-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

As a power system specialist, I tend to see PLCs, UPS systems, inverters, and power protection equipment as one reliability stack. When the PLC at the top of that stack goes down, it does not matter how robust the UPS or DC bus is: you are still offline. That is why a realistic plan for Omron PLC replacement parts is as critical as transformer sizing or battery autonomy.

This article walks through how Omron PLC users can understand module availability, source replacement components, and decide when to repair, replace, or retrofit, drawing on guidance from Omron tools, Omron-focused distributors, and multiple independent automation reliability sources.

Unplanned downtime remains brutally expensive. A 2023 report from The Manufacturer put average unplanned downtime in UK factories at around ┬Ż180,000 per hour, which translates into a six-figure-per-hour problem in US dollar terms. Even if your own cost is half that, a single failed PLC power supply or I/O module can burn through the annual maintenance budget in an afternoon.

PLCs sit at the center of that risk. UpKeepŌĆÖs guidance on PLCs describes them as the industrial digital computers that monitor inputs, run logic, and drive outputs to motors, valves, and relays. When the PLC or one of its key modules fails, whole lines stop, and even a perfect UPS cannot compensate.

For Omron users, the challenge is that many installed systems mix generations. ProaxŌĆÖs overview of Omron PLCs highlights compact series such as CP1E, CP1L, CP1H, and CP2E for small and medium machines, alongside rack-based CS1 systems capable of handling up to about 5,120 local digital I/O points with multiple expansion racks. PDFSupplyŌĆÖs deep dive into the Omron 3G2 series shows that there are still many legacy systems running older modular platforms with dedicated power supplies, I/O modules, and communication units.

These platforms can run reliably for decades, but the parts that support them gradually move from ŌĆ£standard stockedŌĆØ to ŌĆ£legacyŌĆØ to ŌĆ£obsolete.ŌĆØ Industrial Automation Co and Hasuka Automation both point out that automation components in the 10ŌĆō20 year age range are common, and yet a single discontinued part can force a line to a standstill. That is why a structured approach to Omron spare parts, replacement modules, and sourcing partners is now a core element of reliability engineering.

