-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Rock-solid power reliability no longer depends only on well-sized UPS systems, resilient inverters, and robust switchgear. In modern industrial and commercial facilities, uptime depends just as much on the way those assets are integrated into PLCs, distributed control systems, HMIs, and data platformsŌĆöand on how well your team is trained to design, program, and maintain that integration.

From my perspective as a power system specialist and reliability advisor, the most sustainable gains in availability come from pairing resilient electrical design with a disciplined approach to workforce development. Rockwell AutomationŌĆōcentric training, when used strategically, can form the backbone of a comprehensive system integration program that supports UPS-backed automation, process control, and power protection across a fleet of facilities.

This article walks through how Rockwell-oriented trainingŌĆöcombined with vendor-neutral conceptsŌĆöcan be structured to build an integration-ready workforce, what the key components are, and how to align them with real reliability outcomes.

Well-trained industrial workforces do more than pass exams. Rockwell Automation highlights that capable teams reduce costly mistakes, unplanned downtime, and safety incidents while improving productivity and job satisfaction. When your power protection and automation layers are tightly coupled, these benefits are amplified. A misapplied firmware update in a controller or a poorly designed alarm strategy can be just as damaging to uptime as a mis-sized UPS.

Automation engineers are expected to understand client processes, chemicals, and materials in greater depth than many on-site operators or even specialized engineers. Practitioners in the field describe repeatedly having to ŌĆ£rescueŌĆØ IT staff who may know networking theory but lack practical experience with industrial computers and networks. This gap becomes acute when the control system is the brain that orchestrates automatic transfer switches, UPS bypass, and load shedding schemes.

Real-world experience shared in automation forums emphasizes that engineers often have to reverse-engineer existing systems before they can teach maintenance supervisors how to monitor and service them. In power applications, that might mean unpacking how a PlantPAx-based system sequences generator starts, how a PLC decides when to shed noncritical loads, and how HMI alarms escalate when a UPS moves to battery.

The takeaway is simple: without a structured training path in system integration, you are relying on tribal knowledge and ad hoc learning to protect multi-million-dollar power assets. That is not a sustainable reliability strategy.

A useful way to look at Rockwell-related training is as an ecosystem rather than a single course or platform. At a high level, the ecosystem includes vendor-neutral curriculum delivered on Rockwell platforms, vendor-developed e-learning and subscriptions, specialized PlantPAx and analytics programs, and hands-on training workstations. Together, these form a continuum from basic PLC skills to full DCS design and data-driven optimization.

BIN95ŌĆÖs Koldwater Rockwell Automation Control Concept Training Series illustrates how you can use Rockwell technology as a teaching vehicle while still building broadly transferable skills. This courseware is used by technical colleges, unions, manufacturing programs, and corporate training departments around the world to teach industrial and building automation.

The design philosophy is deliberate: Rockwell Automation is used as the primary platform because the tools are considered intuitive for beginners, yet about 80% of the automation knowledge taught is brand-agnostic and can be applied to other PLC and automation platforms. In a UPS or inverter-rich environment, that means your technicians are learning core control concepts and troubleshooting methods they can carry across different vendorsŌĆÖ static switches, battery systems, and intelligent relays.

BIN95 offers two perpetual licensing models. A Site License allows unlimited students and installations at a single physical facility, while an Enterprise License provides unlimited site licenses across all facilities. There are no annual fees, licenses never expire, and installations can operate offline after initial setup. Lab manuals are provided in PDF, and course assets can be repurposed to fit local learning management systems through an MS Access score database that behaves as a mini-LMS.

Each trade or technical course typically includes multiple-choice questions, a troubleshooting section, videos and simulations, closed captions, a glossary, lab manual, and a printable completion certificate. The focus is on interactivity: students flip virtual switches, operate simulated PLCs and HMIs, and immediately see system responses instead of passively watching slides. For power-focused technicians, this is an effective stepping stone before they touch live breaker control circuits or UPS interfaces.

