-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

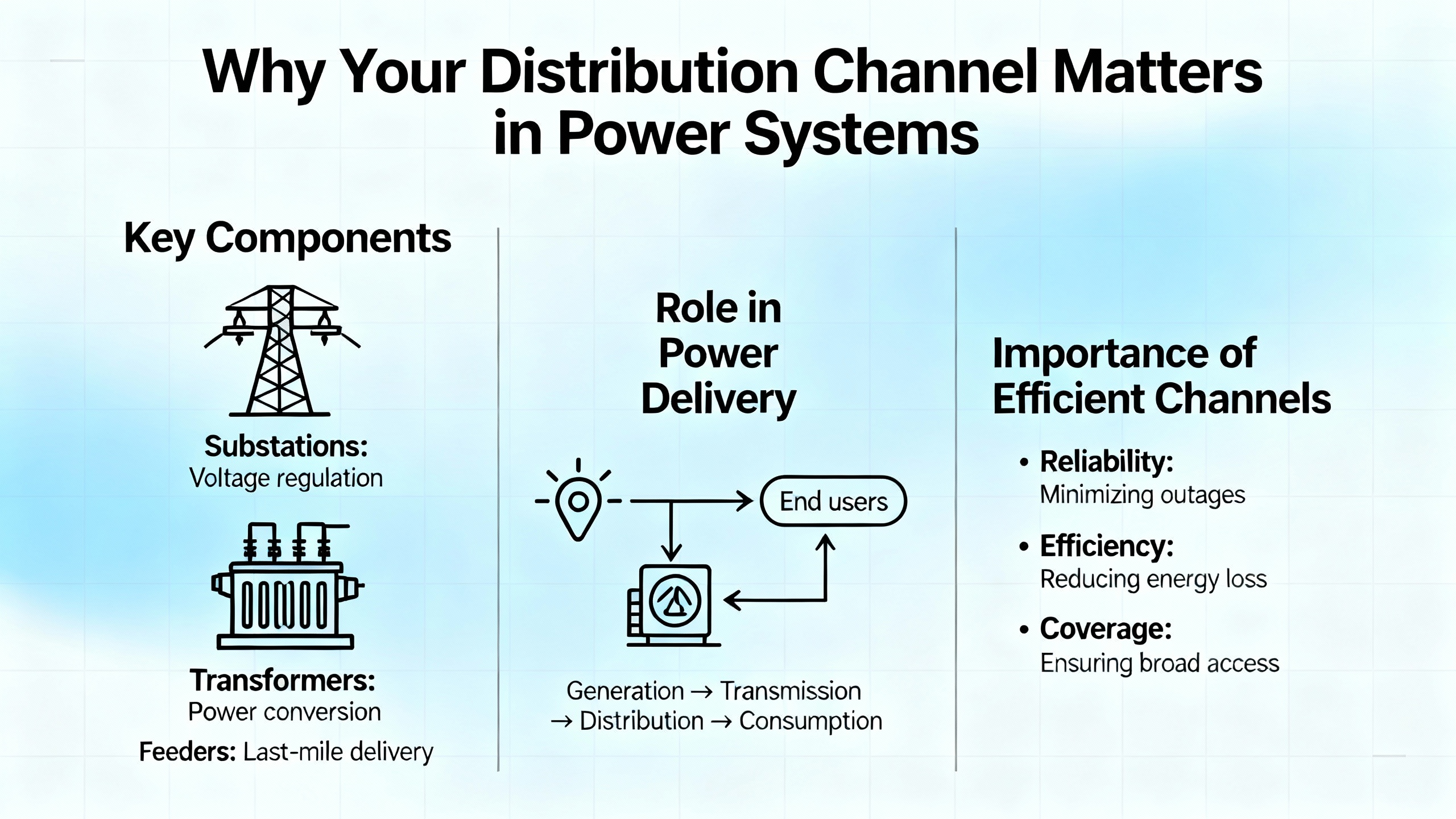

In industrial and commercial facilities, power systems are unforgiving. A failed UPS transfer, an inverter that trips under load, or a misbehaving breaker control can take down production lines, data halls, or life-safety systems in seconds. In my work with critical power and power protection, I have learned that hardware reliability is only half the story. The supply chain behind that hardware, especially for automation and control, is just as critical. That is where Rockwell AutomationŌĆÖs authorized distributor model becomes a key risk-control tool rather than a purchasing formality.

