-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

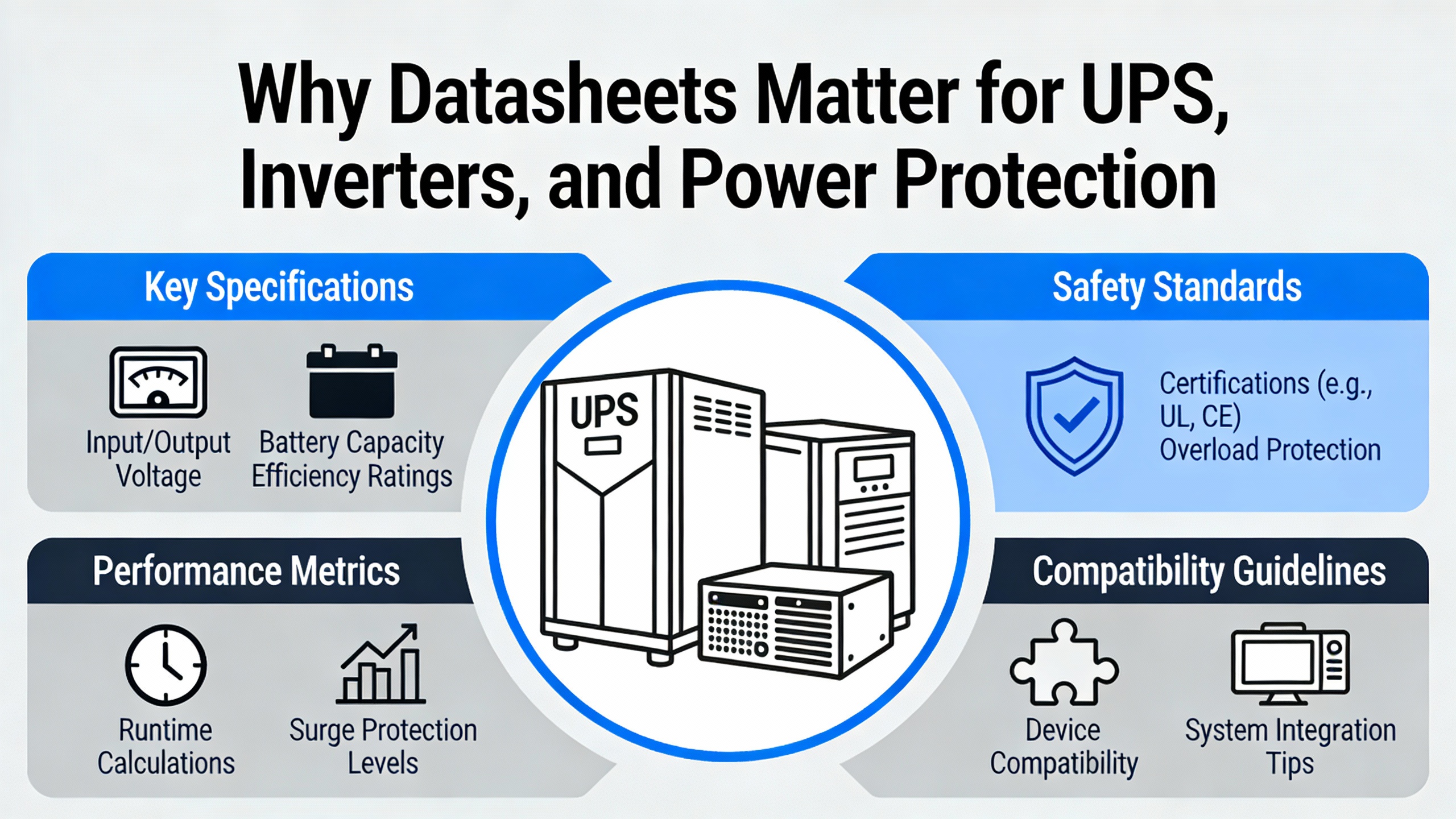

In modern industrial and commercial power systems, the temperature instrumentation around UPS lineups, static and rotary inverters, and power protection gear is no longer ŌĆ£nice to have.ŌĆØ It is part of the protection envelope. Heatsink hot spots, transformer windings, DC busbars, power semiconductors, and battery strings all depend on accurate, stable temperature measurement. That measurement usually does not go straight from a bare sensor into a control system. It goes through a temperature transmitter.

Articles from Process Heating Magazine and application notes summarized by Miinet describe the fundamental role of the temperature transmitter as converting a sensorŌĆÖs low-level signal into a robust, standard 4ŌĆō20 mA signal that a monitoring or control system can safely accept while maintaining measurement integrity. When that transmitter is mis-specified, the power system may see the wrong temperature at exactly the wrong time.