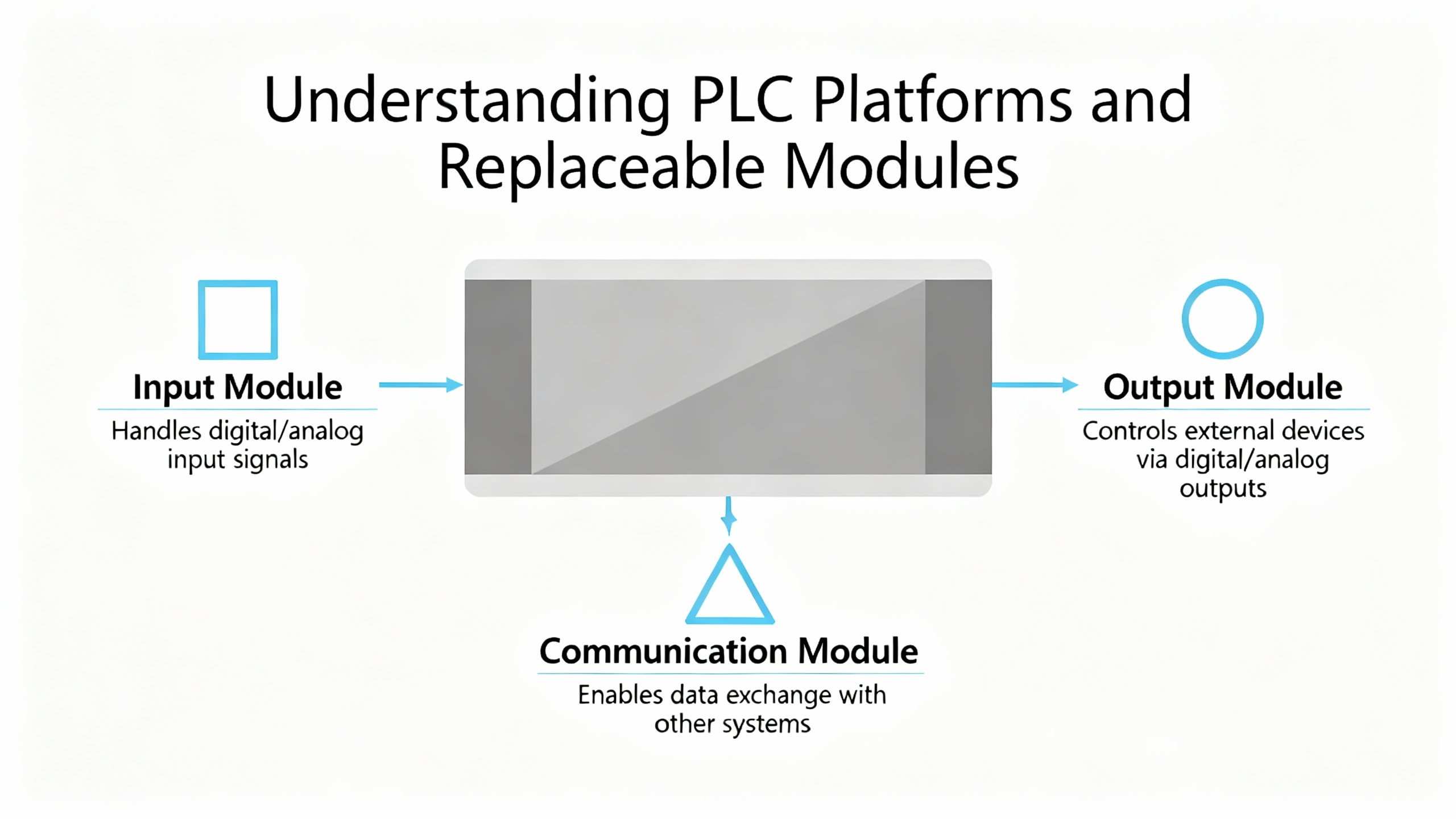

Before you can talk about replacement parts, you need a clear mental model of what is actually replaceable in an Omron PLC system. Across the series covered by Proax, PDFSupply, and other sources, a few patterns emerge.

Compact Omron PLCs such as the CP1E, CP1L, CP1H, and CP2E integrate CPU, power, and base I/O into a single package, then allow limited expansion via option boards and add-on I/O modules. For example, the CP2E adds up to two option boards and up to three expansion modules, supporting as many as 180 I/O points in small and medium machines. In practice, this means your most likely replacements are the entire CPU unit, specific expansion modules, and occasionally the power supply feeding the PLCŌĆÖs 24 VDC input.

Rack-based systems such as the CS1 family are more modular. Proax notes that a CS1 rack can host many I/O units, can be extended with up to seven expansion racks, and supports advanced motion, communication, and redundancy options. Here, you are dealing with a catalog of separate replacement items: CPU racks, expansion I/O racks, digital and analog I/O modules, communication modules, and power supplies. PDFSupplyŌĆÖs 3G2 series article shows similar modularity in an older Omron platform, with part numbers like 3G2A3-ID411 for DC input modules, 3G2A3-OC221 for relay outputs, and 3G2A3-PS221 for the 24 VDC power supply.

To ground this in practice, the table below summarizes common module types and how they show up in the Omron ecosystem, using only examples from the cited sources.

| Module type | Example Omron items or families | Typical role in the system | Availability considerations |

|---|---|---|---|

| CPU / controller | CS1 CPUs, 3G2C4-SC021 CPU rack, CP1/CP2E CPUs | Executes logic, coordinates I/O, communications, motion | Higher cost, longer lifecycle; often targeted for repair and selective upgrades |

| Power supply | 3G2A3-PS221 24 VDC supply | Feeds PLC racks and field devices at 24 VDC | High wear from heat and transients; good candidates for stocked spares |

| Digital I/O | 3G2A3-ID411 DC input modules, CS1 I/O units | Interface to switches, sensors, contactors | Multiple variants; may become obsolete while machines remain in service |

