-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

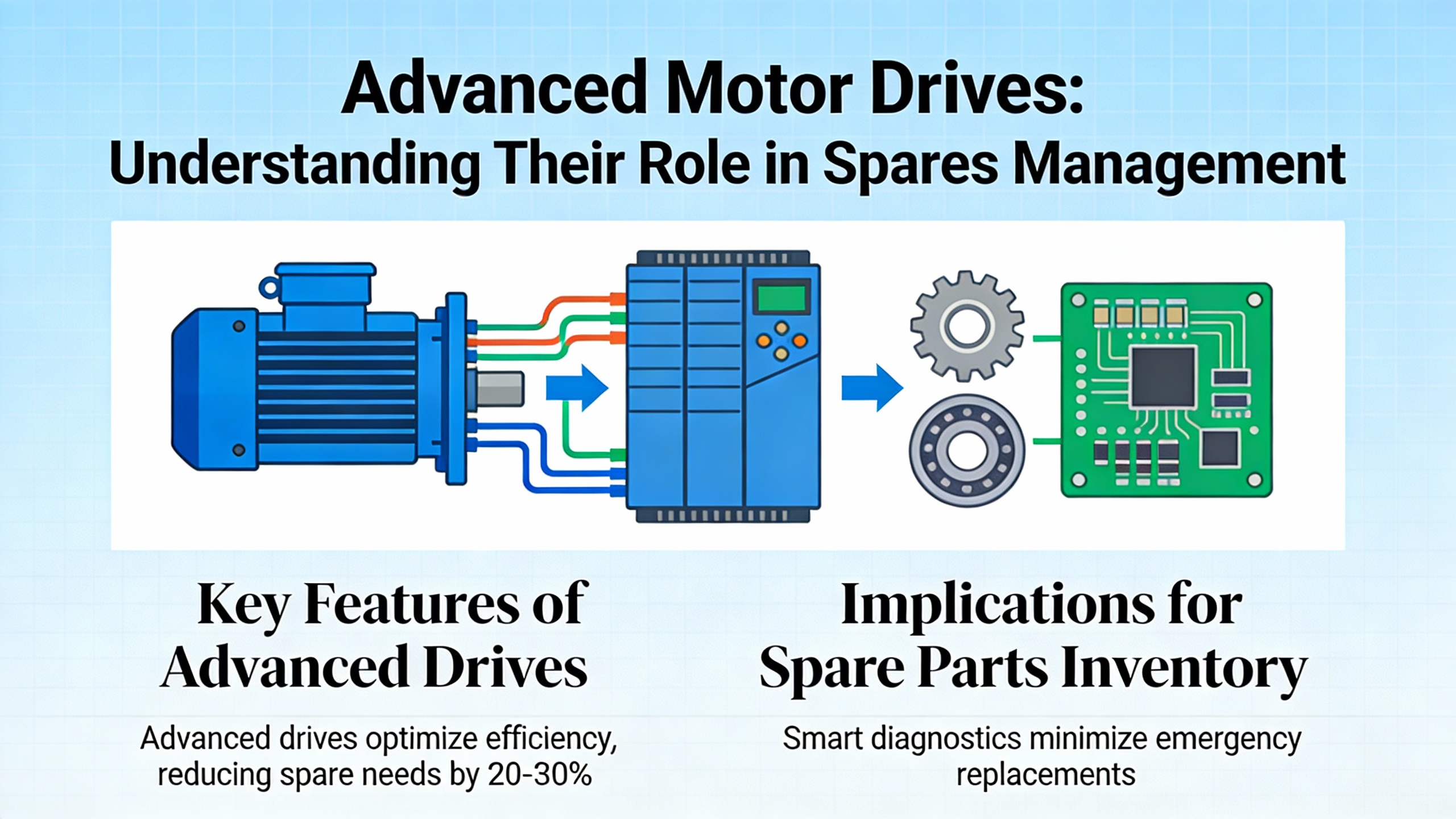

In modern plants, almost every critical process leans on motor drives. Variable frequency drives and inverter-fed motors run fans, pumps, compressors, conveyors, mixers, and material handling systems. A single failed drive can idle an entire line, jeopardize product quality, and erode the efficiency gains that justified the investment in the first place.

Industry guidance from sources such as Canroon and Sulzer is clear: AC drives are now a cornerstone of energy-efficient production, but they are also service items that degrade under heat, dust, poor power quality, and age. When one fails unexpectedly, the difference between hours and days of downtime often comes down to whether the right inverter parts can be delivered and installed immediately.

In this article, I will walk through how to build an emergency inverter parts delivery strategy specifically for motor drive applications, drawing on practical repair and power-quality guidance from Amikong, lifecycle insights from Sulzer, efficiency research from Accure, and spare-parts models from Siemens, NORD DRIVESYSTEMS, and Menzel Motors. The goal is simple and technical: shorter outages, safer restarts, and a more resilient drive fleet.

AC drive systems exist to match motor speed and torque to process demand. Canroon highlights that AC drives, including VFDs and servo drives, can cut motor-related energy use in industrial plants by up to roughly fifty percent and reduce global electrical energy use by about ten percent. In HVAC fan and pump applications, they report savings around thirtyŌĆæfive to fifty percent, often with payback in six to twentyŌĆæfour months. With a global AC drive market estimated at about $24.3 billion in 2023 and projected to reach around $52.7 billion by 2033, these drives are no longer niche accessories; they are fundamental infrastructure.

Sulzer emphasizes that variable speed drives, inverters, and soft starters must be treated as service items. Without regular maintenance, cooling path cleaning, and periodic component replacement, they lose efficiency and are more likely to fail, dragging down Overall Equipment Effectiveness. When failure does occur, Sulzer recommends emergency repair, particularly for legacy systems where direct offŌĆætheŌĆæshelf replacements simply do not exist anymore.