HoneywellŌĆÖs SmartLine temperature transmitters are positioned, in HoneywellŌĆÖs own field-instrumentation material and in independent coverage from Control Engineering, as ŌĆ£smarter field devicesŌĆØ aimed at improving accuracy, reliability, and diagnostics while reducing lifecycle cost. In a large plant with thousands of field transmitters, even modest gains in measurement quality or maintenance efficiency can scale into significant improvements in availability and labor use. In a UPS or critical power environment, those same gains translate directly into fewer nuisance trips, fewer undetected overloads, and a more predictable thermal profile of your assets.

Official product datasheets are where Honeywell states the capabilities, limits, and conditions under which those claims are valid. Marketing pages, distributor blogs, and high-level overviews can help with orientation, but for engineering decisions on protection thresholds or interlocks, you should treat the datasheet as the governing document.

HoneywellŌĆÖs temperature portfolio is broad, but several families appear repeatedly across reputable summaries such as those from Linc Energy Systems, Control Engineering, and third-party integrators. These families cover economy, mid-tier, and high-performance needs.

Linc Energy Systems describes SmartLine temperature transmitters as high-accuracy, high-stability devices designed for industrial environments, including noisy plants. Within SmartLine, they call out the STT650, STT700, STT750, and STT850, plus the STT170 as an economy-tier range within the STT 3000 family. A separate distributor summary of the STT250 (and its STT25H variant) highlights a mature but still widely used smart transmitter design.

At a high level, HoneywellŌĆÖs SmartLine value proposition, as described in HoneywellŌĆÖs own SmartLine initiative material and echoed by Control Engineering, rests on three pillars: smart performance, smart design, and a smart user experience. Smart performance covers better measurements and diagnostics. Smart design covers robust hardware, modular construction, and standardization across models. Smart user experience covers displays, easier configuration, and diagnostics that help people, not just systems.

The table below consolidates how different sources position several Honeywell temperature transmitter families. It is not a replacement for individual datasheets, but it helps frame which documents you should be pulling when specifying devices around a UPS or inverter line.

| Model / Family | Tier / Positioning (per sources) | Form Factor / Inputs (per sources) | Noted capabilities from sources |

|---|---|---|---|

| STT170 (STT 3000 family) | Economy-tier, flanking mid-tier STT700 and high-tier STT750/STT850 (Linc Energy Systems) | Family with multiple variants: STT171 analog, RTD-only; STT173 analog, RTD or thermocouple; STT17H HART with RTD and thermocouple; configured via STT17C PC tool | Designed for cost-effective temperature monitoring; converts low-level RTD/thermocouple signals into current signals that can travel long distances through noisy plant environments |

| STT650 | High-performance DIN-rail mounted SmartLine transmitter (Linc Energy Systems) | Compact, dual-channel options; panel-mounted | High measurement accuracy, stability, and reliability; dual channels allow multiple temperature points per panel, helping reduce hardware and inventory; positioned as able to replace virtually any transmitter |

| STT700 | Mid-tier SmartLine, direct replacement for STT250 (Linc Energy Systems) | Standard SmartLine field-mount form factor | Described as suitable for most process applications, including control and safety, while delivering excellent performance at low installed cost |

| STT750 | High-tier SmartLine (Linc Energy Systems) | Field mount | Suitable for a wide range of control and safety applications; leverages SmartLine modularity, easier maintenance, and lower total cost of ownership |

| STT850 | Highest-performing SmartLine temperature transmitter (Linc Energy Systems and Ahock) | Field mount with dual measurement inputs | Very high performance across varying ambient temperatures; ŌĆ£total installed accuracyŌĆØ high enough that it can replace virtually any transmitter; in heat-exchanger applications, dual inputs measure temperature difference across the exchanger, with configurable high and low limits |

| STT250 / STT25H | Established industrial smart transmitter line (XKTransmitter summary) | Typically head-mounted; supports thermocouples and RTDs; multi-protocol (DE and HART) | Designed as a drop-in replacement for conventional and many smart transmitters; internal memory stores sensor characteristics; specified accuracy achievable through sensor type and range selection; environmental stress screening from roughly -40┬░F to about 185┬░F equivalent; supports upscale/downscale failsafe, online diagnostics, and fully remote configuration |

In Control EngineeringŌĆÖs coverage, SmartLine temperature transmitters also share modular hardware and common parts with SmartLine pressure transmitters. This matters for a power system owner with thousands of loops, because shared modules simplify spares management and reduce training overhead. The same article notes features such as an advanced graphic display, dual-input with digital output options, and intuitive onboard diagnostics, all of which are relevant when you want local information at a UPS board or inverter cabinet without opening a laptop.

