-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Proximity sensors sit in the same category as your UPS, inverters, and protective relays: if they fail when the environment gets ugly, the rest of the system will eventually follow. In modern power and industrial plants, these contactless ŌĆ£eyesŌĆØ report door status, breaker or disconnect position, material flow, shaft speed, and countless interlocks that keep equipment and people safe. When those sensors live in heat, vibration, washdown, or chemically aggressive zones, ordinary ŌĆ£catalog specialŌĆØ devices tend to die early, drift out of spec, or generate nuisance trips.

Drawing on guidance from sources such as Newark, Misumi, Eaton, Contrinex, SiliconExpert, and UnseenEra, this article focuses on how to choose proximity sensors that survive harsh conditions without sacrificing performance. The emphasis is practical: what to look for in real datasheets, how to interpret ruggedness claims, and how to design in a margin that keeps your UPS rooms, switchgear, and process equipment reliable over years, not months.

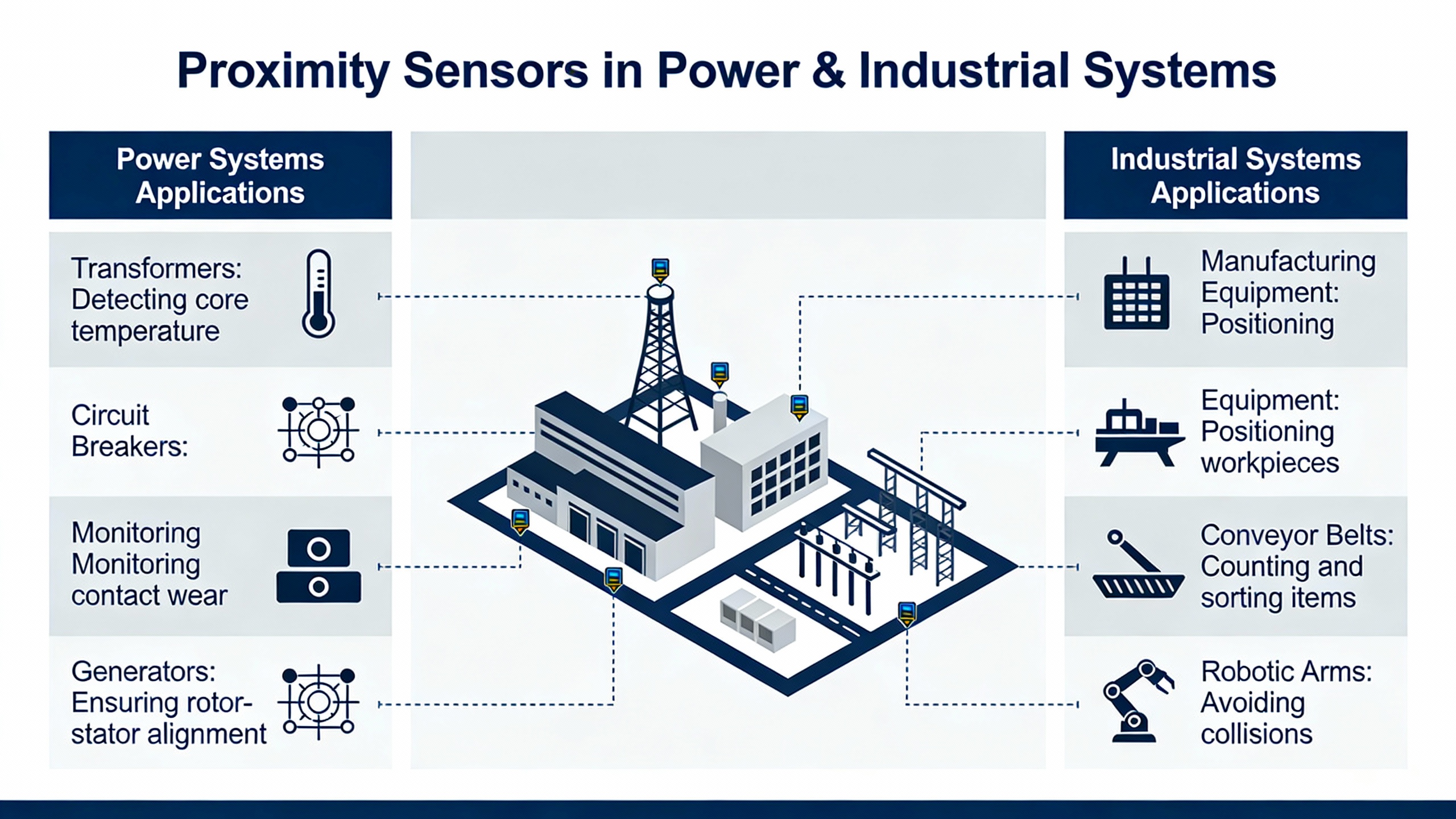

Proximity sensors are non-contact devices that detect the presence or absence of an object within a defined range and convert that into an electrical signal for monitoring or control. Newark and Misumi both describe them as core building blocks of industrial automation, feeding PLCs, drives, and safety systems on conveyors, packaging lines, material handling systems, and process equipment. In power and power-conversion contexts, the same core functions apply: confirming that a breaker is in the correct position, verifying that a cabinet door is closed before enabling high voltage, or ensuring that a mechanical bypass path is correctly seated.