To give a sense of scale, BIN95 publishes transparent pricing for site-license bundles targeted at different audiences:

| Bundle Name | Approximate Training Hours | Site License Price | Example Discount |

|---|---|---|---|

| TechnicianŌĆÖs Dream | 150 hours | $19,780.00 | about 36% |

| Maintenance TechnicianŌĆÖs Bundle | 175 hours | $15,780.00 | about 31% |

| Automation Control Specialist Bundle | 150 hours | $13,780.00 | about 32% |

| PLC Technician Training Bundle | 95 hours | $9,780.00 | about 25% |

These bundles let organizations standardize foundational skills across electrical maintenance staff before layering on more specialized Rockwell or PlantPAx content.

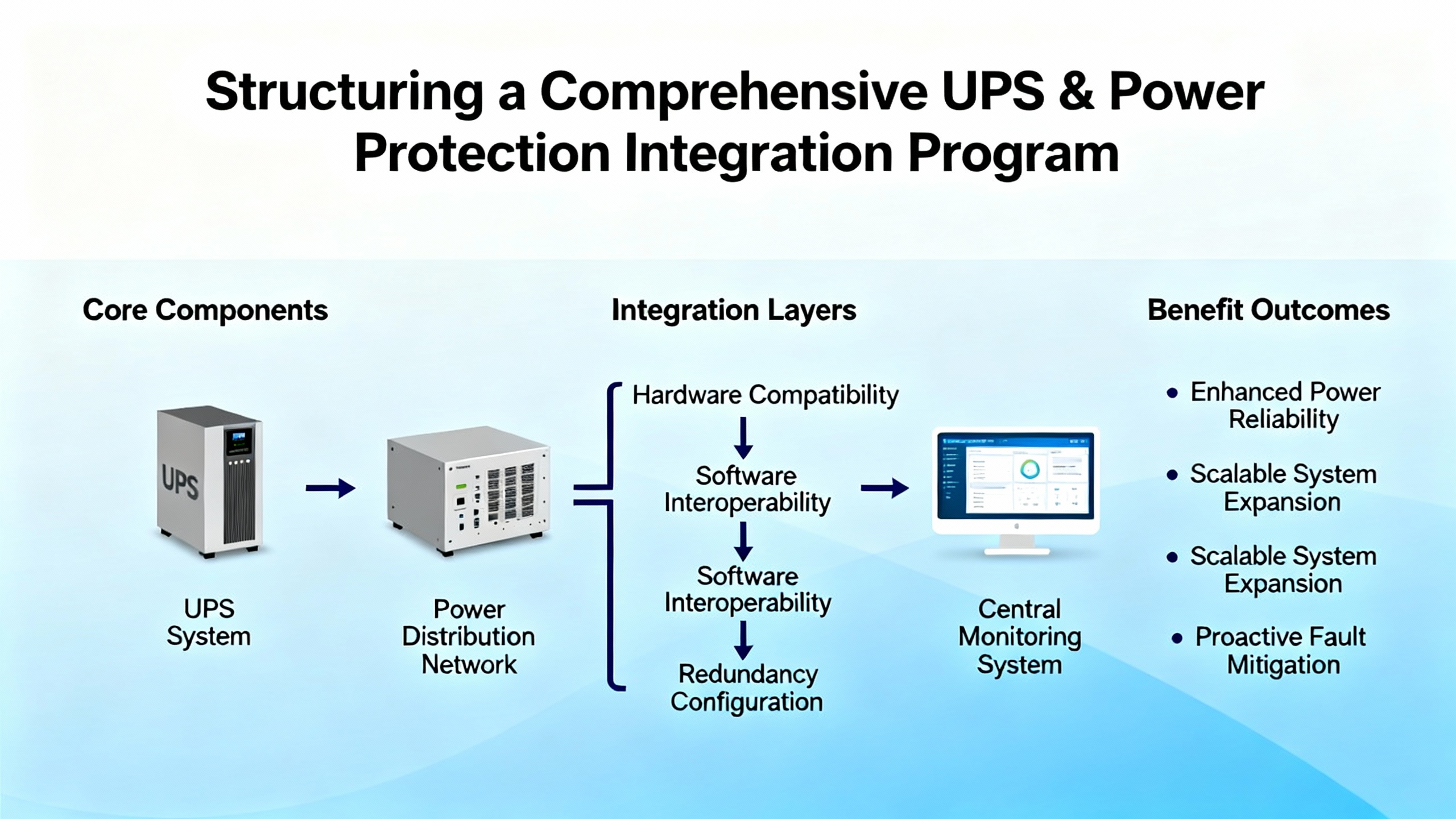

For power-intensive process plants, the system integration story does not stop at standalone PLCs. Distributed control systems such as PlantPAx are increasingly used to orchestrate entire process trains, including generators, UPS systems, and critical loads.

A course overview from RockwellŌĆÖs partners on PlantPAx 5.0 describes a curriculum that introduces the core components of a PlantPAx distributed control system, including system architecture, configuration, alarms, and security. The stated goal is for participants to be able to design and configure a complete PlantPAx 5.0 process automation system and to define requirements for procuring a PlantPAx solution.

Learners work with the PlantPAx library of add-on instructions, faceplates, and process strategies to create process control applications. They also build operator workstation displays and configure alarm visualizations, so operators see the right power and process status in real time. Security topics focus on integrating PlantPAx into a broader control architecture, reinforcing the importance of securing the DCS that may be commanding breaker operations or coordinating with protective relays.

Verification is built into the curriculum. Participants are trained to verify that the configured PlantPAx system operates as intended, and upon completion they are expected to design, configure, and secure a PlantPAx application independently. While the course description does not provide quantitative reliability statistics, the qualitative focus on standardized approaches to design, configuration, alarming, and security is directly relevant to power system stability.