| Analog I/O | CP1H-XA analog I/O, 3G2 analog capabilities | Read process variables and drive analog outputs | Critical for process quality; fewer direct replacements as platforms age |

| Communication | 3G2A6-PR015E Host Link, 3G2A3-IF233, CS1 network cards | Connect PLCs to HMIs, SCADA, DeviceNet, PROFIBUS-DP | Vulnerable to surges; often discontinued before base CPUs |

| Expansion / option | CP2E option boards and expansion modules | Add specialized I/O or communication to compact CPUs | Platform specific; availability can constrain how long machines can be expanded |

Each of these categories behaves differently when you start hunting for spares. CPUs and power supplies are prime candidates for repair, as Industrial Automation Co emphasizes in its repair-versus-replace guidance. Communication modules and older analog I/O often move into the ŌĆ£hard-to-findŌĆØ category sooner and must be sourced via specialist obsolete-parts suppliers.

When a part is still officially supported, the most reliable way to validate replacements is through OmronŌĆÖs own ecosystem. OmronŌĆÖs Navigated Selection Tool, often referred to as ONSeT, is designed exactly for this.

According to OmronŌĆÖs description, ONSeT lets you search across thousands of part numbers with detailed filters. Its configuration features allow you to cross-reference dependencies, accessories, and spare parts for each product, so you can build a complete bill of materials rather than treating a PLC module in isolation. Critically for replacement work, the tool includes an obsolete-part function that allows you to look up replacement parts when an item has reached end of life.

In practical terms, the first step is to register for ONSeT, validate the account, and then create a proposal. You can then add your current PLC model, view related spare parts and accessories, and see which items are marked as ŌĆ£StandardŌĆØ in the catalog, indicating they are typically stocked. For plants trying to standardize spare parts across lines, this is a powerful way to move from part-by-part decisions to a structured Omron-wide approach.

OmronŌĆÖs own distributors play a parallel role. AnyPCBŌĆÖs guidance on finding reliable Omron distributors explains that ŌĆ£authorized Omron distributorsŌĆØ are vetted partners who source directly from Omron, follow the manufacturerŌĆÖs quality standards, and provide factory-backed warranties and support. Large global distributors such as Arrow Electronics, Mouser Electronics, DigiKey, Avnet, and the TrustedParts network are cited as major Omron channels.

Working through these channels has clear advantages when your PLC family is still active. You get genuine parts with traceable origin, consistent storage and handling, and clearer visibility on lead times. You also gain access to OmronŌĆÖs official product literature, which is particularly valuable when you are cross-referencing CPU versions or I/O module revisions to guarantee compatibility.