Compared with mechanical limit switches, proximity sensors avoid contact wear and bounce, are easier to seal against dust and liquids, and tolerate higher speeds. RS Components notes that non-contact sensors can operate reliably for years or decades if the environment and installation are done correctly. For a UPS or inverter system whose expected life is measured in decades, that matters as much as transformer insulation or capacitor quality.

To choose the right proximity sensor for harsh locations, it helps to understand the main sensing technologies, how each behaves when things get dirty or hot, and what that means for durability and performance.

Inductive proximity sensors generate an electromagnetic field and detect the disturbance caused by nearby metal. Newark highlights them as robust, fast, and well suited to harsh environments, while Misumi emphasizes that they are largely unaffected by non-metallic contaminants such as dirt or moisture and can detect metal through non-metallic barriers like plastic or cardboard.

A typical inductive sensorŌĆÖs range is short: Newark cites roughly 1 to 40 millimeters, which corresponds to about 0.05 to 1.6 inches depending on sensor size. That limited range is a tradeoff for excellent immunity to dust, oil film, and non-metal debris. ContrinexŌĆÖs EXTREME inductive range pushes that envelope with operating distances up to about 1.6 inches while maintaining so-called Factor 1 performance, meaning ferrous and non-ferrous metals are detected at essentially the same distance. For applications like breaker position detection behind a stainless barrier or metallic target confirmation inside an oily panel, this combination of rugged housing and predictable range is ideal.

As an example, consider a metal door interlock in a battery room with corrosive vapors and occasional washdown. A compact inductive sensor with a nominal range of, say, 0.6 inches can easily detect a steel flag on the door hinge, even if a paint layer or plastic guard sits between sensor and target. Dirt accumulation that would cripple a mechanical limit switch usually has no effect until it becomes physically obstructive.

Capacitive proximity sensors generate an electric field and sense changes in capacitance as different materials enter that field. Misumi notes that they can detect both metallic and non-metallic targets such as plastics and liquids. Newark points out that this makes them useful for level detection and foreign-object detection, for example looking for liquid in a tank or plastic parts on a conveyor.

The tradeoff is environmental sensitivity. Misumi explicitly calls out that capacitive sensors are more responsive to moisture, temperature shifts, and airborne contaminants. In a humid, dusty switchgear vault or near open process vessels, drift and false trips can appear if the sensing face gets coated or the airŌĆÖs dielectric properties vary widely. That does not mean capacitive sensors are inappropriate for harsh environments; rather, they demand better shielding, more frequent cleaning, and sometimes adjustable sensitivity.

A simple example illustrates the risk. Suppose you use a capacitive sensor to detect the presence of plastic trays near a UPS assembly line. In clean, dry conditions at the factory, a 0.8 inch setpoint behaves perfectly. In the field, where moisture and airborne lint raise the background capacitance, the same sensor may begin to ŌĆ£seeŌĆØ the tray earlier, effectively moving the switch point out to an inch or more and causing early triggers. Unless you design a comfortable margin and include a way to fine-tune sensitivity, that drift can cause nuisance stops or missed items.

Ultrasonic sensors emit high-frequency sound pulses and measure the echoŌĆÖs return time to infer distance. Misumi compares them to sonar and notes that they cover a wide range of distances depending on configuration. Newark points out that ultrasonic and photoelectric devices typically handle longer ranges than inductive or capacitive sensors, from inches to several feet or more, which is useful for level and distance measurements.

Ultrasonic sensors are attractive in dusty or visually opaque environments where optical beams struggle. However, Misumi warns that they are susceptible to acoustic background noise and temperature variation, both of which change the apparent speed of sound and the echo characteristics. In a generator hall or compressor room where vibration and noise are intense, ultrasonic sensors can be pushed to their limits unless carefully sited and configured.

Imagine a sump level application in a wastewater treatment facility. The ultrasonic sensor looks down into a pit full of foam and vapor, conditions that would foul a simple optical sensor. The tradeoff is that steam plumes and hot air can slightly alter the measured distance, so the engineer must choose a sensor with the right temperature compensation and design sufficient distance between ŌĆ£pump onŌĆØ and ŌĆ£pump offŌĆØ thresholds to absorb that variability.

Photoelectric sensors rely on a light emitter and a receiver. RS Components describes common modes: through-beam (separate emitter and receiver for long range and high excess gain), retroreflective (emitter and receiver in one housing with a reflector opposite), and diffuse (target acts as the reflector). More advanced background-suppression models use a defined cutoff distance, prioritizing distance over target color to ignore background clutter.

Misumi argues that photoelectric sensors are generally immune to moisture, temperature, and sound but can be disturbed by ambient lighting. RS Components adds that they provide very fast response, which is critical for high-speed counting or presence detection.

