-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

When a variable frequency drive fails, you are not just troubleshooting electronics. You are staring at idle conveyors, stalled pumps, rising scrap, and a line of people waiting for you to make the right call under pressure. In many plants today, a single failed VFD can cost tens of thousands of dollars per hour in lost production, especially when supply chains are stretched and replacement parts are weeks away.

As a power system specialist focused on reliability, I see the same pattern over and over. Facilities either treat VFD failures as isolated one-off events, scrambling for whatever part they can find, or they treat drives as critical power assets and build a same-day parts and support strategy around them. The difference in downtime, safety, and cost is dramatic.

This article walks through how to think about emergency VFD parts, what actually needs to be on the shelf, how to work with same-day suppliers and repair partners, and how to reduce the chances that you will need that emergency kit in the first place. The guidance draws on field experience and on best practices documented by OEMs, integrators, and reliability organizations such as ABB, EMA, IEEE, and others.

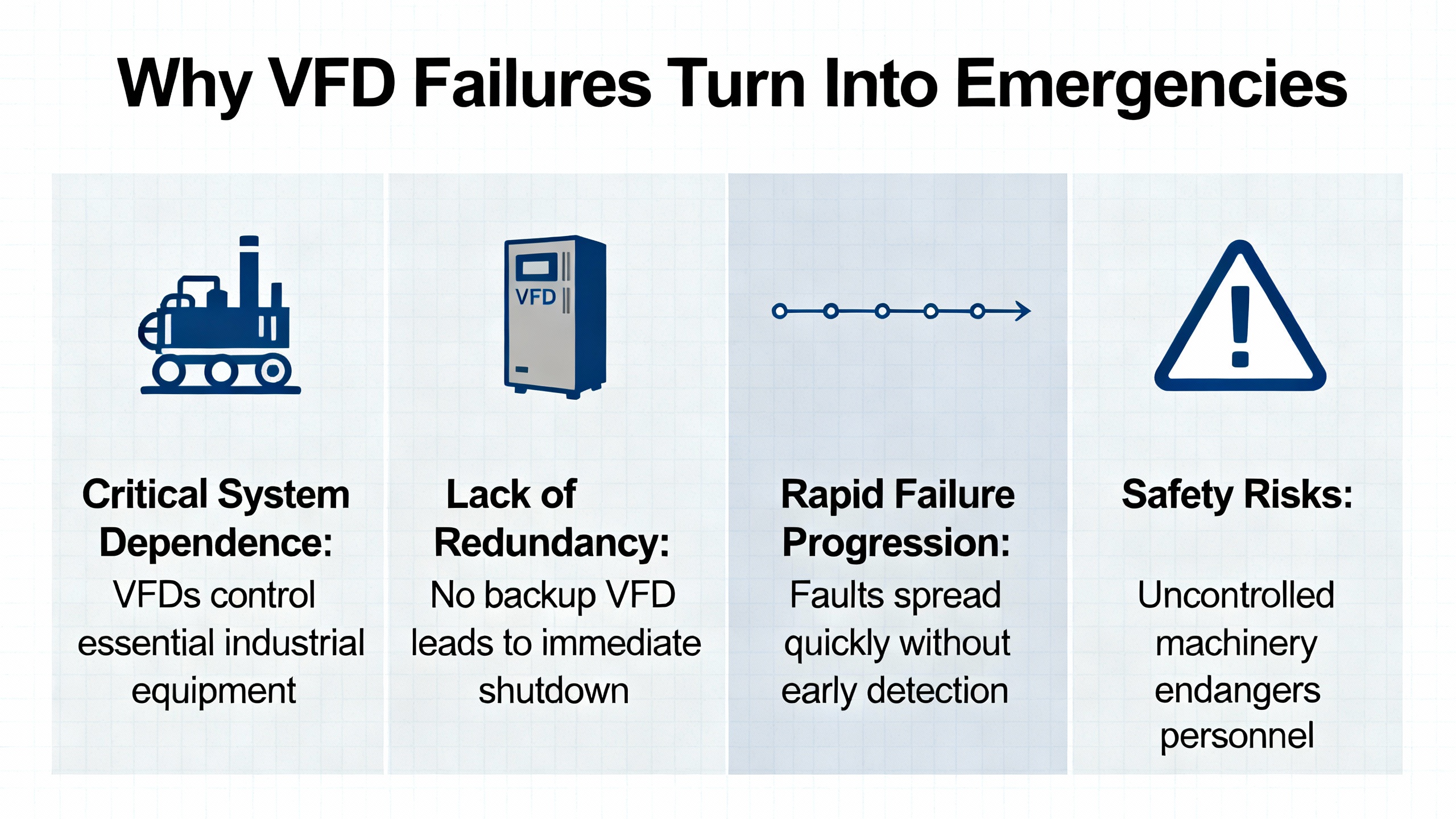

A variable frequency drive controls AC motor speed and torque by modulating output frequency and voltage. In modern plants, that means drives sit in front of critical equipment: main conveyors feeding multiple lines, chilled water pumps, fans in HVAC systems, compressors, blowers, and process pumps. When the drive stops, the motor stops, and frequently there is no easy manual bypass.

Common failure drivers are remarkably consistent across facilities. Articles from automation and repair specialists describe electrical stress from overvoltage or undervoltage events, line disturbances, and short circuits; thermal stress from poor ventilation or clogged filters; harsh environments with dust, moisture, or corrosive contaminants; and simple aging of components. Electrolytic capacitors in the DC link are especially vulnerable, with typical useful life in the range of about five to seven years depending on temperature and loading, according to field experience cited by EMA and ABB.

Symptoms of trouble are equally familiar. Drives that will not power up, repeated fault codes, nuisance trips on overcurrent or overvoltage during acceleration, erratic motor speed, or a telltale smell from overheated components all signal that the drive and its surrounding system need attention. For a 480 V-class drive, emergency repair specialists note that a healthy DC bus should sit a little above about 678 VDC; a bus that is low, highly unstable, or showing heavy ripple points toward incoming power issues or degraded bus capacitors.

The emergency is rarely ŌĆ£the driveŌĆØ alone. You are dealing with a system that includes incoming power, protection devices, the DC bus, control electronics, cooling, cables, and the motor. That is why a proper same-day parts strategy has to look beyond simply buying a spare drive and hoping for the best.