A separate Rockwell-focused training provider emphasizes PlantPAx in the context of data management and analytics. Here, participants learn to configure PlantPAx system architecture, I/O modules, communication settings, and system logic for process control environments. They develop and implement process control strategies tailored to specific applications using PlantPAx tools, with a particular emphasis on analytics and reporting.

Data management is framed as critical for optimizing automation systems. Trainees learn to use built-in analytics to perform data analysis, generate operational reports, and identify trends, inefficiencies, and bottlenecks. A key outcome is the ability to use data from AllenŌĆæBradley PLCs to drive decisions that improve process control and productivity.

Dedicated modules on PLC data logging guide learners through tag selection, data sampling techniques, and optimizing data collection from AllenŌĆæBradley PLCs. Training compares data storage options, including local PLC storage, integration with external databases, and cloud-based storage solutions for scalability and accessibility. For power protection, this capability translates directly into better visibility into UPS health, transfer events, inverter load, and harmonic issues across the plant.

The same program stresses proactive maintenance strategies built on historical and real-time data to predict and prevent potential issues. For power systems, this can mean trending inverter temperature, battery discharge events, or nuisance trips in motor control centers, then acting before those indicators coalesce into an outage.

Technical depth alone is not enough; training modes must fit shift schedules and distributed operations common in mission-critical power environments.

Rockwell Automation has introduced a suite of e-learning courses designed to help industrial companies train engineers, technicians, and IT personnel to design, implement, and maintain industrial control systems. These offerings currently include 14 e-learning courses organized across six technology areas: industrial control, motion control, safety, power control, visualization, and industrial networking.

All courses are delivered online, self-paced, and self-directed. Trainees access them from compatible tablets or PCs, starting and stopping as their schedules allow. The content is interactive, mixing activities, simulations, and videos. Every module is narrated and includes a viewable transcript, improving accessibility for different learning styles. After completing the content and required assessments, participants earn continuing education units, providing formal recognition that can support professional development or certification requirements.