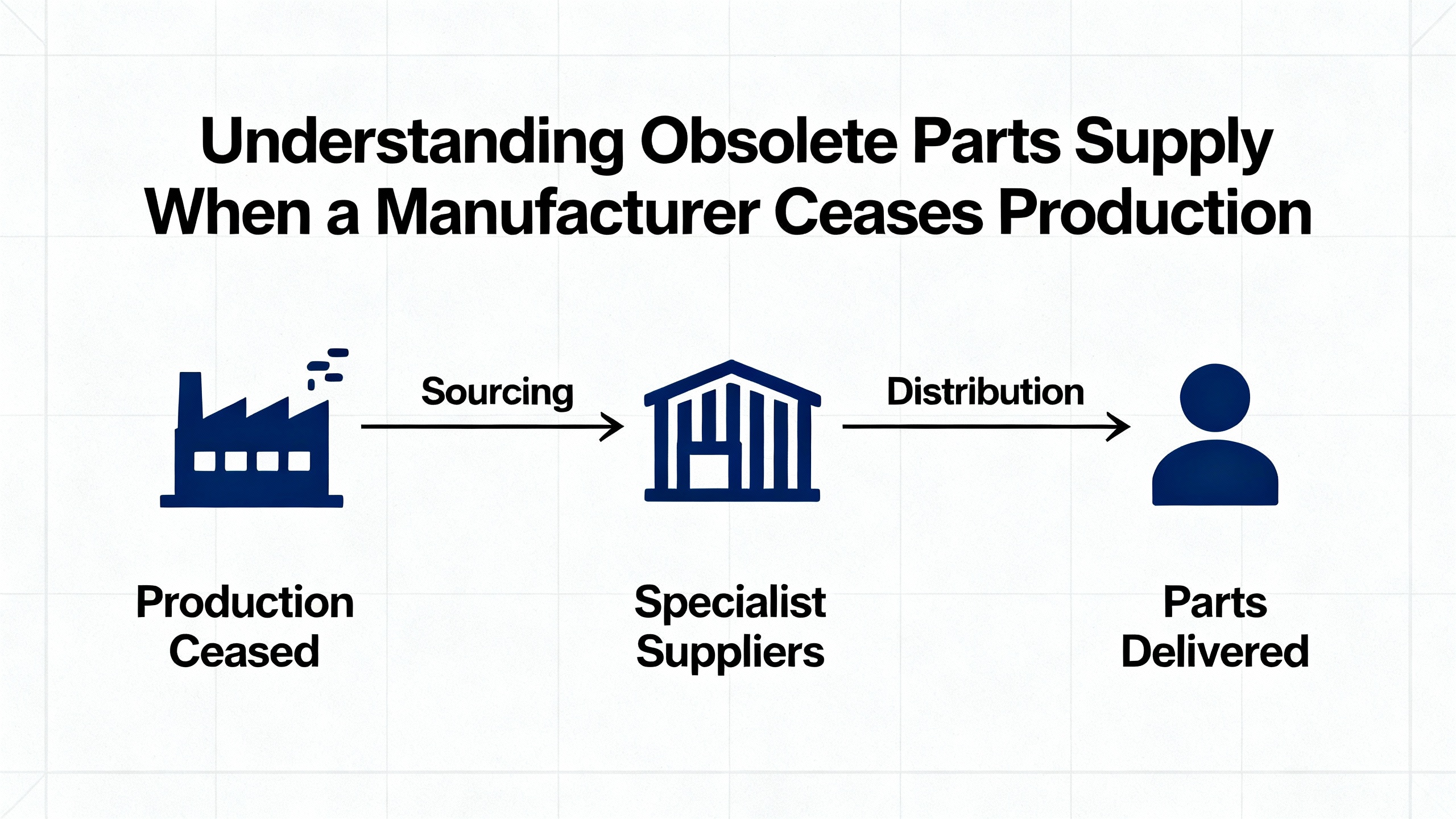

For legacy Omron platforms like the 3G2 series and older CS/CJ variants, you will eventually run into ŌĆ£no longer manufacturedŌĆØ notices. At that point, simply relying on mainstream distributors is not enough.

Industrial Automation Co, Hasuka Automation, and PLC Automation Group all describe the role of specialist obsolete automation parts suppliers. PLC Automation Group defines them as third-party vendors focused on discontinued or hard-to-find components, originally made by OEMs, that they source, test, certify, and supply. Hasuka adds that these parts are often ten to twenty years old but still central to production lines, and that OEMs may have long since dropped support.

The benefits of working with such specialists, rather than general marketplaces, are significant. Industrial Automation Co emphasizes that good suppliers offer cross-references, retrofit advice, and technical support, rather than just selling part numbers. They also stress thorough testing and meaningful warranties: their own practice is multi-point functional testing with detailed reports, and they note that many of their repaired items carry warranties up to about twenty-four months. This is one of the clearest ways to differentiate legitimate refurbished modules from untested surplus or counterfeits.

Hasuka adds practical checks that apply directly to Omron modules. You should verify the exact part number, including series or revision, before ordering. That means checking manuals, nameplates, and archived project files, not just reading the label you can see from the cabinet door. They recommend confirming that suppliers hold real stock rather than ŌĆ£virtual inventory,ŌĆØ and that they can provide photos, test reports, and clear condition descriptions.