This article looks at Rockwell Automation distributors through the lens of power system reliability. Drawing on documented experience from Rockwell Automation literature, HESCO, Electronics Sourcing, EE Times, ABB, and others, I will explain how authorized parts and support directly affect uptime, safety, and lifecycle cost for UPS, inverter, and power protection applications.

Power-critical facilities are increasingly dense with electronics. Even a medium-voltage lineup now depends on PLCs, intelligent relays, networked metering, and safety-rated I/O. The components inside those systems live in the same global supply chain that has been under pressure for years.

Electronics Sourcing and EE Times both describe how lead times for some microcontrollers and sensors have stretched to about 40 weeks, while other devices such as CPUs and memories can swing into surplus. During peak demand, lead times for certain electronic components have exceeded 300 days. McKinseyŌĆÖs analysis, cited in industry coverage, suggests that these mismatches between supply and demand are no longer rare anomalies but the new normal across chip types, sectors, and regions.

At the same time, counterfeit risk has increased. EE Times reports that from 2021 to 2022, reported counterfeit electronic components rose by about 35 percent even though total semiconductor sales remained flat, with analog and programmable logic devices among the most affected. Authorized distributors and manufacturers like ABB warn that unauthorized channels frequently mix genuine, aged, refurbished, and counterfeit stock, often without any warranty or traceability.

In power systems, the stakes are higher than a consumer gadget failing on a desk. A counterfeit IGBT or control module in a UPS can fail under fault conditions instead of clearing them. A nonconforming safety input card in a generator control system might pass initial commissioning only to misread a critical signal during a grid disturbance. These are low-probability, high-consequence events, and the path they most often travel is gray-market sourcing under schedule pressure.

This is why the structure behind Rockwell AutomationŌĆÖs distribution network matters. It is not just about who can sell you a drives card or a controller chassis. It is about who is accountable for authenticity, who stands behind the warranty, and who will still be picking up the phone when those components are in the middle of a fault sequence.