In typical field audits, I see two contrasting patterns. Plants that rely entirely on ad hoc sourcing often discover that a specific braking resistor, DC bus capacitor set, or control board is on a multi-week lead time. Production then runs on temporary work-arounds, if it runs at all. Plants that have thought through emergency parts delivery, by contrast, may not hold every part on a shelf, but they know exactly which components they will stock, which will be drop-shipped from OEM warehouses, and which will be covered by rapid repair or exŌĆæstock motor replacement services.

The common theme across these experiences and the referenced sources is that emergency inverter parts delivery is not just a logistics question. It is part of your reliability architecture, and it must be designed with a clear understanding of how drives fail and how they recover.

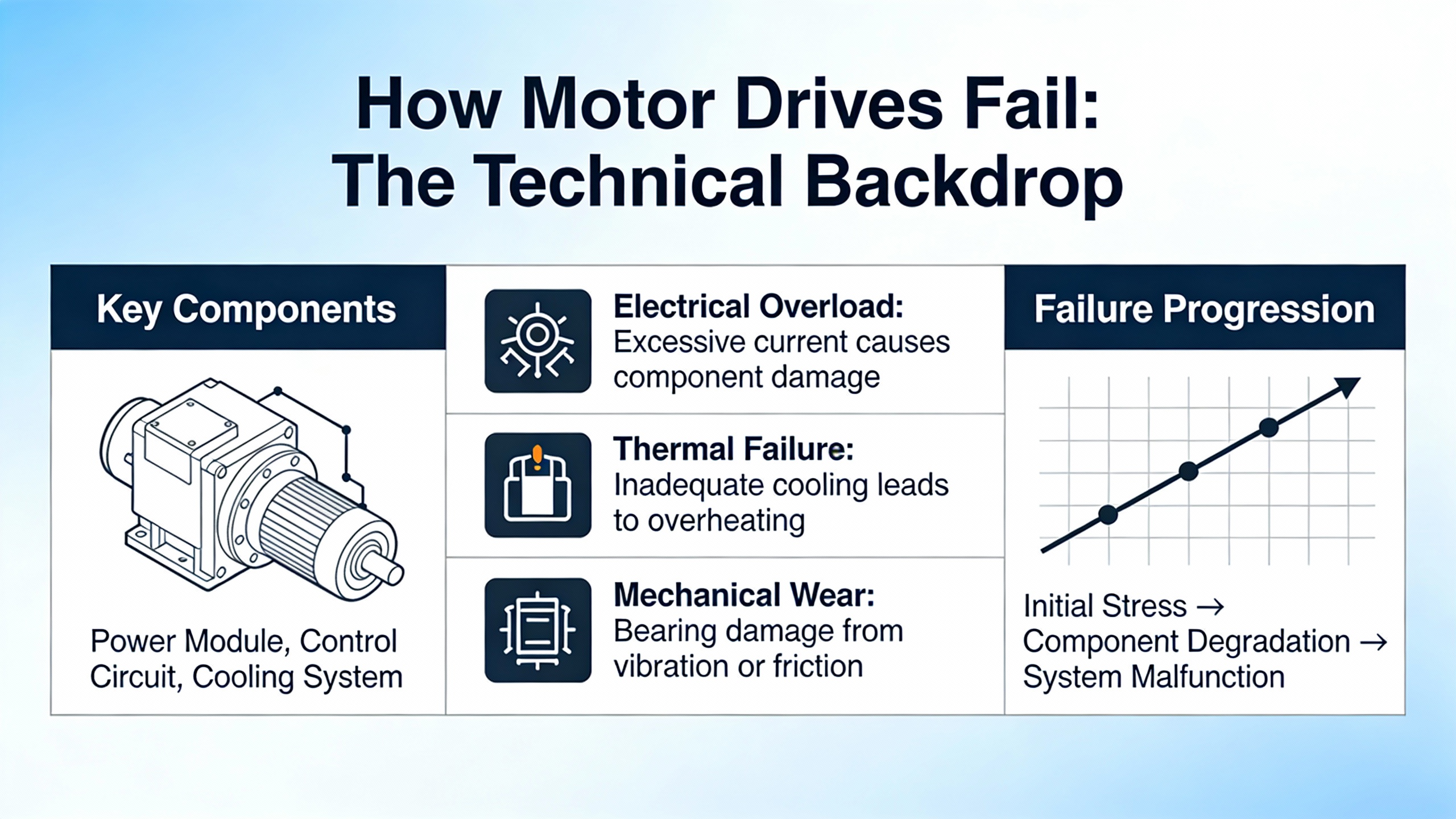

To design any credible emergency parts strategy, you first need a working model of how your drives operate and fail.

Canroon describes a typical AC drive as having three main hardware sections: a rectifier that converts grid AC to DC, a DC link made of capacitors that stabilize the DC voltage, and an inverter that converts this DC back to AC at variable voltage and frequency. By adjusting frequency and voltage, the drive maintains efficient torque production for the motor under changing loads.

Amikong stresses that variable frequency drives are highly sensitive to heat, contamination, poor terminations, and power disturbances. Many manufacturers cite about 104┬░F as a common upper ambient limit for full-capacity operation; clogged heat sinks, failed fans, dirty enclosures, and high humidity all shorten drive life and trigger overtemperature faults. Sulzer echoes this point, noting that open cooling apertures draw in dust, fans have limited lifespans, and even passive cooling fins clog over time. The result is overheating, derating, and eventually stoppage.

Power quality plays an equally important role. Amikong notes that for a 480 VAC-class drive, a healthy DC bus typically measures a little over about 678 VDC. A significantly low or unstable DC bus indicates upstream voltage problems or aged DC bus capacitors. Measuring that bus correctly requires a trueŌĆæRMS meter; averaging meters can be off by roughly forty percent on the pulse-width-modulated outputs of a VFD, which leads to misdiagnosis and wasted parts.