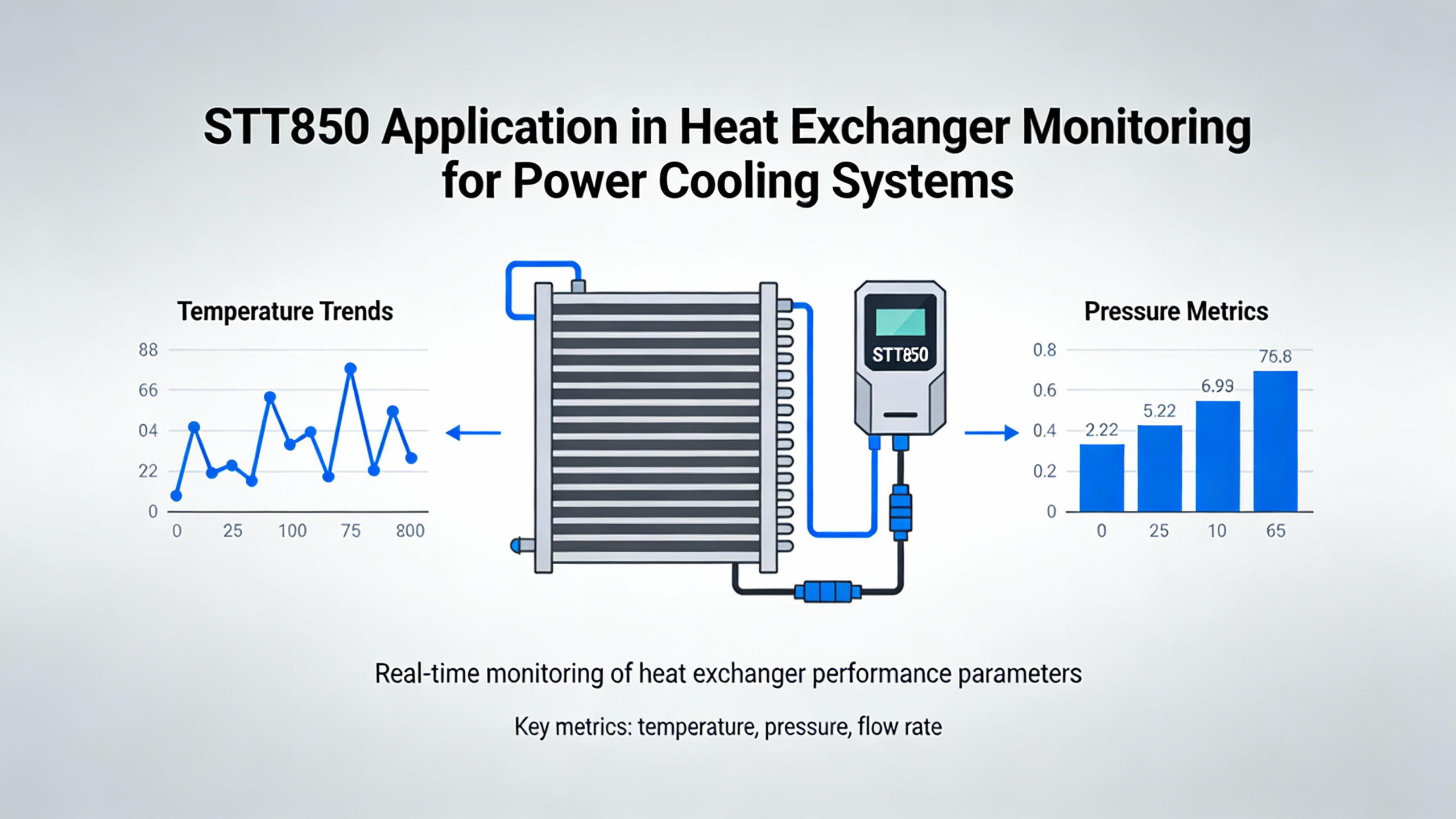

A practical example from a Honeywell partner focused on heat exchangers illustrates why datasheet details around inputs and functions are worth studying. In that application, HoneywellŌĆÖs SmartLine STT850 is highlighted as particularly suitable for monitoring industrial heat exchangers. The STT850 provides two measurement inputs and can display the temperature difference between inlet and outlet. The same summary notes that high and low temperature limits are configurable to monitor process conditions and detect deviations.

Translating that into a power context, think about a chilled-water or glycol loop used to cool UPS rooms or inverter galleries. If you assign one STT850 input to the supply temperature and the second to the return, the transmitter can calculate and present the differential directly. The datasheet will tell you whether that differential calculation is native and what the scaling and accuracy look like.