PLC Automation Group further recommends selecting obsolete-parts partners with a strong reputation, the ability to interpret alternative or cross-reference part numbers, and customer-friendly policies such as reliable shipping and workable returns if a part is not suitable.

For Omron 3G2 and CS1 modules, this kind of partner is often the only practical path to maintaining a legacy line while you budget and plan a longer-term migration to a newer Omron platform.

Even with good sourcing, not every failure should be answered with ŌĆ£buy another module.ŌĆØ The Industrial Automation Co guidance on ŌĆ£Repair or Replace?ŌĆØ for drives, PLCs, and HMIs offers a framework that applies well to Omron PLC components.

Economically, they note that repairing industrial automation parts typically costs roughly thirty to sixty percent less than buying new ones. At the same time, new replacement parts often have lead times measured in weeks; they cite two to eight weeks as a common range. Many repair jobs, on the other hand, can be turned around in about three to five days, especially if the failure is localized and parts are available.

That trade-off becomes especially attractive when dealing with obsolete or backordered PLC modules. When a legacy Omron PLC family has already been superseded, or when lead times for a new CPU or I/O card stretch into months, repair can keep your system running without forcing a full platform migration. Industrial Automation Co emphasizes that this is particularly appropriate for expensive or obsolete units and for failures that are physical but not systemic, such as damaged connectors, cracked housings, or localized component failures.

Replacement is the better option when the same part has failed repeatedly, when damage is catastrophic, or when a system upgrade is already on the roadmap. In PLC terms, repeated intermittent faults, unstable communications, or corroded backplanes are red flags suggesting that you are chasing symptoms while the installation as a whole has aged out. In that case, it may be safer and more economical to migrate to a newer Omron family, as suggested in general PLC selection guidance from Maple Systems, Premier Automation, and LC Automation, which all emphasize aligning controller choice with future application needs and avoiding overinvestment in underspecified platforms.

Industrial Automation Co also describes a practical process many plants follow: ship suspect parts out for a free evaluation, receive a no-obligation repair quote and report, and then decide whether the cost and turnaround justify repair versus replacement. With up to two-year warranties on repaired parts in some programs, repair can be more than just a short-term patch.

In reliability studies I run on UPS-backed control systems, the parts most likely to jeopardize uptime are often not the PLC CPUs themselves but the supporting modules that live at the interface between logic and the electrical world. The research sources echo that picture.

Power supply modules are a classic example. The Omron 3G2A3-PS221 module, described by PDFSupply, takes 120ŌĆō240 VAC and outputs regulated 24 VDC at 1.5 A. It is rated for operation from about minus 13┬░F up to roughly 158┬░F and carries an IP20 ingress rating. In other words, it is robust, but it lives in a hostile environment and handles the full distortion, heat, and transients of the plantŌĆÖs power system. Age, thermal cycling, and poor power quality will eventually impact its capacitors and semiconductors, leading to unpredictable faults. In practice, this is one of the first PLC modules I recommend stocking as a spare and protecting via upstream power quality measures: clean feeders, appropriate surge suppression, and well-maintained UPS or DC backup.

Digital I/O modules are the next layer. The Omron 3G2A3-ID411, again described by PDFSupply, provides fourteen DC input points using a 24 VDC supply and accepts inputs from about 12ŌĆō48 VDC, with a sub-millisecond response time. It includes reverse-polarity and over-voltage protection, LED status indicators, and is designed to operate from about 14┬░F to 131┬░F. These features make it well suited to harsh industrial inputs, but the module still sits on the front line with sensors, switches, and wiring runs that carry noise and, occasionally, miswiring. Over many years, the statistical risk of failure accumulates. The good news is that digital I/O modules tend to have multiple part-number equivalents and, in many cases, drop-in replacements from the same platform family.

Analog I/O modules and CPU-integrated analog options, such as those found in CP1H-XA variants, operate under tighter accuracy and drift requirements. They often see service in temperature, pressure, and flow control, where noise and calibration matter. While the research notes do not enumerate specific analog replacement strategies for Omron, broader guidance from Maple Systems and UpKeep makes it clear that analog functionality demands careful attention to both environmental conditions and calibration schedules. Analog modules, once obsolete, can be harder to source and interchange than basic digital cards, so they deserve special attention when you define spare-parts priorities.