When people say they need emergency VFD parts, they usually mean one of three things. Sometimes they need a complete replacement drive they can bolt in and wire the same day. Sometimes they only need one or two high-failure parts, such as fans or capacitors, to get the existing drive safely back online. And quite often they need supporting hardware and tools: fuses, surge protection devices, braking resistors, line reactors, and test instruments.

In practice, the highest-yield emergency items are those that fail often, can be replaced quickly, and have a huge impact on uptime. These often include cooling fans, DC bus capacitors, protective fuses and breakers, surge protective devices, braking hardware, and spare drives that are parameterized and ready. Repair shops and OEMs consistently point to cooling and capacitors as consumables. Articles on VFD maintenance and emergency repair suggest cooling fans typically need replacement every three to five years in continuous service, while large electrolytic capacitors in DC links often require replacement on the order of about five years, depending on ambient temperature and ripple current.

The table below frames the most common emergency-drive-related parts and why they matter.

| Part or category | Why it fails or matters | Typical practice from field experience |

|---|---|---|

| Cooling fans | Bearing wear, dust, and heat; failed fans quickly lead to overtemperature | Replace roughly every 3ŌĆō5 years in hot or dirty environments |

| DC bus electrolytic capacitors | Aging, heat, and ripple current increase DC ripple and failure risk | Inspect annually; plan replacement around 5ŌĆō7 years of service |

| Input fuses and breakers | Surges, short circuits, nuisance trips, mechanical wear | Keep matched spares for each critical drive frame and feeder |

| Surge protection devices and MOVs | Repeated surge absorption degrades clamping capability | Stock replacements for key panels; inspect after major events |

| Braking resistors | Frequent deceleration and regenerative duty causing thermal stress | Keep at least one properly sized spare for high-inertia applications |

| Control and IGBT boards | Thermal cycling, power events, and component aging | Keep board-level spares where downtime cost is high |

| Pre-parameterized spare VFDs | Entire unit failure, obsolescence, catastrophic damage | One compatible spare per critical duty or drive family where justified |

| Test instruments | Diagnostic accuracy (true RMS, insulation tests, thermal imaging) | Maintain good DMM, clamp meter, megohmmeter, and thermal camera |

Having these items available same day can easily be the difference between a quick recovery and the start of a week-long outage. But you still have to decide in the moment whether you truly need parts or whether the issue is something you can correct with configuration or basic repair steps.