Suppose your cooling design expects a 12┬░F temperature drop across the heat exchanger at full load, and you set high and low limits at 8┬░F and 16┬░F based on the datasheet capabilities. A gradual drift down toward 6┬░F over time could point to fouling or flow issues long before a thermal overload alarm appears on the UPS. The STT850ŌĆÖs ability to host two sensors and enforce limits at the transmitter level reduces the need for extra logic, and the datasheet is where you verify that this behavior is supported, how the alarms are wired, and what happens on fault.

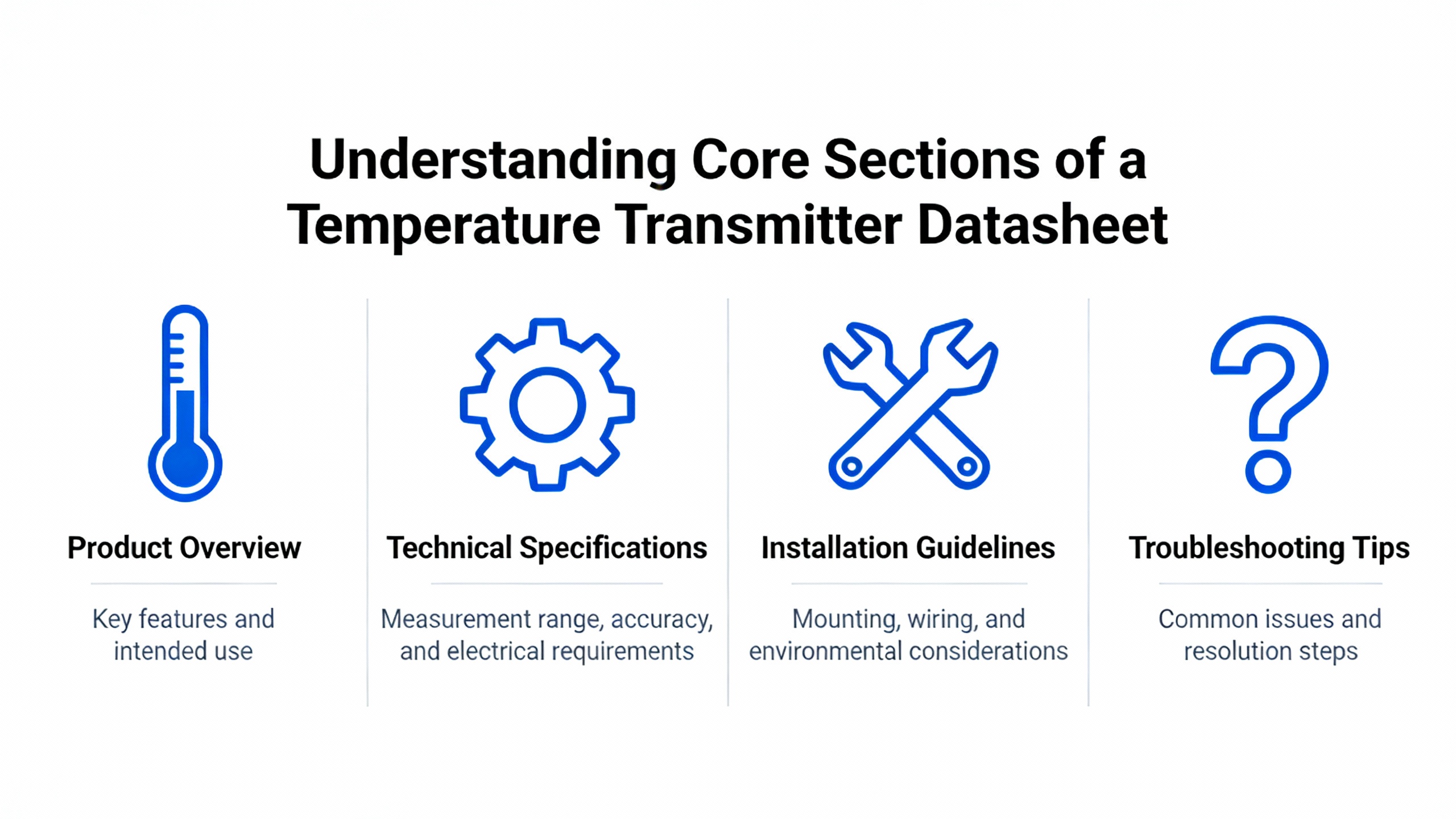

When you open a Honeywell temperature transmitter datasheet, especially for SmartLine models, several sections matter disproportionately for UPS, inverter, and protection applications. The research summaries from Miinet, The Transmitter Shop, Linc Energy Systems, Control Engineering, and the STT250 technical overview all point toward the same clusters of information.