Canroon lists typical drive fault categories as overcurrent, overvoltage, undervoltage, overheating, and ground faults. Each of these faults points toward a different class of components and potential emergency replacement. For example, overvoltage during deceleration can be linked to missing or undersized braking resistors, while repeated undervoltage faults may suggest upstream supply issues, wired terminations, or DC link capacitor degradation.

The practical implication is straightforward. Emergency inverter parts delivery has to be tightly coupled with an accurate diagnosis. The aim is not merely having ŌĆ£a spare drive somewhere,ŌĆØ but having the correct high-yield components and partners ready once you know what failed and why.

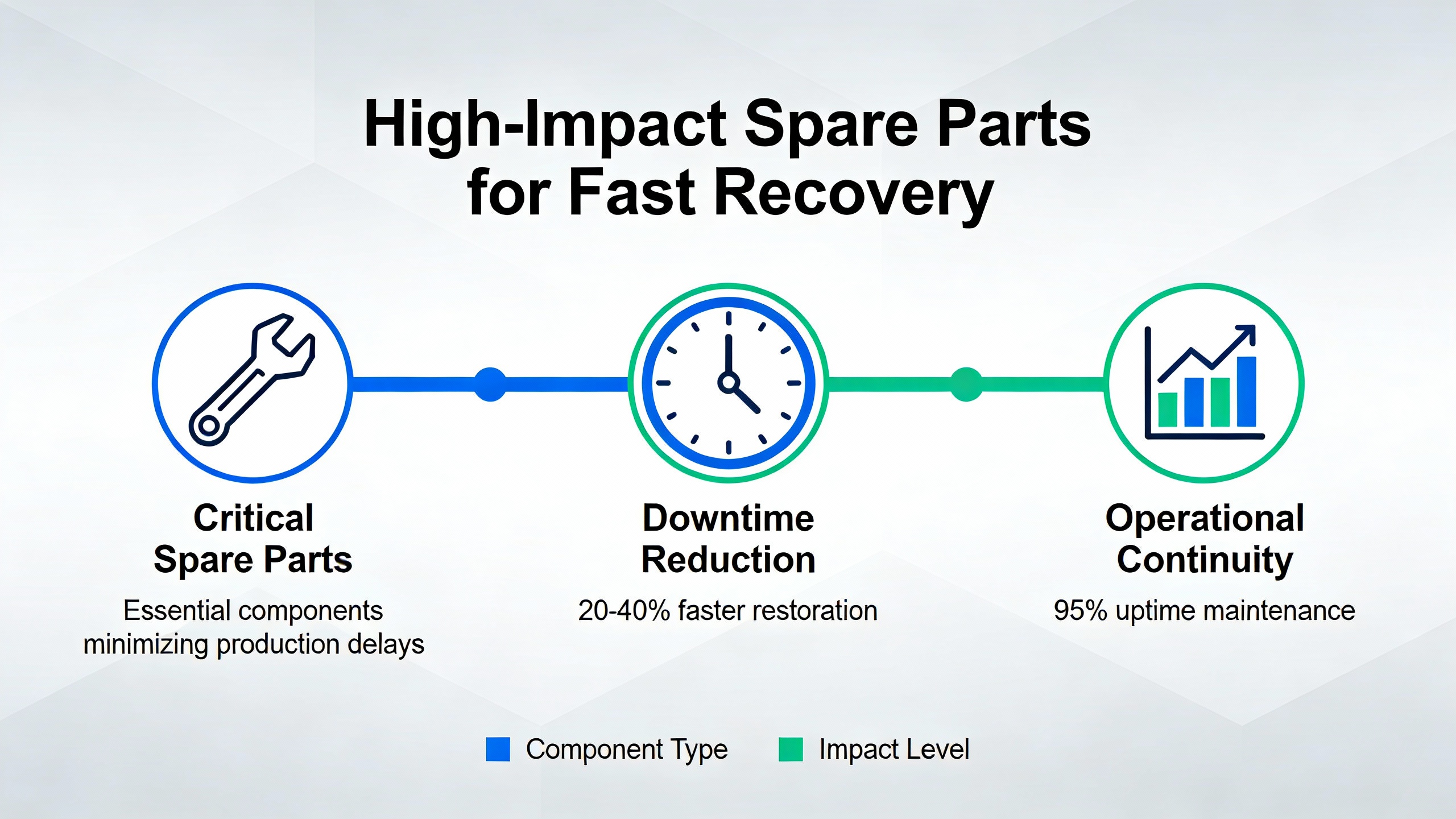

Not every inverter part is equal in an emergency. Amikong highlights a set of components that dramatically increase the chances of a quick and reliable restart when kept as spares or sourced via fast delivery. CNInverter adds maintenance and surge-protection details that help prioritize these parts.

Cooling fans are one of the highest-yield spares. Amikong notes that fans are often replaced every three to five years. When fans slow down or fail, heat sinks run hotter, internal temperatures rise, and overtemperature faults appear under otherwise normal loading. Since fans are relatively inexpensive and easy to swap, they are ideal for both on-site stocking and emergency shipping. SulzerŌĆÖs observation about clogged cooling fins reinforces this: even with replacement fans, keeping airflow paths clean is essential.

DC bus capacitors form the heart of the driveŌĆÖs DC link. Amikong recommends planning to replace them roughly every seven years. When they age, the DC bus voltage starts to sag and ripple. Using their 480 VAC example, if you measure far below the expected DC bus level of about 678 VDC, or you see unstable readings under steady load, it is a strong indicator that the bus capacitors are tired. Because capacitor failures can mimic upstream power issues, having known-good replacement capacitor banks available through rapid delivery helps confirm the diagnosis and restore drive stability.