Communication modules are another high-risk, high-impact category. In the 3G2 family, PDFSupply describes several such modules, including the 3G2A6-PR015E Host Link unit and the 3G2A3-IF233, which support serial communications like RS-232C and RS-422/485, with baud rates between 300 and 19,200 bps and options for optical fiber. There are also bus couplers such as the 3G2A3-BC003, integrating PLCs into DeviceNet and PROFIBUS-DP networks. These units sit at the electrical and network boundary, where surges, grounding issues, and external equipment faults are common. They are also often the first devices to be discontinued when vendor network strategies evolve. From an availability standpoint, that means you should plan to identify modern replacement paths early, possibly migrating communications onto newer Omron network modules, even while keeping the base PLC and I/O intact.

Finally, programming devices and cabling deserve mention. PDFSupply notes programming consoles like the 3G2A6-PRO15-E, which support ladder logic and structured text programming with multiple operating modes. While many modern Omron PLCs are programmed via PC software such as CX-Programmer or Sysmac Studio, legacy platforms may still rely on specialized consoles or interface modules. These items can become obscure surprisingly quickly, and a failed programming interface can turn a minor logic change into a multi-day hunt for the right hardware. For legacy Omron systems, having at least one verified programming device and the necessary communication modules in working order is a key piece of availability planning.

All of this points to a simple reality: Omron PLC spare-parts planning is not just an inventory question, it is a reliability strategy that ties directly into power quality, maintenance practices, and modernization planning.

Industrial Automation CoŌĆÖs article on sourcing obsolete parts fast recommends starting with a line-by-line audit and building a detailed inventory of critical components, including PLCs, drives, HMIs, and servo systems. That inventory should capture part and serial numbers, installation dates, firmware versions, configuration notes, and maintenance history. For Omron PLCs, I would add ONSeT proposal IDs and cross-reference results, so you can see at a glance which modules already have vetted replacements and which are drifting into obsolete territory.

They also recommend categorizing components by risk level: high-risk items with no easy alternatives versus lower-risk items with clear drop-in replacements. For Omron PLCs, high-risk items might include unique communication modules, special analog or motion cards, and power supplies that are specific to a legacy rack. Lower-risk items might include standard digital I/O modules that are widely available on the secondary market.

UpKeepŌĆÖs PLC maintenance guidance complements this by emphasizing preventive practices: keeping cabinets clean and dust-free, inspecting and tightening terminals in high-vibration areas, monitoring temperature and humidity, backing up PLC data at least twice a year, and reviewing error and scan histories. They also advise maintaining an inventory of spare PLC parts and protecting equipment with appropriate enclosures and power protection.

Hasuka and PLC Automation Group both highlight the strategic dimension: partnering with dedicated obsolete-parts suppliers turns emergency sourcing into a managed process. HasukaŌĆÖs case study of a food manufacturer restored within hours thanks to a stocked obsolete valve manifold illustrates how this can avoid a forced, premature system replacement when only a single component has failed. The same logic applies to Omron PLC modules, particularly in older lines where the core mechanical equipment still has decades of life left.

Finally, multiple controller-specification sources, including Maple Systems, Premier Automation, LC Automation, and PDFSupplyŌĆÖs comparison of AllenŌĆæBradley and Omron, converge on the importance of future-proofing: when you do decide to replace or upgrade an Omron PLC, you should choose a family with spare CPU capacity, expansion options, and strong communication support, rather than simply buying the smallest unit that can run todayŌĆÖs program. That mindset reduces the long-term demand for obscure spares and makes your future replacement decisions more straightforward.

