-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Summary: Modern pulp and paper mills need tightly integrated automation and rock-solid power infrastructure to squeeze more tons, better quality, and lower energy use out of every production line without sacrificing reliability.

The pulp and paper industry is brutally energy- and capitalŌĆæintensive, so every minute of uptime and every kilowatt saved matters. Studies from North Carolina State University show that basic efficiency and reliability upgrades alone can cut mill energy use by roughly 20%, with 10ŌĆō30% greenhouseŌĆægas reductions from simple loss elimination.

Vendors like ABB, Emerson, Rockwell Automation, and Valmet now design millŌĆæwide automation platforms that go far beyond standalone PLCs. Their distributed control systems, advanced process control (APC), and analyzer packages span the entire flow: woodyard, pulping, recovery, utilities, paper machine, and finishing.

ARC and other analysts highlight a clear trend: new greenfield megamills are specified as ŌĆ£connected millsŌĆØ from day one, while mature plants pursue brownfield modernizationŌĆölayering advanced control, analytics, and energy management onto existing assets. In both cases, a coherent architecture beats patchwork upgrades.

Complete systems start with good frontŌĆæend engineering. ABB and ANDRITZ, for example, use simulation tools and FEED studies to validate process concepts and control strategies before hardware is ordered. ANDRITZŌĆÖs IDEAS simulator is widely used in kraft mills to test process design and control logic so startup is faster, smoother, and safer.

