-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Summary: ABB variable frequency drives combine wide electrical ratings, advanced control modes, and robust environmental protection to deliver efficient, reliable motor controlŌĆöprovided you match the specs carefully to your load, environment, and power system.

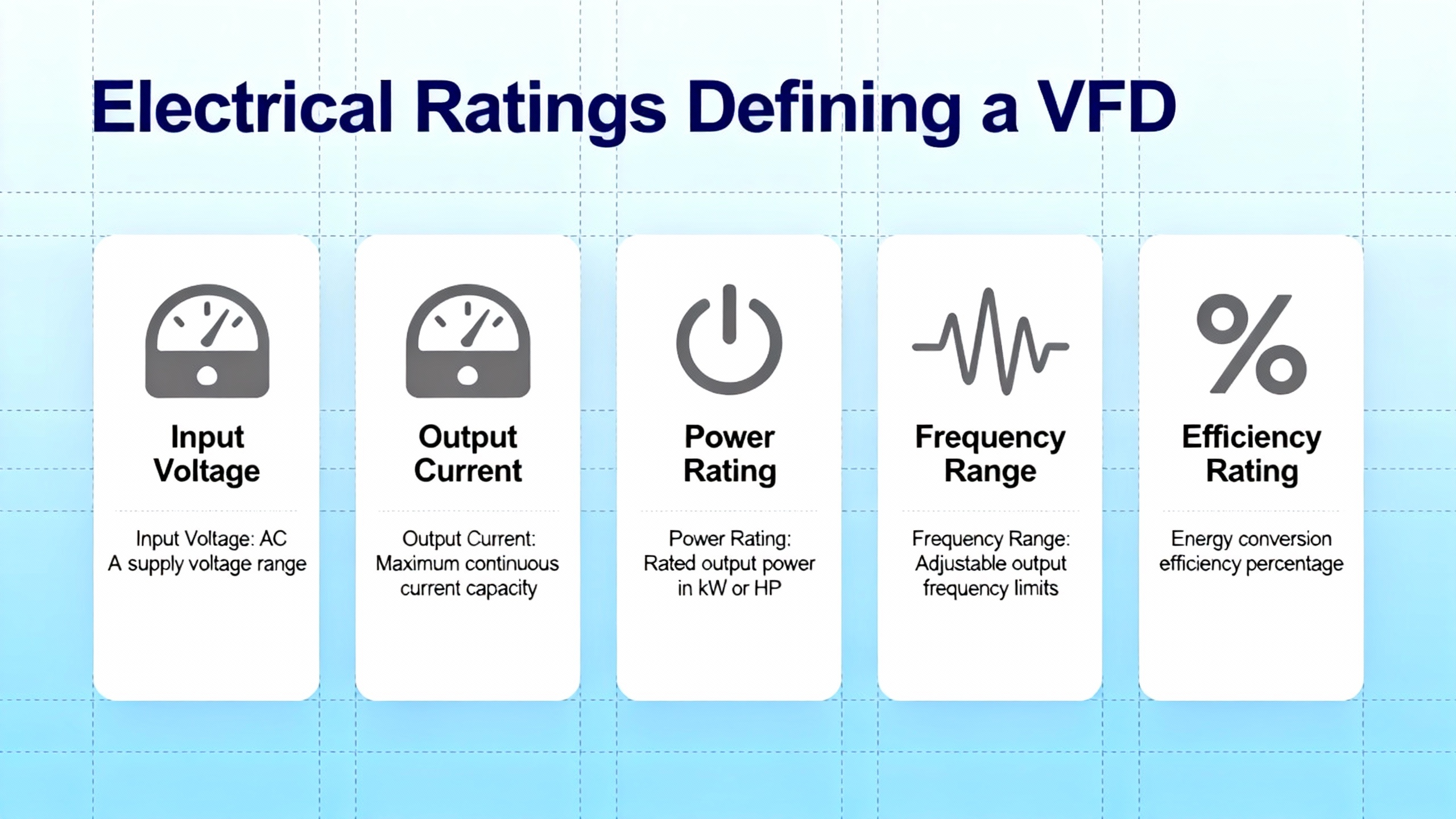

When you size an ABB VFD, the first filter is basic electrical ratings: voltage, horsepower, and current. Across the ACS family alone, you can cover everything from fractional horsepower OEM machines to multiŌĆæmegawatt process drives.

