-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Summary: Reliable terminal blocks are often the smallest parts in a power system, but they control whether your UPS, inverter, and protection gear run cool and troubleŌĆæfree or fail under load. The right supplier gives you a connection ŌĆ£ecosystem,ŌĆØ not just a block.

In industrial UPS rooms, inverter skids, and switchgear lineups, most failures IŌĆÖm called to investigate do not start in the siliconŌĆöthey start at the connections. Loose, undersized, or corroded terminal blocks are frequent hot spots.

Industry studies cited by Utility Electric and others suggest that about 30% of electrical service interruptions trace back to connector issues. For a critical UPS or power distribution unit, that means a $15.00 terminal block can jeopardize a $50,000.00 system.

Terminal blocks also shape how fast you can isolate faults, swap modules, or expand capacity. MultiŌĆælevel and pluggable designs highlighted by C3 Controls and RealPars routinely cut panel space by up to half and simplify field work.

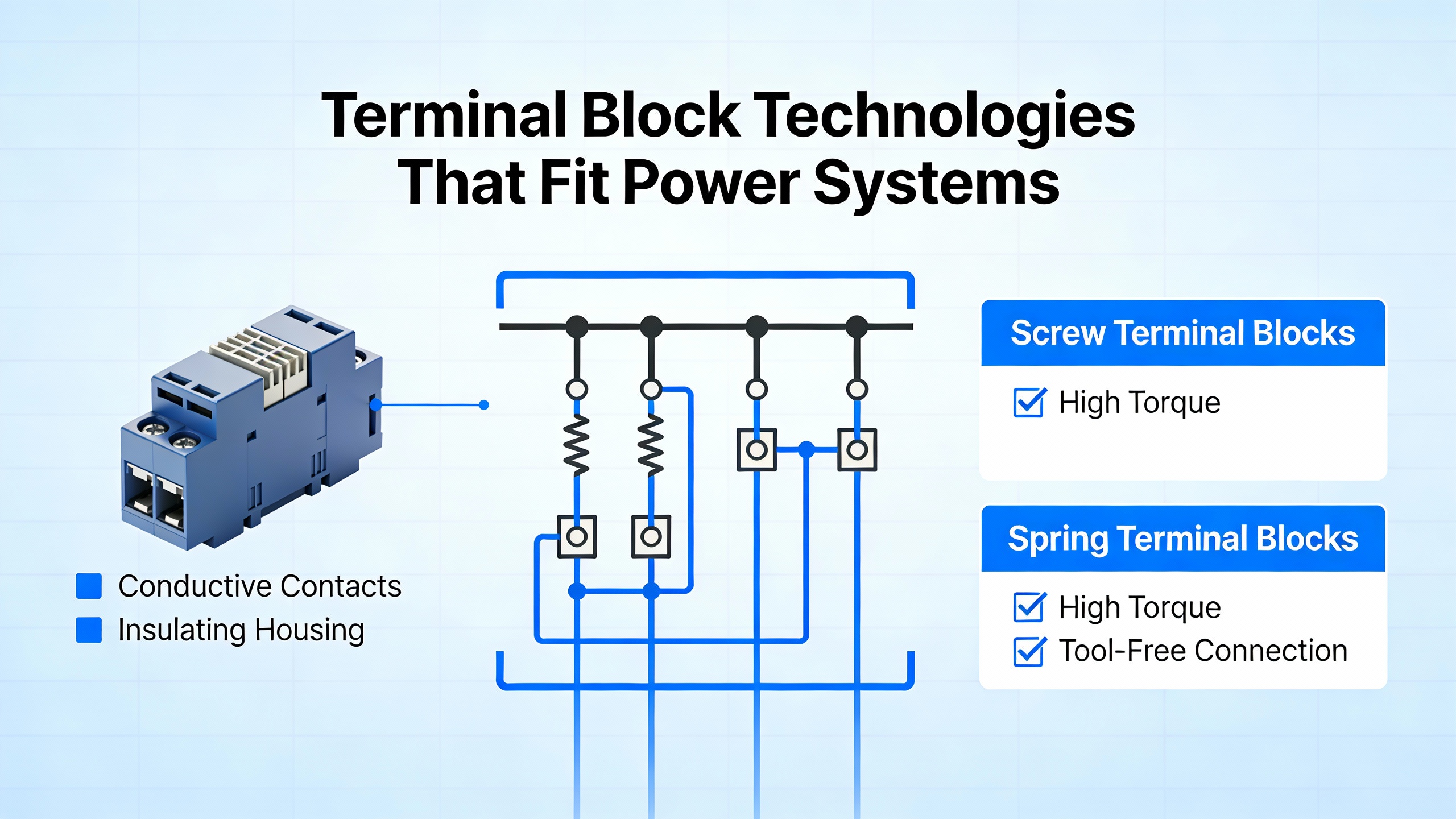

At the core, a terminal block is a modular, insulated connector that clamps two or more wires together safely, usually on a DIN rail. Barrier and screwŌĆæclamp styles remain the workhorse for highŌĆæcurrent AC and DC power circuits. They accept heavy conductors and ring lugs and are widely available at 600 V ratings.

SpringŌĆæcage and pushŌĆæin designs, emphasized by Simcona and Weidm├╝ller, trade torque wrenches for preloaded springs. They keep constant contact pressure, run cooler, and are much less prone to loosening in vibrationŌĆöideal around generators, motor loads, and floorŌĆæmounted UPS cabinets.

FunctionŌĆæspecific blocks add protection and organization: fused blocks for branch protection with LED blownŌĆæfuse indication, ground blocks that bond reliably to the DIN rail, and highŌĆæcurrent powerŌĆædistribution blocks that fan one feeder into many loads. As DigiKeyŌĆÖs jumper guidance reminds us, do not assume jumpers share the same amp rating as the main block; for heavy UPS feeders, a dedicated distribution block is safer than daisyŌĆæchained jumpers.

Serious suppliers sell complete ŌĆ£families,ŌĆØ not oneŌĆæoff parts. As DigiKey and C3 Controls point out, you want matching end plates, partition plates, jumpers, test plugs, labels, and multiŌĆælevel variants so your power, control, and signal wiring all share a consistent platform.