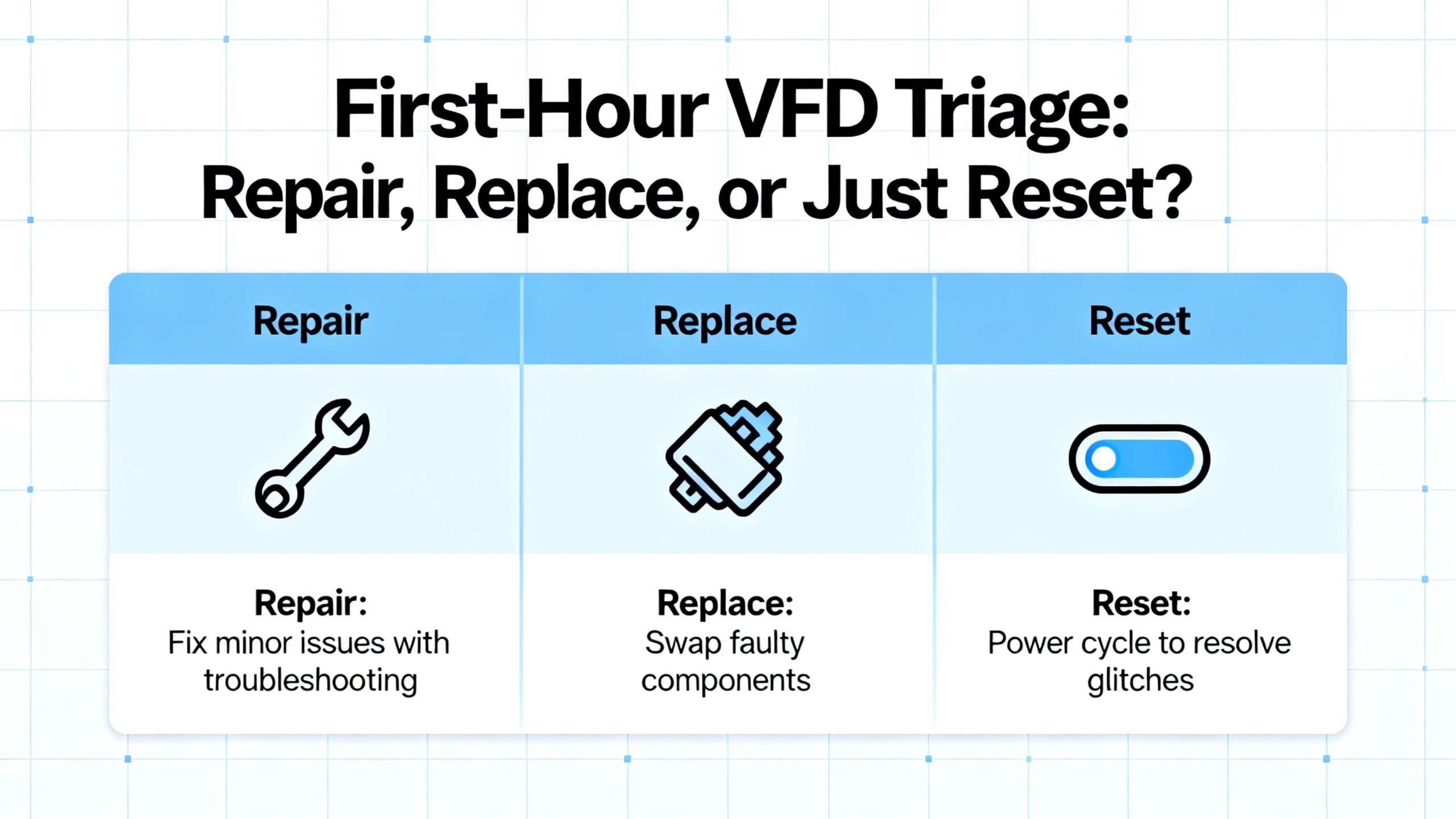

In an emergency, your first hour is the most valuable. Experienced drive technicians follow a disciplined triage sequence that often restores operation without consuming a single spare, or at least narrows the parts needed to a very short list.