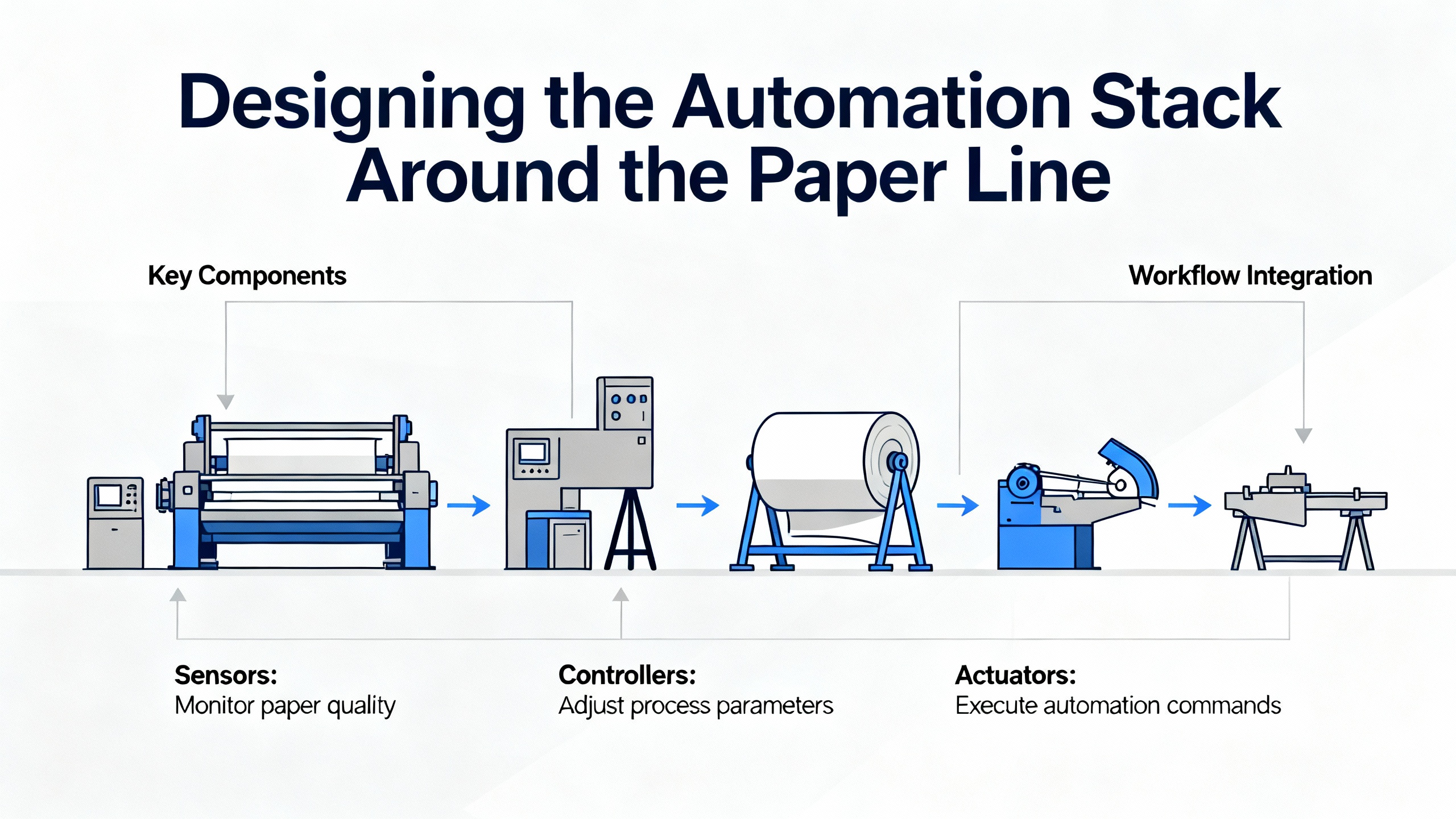

On the shop floor, the core stack typically includes:

Woodyard projects documented by EOSYS show how migrating obsolete PLCs to modern ControlLogix platforms, redesigning networks, and updating HMI graphics can radically improve visibility and reliability before a single new motor or conveyor is installed. In parallel, analyzers and realŌĆætime quality measurements (moisture, basis weight, chemical concentrations) close the loop on product quality.

As a power systems engineer, IŌĆÖve seen that the most successful projects insist on first proving control logic in simulation, then in an isolated factory acceptance test, before touching the running paper machine. That discipline saves both downtime and burned motors.

None of this automation delivers value if the electrical supply is unstable. A typical paper mill can burn through as much as half the heating value of incoming biomass just to generate steam and power; another large fraction is purchased from the grid. North Carolina StateŌĆÖs review notes that 40% of sector energy losses stem from equipment inefficiency and 28% from distribution systemsŌĆöexactly where power quality and protection live.

Modern mills are steadily upgrading to highŌĆæefficiency motors, intelligent MCCs, and variableŌĆæfrequency drives, as seen in projects using Rockwell IntelliCENTER and ControlNetŌĆæconnected VFDs. That cuts frictional lossesŌĆöoften 15ŌĆō25% of total mill energyŌĆöwhile giving fineŌĆægrained speed and torque control for web handling.

Equally important is protecting the automation layer itself:

In my mill projects, a properly engineered UPS and powerŌĆæquality scheme routinely pays for itself in avoided forced shutdowns. One unplanned paper machine stop, plus restart waste, often costs more than a decade of UPS maintenance.

Automation hardware is only half the story; data and people determine whether you capture its value. A Kaizen Institute case in pulp, paper, and packaging reported a 20% reduction in unplanned stoppages, 26% fewer planned stoppages, and over Ōé¼1.7 million in annual savings by combining lean methods, rootŌĆæcause analysis, and standardized work.

Digital toolsŌĆöAI, machine learning, and analyticsŌĆöare being adopted across mills, as described by the UMaine Pulp and Paper Foundation and Vector Solutions. Predictive maintenance, realŌĆætime monitoring, and connectedŌĆæworker platforms help teams spot microŌĆæstoppages, lubrication issues, levelŌĆæmeasurement problems, and quality drifts before they become outages.

There is a nuance: global surveys cited by Vector Solutions show large manufacturers have realized only a fraction of the revenue and cost benefits they expected from digital and AI initiatives. The gap usually traces back to weak change management, poor data discipline, and undertrained operators.

For a resilient, highŌĆæperformance paper mill, the recipe is consistent across the best performers:

Leave Your Comment