Across the Honeywell portfolio, the datasheet will clearly state which sensor types are supported. Linc Energy Systems notes that the STT170 line has RTD-only and RTD or thermocouple variants (STT171 and STT173 respectively) and that the STT17H adds HART digital communication while still supporting both RTDs and thermocouples. The STT250 summary describes ŌĆ£universal input compatibility with thermocouple or RTD sensorsŌĆØ and mentions that internal memory stores the characteristics of commonly used sensors.

Those two patterns have direct implications in a power system. If your UPS busbars or transformer windings already have embedded RTDs, a transmitter that only accepts thermocouples would force sensor replacement. Conversely, if your battery racks have existing thermocouples, you need a model that supports those inputs. The datasheet section on inputs will not just say ŌĆ£RTDŌĆØ or ŌĆ£TCŌĆØ but often list specific types, wiring (two-wire, three-wire, or four-wire for RTDs), and ranges.

Sensor-type memory, as described for the STT250, also matters. When a transmitter knows the non-linearities of each sensor type and corrects them internally, the field technician only needs to select the right sensor and range. According to that STT250 technical summary, simply selecting the correct sensor type and range is sufficient to achieve the specified measurement accuracy, with optional calibration improving it further. That is an important point to verify in the datasheet, especially if you want to standardize on one calibration procedure across all transmitters in a power block.

MiinetŌĆÖs Process Heating article and The Transmitter ShopŌĆÖs guidance both emphasize that the primary job of a temperature transmitter is to convert the sensorŌĆÖs low-level signal into a standard signal, usually 4ŌĆō20 mA. That current-loop signal is the backbone of most analog I/O on power system controllers and protection relays. The same sources highlight that you should verify compatibility between the transmitterŌĆÖs output and the input requirements of your monitoring and control systems.

Honeywell goes beyond simple analog output. The STT25H, for example, supports the HART protocol, and the STT250 family supports both DE and HART according to the XiŌĆÖan XK summary. The STT17H variant in the STT170 economy family also uses HART for digital communication. The Transmitter Shop notes that smart transmitters in general may also use protocols such as Profibus or Foundation Fieldbus, especially when PC-based configuration is involved.

On the datasheet, look for dedicated sections on communication and configuration. They should tell you whether the device supports analog-only output, analog plus HART, or purely digital buses, and which configuration tools are required. For a power engineer, this determines whether a relay with analog-only inputs can read the transmitter directly, or whether you must route the signal through a DCS or PLC that understands HART or fieldbus.

Configuration detail matters during commissioning. The STT250 write-up notes that configuration is possible completely over the existing signal wires using standard HART tools, and that remote configuration is fully supported. That kind of capability cuts commissioning time in crowded UPS galleries where moving a laptop to every transmitter is cumbersome. If you plan to rely on remote configuration, the datasheet needs to confirm exactly which functions are accessible digitally and which require local access.

For critical power assets, temperature accuracy is not an academic question. The Transmitter ShopŌĆÖs selection article argues that measurement accuracy should be a primary decision factor and suggests that, given industrial demands, engineers should look for temperature transmitters with accuracy in the range of roughly ┬▒0.0025┬░F up to about ┬▒1┬░F, while steering away from low-accuracy devices. That is consistent with the way Linc Energy Systems positions SmartLine transmitters as high-accuracy, high-stability devices suitable for demanding applications.

Honeywell and its partners often talk about ŌĆ£total installed accuracy,ŌĆØ particularly for the STT850. Linc Energy Systems states that the STT850ŌĆÖs total installed accuracy allows it to replace virtually any transmitter, and their description of the STT650 similarly claims that it is designed to replace virtually any existing device in demanding applications. Total installed accuracy takes into account not just the electronics but also sensor effects, wiring, and environmental variations. The STT250 documentation, for example, describes how each unit undergoes environmental stress screening with rapid thermal cycling roughly between -40┬░F and about 185┬░F equivalent, during which ambient temperature coefficients are characterized and stored. That is part of how Honeywell keeps the device accurate across wide ambient swings.

When you review the datasheet for a UPS or inverter project, focus on three aspects of the accuracy section. First, identify the base accuracy under reference conditions. Second, see how it is affected by ambient temperature range, sensor type, and span. Third, check how much calibration can improve it. The STT250-specific summary indicates that calibrating the lower and upper range values can improve accuracy by about a factor of two, and that sensor-specific calibration can remove much of the remaining sensor error.

A simple thought experiment shows why this matters. Imagine two transmitters for a transformer winding running nominally at 167┬░F during heavy load. One has a total installed accuracy of ┬▒1┬░F and the other effectively ┬▒0.25┬░F after calibration. For alarm setpoints near insulation limits, the second provides much more confidence that a rising trend is real and not just measurement noise. Datasheets provide the numbers that allow that kind of comparison; marketing text does not.