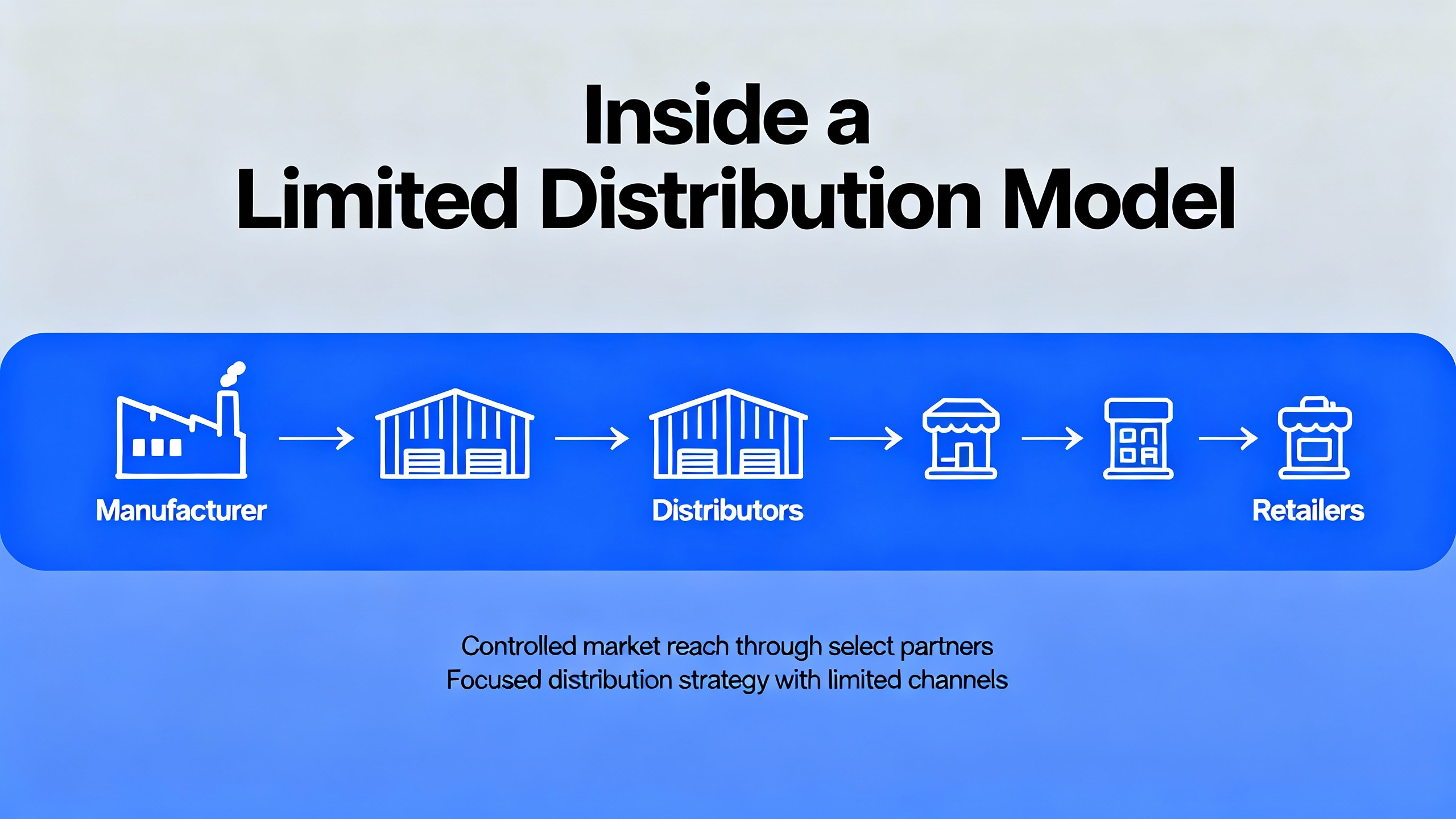

Rockwell Automation does not treat distribution as an open marketplace. HESCO, a long-standing Rockwell Automation distributor in Connecticut, explains that Rockwell uses what they call a limited distribution model. In this model, Rockwell authorizes exactly one distributor per geographic region. That distributor is responsible not just for selling products but also for stocking inventory, providing technical support and training, helping customers apply products, and handling warranty-related issues.

The rationale, as described in HESCOŌĆÖs explanation and Rockwell AutomationŌĆÖs own PartnerNetwork materials, is straightforward. By working deeply with a small number of distributors, Rockwell can disseminate consistent training, preserve product quality, and maintain strong feedback loops from the field back into engineering. Instead of many resellers competing mainly on price and leaving customers to fend for themselves on application support, a single authorized distributor is accountable for both supply and outcomes.

There is a perceived trade-off. HESCO notes that with one authorized distributor in a region, buyers may feel they have less choice and less direct price competition. Discounts tend to be driven by overall value, lifecycle partnership, and project scope rather than aggressive spot pricing. However, for high-consequence environments like power systems, the model is designed to trade a small amount of price flexibility for significantly better reliability, support, and risk control.

Rockwell AutomationŌĆÖs official description of its authorized distributor program reinforces that point. Authorized distributors are positioned as partners who deliver automation sophistication, manage the electrical supply chain, provide world-class local support, and train customer personnel. They are measured on helping customers realize quantifiable cost savings and on freeing plant teams to focus on their core operations rather than chasing parts and solving integration problems alone.

For power and protection applications, this structure means that the same organization that sells you a PLC for generator control, a safety relay for an emergency shutdown system, or a software license for monitoring is also expected to help ensure those elements work together reliably across the system lifecycle.

