new systems around discontinued parts, but you must understand and respect their specifications where they are already deployed. That includes stocking certified refurbished components where necessary, as Industrial Automation Co. offers for some modules, and explicitly planning migration paths for both controllers and network modules.

Redundancy strategies should align with both controller and network capabilities. Industrial Automation Co. notes that multiple 1756-L61 controllers can operate independently in the same chassis, supporting scalable and redundant architectures, and that the 1756-EN2TR supports Device Level Ring and PRP. For power systems, this could mean running separate controllers for protection and for non-critical automation in the same chassis, or designing ring architectures where a single switch failure does not isolate protective relays from the main controller. While the specifics of redundancy implementation depend on Rockwell AutomationŌĆÖs detailed guidelines, the core point is that the underlying specifications enable architectures where no single hardware failure forces a loss of visibility or control.

The commissioning guidance from Industrial Automation Co.ŌĆÖs ControlLogix installation article rounds out the picture. After mounting the chassis and installing a correctly sized power supply, the controller is typically inserted into slot zero, respecting ESD precautions. Commissioning involves applying power, checking status LEDs such as RUN and OK for normal states, and going online in Studio 5000 to verify communication with all I/O modules and networked devices. In a beverage plant example, the article describes installing a 1756-L75 in a 10-slot chassis, connecting it via Ethernet to the plant network and to an HMI, and then configuring and testing communications to support increased production with minimal downtime. The same disciplined commissioning approach, translated to power-centric equipment, is what keeps your UPS, switchgear, and process running through system changes.

Industrial Automation Co. clearly notes that the 1756-L61 reached its end of lifecycle on June 1, 2017. While it remains technically capable with up to 128,000 I/O points, fast scan times, and robust environmental ratings, it is best suited for sustaining and expanding existing ControlLogix installations rather than new greenfield designs. For new power projects, it is generally wiser to select current-generation Logix controllers that offer similar or better specifications with longer support horizons, while reserving L61 units and spares for maintaining existing assets.

SolisPLC points to the 1756-EN2T as the recommended replacement for the discontinued 1756-ENBT, while Industrial Automation Co. highlights the 1756-EN2TRŌĆÖs dual-port architecture, DLR and PRP support, and CIP Safety capability. In a simple topology where you only need a single Ethernet port and are not using ring redundancy, an EN2T may suffice. In more demanding power applications where you want device-level rings, network-level redundancy, or segregation of critical and non-critical traffic across dual ports, the EN2TRŌĆÖs additional capabilities make it a better fit. The choice ultimately hinges on how much network resilience your power system design requires and how many EtherNet/IP devices you expect to support.

As a power system specialist and reliability advisor, I view the Allen-Bradley 1756 platform as a robust foundation, provided you respect its detailed specifications and lifecycle realities. When you align controller capacity, Ethernet module capabilities, environmental ratings, and data-access practices with the actual needs of your power system, you gain a control architecture that can ride through faults, feed reliable data to your operators, and scale with your facility for years to come.

Leave Your Comment