Power rooms and inverter halls are ŌĆ£cleanerŌĆØ than many process plants, but they are still subject to ambient temperature swings, electromagnetic noise from switching devices, and sometimes corrosive atmospheres, especially near battery rooms.

The STT170 overview from Linc Energy Systems notes that this economy-tier family is designed to convert low-level sensor signals into current signals that can travel long distances through noisy plant environments. The STT250 technical description reinforces that theme by calling out environmental stress screening with thermal cycling and by highlighting that ambient temperature coefficients are stored for reliable compensation.

Selection guidance from The Transmitter Shop emphasizes the need for strong electromagnetic interference (EMI) and radio-frequency interference (RFI) immunity and proper signal isolation. They note that without these, devices can suffer signal degradation, non-repeatability, and loss of accuracy. In UPS rooms filled with power electronics, these issues are not theoretical.

The datasheetŌĆÖs environmental section is where Honeywell states the operating ambient temperature range, the effect of ambient on accuracy, the level of EMI/RFI immunity, and any hazardous-location approvals. ITT NeoDynŌĆÖs positioning of its own switches for both general and hazardous locations is a useful reminder that devices intended for hazardous areas have specific design and testing behind them. For temperature transmitters in battery rooms with hydrogen risk or in generator halls with fuel vapor, it is essential to rely on the transmitterŌĆÖs own hazardous-area certifications as listed in the official Honeywell datasheet or safety manual, rather than assuming suitability from a generic product page.

HoneywellŌĆÖs SmartLine material stresses that its transmitters are not just measurement devices but also diagnostic tools. Control EngineeringŌĆÖs article mentions an advanced graphic display that presents data clearly and exposes key device information in the field, plus intuitive onboard diagnostics that show transmitter health in real time. That is echoed in the broader Honeywell SmartLine device narrative about improving user experience and enabling predictive maintenance.

The STT250 summary adds several concrete diagnostic and safety features: instant alarm generation upon sensor fault, post-read validation, online diagnostics, and fully remote configuration. It also describes a hard-wired link that supports upscale or downscale failsafe behavior when a fault occurs. These behaviors matter for protection logic. An upscale failsafe may be appropriate where you want a ŌĆ£hotŌĆØ reading to force conservative action on fault, while downscale may be better when a low reading should trigger a trip.

Most datasheets for SmartLine transmitters also spell out reversal protection and fault handling. Control Engineering highlights that SmartLine devices are protected against damage from reversed loop wiring polarity, which removes one common start-up failure mode and saves time during commissioning. When you are working through hundreds of cabinet terminations, that protection is worth confirming in the datasheet.

In a safety or protection context, the key questions are what the transmitter does when the sensor fails, how it signals internal failures, and how readable those states are from the control system and in the field. The datasheet and the associated safety manual should be your authoritative sources for that, especially if measurements are part of a safety instrumented function or a critical trip scheme around a UPS or inverter.