Protection components at the line side handle many of the violent events that disable drives. Amikong lists line fuses or breakers and metal oxide varistor surge suppressors as key emergency items. After a lightning event or large switching surge, you might find open fuses and stressed MOVs that sacrificed themselves to protect the electronics. CNInverter notes that using surge protectors and correctly sized fuses can reduce inverter failures by up to roughly fifty percent, underscoring why these devices belong both in your preventive design and in your emergency spares kit.

On the braking side, Amikong points out that drives often trip on DC bus overvoltage during deceleration or when handling overhauling loads. In these cases, the emergency fix can be as simple and specific as installing a properly sized braking resistor or dynamic braking package, combined with tuning deceleration ramps. When a production line cannot slow a conveyor or hoist without tripping the drive, expedited delivery of the correct resistor can be the difference between limping along and returning to stable operation.

Power-quality conditioning hardware deserves more attention than it usually gets in spares planning. Amikong describes how surge protective devices coordinated with upstream protection, plus AC line reactors or DC link chokes, improve surge ride-through and reduce ripple and current spikes. They caution that these components must be sized carefully to avoid excessive voltage drop and undervoltage trips. In multi-drive systems, they also warn about harmonic distortion causing overnight trips. Passive harmonic filters provide a tuned, cost-effective solution when the harmonic spectrum is stable, while active filters adapt to varying loads at higher cost but with more flexible performance. Although these filters are not replaced as often as fans or fuses, having a small selection of appropriately rated reactors and filters identified in advance, and knowing which supplier can ship them same day, enables targeted recovery when the root cause is upstream distortion.

Finally, output-side protection for the motor and cables cannot be ignored. Amikong notes that long VFD output leads can create reflected-wave voltage spikes at the motor terminals, sometimes roughly two to four times the line voltage. These spikes stress insulation and cause premature motor failures. Using motors built to VFD-specific standards, such as NEMA MG 1 Part 30/31, or adding output filters and better environmental control, is primarily a design-time decision, but these same components can be deployed in an emergency to stop a pattern of repeated drive and motor failures on long runs.

The table below summarizes how several of these components interact with emergency response, using only the signals and recommendations described in the referenced material.

| Component | Role in the drive system | Typical failure signal (per sources) | Emergency response focus |

|---|---|---|---|

| Cooling fans | Move air across heat sinks and internal components | Overtemperature faults, hot heat sinks, dust buildup in fins | Keep replacement fans on hand or rush-ship; clean cooling paths as Sulzer advises |

| DC bus capacitors | Stabilize DC link voltage | DC bus well below expected level (for example, under about 678 VDC on a 480 VAC-class drive) or unstable under steady load, as Amikong notes | Use trueŌĆæRMS measurements to confirm; replace capacitor banks and evaluate line reactors or chokes |

| Line fuses and MOV SPDs | Protect against surges and faults | Blown fuses after storms or switching events, visible MOV damage | Replace fuses and SPDs; follow CNInverterŌĆÖs guidance that robust surge protection can halve failure rates |

| Braking resistors | Absorb regenerative energy during deceleration | Overvoltage trips on deceleration or with overhauling loads | Increase decel time or add correctly rated braking resistors as emergency parts |

| Line reactors and DC chokes | Smooth line current and reduce ripple | Frequent DC bus ripple-related alarms, nuisance trips from spikes | Add or replace reactors/chokes, balancing improved filtering with acceptable voltage drop |

| Harmonic filters | Reduce THD from multiple drives on a network | Repeated trips on panels with many VFDs, especially overnight | Install passive or active filters sized to the drive group and harmonic profile |

| Output filters / VFD-rated motors | Protect motors and cables from reflected waves | Motor insulation failures at the end of long cable runs | Add output filters and use VFD-rated motors to stop recurring failures |

CNInverter also emphasizes low total harmonic distortion and stable voltage as key inverter quality indicators, along with the importance of routine maintenance: monthly cleaning to remove dust from cooling paths and quarterly leakage tests. In practice, these habits reduce the number of emergencies. When emergencies still occur, the same parts and measurements become your roadmap to a fast, reliable repair.