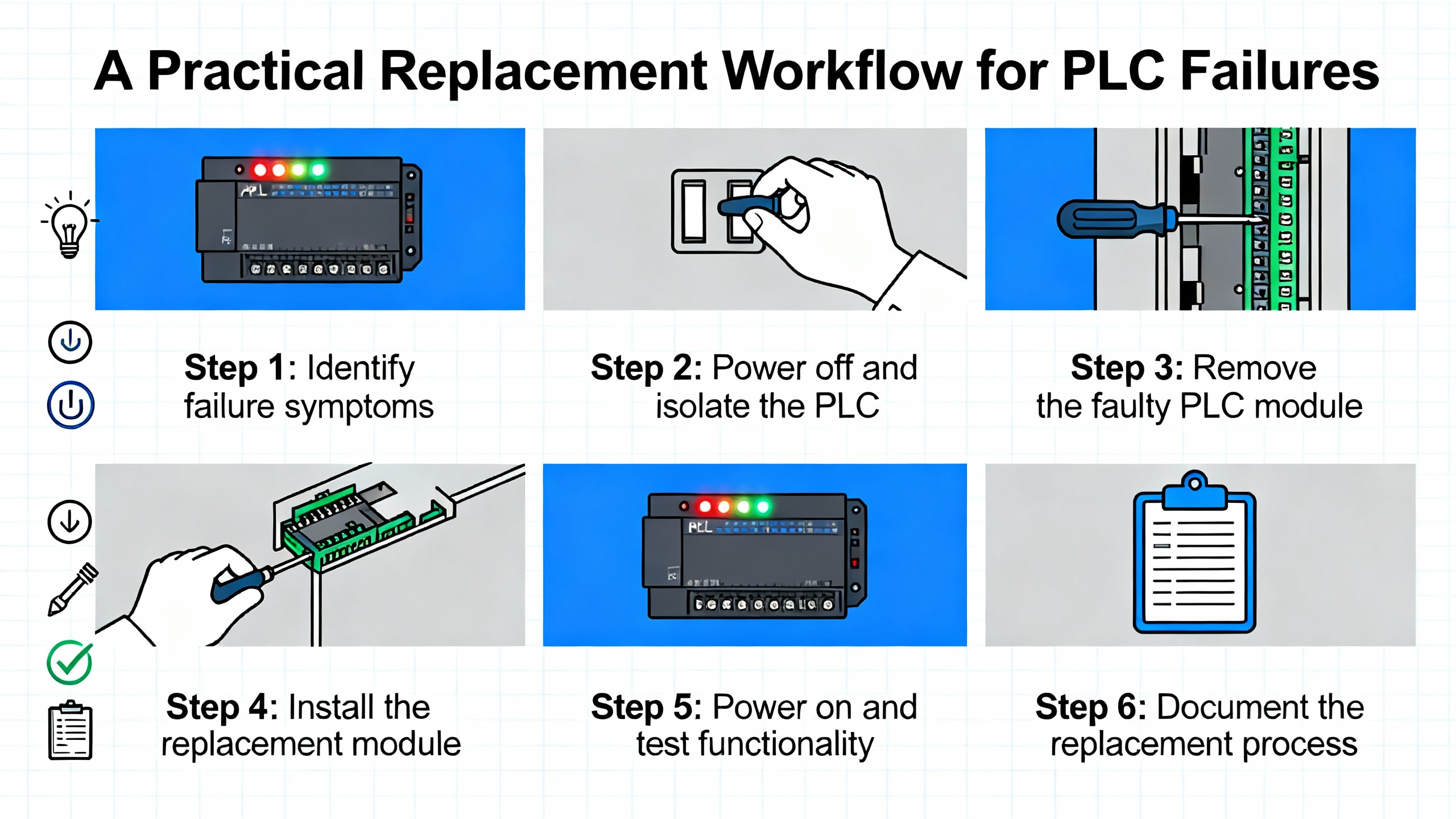

In real plants, Omron PLC replacement rarely follows a tidy textbook script. Still, it helps to think in terms of a practical workflow grounded in the research and in field experience.