RockwellŌĆÖs Learning+ Training Subscription adds another dimension. Public materials describe Learning+ as a subscription-based program focused on Rockwell and AllenŌĆæBradley automation products, combining self-paced e-learning modules with optional instructor-led virtual sessions and labs. Subscriptions are typically time-limited, often structured as 12-month access per learner, with the ability to revisit modules as needed. Rockwell recommends blending Learning+ with hands-on labs or traditional classes to maximize retention and effectiveness.

The company also emphasizes training workstations built from the same technologies used in live production environments. These workstations are realistic, small-scale replicas of manufacturing processes designed for hands-on learning and testing. Because they mirror real processes, they provide a realistic environment for operators and engineers to practice. Rockwell explicitly recommends using workstations to introduce new skills before employees interact with live production systems, to refresh skills as processes and standards evolve, and to test new configurations before deployment.

For a power reliability program, that means you can validate new UPS control logic, automatic transfer schemes, or generator start sequences on a workstation-style environment rather than experimenting on live critical loads.

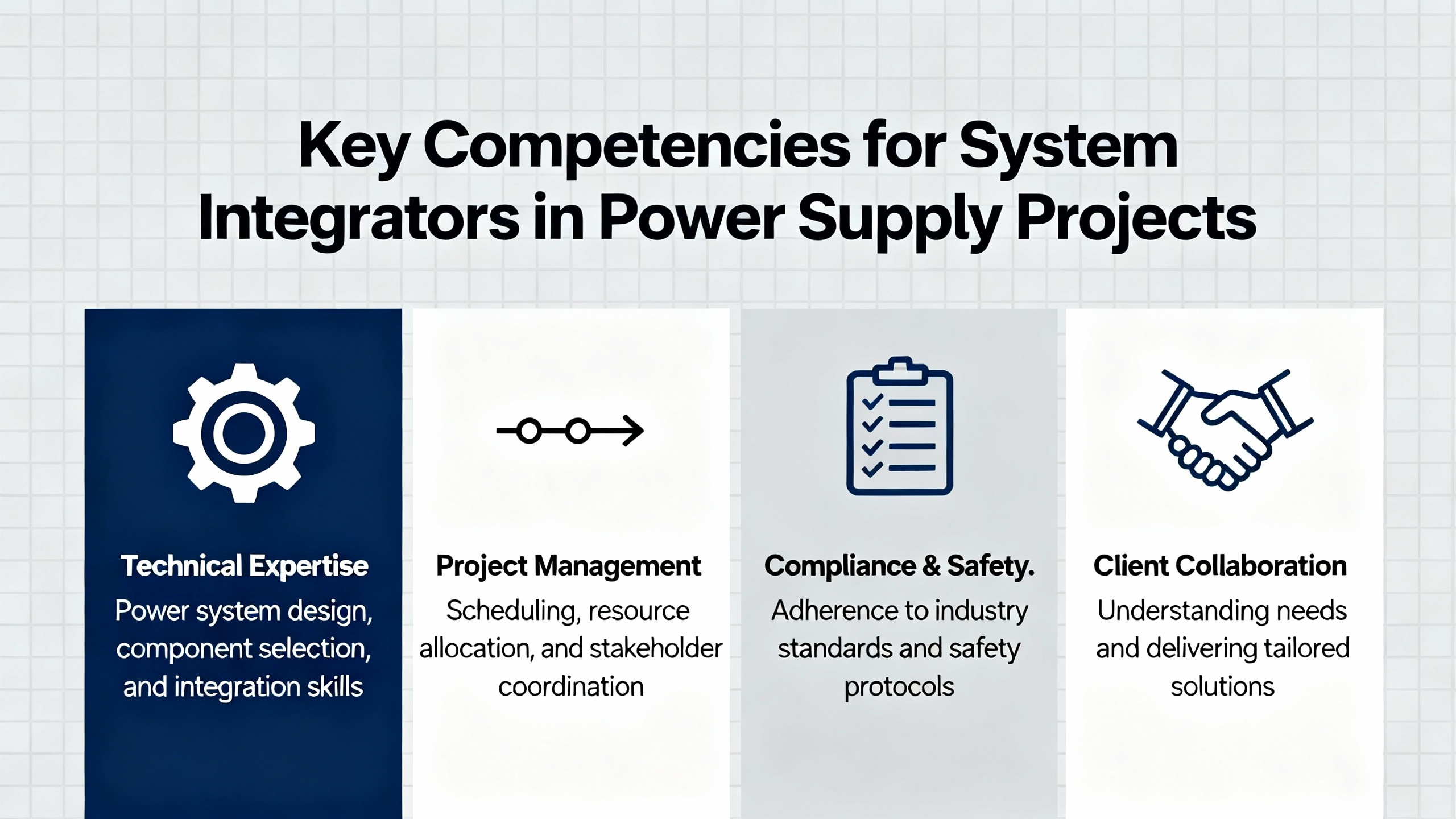

Training platforms are only useful if they map to the skills your integrators and technicians actually need. Several independent sources converge on a set of competencies that matter for Rockwell-based system integration, particularly in high-stakes environments like power and process industries.

Rockwell PLC system programmers design, program, test, and maintain PLC-based automation systems that underpin modern production lines. Core technical competency includes strong proficiency with Rockwell software platforms, especially RSLogix 5000 and Studio 5000, which are central to developing and managing Rockwell PLC programs. For teams integrating UPS and power systems, these platforms are where transfer logic, load shedding rules, and alarm workflows are implemented.

Effective work with Rockwell PLC systems also requires knowledge of industrial communication networks such as EtherNet/IP, DeviceNet, and ControlNet. Engineers must be able to design reliable architectures and troubleshoot connectivity issues between PLCs, HMIs, power meters, and intelligent electronic devices. Knowledge of SCADA systems is equally important to monitor, visualize, and control industrial processes.

Rockwell Automation itself provides extensive manuals, webinars, forums, and formal training that practitioners are advised to use to stay current with tools, features, and best practices. Industry-recognized certifications, such as the Certified Automation Professional credential and RockwellŌĆÖs own training programs, are highlighted as signals of expertise that support continuous learning and career growth.