To understand why RockwellŌĆÖs approach matters, it helps to look at what ŌĆ£authorized distributionŌĆØ actually means in a broader electronic components context.

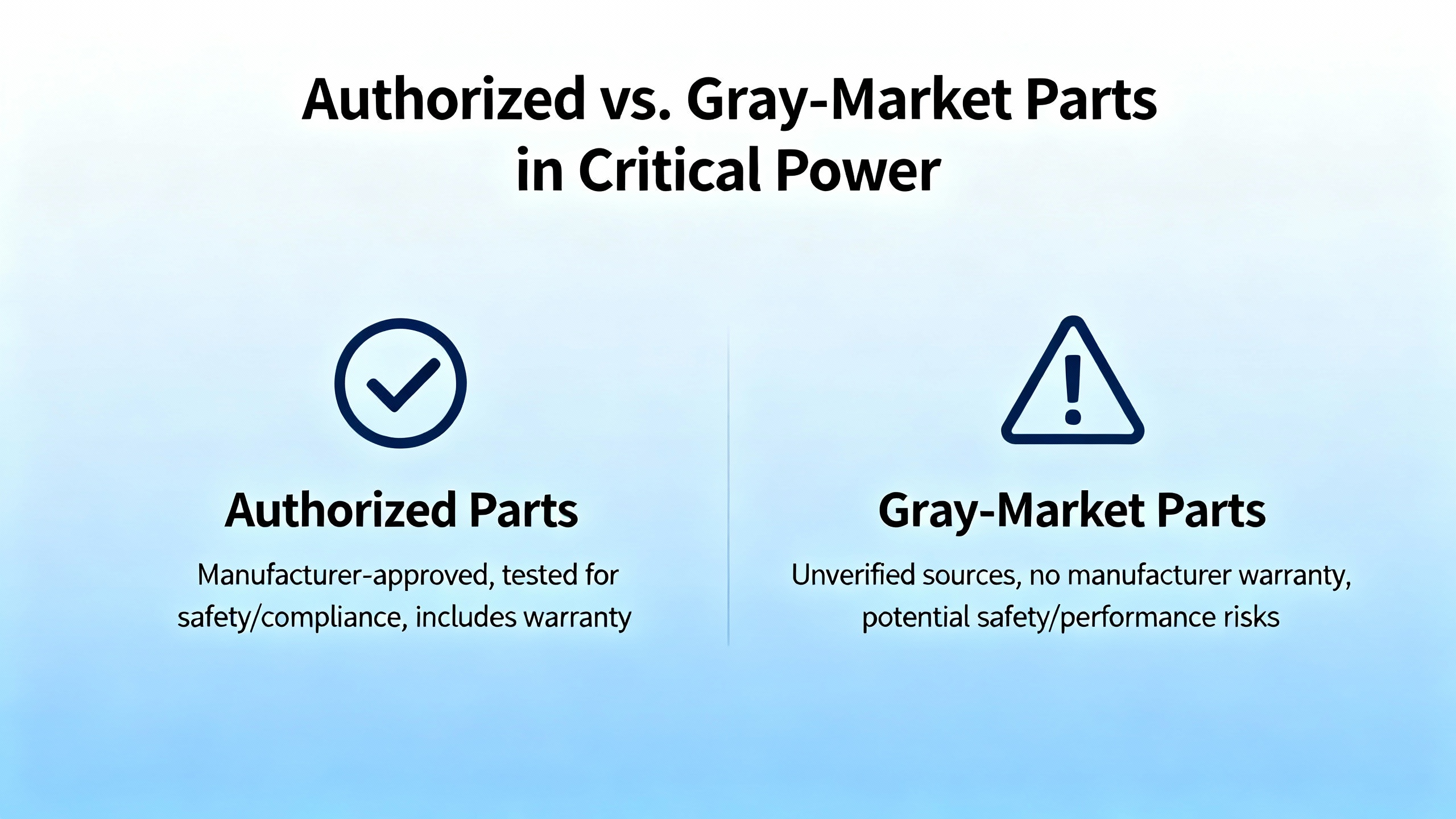

Electronics Sourcing defines authorized distribution as sourcing components through distributors that have direct, contractual relationships with the component manufacturers. These distributors receive factory-direct products, handle them under controlled conditions, and operate under the manufacturersŌĆÖ quality, storage, and traceability requirements. Similarly, ABB describes an authorized distributor as a seller vetted and approved by the manufacturer, following strict guidelines for sourcing, handling, and distribution.