When a module fails or behaves intermittently, the first step is accurate identification. That means isolating the failure to a specific module, confirming its exact part number and revision from the device label, manuals, and stored documentation, and backing up the PLC program and configuration if possible. HasukaŌĆÖs advice on double-checking part numbers before ordering is worth following rigidly, especially for modules that have multiple series or firmware variants.

Once you know what has failed, you can check OmronŌĆÖs ONSeT tool to see whether the part is still current, whether it has a recommended successor, and whether it is marked as ŌĆ£StandardŌĆØ (indicating typical stock). If ONSeT indicates an official replacement, you can take that to an authorized Omron distributor, where you can also confirm pricing, lead time, and any required accessories.

In parallel, particularly when the failed module looks obsolete or lead times are long, it makes sense to contact a specialist obsolete-parts supplier. Industrial Automation Co suggests asking detailed questions about testing procedures, whether tests are done under load, how results are documented, and what warranties are offered. Their typical twenty-four-month warranty on many repaired items is a good benchmark when evaluating others. PLC Automation Group and Hasuka both emphasize confirming real-time stock and shipping capability to avoid discovering that the part is not actually available when you need it.

With that information in hand, you can apply the repair-versus-replace criteria from Industrial Automation Co. If the part is costly, obsolete, and has not failed repeatedly, and if a reputable repair partner can turn it around in about three to five days with a solid warranty, repair is usually rational. If the damage is widespread, the module or family is known for instability, or the system is due for modernization, it may be better to migrate to a newer Omron platform, guided by the PLC selection practices described by Maple Systems, Premier Automation, and LC Automation.

Throughout this process, power quality and protection should not be an afterthought. UpKeep stresses the role of clean power, proper grounding, and environmental control in extending PLC life. For Omron PLCs fed by 24 VDC power supplies and protected by UPS systems, that means verifying that the UPS, inverters, and distribution are sized correctly, that voltage levels align with PLC specifications, and that surge and noise mitigation are in place. Otherwise, you risk burning through replacement parts regardless of how well you manage availability.

Start with the exact part number and series printed on the module and confirm it against manuals or archived project documentation. Then use OmronŌĆÖs Navigated Selection Tool (ONSeT) to search by part number, view associated dependencies and spare parts, and check the obsolete-part function for recommended successors. Once you have a candidate replacement, validate it through an authorized Omron distributor and, for older modules, cross-check with a specialist obsolete-parts supplier that can confirm real stock and compatibility.

They can be, provided the supplier follows rigorous testing and offers meaningful warranties. Industrial Automation Co, for example, describes multi-point functional testing with detailed reports and typical warranties up to around twenty-four months on many repaired items. PLC Automation Group and Hasuka both recommend asking how tests are performed, whether they simulate real operating conditions, and what happens if a refurbished part fails in service. For critical lines, I recommend treating refurbished modules like any other change: review test documentation, apply your plantŌĆÖs change-control process, and keep at least one proven spare on hand once you have validated the first replacement in operation.

UpKeepŌĆÖs PLC guide makes it clear that poor power quality accelerates failures in PLC hardware, especially power supplies and I/O modules. For Omron systems, modules like the 3G2A3-PS221 and other 24 VDC supplies sit directly between the plantŌĆÖs AC system and delicate logic electronics. Voltage spikes, sags, and excessive heat shorten their life and increase the frequency of replacements, which stresses spare-parts inventories and availability. Using properly sized UPS systems, well-configured inverters, clean distribution, and surge protection, combined with regular cabinet inspections and filter maintenance, reduces that stress and stretches the useful life of both original and replacement modules.

When I walk through a plant, I do not just ask, ŌĆ£Where is your UPS?ŌĆØ I also ask, ŌĆ£If that Omron PLC lost a power supply or network card today, how fast could you recover?ŌĆØ A thoughtful plan for Omron PLC replacement parts, anchored in OmronŌĆÖs tools, reliable distributors, and proven obsolete-parts partners, turns that question from a gamble into a manageable risk. Combine that with solid power protection and maintenance, and you give your automationŌĆöand your businessŌĆöthe best chance of staying online when it matters most.

Leave Your Comment