The first move is to safely capture what the drive is telling you. Document fault codes and any text the keypad shows, as well as the operating point when the trip occurred. Photograph the HMI or drive keypad. Then apply lockout/tagout and open the enclosure so you can see the physical condition of the drive and its surroundings. Note cabinet temperature, dust buildup, humidity, and the presence of welders, large motors, or other heavy loads nearby that might be causing power quality problems.

Next, verify that the basics are healthy before you assume the drive itself has failed. Use a true RMS meter to confirm balanced, in-tolerance line voltage phase to phase. Check the DC bus voltage against the expected value for your input class; a low, uneven, or heavily rippled bus points you toward rectifier issues, failing capacitors, or upstream power disturbances rather than a control-board problem. Confirm that fuses and breakers are correctly sized and tight, and investigate any history of browning or flicker events.

Cooling and environment come immediately afterward. Overtemperature faults can be triggered by something as simple as clogged filters or a failed fan. Field reports show that a fifteen-dollar fan often appears to ŌĆ£killŌĆØ a drive worth thousands of dollars. Opening the cabinet and confirming that fans are running, heat sink fins are clean, and airflow is in the correct direction is one of the fastest high-value checks you can make.

If power and cooling look good, turn attention to the motor and cables. Disconnect and megger the motor according to the manufacturerŌĆÖs insulation guidelines. Inspect cables for damaged insulation, loose lugs, and overheated terminal blocks. In long-lead applications, especially with older motors, reflected-wave voltage spikes can cause overcurrent trips and stress insulation; in those cases you may need output reactors or dv/dt filters rather than a new drive.

Only then is it time to look hard at parameters and control logic. Ensure the motor full-load current, base frequency, and control mode (for example, volts-per-hertz versus sensorless vector) match the actual motor and duty. Confirm acceleration and deceleration times are realistic for the mechanical system rather than copied from a different application. Check that run, enable, and safety inputs are wired and energized as intended, and that any fieldbus communication, such as Ethernet-based protocols, is healthy and at the correct addressing.

If you reach this point and still see persistent defects, you have a much clearer choice. Evidence of bulging capacitors, burnt boards, or failed semiconductors means you need replacement parts or a spare drive. A lack of visible damage combined with repeatable faults on a specific board or function suggests a targeted board-level spare or emergency repair may be the best path. Either way, you are no longer guessing.

A true same-day VFD support plan starts long before a drive ever trips. It combines critical spare planning, smart stocking of high-impact parts, and relationships with the right suppliers and repair partners.

Critical spare planning is a structured process rather than a gut feel. Reliability specialists recommend starting by mapping your most important processes, using up-to-date one-line diagrams and, where available, arc flash studies to highlight the components through which all power or production flows. For drives, that typically means the VFDs feeding common conveyors, key pumps and compressors, main fans, and any motion that is a single point of failure.

Equipment is then classified by business impact and likelihood of failure. Drives whose loss halts high-value production or creates safety risk sit at the top. Failure likelihood rises with harsh environments, extremes of temperature, poor power quality, vibration, heavy cycling, and age. Articles on spare planning point out that, in todayŌĆÖs supply climate, lead times for new equipment can be far longer than expected, while repair for some assets may be faster, which makes on-site spares even more important.

Good spare planning also considers logistics. Large or custom medium-voltage drives may require cranes, special rigging, or oversized-load permits to move, making it difficult or impossible to rely on distant warehouses in an emergency. Many facilities mitigate this by pre-positioning VFD spares either on-site or very close by through arrangements with trusted vendors.