Unauthorized or grayŌĆæmarket sellers operate outside these agreements. They may obtain parts through excess inventory, brokered deals, or unknown intermediaries. Even if the packaging looks genuine, there is typically no guarantee that the components were stored correctly, have not been refurbished, or are even authentic. Electronics Sourcing and EE Times both describe the consequences for OEMs: higher risk of product failures, safety incidents, recalls, lawsuits, and reputational damage.

In a power system, counterfeits and mishandled components rarely fail in polite conditions. They fail when the UPS transfers on a deep sag, when the inverter blocks a fault, when an upstream breaker clears a short on a bus duct, or when an emergency generator starts under load. Those are precisely the moments when you are depending on Rockwell controllers, networks, and safety systems to behave predictably.

Authorized distribution reduces these systemic risks in three ways, as highlighted across industry sources like EE Times, Electronics Sourcing, ABB, and Area51 Electronics. First, authenticity is guaranteed because components travel directly from the manufacturer to the authorized distributor and then to you. Second, warranties remain intact. Components purchased through unauthorized channels are often ineligible for manufacturerŌĆæbacked warranty support. Third, quality and compliance are monitored through formal quality management systems and certifications, such as AS6081 in the broader electronic component world, which define methods for detecting and avoiding fraudulent parts.

For Rockwell Automation equipment that underpins critical power systems, authorized distributors are the formal channel for ensuring that these protections actually apply.

From a power system reliability standpoint, a Rockwell authorized distributor is not simply a store for AllenŌĆæBradley hardware and FactoryTalk software. The value shows up in daily operations, in upgrade projects, and especially when something goes wrong.

Across multiple publications, including Electronics Sourcing and EE Times, the consensus is clear. Authorized distributors are the only way to be certain that parts are genuine, compliant with the manufacturerŌĆÖs specifications, and covered by the original warranty. Buying through unauthorized channels often voids manufacturer warranties, shifting the entire risk of defects and failures to you.

For Rockwell Automation, authorized distributors are directly connected to RockwellŌĆÖs own support and warranty systems. If a critical input card, drive control module, or communication interface fails prematurely, your authorized distributor can validate the serial number, confirm that it moved through legitimate channels, and help coordinate repair or replacement within the warranty terms.

The relationship between Rockwell distributors and Rockwell Automation Gold System Integrator Partners, described by Hargrove Controls & Automation, takes this a step further in project contexts. When products are registered and purchased through a Gold System Integrator, Rockwell extends the standard oneŌĆæyear manufacturing warranty by an additional two years, for a total of three years of coverage. Gold System Integrators are required to maintain a certain number of trained personnel and to implement Rockwell solutions using best practices. They coordinate directly with Rockwell and the distributor, meaning the whole chain from specification to commissioning to warranty sits inside a single, aligned ecosystem.

In practical terms, if you are deploying a new mediumŌĆævoltage switchgear lineup with Rockwell-based control and monitoring, or a coordinated UPS and generator control scheme, structuring that project through an authorized distributor and, when appropriate, a Gold System Integrator, gives you stronger warranty protection and a clearer path to resolution if any component underperforms.

HESCOŌĆÖs description of RockwellŌĆÖs limited distribution model emphasizes another reliability benefit: local, tailored inventory. The exclusive distributor in a region is expected to carry stock suited to local demand. That can mean critical spares for common controller families, safety relays, communication modules, and other items that plants in the area depend on.