Technical control skills alone are not sufficient. Practitioners emphasize that automation engineers often must understand each process being automated in breadth and depth, not just control systems or programming. They frequently find themselves reverse-engineering existing solutions so they can explain operations and maintenance requirements to client teams.

In a power-protection context, this translates into understanding how power quality, load profiles, and redundancy schemes interact with control logic. While that domain-specific knowledge is typically built from on-the-job experience and power engineering training rather than Rockwell curricula, a good system integration training plan should explicitly make room for it alongside PLC and DCS content.

Familiarity with safety regulations and standards, including OSHA and machine safety requirements, is essential to ensure PLC-controlled systems are safe for workers and compliant with legal guidelines. RockwellŌĆÖs training catalog includes safety-focused content, and professional guidance recommends weaving safety throughout any curriculum rather than treating it as a single course to be checked off.

Robust documentation practices are another recurring theme. Clear records of configurations and changes, coupled with regular system verification checks, support faster troubleshooting, easier future modifications, and early detection of issues. For power systems, that means being able to trace why a particular UPS is shedding load at a given point, or how a generator start sequence changed after the last software update.

Soft skills matter as well. Automation integration roles benefit from project management capabilities, including planning and scheduling work, coordinating stakeholders, and tracking progress. Effective communication is needed to collaborate with engineering, operations, IT, and management, and to translate technical issues into actionable plans.

Putting these elements together into an actionable training program requires more than buying a course bundle. Based on the published approaches and recommendations, a staged strategy works best.

An effective starting point is foundational PLC education using vendor-neutral courses that run on Rockwell platforms. For example, BIN95 recommends taking a PLC basics course before more advanced PAC-focused training, and optionally using PLC simulators such as PLCLogix 500 or 5000 for additional practice. In a power context, this foundational stage can focus on discrete control concepts, interlocks, and basic fault handling, using simulated examples that mirror breaker and contactor controls rather than complex process loops.