Finally, spares themselves require maintenance. Medium-voltage VFD guidance from EMA stresses that electrolytic capacitors stored for more than a year should be reformed before installation and that spare cells and parts should be rotated on a yearly basis so they remain ready for emergency use without extra steps. Motors need periodic shaft rotation and insulation checks, and stored drives benefit from periodic inspection, cleaning, and parameter verification.

In my experience, and backed up by multiple industry articles, there are a few categories of parts that create the most leverage in a same-day VFD strategy. The first is complete spare drives for your true Tier 1 loads. You do not need a duplicate for every small fan, but you do want a fully compatible spare for the conveyor VFD that stops the entire plant or the pump drive that feeds multiple lines. These spares do not always have to be the exact same model number; guidance from industrial automation specialists notes that a well-chosen compatible spare, with the correct voltage, current rating, enclosure, and communication options, can be swapped in quickly without major re-engineering.

The second group is consumables and high-failure components. Cooling fans, DC bus capacitors, control fuses, and power supplies show up repeatedly in failure reports. Having matched fuses and fan assemblies for your main drive families on hand, along with replacement DC capacitors for critical frames, turns many ŌĆ£drive failuresŌĆØ into short planned outages. Articles on which VFD parts need regular replacement point out that fans and large capacitors often reach the end of their reliable life after several years of service and should be on a scheduled replacement and stocking plan.

The third group is infrastructure that prevents repeat trips. Surge protection devices and MOV arrays, properly sized braking resistors for high-inertia loads, and line reactors or DC chokes are all inexpensive compared with the cost of downtime. Emergency VFD repair specialists emphasize that these components are not just nice accessories; they directly shape DC bus ripple, surge resilience, and thermal stress on the drive. Keeping one or two correctly sized line reactors and braking resistors in your emergency kit is a strategic decision, not an afterthought.

Lastly, consider the non-drive items that have a drive-sized impact on uptime. Industrial emergency-parts articles repeatedly highlight PLC CPUs, I/O modules, HMIs, and 24 VDC control power supplies as line-stopping components. Having at least one spare controller, HMI, and control power package for each major line is entirely consistent with a serious VFD emergency strategy because those elements are tightly coupled.

Even with excellent planning, situations arise where you do not have the drive, board, or accessory you need on the shelf. At that point, the partners you choose can determine whether you are down for hours or for weeks.

System integrators such as Electronic Drives and Controls have described how they evolved their project process in response to supply chain shocks. They now check parts availability at the very start of a project and design around what can actually be obtained, rather than engineering first and discovering shortages later. Their vendor-neutral stance, with experience across dozens of drive brands, lets them ŌĆ£mix and matchŌĆØ hardware from multiple manufacturers to meet deadlines, which is exactly the mindset you want in an emergency.

Third-party stocking specialists also play a crucial role. Companies focused on industrial automation spares report thousands of in-stock drives, PLCs, and HMIs, with fast same-day shipping and multi-year warranties, giving plants options when OEM channels quote lead times in weeks. Other vendors specialize in surplus, reconditioned, and refurbished VFDs. Firms such as EMSCO test and certify these drives against industry specifications, offering a lower-cost and often faster option for legacy or hard-to-find units. Choosing a reputable surplus provider combines speed with safety and sustainability by reusing reliable electrical equipment rather than scrapping it.

At the same time, there are serious risks if you treat the entire internet as a parts bin. ABB has warned that a significant fraction of industrial components in circulation are counterfeit or substandard, and has documented cases where a low-cost counterfeit control board caused catastrophic equipment damage and extended downtime that dwarfed the savings on the part. Their guidance is clear: use official distributor locators, verify that suppliers are authorized, demand serial numbers and certificates of conformity, and be suspicious of deep discounts and generic packaging.

This does not mean you must always buy new from the OEM. It does mean you should differentiate between used equipment sourced and tested by a reputable industrial supplier and parts of unknown origin from generic marketplaces. For drives where downtime costs are extremely high, ABB also recommends stocking high-failure components such as electrolytic capacitors and cooling fans and even keeping spare IGBT modules on hand, supported by consignment and lifecycle-notification programs.