When a power or control failure occurs, the time to replacement part matters. Authorized distributors are tasked with getting critical parts to you in hours or days rather than waiting for distant warehouses. That is particularly important in power systems, where a failed communication card on a generator control panel or a blown I/O module in an automatic transfer scheme can leave you operating without redundancy or running on manual workarounds.

Industry commentary from Rockwell AutomationŌĆÖs authorized distributor program also highlights that these distributors manage customersŌĆÖ electrical supply inventory. In practice, that often means helping you design a critical spares strategy, stocking those spares locally, and maintaining visibility into usage so that replacements are reordered before you unknowingly run terminal inventory.

In the context of global shortages and long lead times, this local buffer can be the difference between a short outage and a prolonged period of degraded protection or limited redundancy.

One of the less obvious but most valuable aspects of RockwellŌĆÖs distribution model is expertise. HESCO notes that exclusive Rockwell distributors invest heavily in inŌĆæhouse engineers and product specialists trained by Rockwell. RockwellŌĆÖs own materials describe authorized distributors as delivering automation sophistication, not just product fulfillment.

At the same time, industry trends described by Schneider Electric and others show that industrial automation distributors are shifting from hardware suppliers to consultative partners. They are expected to be conversant in industrial software, data connectivity, and remote diagnostics, not just in catalog part numbers.

Bringing this into the power domain, a strong Rockwell authorized distributor will typically help you with tasks such as selecting the right PLC platform and I/O modules for generator paralleling, designing network architectures for redundant control of UPS systems, applying safety-rated controllers for emergency shutdown (ESD) and fire-and-gas functions, and integrating power monitoring into enterprise-level platforms.

Articles on process and machinery safety from partners that represent Rockwell emphasize that RockwellŌĆÖs safety systems are designed to meet Safety Integrity Level requirements for applications such as ESD, fire and gas, turbine and compressor control, combustion control, and critical process control. For a power engineer, that means your distributor should be capable of helping you choose and apply the right safety architectures around those systems, rather than leaving you to interpret standards and application guides solo.

Modern power systems are no longer static. Plants are layering in digitalization, remote monitoring, and advanced analytics to understand power quality, load behavior, and asset health. Rockwell Automation and its partners, including distributors like WESCO and system integrators highlighted by Rockwell, stress that their value is not limited to initial sale and startup.

RockwellŌĆÖs authorized distributors provide training for customer personnel, helping them build internal capability on Rockwell platforms. Hargrove describes how Gold System Integrators create technology roadmaps aligned with a clientŌĆÖs current reality and future vision. PIMA, writing as a Rockwell-related partner for Aveva System Platform, explains how a scalable industrial software platform can standardize operations and integrate disparate systems across manufacturing, energy, and infrastructure environments.

Taken together, these capabilities enable a production or facility team to move from islands of automation toward something closer to RockwellŌĆÖs Connected Enterprise vision, where control and information are unified across the enterprise. For power systems, that can translate into integrated dashboards showing UPS status, breaker trip histories, generator availability, and power quality incidents alongside production metrics and maintenance work orders.

A distributor that understands both the hardware and the software stack can help you design and implement these integrations incrementally, instead of forcing costly ripŌĆæandŌĆæreplace projects.

It is helpful to make this concrete. Consider a facility where Rockwell equipment is central to power and protection: UPS systems interfaced via Ethernet to Rockwell PLCs, generators managed by Rockwell-based control panels, safety functions implemented with Rockwell safety controllers, and power monitoring distributed through Rockwell networks.

In such a facility, unauthorized sourcing can introduce hidden failure modes at several levels.

At the component layer, using nonŌĆæauthorized vendors for key items like PLC processors, communication modules, or safety I/O can weaken the integrity of the entire protection chain. Electronics Sourcing documents that substandard or counterfeit components can result in higher failure rates, increased warranty claims, and customer dissatisfaction, along with potential liability if failures cause damage or injury. When those components sit inside a power protection system, their failure can translate directly into unplanned outages and unsafe conditions.