Once the basics are in place, you can move into Rockwell and PlantPAx-specific content. The PlantPAx 5.0 course that teaches system architecture, configuration, alarms, and security is particularly relevant when you are centralizing power monitoring, generation, and critical loads under a DCS. At this stage, trainees should practice building operator displays that provide clear visibility into UPS status, battery conditions, generator availability, and transfer paths, along with alarm strategies that avoid both alarm floods and missed critical events.

In parallel, data and analytics training focused on PlantPAx and AllenŌĆæBradley PLC data logging should be introduced. Here, the goal is to enable engineers and analysts to log, store, and retrieve production and power information and to use it for trend analysis and proactive maintenance. Training that compares local PLC storage, external databases, and cloud-based storage helps teams make informed decisions about architecture, latency, and resilience.

Scaling this program across a fleet of facilities or campuses is where subscriptions and licensing models matter. For organizations with multiple locations, BIN95 explicitly recommends considering Enterprise Licenses to reduce cost compared with buying separate site licenses, especially when three or more locations are involved. RockwellŌĆÖs Learning+ subscriptions and e-learning catalogs can then be mapped to job roles and competency levels, giving each technician a defined progression path that they can follow at their own pace.

Hands-on training workstations should be used as the bridge between classroom or online knowledge and live production systems. By building or procuring workstations that mirror your actual Rockwell hardware and typical power control scenarios, you can introduce new skills, refresh existing ones, and test new control strategies without risking uptime in production.

Behind the scenes, formal workforce development and training services from Rockwell bring structure and governance. Their Global Workforce Solutions team, for example, offers consultation-based programs that assess, train, and measure workforce competency using a mix of self-paced, virtual, and instructor-led training. RockwellŌĆÖs published training policies, including clear cancellation and refund rules and limits on class sizes, reflect this structured approach and support better planning of travel and staffing.

From a reliability advisorŌĆÖs standpoint, a Rockwell-centered training strategy offers substantial benefits, but it is not without trade-offs.

On the positive side, Rockwell platforms are widely used and are considered intuitive for beginners in many training programs. This makes Rockwell-based courseware a practical way to onboard new technicians and engineers. BIN95ŌĆÖs approach, where roughly 80% of content is brand-agnostic despite using Rockwell as the primary platform, mitigates the risk of creating skills that are too narrow. RockwellŌĆÖs own e-learning offerings, along with Learning+ subscriptions, CEU-bearing online courses, and structured PlantPAx training, give you a rich catalog to align with core automation domains: control, motion, safety, power control, visualization, and networking.

Flexible delivery is another clear advantage. Self-paced online courses, narrated modules with transcripts, virtual labs, and virtual coaching sessions allow training to fit around shift work, maintenance windows, and travel constraints. For distributed operations and multi-site power portfolios, the ability to deploy a consistent Rockwell training curriculum across locationsŌĆövia enterprise site licenses and centrally managed subscriptionsŌĆöis a major benefit.

The downsides are mostly strategic rather than technical. A heavy emphasis on Rockwell can, over time, bias your engineering practices and architectures toward a single vendor. In practice, most power systems are multi-vendor ecosystems. You may have Rockwell PLCs and HMIs alongside third-party protective relays, metering systems, and specialized UPS controllers. A strong Rockwell curriculum needs to be balanced with training in open protocols, non-Rockwell devices, and power engineering fundamentals so your team can integrate rather than simply standardize.

Cost is another consideration. While licensing models such as perpetual site and enterprise licenses can be economical over time, the absolute dollar values for bundles are significant, especially for smaller organizations. You need to align spending with clear competency maps and measurable reliability outcomes, rather than purchasing training ad hoc.