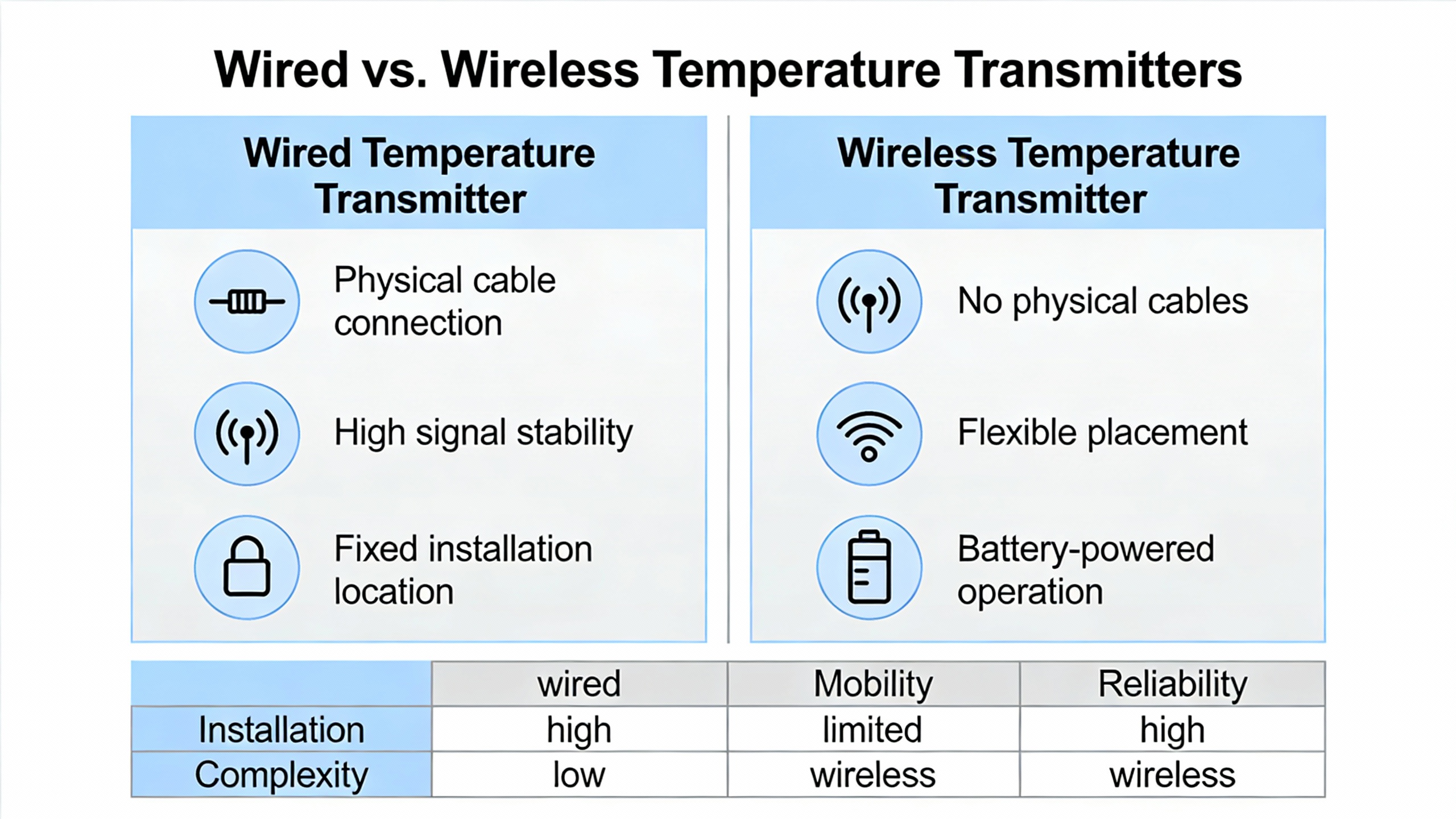

While wired 4ŌĆō20 mA transmitters remain the default in many power systems, Honeywell and its partners also offer wireless temperature transmitters. An article from AWC, Inc. titled ŌĆ£Honeywell: Why implement SmartLine Wireless Temperature Transmitters?ŌĆØ describes these as industrial temperature sensors that measure process temperature and send data wirelessly instead of over hardwired signal cables. The article notes that such devices are particularly useful where running cables is expensive, physically difficult, or disruptive. That includes remote assets, moving equipment, or brownfield plants where adding new conduits to an energized UPS room is not desirable.

In that piece, the expected benefits of HoneywellŌĆÖs wireless temperature transmitters are lower installation and wiring costs, faster deployment, flexibility to add or relocate points, and tighter integration with Honeywell control and monitoring systems. It also points out that engineers evaluating wireless solutions should consider wireless coverage and network reliability, battery-life expectations, and whether wireless is appropriate for the criticality of each measurement.

A Honeywell web path referencing XYR 6000 temperature transmitters indicates that these are part of a wireless network product line, even though the captured page content is limited to a cookie notice and does not include technical details. Without a datasheet, you do not know update rates, battery-life curves, or specific environmental ratings, all of which are essential for power applications.

From a reliability standpoint in a power system, it is usually sensible to keep safety-critical or trip-related temperature measurements on wired transmitters with clearly defined fail-safe behaviors and to use wireless temperature transmitters for monitoring, trending, and non-trip alarms. The datasheets for both wired and wireless devices should be compared carefully on accuracy, latency, diagnostics, and environmental limits before you extend wireless measurements into protective roles.

The research summaries provide a reasonably clear hierarchy for HoneywellŌĆÖs temperature transmitter families, even without full datasheets in hand. Linc Energy Systems positions the STT170 as an economy-tier line for cost-effective temperature monitoring, complementing the mid-tier STT700 and high-tier STT750 and STT850. The STT650 is described as a high-performance DIN-rail device with dual-channel capability, while the STT700 is a direct replacement for the older STT250 and is suitable for most control and safety applications. The STT750 and STT850 extend this into higher performance and broader control and safety coverage, with the STT850 singled out for very high installed accuracy across varying ambient conditions.

The Transmitter ShopŌĆÖs guidance on selection provides a useful structure for mapping this hierarchy into a power system specification. They recommend focusing on sensor type compatibility, mounting location and noise environment, configuration protocol, measurement accuracy, EMI/RFI immunity, diagnostics, and any special functionality.