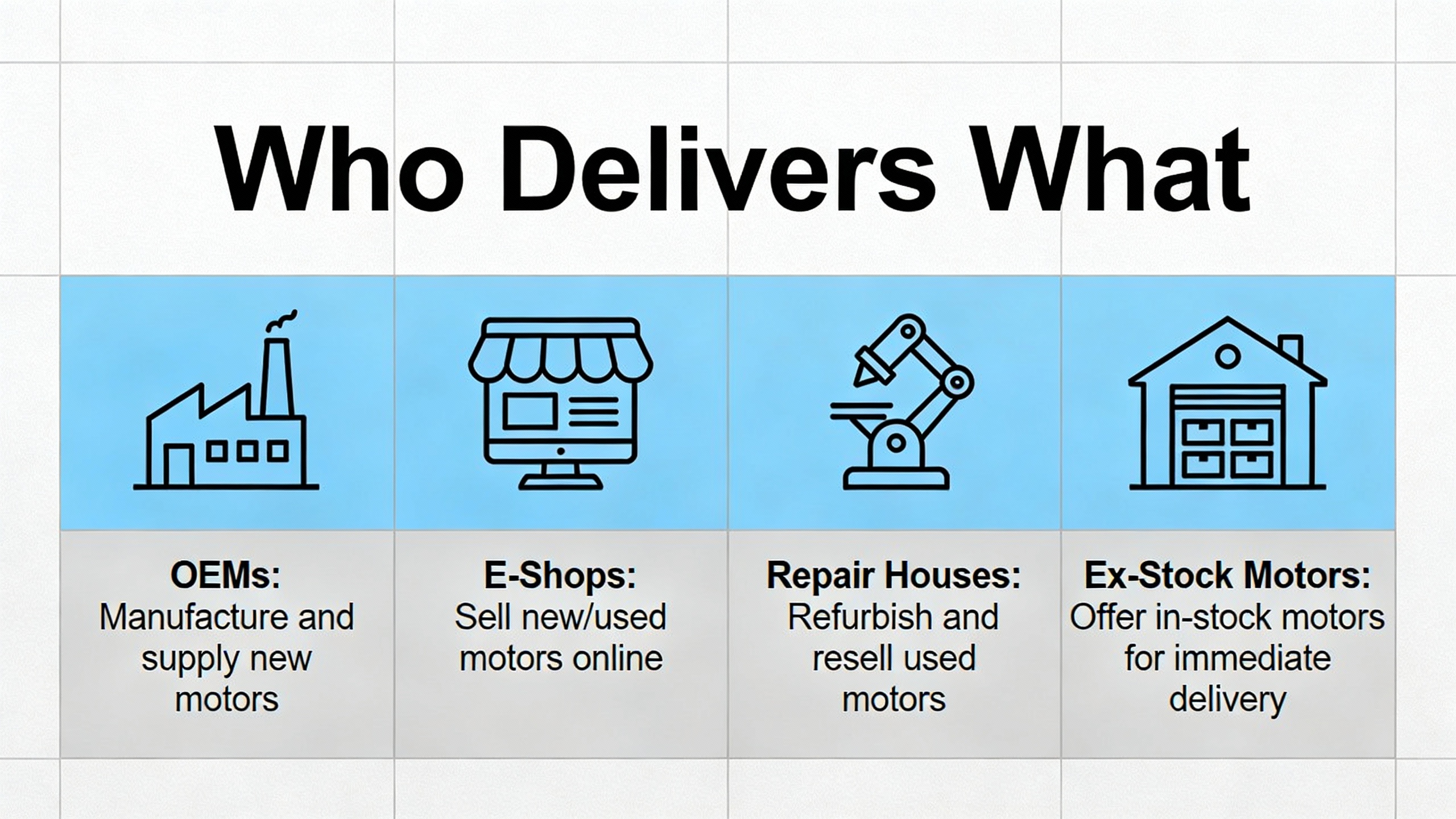

Having identified which parts matter, the next question is who will supply them on short notice. The research notes show several complementary models used in industry.

Siemens describes a spare parts service with regional warehousing focused on delivering the right parts at the right time to minimize downtime and maintenance costs. They report stocking more than twenty thousand new and refurbished items, covering automation, controls, drive components, and CNC parts. The emphasis is on system-compatible components that can be delivered quickly to a customer site. For many plants, this type of regional warehouse relationship is the backbone of emergency delivery for drive electronics and control modules.

NORD DRIVESYSTEMS offers a different but compatible model through its eŌĆæshop. NORD has supplied drive solutions for more than fifty years, with a modular system that lets users combine gear units, motors, and inverters to match specific applications. Their online platform allows customers to enter a serial or order number and immediately view the parts list for that specific drive unit, from small items like bearings and seals to complete frequency inverters and geared motors. Once a plant is registered, this makes identifying and ordering exact replacement parts much faster, which is invaluable when a drive fails and you need a specific board or motor variant shipped the same day.

Sulzer positions itself as a specialist in repair and lifecycle support for inverter drives, including both modern and obsolete systems. They advise building a facility-wide inventory of all drives and marking the ones that are critical to production. When one of those critical drives fails, particularly if it is from a discontinued product line, emergency repair can be the only practical option. Sulzer notes that routine servicing costs are vastly lower than unscheduled plant downtime, but when prevention falls short, the ability to restore a complex or legacy drive quickly becomes a major resilience asset.

Amikong references a repair provider, UpFix, reporting typical turnarounds of about two to five business days and up to roughly eighty percent cost savings compared with buying new drives. This does not eliminate the need for emergency on-site repairs or temporary replacements, but it underscores the role of rapid repair as part of the overall parts strategy, especially for expensive or specialized drives.

Menzel Motors addresses a different but related class of emergencies: failures of the motors themselves. They offer emergency replacement electric motors up to about 20,000 kW, specializing in replacing obsolete or discontinued units from a wide range of manufacturers, including major brands such as ABB, Siemens, WEG, and others. Menzel maintains extensive ex-stock inventories of modular motors, including large sizes, and adapts these models to match mechanical and electrical interface requirements so that ŌĆ£what does not fit directly is modified to fit immediately.ŌĆØ When a critical motor-drive combination fails and the motor is the limiting factor, this type of ex-stock supply can keep a plant running even when the original OEM can no longer deliver.

Taken together, these examples suggest that a robust emergency inverter parts strategy rarely relies on a single supplier. A realistic plan blends OEM regional warehouses, configurable eŌĆæshops, specialist repair houses, and emergency motor replacement services, with each channel aligned to a different class of failure and time horizon.