At the system layer, bypassing the authorized distributor cuts off a line of engineering support. HESCO and Rockwell emphasize that authorized distributors are trained specifically on Rockwell products and are expected to help with design, troubleshooting, and optimization. Without that support, plants often implement adŌĆæhoc modifications, firmware mismatches, or nonŌĆæstandard wiring schemes that work just well enough to pass initial tests but cause intermittent issues later.

At the lifecycle layer, unauthorized channels often provide no structured support for endŌĆæofŌĆælife (EOL) planning. Electronics Sourcing points out that authorized distributors help manage component EOL by leveraging factoryŌĆædirect lines and proactive EOL mitigation strategies so that longŌĆælived systems remain maintainable. In power systems, where switchgear, UPS, and generator assets can remain in service for decades, this longŌĆæterm visibility is essential. Losing it can leave you scrambling for obsolete parts in the gray market at exactly the wrong time.

By contrast, staying within RockwellŌĆÖs authorized distribution network aligns your interests with those of Rockwell and its partners. The distributor has an incentive to protect your uptime because their longŌĆæterm relationship and performance metrics depend on it. If an issue escalates, Gold System Integrator partners can take it directly to Rockwell technical support, as Hargrove describes, accelerating rootŌĆæcause analysis and resolution.

From a power system specialistŌĆÖs standpoint, the relationship with the Rockwell distributor works best when it is treated as a strategic collaboration, not an occasional transaction.

For engineering and maintenance leaders, that begins with transparent sharing of your power architecture and reliability objectives. Providing oneŌĆæline diagrams, protection philosophies, critical load hierarchies, and target redundancy levels helps your distributor recommend the right controllers, networks, and safety architectures. They can, for example, help you choose between different PLC families for generator paralleling, size communication networks for redundant UPS monitoring, or select safety system topologies that meet your required risk reduction.

Early engagement also aligns projects with warranty and support structures. If you are planning a major power upgrade or migration, engaging both the authorized distributor and a Rockwell Gold System Integrator, where appropriate, can ensure that product registration, configuration, and documentation are all handled in ways that unlock extended warranty and highŌĆælevel escalation pathways.

On the operational side, facility teams can lean on authorized distributors for spare parts strategy and training. Authorized distribution programs, as described by Rockwell, include management of electrical supply inventory and training for plant personnel. For a power system, that might translate into agreed minimum stock levels for critical Rockwell modules, standardization across similar assets to simplify spares, and training sessions that keep technicians current on firmware, configuration tools, and diagnostic techniques.

No plant is entirely singleŌĆævendor. Most facilities run mixed ecosystems of automation and power equipment, and older assets may require components that are no longer available through primary channels. Industry articles from Area51 Electronics, Automa.Net, ETI Systems, and others explain how independent distributors can play an important role in sourcing obsolete or multiŌĆævendor industrial automation parts.

These sources also caution that independent distribution is a doubleŌĆæedged sword. Area51 Electronics points out that independent channels, if not properly certified, can introduce high counterfeit risk, especially during shortages. At the same time, they note that independent distributors with certifications such as AS6081 implement rigorous processes to detect fraudulent parts and manage obsolescence responsibly. Automa.NetŌĆÖs coverage of independent distributors highlights how curated portfolios and strong supplier relationships can reduce lead times and improve access to specialized brands.

For Rockwell-based power systems, the practical advice is to use independent distributors judiciously, mainly for nonŌĆæRockwell components or truly obsolete items where the authorized path is closed. When you do, favor independents that can demonstrate certifications, documented quality systems, and traceability. For active Rockwell products, the balance of evidence strongly supports staying firmly within the authorized channel.

The temptation to buy Rockwell hardware from generic online marketplaces is real, especially when a listing appears to offer lower prices or faster delivery. ABBŌĆÖs guidance on authorized distribution warns that unauthorized sellers often compete primarily on price while increasing the risk of counterfeit or mishandled parts and undermining warranty coverage. Authorized dealer analyses from other sectors reinforce that while online channels can be legitimate, authorized status and adherence to manufacturer agreements are the critical differentiators.