For a large UPS plant or data center power system, that might translate into using STT170-class devices for non-critical monitoring where cost pressure is high and where long cable runs through noisy environments make robust current outputs valuable; STT650 or STT700-class devices as the default for standard control loops and non-SIL protection where DIN-rail mounting and dual-channel options save panel space; and STT750 or STT850-class devices where heat exchanger performance, semiconductor junction temperatures, or transformer winding temperatures feed interlocks or safety functions and justify the highest available accuracy and diagnostic coverage.

The STT250 remains relevant in many existing plants as a mature, smart transmitter with universal inputs, multi-protocol support, and robust diagnostics. Its stress-screened design and calibration options, including the ability to improve accuracy by roughly a factor of two through range calibration, make it a useful analog when you are assessing newer SmartLine datasheets in retrofit projects.

These recommendations are not a substitute for the exact model-by-model limits and certifications shown on HoneywellŌĆÖs datasheets and manuals, but they provide a practical way to narrow down which documents you need to study for each section of a power system design.

HoneywellŌĆÖs own SmartLine literature advises evaluating ŌĆ£smart transmitter platformsŌĆØ not only on unit cost but on total lifecycle value, including reduced labor, lower maintenance frequency, and better process visibility. Control EngineeringŌĆÖs review of SmartLine temperature transmitters echoes this, pointing to modular parts shared across pressure and temperature devices, improved displays, and onboard diagnostics as levers that reduce long-term cost and complexity for plants that operate thousands of transmitters.

If you translate that into a power system context, a systematic approach to datasheets helps. Start by aligning the sensor types and mechanical form factor in the datasheet with your existing or planned sensors around UPS, inverters, transformers, and battery systems. Then compare accuracy, stability, and environmental limits with the temperature ranges and ambient conditions you expect. Next, check communication and configuration sections against your control and protection platforms. Finally, scrutinize diagnostics and fail-safe behavior, especially where measurements influence tripping or load shedding.

Even in a relatively modest facility with, say, several hundred temperature points across UPS rooms, battery areas, and switchgear, small gains in commissioning efficiency and diagnostic clarity compound quickly. Honeywell sources emphasize that standardized smart transmitters simplify training and spare-parts holdings. For a power system owner, that often matters as much as the difference between two neighboring accuracy numbers on a single datasheet.

Q: How important is total installed accuracy for UPS and inverter protection compared with basic sensor accuracy?

A: Sources such as Linc Energy Systems and the STT250 technical summary make it clear that Honeywell treats total installed accuracy as a key performance measure, especially for models like the STT850. Total installed accuracy includes sensor behavior, wiring, ambient temperature effects, and transmitter electronics. For protection functions around UPS and inverters, that combined number is more relevant than bare sensor accuracy because it reflects what the control system actually sees under real conditions. The XKTransmitter summary of the STT250 shows how environmental stress screening and stored temperature coefficients help stabilize performance, and The Transmitter ShopŌĆÖs selection guidance underscores the need to consider all error sources, not just the sensor itself.

Q: When is it reasonable to use an economy-tier transmitter like the STT170 in a critical power installation?

A: According to Linc Energy Systems, the STT170 is positioned as an economy-tier transmitter intended for reliable, accurate temperature measurement at lower cost and is designed to send current signals over long distances in noisy environments. It can be a solid choice for non-trip monitoring points in a power system, such as general room temperatures, non-critical transformer surfaces, or auxiliary equipment where an alarm rather than a trip is adequate. For direct protection of high-value assets where temperature feeds a shutdown or load-shedding function, higher-tier SmartLine transmitters like the STT750 or STT850, with their greater emphasis on total installed accuracy and diagnostics, are generally more aligned with the intent described in Control EngineeringŌĆÖs coverage and HoneywellŌĆÖs own SmartLine documentation.

Q: How should I factor diagnostics into a spec for temperature transmitters in a data center UPS plant?

A: Control Engineering notes that SmartLine temperature transmitters provide advanced graphic displays and intuitive onboard diagnostics, while the STT250 technical summary describes online diagnostics, instant sensor-fault alarms, and configurable failsafe behavior. In a data center UPS plant, those capabilities help operators distinguish between real thermal problems and instrumentation issues, reduce time spent troubleshooting, and support more proactive maintenance. When drafting a specification, it is worthwhile to make explicit use of diagnostics mentioned in the datasheet, such as requiring that transmitters indicate sensor faults, support remote configuration, and be protected against reversed polarity. HoneywellŌĆÖs SmartLine overview suggests that such features are central to the platform, and integrating them into your spec ensures you actually benefit from them once devices are installed.

As a power system specialist and reliability advisor, I treat Honeywell temperature transmitter datasheets as working documents rather than filing requirements. If you consistently translate their accuracy, environmental, communication, and diagnostic details into clear requirements aligned with your UPS and inverter risks, those datasheets become one of the most practical tools you have for keeping critical power equipment running within safe thermal limits.

Leave Your Comment