On the standards side, Eaton stresses IEC 60947ŌĆæ7ŌĆæ1 and UL 1059 compliance, as well as pollution degree and impulseŌĆæwithstand ratings. For equipment rooms that may see condensation or dust, selecting the right pollution degree (typically 3 for industrial) is just as important as picking the right amp rating.

Quick supplier checklist:

Multiple sources, including Misumi, FerrulesDirect, and Samesky Devices, converge on one simple rule: size current at about 150% of expected load. If your DC bus can see 80 A, specify at least a 120 A terminal block and use a true powerŌĆædistribution block for further branching.

Voltage rating is usually straightforward in North American power systems: for 208ŌĆō480 V applications, 600 VŌĆærated DINŌĆærail blocks provide comfortable margin, assuming creepage and clearance suit the pollution degree in your enclosure. EatonŌĆÖs work on microŌĆæenvironments is a reminder that a sealed UPS cabinet in a clean room is very different from one near a loading dock.

Mechanical and material choices matter as much as nameplate ratings. Electron and GKoncy highlight the benefits of copper or nickelŌĆæplated copper conductors, stainless hardware, and corrosionŌĆæresistant housings in damp or chemicalŌĆæladen air. In battery rooms and inverter skids, thatŌĆÖs how you avoid the slow creep from ŌĆ£slightly dullŌĆØ copper to a hot connection.

From an installation standpoint, follow the basics religiously: strip only the specified length (around 0.4 in for many blocks), fully insert the conductor, and tighten screws to the manufacturerŌĆÖs torque. Where vibration is high or retorquing is unlikely, favor spring or pushŌĆæin blocks from vendors like WAGO, Phoenix Contact, or Weidm├╝ller; in practice they hold up better than even wellŌĆæinstalled screw clamps.

A nuanced point: many panel builders still trust screw terminals out of habit, but modern spring and pushŌĆæin blocks deliver equal or better reliability when correctly specified. The real differentiator is not screw versus springŌĆöit is choosing a reputable supplier, sizing with margin, and treating every terminal as a critical component in your powerŌĆæprotection chain.

Leave Your Comment