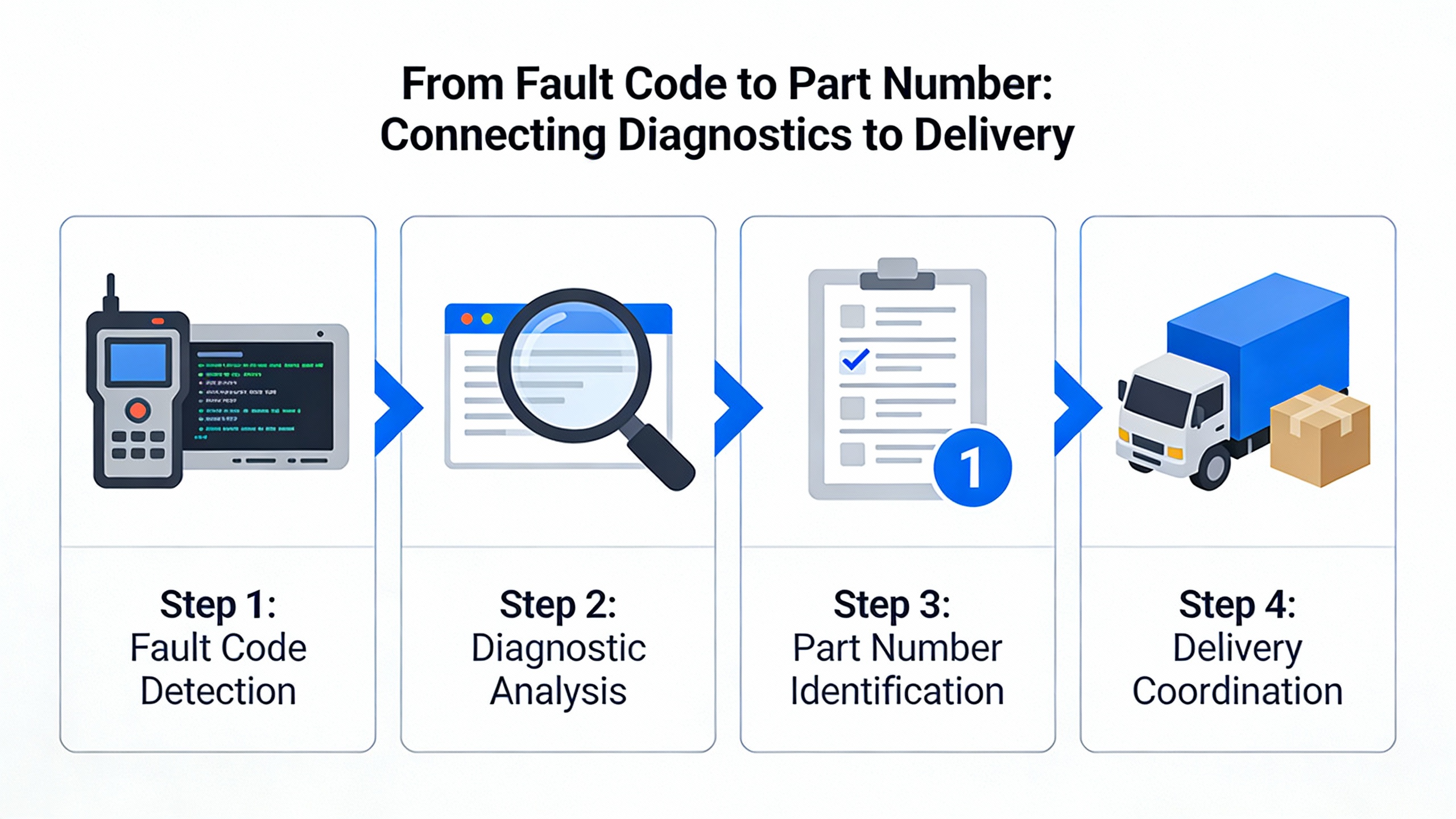

Successful emergency parts delivery starts at the drive, not at the warehouse. Amikong advocates a disciplined first-hour triage approach rather than random board swapping. Their recommended sequence is to read the drive fault code, check incoming power and terminations, inspect the environment and cooling, inspect the motor and mechanical load, then reset the drive and observe. This structured approach links symptoms to the right component class, which in turn tells you which part to pull from the shelf or order for expedited shipping.

Consider a practical example grounded in their guidance. A 480 VAC-class conveyor drive repeatedly trips on DC bus overvoltage whenever the system decelerates. The DC bus measurement matches the expected healthy level of a little over 678 VDC when running, but spikes on deceleration. The load is overhauling, meaning it drives the motor rather than the other way around during slowdown. In this situation, Amikong notes that missing or undersized braking resistors are a common culprit. The emergency remedy is not a new drive, but a correctly sized braking resistor or dynamic braking module, combined with more conservative deceleration ramps. Having a compatible resistor in your emergency inventory or a supplier prepared to ship one immediately is the shortest path back to reliable operation.

Another scenario involves repeated overnight trips in a panel with many VFDs. Amikong points to harmonic distortion as an often-overlooked cause of such behavior. Drives interacting through the shared supply can create high-order harmonics that stress not only the drives themselves but also upstream transformers and conductors. Passive harmonic filters tuned to the known spectrum can be a cost-effective addition where loads are relatively stable, while active filters that inject compensating current offer adaptable mitigation in mixed-load panels. If you monitor harmonic levels and see them trending upward, identifying and pre-qualifying filter packages that can be delivered quickly puts you in position to intervene before an overnight nuisance trip becomes a daytime production crisis.

Instrumentation is critical in both diagnosing and justifying which parts to order. Amikong underscores the need for a trueŌĆæRMS digital multimeter to measure line voltage and DC bus, an oscilloscope for high-frequency noise and transient analysis, a megohmmeter for motor insulation tests, clamp meters for current balancing, and thermal cameras for spotting localized heating. CNInverterŌĆÖs advice to perform quarterly leakage checks and to monitor for voltage stability dovetails with this; together, these tools transform a vague ŌĆ£drive keeps trippingŌĆØ complaint into a specific action such as ŌĆ£replace DC bus capacitors,ŌĆØ ŌĆ£install a line reactor,ŌĆØ or ŌĆ£add a braking resistor and adjust decel time,ŌĆØ each of which can be backed by an emergency parts order.

AccureŌĆÖs work on battery energy storage inverters adds a useful perspective on analytics. They show that round-trip efficiency and inverter performance are strongly dependent on loading profile and that standby and auxiliary losses can be disproportionately harmful when inverters operate at low power. Their example of a 100 MW storage system with twenty 5 MW inverters delivering only 10 MW illustrates that dispatching just two or three inverters at higher load is more efficient than running all twenty at partial load. In a motor-drive context, similar fleet-level analytics can reveal drives that are running in unusual conditions, indicating pending failures. Accure also recommends tracking parameters such as input and output voltage and current, switching frequency, temperature, and harmonic distortion over time. When those trends show deviation, you can pre-position the likely spare parts or schedule emergency delivery before a hard failure.