In the context of RockwellŌĆÖs limited distribution model, it is important to verify whether any online seller is part of RockwellŌĆÖs authorized network in your region or is working legitimately through that network. Otherwise, you may be stepping outside the traceable supply chain without realizing it. The shortŌĆæterm savings can evaporate quickly the first time a suspect part causes a protective misoperation or voids a warranty claim.

The benefits and trade-offs of RockwellŌĆÖs authorized distribution model become clearer when viewed through a power-systems lens. The following table summarizes key points derived from Rockwell Automation literature, HESCO, Electronics Sourcing, EE Times, and related sources.

| Aspect | Primary benefit for power systems | Trade-off or consideration |

|---|---|---|

| Authenticity and quality | Genuine, specification-compliant Rockwell parts in protection and control paths reduce hidden failure modes during faults and disturbances. | You may see less aggressive price competition than on gray-market or brokered channels. |

| Warranty and accountability | Clear access to manufacturer-backed warranty and structured escalation through distributors and Gold System Integrators. | Warranty terms typically require purchases through authorized channels, limiting flexibility to chase unverified deals. |

| Local inventory and logistics | Regional stock of critical controllers, I/O, and communication modules shortens recovery time after failures. | You may need to coordinate with the distributor on planned spares strategies rather than buying ad hoc. |

| Engineering and safety support | Trained engineers help design and troubleshoot generator controls, UPS interfaces, safety systems, and digital integration. | Design discussions require sharing more system detail than a pure price-quote transaction. |

| Lifecycle and EOL planning | Guidance on migration paths and EOL management keeps long-lived power assets maintainable. | You may need to align upgrade timing and standards with Rockwell roadmaps rather than one-off component swaps. |

From a reliability advisorŌĆÖs standpoint, these trade-offs are usually favorable wherever power availability and safety are critical to business outcomes.

Industry evidence suggests that visual inspection and even original-looking packaging are not reliable guarantees of authenticity. EE Times and Electronics Sourcing highlight that counterfeit electronic components can pass initial inspection and still fail under real operating conditions. ABB emphasizes that purchases from unauthorized sellers commonly void manufacturer warranty coverage. For Rockwell equipment in critical power applications, buying from non-authorized sellers introduces unnecessary risk. Even if the upfront price is attractive, you are trading traceability, warranty, and support for uncertainty at the very points in your system where failure hurts most.

According to Hargrove Controls & Automation, Rockwell Gold System Integrators are recognized partners with expanded capabilities and competencies on Rockwell platforms. They are required to maintain certified personnel and to apply Rockwell products using vetted best practices. For power projects, a Gold System Integrator often works alongside the authorized distributor. The distributor manages product availability, pricing, and local support, while the integrator handles detailed design, configuration, and commissioning. When products are registered and purchased through a Gold System Integrator, Rockwell extends the warranty to a total of three years, and the integrator can escalate critical issues directly into RockwellŌĆÖs technical organization. Together, they create a more robust safety net than either could alone.

Independent distributors, as described by Automa.Net, ETI Systems, and Area51 Electronics, excel at sourcing multiŌĆævendor and obsolete automation parts and at offering customized solutions across brands. In a Rockwell-based power system, they can be valuable allies for nonŌĆæRockwell components, legacy devices that are no longer supported through primary channels, or specialized items that fall outside the Rockwell ecosystem. However, Area51 Electronics stresses that independent distribution without strong quality management and certifications, such as AS6081 for counterfeit avoidance, carries elevated risk. Use independent distributors selectively, favor those with documented quality systems and certifications, and keep active Rockwell Automation components on the authorized distributor path.

In critical power environments, you are not just buying PLC racks, safety relays, or software licenses. You are buying confidence that when the grid flickers, a breaker trips, or a generator starts, every link in your control and protection chain behaves as designed. Rockwell AutomationŌĆÖs authorized distributors exist to make that confidence defensible. As a power system specialist, my advice is simple: treat the authorized Rockwell channel not as a constraint but as a core part of your reliability strategy, and use it deliberately to protect the systems you cannot afford to see fail.

Leave Your Comment