For Eaton drives, aftermarket programs provide around-the-clock access to information and support through their technical centers and distributor networks, helping you identify the correct parts and arrange expedited repairs. For Schneider Electric and Modicon drives, specialized repair houses provide emergency diagnosis and firmware recovery, often with very fast turnarounds for critical production-down situations.

The point is simple. Same-day VFD parts support is not just about what you keep on your own shelves. It is about the ecosystem of authorized OEM channels, vetted surplus providers, and experienced repair partners you can call on without hesitation when something fails.

In the heat of an outage, it is tempting to assume that a failed VFD automatically needs to be replaced. In reality, there is a large gray zone where board-level repair is faster, cheaper, and more sustainable than swapping the entire unit, especially for medium-voltage or specialized drives.

Repair firms specializing in VFDs report that when physical damage is limited and parts are available, a well-maintained repaired drive can return to service with many years of remaining life. For many low- and medium-voltage units, repair can cost significantly less than a new drive. In some cases, the repair turnaround is on the order of a few business days, which, while not ŌĆ£same day,ŌĆØ may still beat the delivery time of a new unit.

For medium-voltage drives, the economic argument is even stronger. EMA cites examples where emergency service mobilization alone can approach about seventy thousand dollars before any parts or lost production are counted. In that context, investing in preventive maintenance, stocking key parts, and using qualified repair services is a highly cost-effective risk reduction strategy.

The practical rule is this. If the drive is catastrophically damaged, with burnt-through bus bars or shattered components, replacement is usually the only rational choice. If the chassis is intact, the enclosure is in good shape, and failure is limited to capacitors, fans, or individual boards, then a combination of targeted parts and professional repair is often the fastest route back to reliable operation. Many plants pair this approach with pre-parameterized spares: a repaired drive returns to the shelf as a backup while a newer model runs in service.

Same-day parts support is your last line of defense. The more you invest in reliability and preventive maintenance, the less often you will need to rely on that emergency kit.

Medium-voltage VFD guidance from EMA recommends annual preventive maintenance for critical drives. Despite differences in design, certain checks are universal. Engineers measure DC bus ripple and low-voltage supply rails to verify they remain within manufacturer tolerances. As capacitors age, ripple increases and filtering degrades, signaling that replacement is needed before a catastrophic failure occurs. Given how expensive emergency mobilization can be, catching these trends early is one of the highest-value maintenance actions you can take.

Switchgear interfaces also deserve attention. Service engineers verify readiness, open/close, and no-fault handshakes between switchgear and the VFD using control voltage while the medium-voltage feed is off. IEEE data cited in maintenance articles indicates that roughly thirty percent of electrical failures trace back to loose connections, reinforcing the importance of torque checks and mechanical inspection.

Insulation condition is assessed by megging the motor from the VFD output side, with the drive fully disconnected and isolated. For example, for a 4,160 V motor, a five kilovolt insulation test is recommended and readings significantly below about five gigohms indicate degrading insulation or moisture problems that must be corrected before a new or repaired drive is exposed to that load.

Cleaning tasks focus on removing dust and dirt without introducing moisture. At medium voltage, contamination can lead to small arcs and cumulative damage even before a visible failure occurs. Cooling paths, filters, blowers, and fans must be verified regularly; maintaining proper internal temperature has a direct impact on capacitor and semiconductor life.

Industry data summarized by IEEE shows that electrical systems not subjected to preventive maintenance are roughly three times more likely to experience failures than systems that are maintained. Given the scale of drive-related downtime in many plants, annual PM on critical VFDs is a cost-effective insurance policy, not a luxury.

Even with great maintenance, drives have finite lifecycles. Hitachi and other manufacturers describe a product life of about fifteen to twenty years, moving through active, mature, and discontinued phases. Active products carry full support and spare parts. Mature products have limited support. Discontinued units may have only refurbished or made-to-order parts available at higher cost and longer lead time.