Finally, Rockwell itself is clear that training tools and AI-based navigators do not replace product-specific documentation or professional advice. Disclaimers on several Rockwell training and catalog pages emphasize that content may contain errors or may not reflect the latest developments, and that AI-based tools collect conversation logs and tracking data for up to 90 days. For critical decisionsŌĆölike modifying transfer logic between redundant UPS systemsŌĆöyour engineers must still refer to official documentation, safety standards, and internal change-control processes.

Building a comprehensive training program around Rockwell technologies also means treating training content and tools as part of your governance landscape.

RockwellŌĆÖs AI Navigator tools, used on some training and catalog pages, explicitly state that they are for general informational purposes, may contain inaccuracies, and do not override product-specific documentation. They also describe how conversation logs and information collected by cookies and other tracking technologies are used to maintain and improve services and for marketing, with a data retention period of about 90 days. Similar disclaimers appear across several training pages.

For a power-focused organization, this is a reminder that AI-generated guidance should be treated as a helpful assistant rather than an authority. Training policies should require engineers to verify AI-surfaced recommendations against official manuals and standards. At the same time, data-collection disclosures underline the need to align your internal privacy, security, and compliance practices when staff use vendor training tools.

Formal policies such as RockwellŌĆÖs cancellation and refund rules for instructor-led trainingŌĆöwhere tuition refunds depend on how many days before the course start date cancellations occur, and no-shows are billed the full tuitionŌĆöalso matter. They encourage booking only refundable travel and underscore that training is a serious operational commitment. For power system teams, aligning project schedules and coverage plans with these policies avoids last-minute cancellations that can delay critical upskilling.

For organizations that depend on UPS systems, inverters, and power protection equipment to keep critical operations running, the most resilient path I see combines several elements.

Start by defining the competencies you need around PLC programming, PlantPAx DCS design, industrial networking, safety, and power system concepts. Then map RockwellŌĆÖs e-learning catalog, Learning+ subscriptions, PlantPAx-focused courses, and BIN95ŌĆÖs Koldwater series onto those competencies. Use site and enterprise licensing strategically to cover all relevant facilities without overbuying.

Next, decide which topics demand hands-on practice on training workstations that mirror your Rockwell hardware and typical power architectures. Reserve instructor-led or virtual coaching for these areas and for complex integration topics such as multi-source generation, load shedding, and coordinated protection.

Finally, embed training into your reliability management system. Track completion, assessments, and on-the-job performance; use data logging and analytics skills not just for process optimization but also to monitor how well your power systems are behaving after changes. Combine vendor training with your own lessons learned and incident reviews so that your training program continually reflects the realities of your plants.

When you treat Rockwell Automation training as a structured, multi-year investment rather than a series of isolated classes, you turn it into a powerful lever for system integration maturity and power reliability.

Is Rockwell-specific training still useful if my power equipment is multi-vendor? Yes, provided you choose programs that emphasize underlying automation concepts. BIN95ŌĆÖs Koldwater curriculum, for example, explicitly states that about 80% of the knowledge taught is brand-agnostic even though Rockwell is the primary platform. Combining that with RockwellŌĆÖs own PlantPAx and PLC courses gives your team a strong foundation that can be applied across different UPS and protection vendors, as long as you supplement with device-specific training.

How much hands-on experience do technicians need beyond simulations and e-learning? Interactive simulations and self-paced e-learning are excellent for core concepts and early troubleshooting skills, but practitioners consistently report that real-world, hands-on exposure is essential. Training workstations that replicate actual manufacturing processes and control hardware are a practical bridge between virtual labs and live power systems, letting technicians practice and test changes before they go anywhere near critical loads.

Where does safety fit into a Rockwell-based integration training plan? Safety should be woven into every stage of the curriculum. Guidance on Rockwell PLC roles stresses the importance of understanding safety regulations and standards such as OSHA requirements. When you connect PLCs and DCS systems to UPSs, switchgear, and generators, safety and compliance considerations must guide how you design interlocks, alarms, and maintenance proceduresŌĆönot just how you write logic.

Leave Your Comment