In practice, the best emergency parts decision is the one supported by clear measurements and trend data. That means the technical workflow from fault code to multimeter reading to part number must be designed ahead of time and rehearsed.

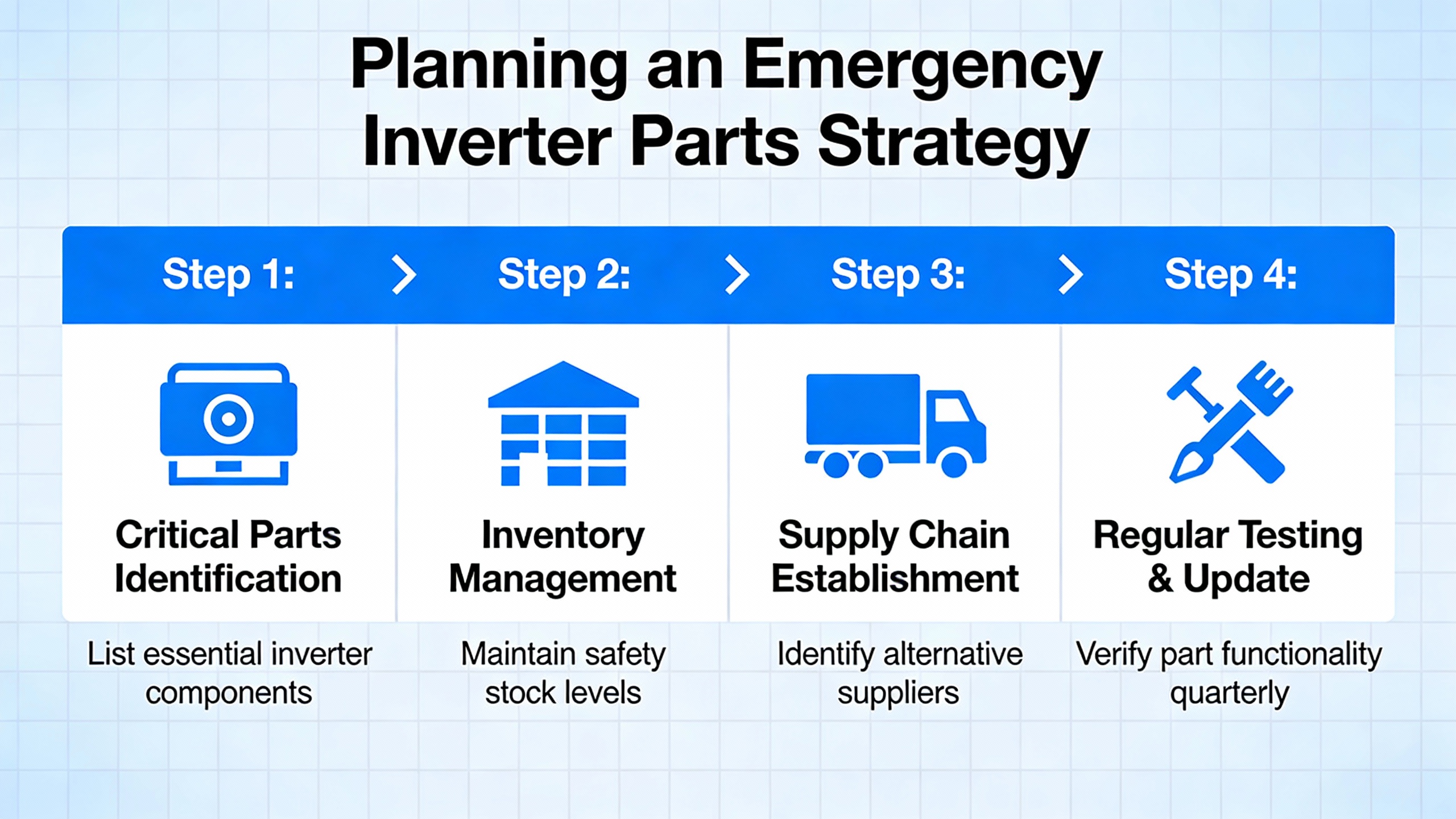

Once you understand your drives, their failure modes, and your supply options, you can begin to formalize an emergency strategy that goes beyond ŌĆ£weŌĆÖll call the supplier if something breaks.ŌĆØ

Sulzer recommends starting with a comprehensive inventory of all drives in the facility and explicitly marking which ones are critical to production. In my experience, this inventory should capture at least the drive rating, application, upstream protection and power-quality equipment, environmental conditions, and any known nuisance behaviors. For each critical drive, it is then possible to define which parts you will stock on-site, which components can be delivered within a few hours or a day from OEM warehouses like those operated by Siemens, and which drives will be covered by fast repair agreements.

The high-yield spares identified by Amikong and CNInverter are usually the first tier for on-site stocking: cooling fans, DC bus capacitors for common drive families, line fuses and breakers, surge protective devices, and a selection of braking resistors. Where your plant has many similar drives, particularly in fan and pump services, stocking a small number of complete spare drives can also be cost-effective, but that approach is often supplemented by a more modular parts strategy and the ability to leverage eŌĆæshops such as NORDŌĆÖs to identify less obvious spare components based on serial numbers.

Next, consider the second tier of emergency parts that you may not stock directly but want to have pre-qualified for rapid delivery. This layer often includes line reactors, DC chokes, passive harmonic filters, and in some cases active filters for heavily distorted networks. From AccureŌĆÖs perspective on inverter efficiency, aligning your parts and delivery contracts with expected use cases and loading patterns helps ensure that whatever you rush in will not only restore operation but also maintain high efficiency over the long term.