Replacement strategies fall into two main categories. Direct replacement uses the same model, often allowing a straightforward swap with minimal engineering if the product is still active or you already have a spare in stock. Migration involves moving to a newer product family that provides equivalent or better functionality. Migration is more complex, but it brings benefits: corrected design weaknesses, improved reliability, better communication interfaces, and easier access to documentation and parts.

Retrofit mistakes tend to be painful and avoidable. Engineers sometimes size replacement drives by horsepower rather than full-load current, ignore changes in overload ratings, or assume the mechanical and cooling arrangements of a new drive will match the old. Industry guidance stresses that VFDs should be sized primarily by current, with full attention to the driven load and any derating factors, and that panel space, cable condition, and cooling clearances must be verified. A retrofit is also the ideal time to add harmonic filters, output reactors, surge protection, and other power-quality devices that protect both the new drive and the broader electrical system.

Managing obsolescence also means watching lifecycle notices from your key vendors. ABB, for example, encourages customers to subscribe to product lifecycle notifications that provide advance warning before drives or critical modules become obsolete. This gives you time to buy final-run stocks of control boards and proprietary modules that have no drop-in replacements, to plan migrations, and to adjust your emergency spare strategy accordingly.

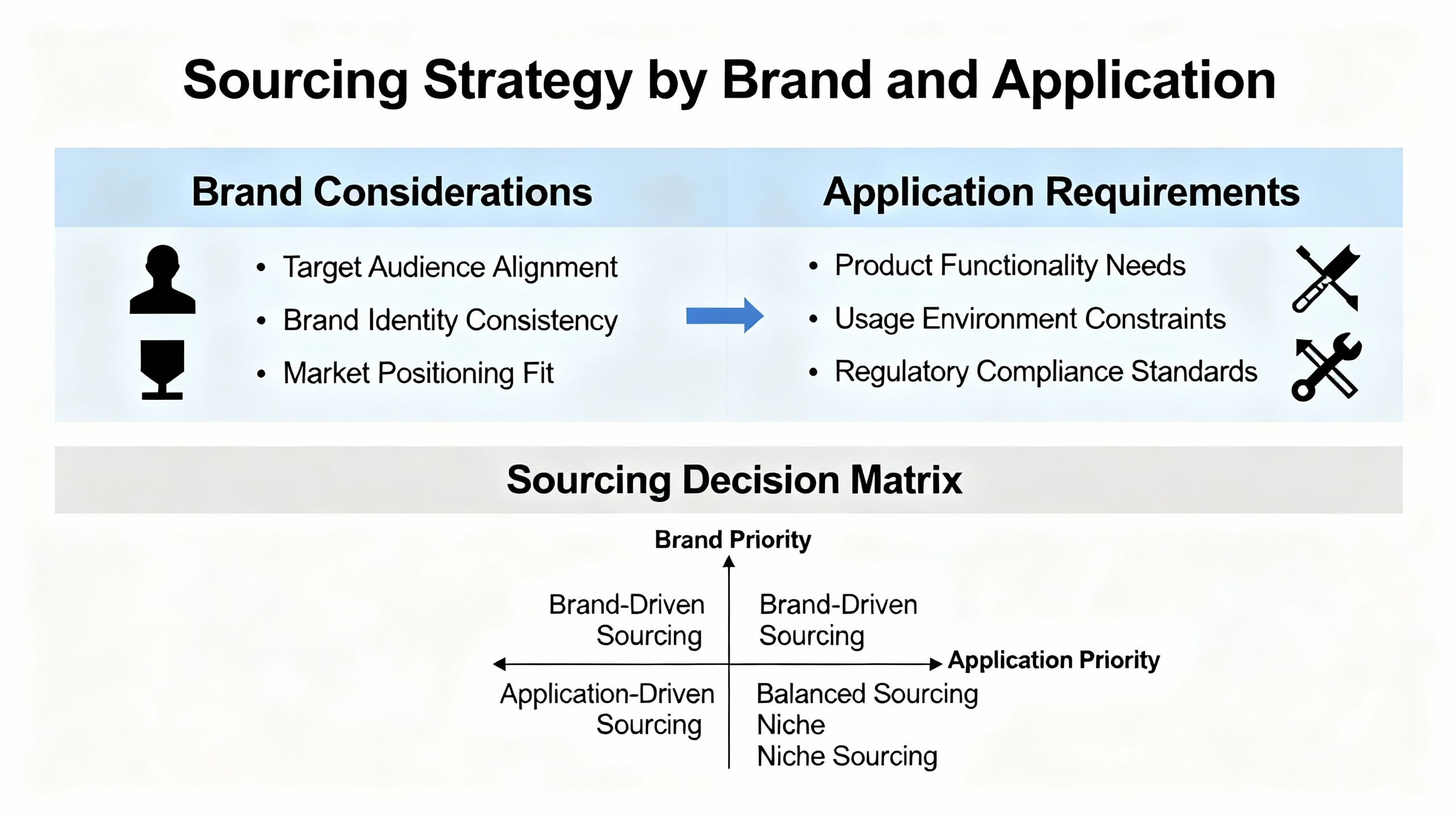

Not every drive in your facility needs to come from the same manufacturer, and not every failure requires a call to the OEM. Choosing brands and suppliers with an eye toward the application, not just price, is part of a resilient parts strategy.

A survey of major North American VFD manufacturers illustrates this point. Allen-Bradley PowerFlex drives from Rockwell Automation integrate tightly with Rockwell PLCs and are common in manufacturing, water, and process applications, but often carry a premium price. ABB drives emphasize energy efficiency, strong diagnostics, and global support, making them a natural fit for many industrial and HVAC systems where uptime and part authenticity are critical. HoneywellŌĆÖs SmartVFD line is aimed squarely at building HVAC applications for fans and pumps. Magnetek, under Columbus McKinnon, concentrates on crane, hoist, and motion-critical applications with specialized software features.

Smaller or more specialized manufacturers also have strong niches. Parker HannifinŌĆÖs drives are popular in OEM machinery and motion control. Benshaw focuses on rugged, customizable drives for harsh duty. Phase Technologies provides VFD-based phase conversion for rural and weak-grid applications.