Micro drives such as the ACS255 typically span about 0.5ŌĆō20 hp on 115ŌĆō600 V systems with simple V/Hz or sensorless vector control, ideal for small pumps, fans, and conveyors. GeneralŌĆæpurpose ACS580 drives extend up to roughly 500 kW, while highŌĆæperformance ACS880 systems reach into the multiŌĆæmegawatt range for cranes, mills, and heavy process lines, as highlighted in Drives & Controls.

Overload capability is just as critical as continuous rating. Check that the selected ABB drive can deliver roughly 150% of rated current for around 60 seconds and up to 200% for brief peaks, as noted in selection guides from SHCKE and ABB partners. If your duty cycle includes frequent starts, jams, or high breakaway torque, you may need to step up one frame size to protect both motor and drive.

ShortŌĆæcircuit ratings are often overlooked at the specification stage. For example, the ACS550 family features shortŌĆæcircuit current ratings around 65 kA according to Industrial Gearbox Solutions. Your upstream protection, bus bracing, and drive SCCR must align, or you risk a noncompliant and unsafe installation.

From a process and reliability standpoint, the control method you choose matters as much as the nameplate amps. ABB gives you a spectrum: scalar V/Hz, sensorless vector, and highŌĆæend Direct Torque Control (DTC) in the ACS880 series.

Scalar control is perfectly adequate for nonŌĆæcritical variableŌĆætorque loads like standard building pumps and fans. When you need fast speed response, tight tension, or high starting torqueŌĆöthink winders, hoists, and highŌĆæspeed machineryŌĆövector or DTC is the right tool, as emphasized in ABBŌĆÖs drive comparison materials.

Motor compatibility is broad. The ACS380, for instance, can run induction, permanent magnet, and synchronous reluctance motors with multiple torque control modes. In food and beverage, the ACH580 Food Safe variants offer 1ŌĆō350 hp at 380ŌĆō480 V with Safe Torque Off, hygienic stainless housings, and conformalŌĆæcoated boards to survive aggressive washdown, while still delivering precise speed control.

In the field, most premature VFD failures I see track back to environment, not silicon. ABBŌĆÖs own guidance calls for typical operating ranges around 32ŌĆō104┬░F for standard indoor drives, with some families (such as ACH580 Food Safe) designed to operate from about 5ŌĆō131┬░F. If you run near the top of that range, derating or forced cooling stops nuisance trips.

Altitude limits are just as important: many ABB drives are rated up to roughly 3,300 ft without derating. Above that, thinner air reduces cooling, and you must apply the manufacturerŌĆÖs derating curves or risk thermal stress on DC bus capacitors and IGBTs.

Ingress protection (IP) ratings should match the real world, not the datasheet wish list. IP20 or IP21 suits clean electrical rooms; dusty or washdown zones push you toward IP54, IP55, or IP66 options found in ACS255, ACS580, and ACH580 families. SHCKE notes that the smallest ABB units can be roughly 4 ├Ś 2 ├Ś 5 in and about 2ŌĆō3 lb, but cabinetŌĆæmounted systems can exceed 200 lbŌĆöso plan structure, airflow paths, and service access early.

Clearances matter for thermal reliability. Industrial Gearbox Solutions recommends around 8 in above and below and about 2 in on the sides of typical wallŌĆæmounted ABB drives to maintain airflow. Cramming drives into undersized enclosures is one of the fastest ways to shorten service life.

From a powerŌĆæsystem perspective, a VFD is another intelligent load on your network. ABB drives support a wide set of fieldbusesŌĆöModbus, BACnet, PROFIBUS, PROFINET, EtherNet/IP, and othersŌĆöso you can supervise energy, alarms, and trends from your plant SCADA or building automation system. In HVACR applications, ABB reports energy savings on the order of 20ŌĆō60% in variableŌĆætorque services when drives are properly applied.

Safety functions are embedded, not boltŌĆæon. Even compact ACS255 and ACS380 models include Safe Torque Off certified up to SIL 3 in many variants, with the ACS880 adding safe speed and other advanced options. Properly wired, these functions let you meet machine safety standards without overŌĆærelying on contactors that introduce mechanical failure points.

When I advise teams on ABB VFD selection, I usually walk through four checkpoints:

One nuance: some thirdŌĆæparty technical PDFs (for example, from Precision Electric) sit behind security checks and were not accessible in this research, so always verify final numeric ratings against the latest ABB datasheet for your exact catalog code.

Done right, ABB VFD specifications become more than catalog numbersŌĆöthey become a design tool to lock in motor reliability, powerŌĆæsystem resilience, and measurable energy savings over the full life of the drive.

Leave Your Comment