Longer-term or more complex repairs fall into a third tier that typically involves partners like Sulzer or the repair providers cited by Amikong. For expensive or specialized drives, particularly those nearing the end of their product lifecycle, negotiating rapid repair services before failure allows you to ship units out immediately after a temporary replacement is installed. Meanwhile, for critical large motors whose replacement lead times may stretch into months, establishing relationships with ex-stock suppliers like Menzel Motors provides a safety net when an OEM no longer supports a specific model.

Throughout this planning, CNInverterŌĆÖs guidance on routine maintenance and environmental control should not be overlooked. Monthly cleaning of dust from cooling paths, observing recommended operating temperatures, and applying surge protection that can cut failure rates significantly reduce the number of emergencies you face. Emergency delivery is most valuable when it is the exception, not the rule.

Motor drive technology continues to evolve toward higher switching frequencies, higher power densities, and more sophisticated control algorithms. This evolution affects how you think about emergency parts.

EPCŌĆÖs EPC91200 board is a good illustration. It is a three-phase brushless DC motor drive inverter demonstration board for 96 V battery-based systems, built around an eGaN FET with a maximum on-resistance of about 3 milliohms and a 150 V device rating. The board can deliver up to 60 A peak, or 40 A RMS, and supports pulse-width modulation frequencies up to roughly 150 kHz. EPC notes that switching is optimized for low distortion to reduce motor acoustic noise and torque ripple, and that dv/dt is limited to less than about 10 V/ns to balance efficiency with electromagnetic interference and insulation stress. The board includes integrated gate drivers, auxiliary power rails, voltage and temperature sensing, accurate current sensing, overcurrent and undervoltage lockout protection, plus an interface for shaft encoders and Hall sensors.

At the control level, TekŌĆÖs analysis of electric vehicle traction inverters shows how digital signal processing algorithms and field-oriented control regulate motor currents in a rotating reference frame to achieve precise torque and speed control. Wolfspeed similarly describes how modern traction inverters use three-phase AC motors driven by SiC MOSFET half-bridge modules, controlled with techniques such as space-vector PWM and closed-loop field-oriented control, typically switching in the range of about 6 to 24 kHz. These architectures are not limited to road vehicles; similar control techniques and semiconductor technologies appear in high-performance industrial drives and servo systems.

From a spares and emergency delivery perspective, several implications follow. First, the complexity of gate-drive circuits and DSP-based controllers means that field replacement often occurs at the module or board level rather than at the component level. You are less likely to swap individual transistors and more likely to replace an entire power module or control board supplied and tested by the manufacturer. This increases the importance of having precise part-number-to-serial-number mapping via tools like the NORD eŌĆæshop and ensuring that OEMs such as Siemens can deliver system-compatible replacement boards from their regional warehouses.

Second, the tight coupling between power electronics, control firmware, and feedback sensors makes it harder to substitute generic components in an emergency. For example, replacing a high-speed eGaN-based power stage with a slower, more conventional design may impact the dv/dt behavior, harmonic profile, and even the motorŌĆÖs acoustic noise. EPCŌĆÖs deliberate tuning of dv/dt to under about 10 V/ns for motor drive applications illustrates how this tuning is now an engineering choice rather than a byproduct. Emergency parts delivery must therefore focus on obtaining correct, compatible modules, not just approximate equivalents.

Third, as Accure emphasizes in the storage context, monitoring detailed parameters such as switching frequency, temperature, and harmonic distortion becomes more important in advanced drives. Changes in those parameters can indicate aging or latent faults in control boards or power modules. Aligning analytics with your spares strategy lets you pre-position advanced modules or schedule expedited shipments before a failure disables the system.

In other words, as drives become more intelligent and power-dense, emergency parts delivery increasingly revolves around pre-tested modules from the OEM or authorized service providers rather than ad hoc substitutions. That shift places even more value on having registrations, part lists, and service agreements in place before you need them.

Q: When should I invest in on-site spare drives versus relying on emergency delivery and repair services? A: The sources suggest focusing on criticality and commonality. Sulzer recommends identifying drives that are critical to production, and for those drives, it often makes sense to keep at least one complete spare on-site if the model is widely used in your facility. High-yield components such as fans, DC bus capacitors, fuses, SPDs, and braking resistors for those same drives should also be stocked, following Amikong and CNInverterŌĆÖs guidance. For less critical or very expensive drives, a combination of emergency delivery from OEM warehouses, eŌĆæshop ordering by serial number, and fast repair arrangements can be more economical. A mixed strategy that pairs a small number of full spare drives with targeted component inventories and rapid supplier support usually delivers the best balance of cost and resilience.

Q: Is expedited repair of a failed drive worth it compared with buying a new one? A: Amikong cites a repair provider reporting typical turnarounds of about two to five business days and up to around eighty percent cost savings compared to buying new. Sulzer similarly positions repair as a cost-effective way to maintain performance, especially for legacy or obsolete drives. The decision in an emergency depends on how long your process can tolerate operating on a spare or temporary workaround. If you can install a spare drive or a temporary replacement, sending the failed unit for rapid repair often gives you back a fully functional, parameterized drive at much lower cost. When the hardware is severely damaged, the firmware is problematic, or the drive is part of a fleet modernization program, replacement may be the better route. Using the measured condition data and failure history recommended by Accure and Amikong can help you make that call on a case-by-case basis.

As a power system specialist, my advice is to treat emergency inverter parts delivery as a design parameter, not just an afterthought. Map your drives, define which components and modules matter most, align them with reliable supply and repair channels, and connect diagnostics to decision-making. The plants that do this rarely talk about ŌĆ£lucky savesŌĆØ after a failure; they talk about predictable recoveries, controlled risk, and drive systems that support their production goals instead of undermining them.

Leave Your Comment