Integrator and repair partners with a vendor-neutral philosophy, such as Electronic Drives and Controls or surplus specialists like EMSCO, help you navigate this landscape. They support multiple brands, compare capabilities and pricing, and mix components from different manufacturers when that delivers better availability or performance for your system. That vendor-neutral mindset is exactly what you want when you are staring at a down line and no easy single-brand solution.

Focus on your true single points of failure. For each, identify the motorŌĆÖs full-load current, voltage class, and overload requirements, then select a spare drive that meets or slightly exceeds those current and thermal ratings and supports the same control and communication methods. Industry guidance is clear that current rating and duty class matter more than nameplate horsepower. A single compatible spare per critical duty or per drive family is often enough to dramatically reduce risk.

That depends on the source. Surplus specialists who focus on VFDs test and certify drives to meet industry specifications and often provide warranties, making them a viable and sustainable option, especially for obsolete models. OEMs such as ABB, however, warn about counterfeit and substandard components on unvetted marketplaces and document serious failures caused by non-authenticated parts. The safest path is to work with reputable surplus providers and authorized distributors, avoid generic marketplaces for critical components, and insist on documented testing and traceability.

Field data and maintenance articles align on approximate ranges. Cooling fans typically last on the order of several years in continuous service and are often replaced in the three- to five-year window in hot or dirty cabinets. Large electrolytic capacitors in the DC link commonly require attention around five years, with some guidance suggesting useful life of roughly five to seven years depending on temperature and loading. Annual inspection, including measuring DC bus ripple and checking for swelling or leakage, lets you schedule replacements before they cause an emergency.

Reliable power and motion control are the backbone of modern production, and VFDs sit right at that intersection. If you treat drives as disposable black boxes, you will live in a world of surprise outages and frantic parts hunts. If you treat them as critical power assets, build a same-day parts and support strategy around high-yield components, cultivate vendor-neutral and OEM-authorized partners, and invest in targeted preventive maintenance, you will see fewer emergencies and shorter ones when they do occur. That is the mindset that keeps your motors turning, your operators working, and your production schedule intact.

Leave Your Comment