In a harsh environment, the key vulnerability is optical: dust, oil film, and mechanical damage to lenses or reflectors. On a conveyor feeding a high-power UPS assembly line, a retroreflective sensor can reliably count module frames at several feet range. If the lens becomes coated with oily mist, however, the signal margin collapses and detection becomes intermittent. Choosing devices with high excess gain, robust housings, and easy-to-clean optical surfaces becomes essential.

NewarkŌĆÖs guide also mentions magnetic proximity devices such as reed and Hall-effect sensors, which act on the presence of a magnet rather than direct contact with a metal or optical target. These can be useful when you need long-term stability through non-metal barriers or heavy contamination, at the expense of changing your target design to include a magnet.

In battery rooms, sealed switchgear, or harsh outdoor cabinets, a sealed reed switch watching a magnet on a rotating or sliding element can simplify mechanical design. The magnet and sensor can both sit behind protective covers, fully isolated from dust or vapors, while still providing reliable position feedback.

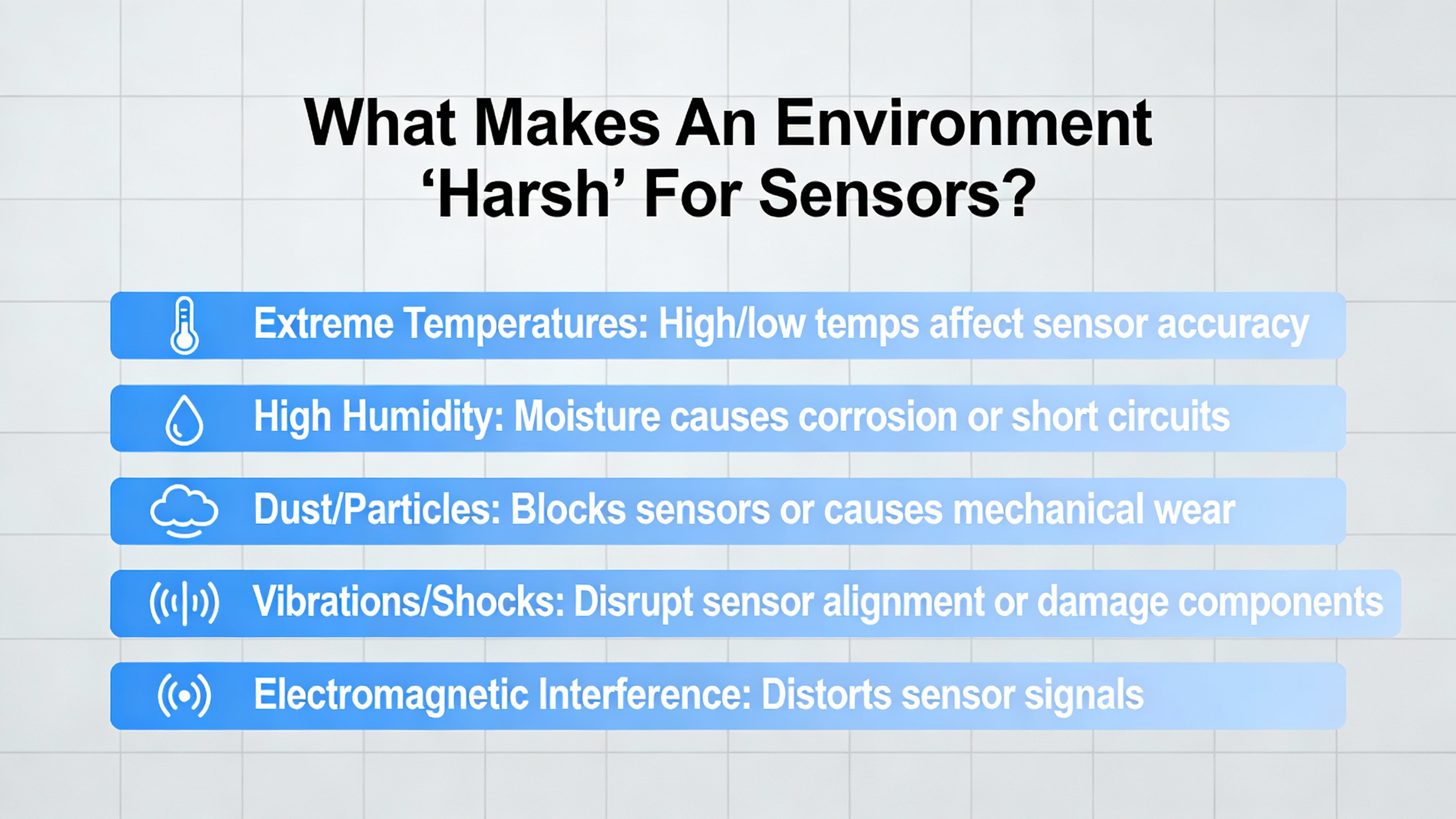

Different manufacturers define ŌĆ£harshŌĆØ differently, but UnseenEraŌĆÖs overview of industrial sensors in harsh environments provides a useful framework. Harsh environments include steel mills, power plants, cement production, chemical facilities, wastewater treatment plants, mining, and food and pharma plants. The common theme is exposure to heat, dust, vibration, and chemicals that would rapidly degrade a general-purpose sensor.

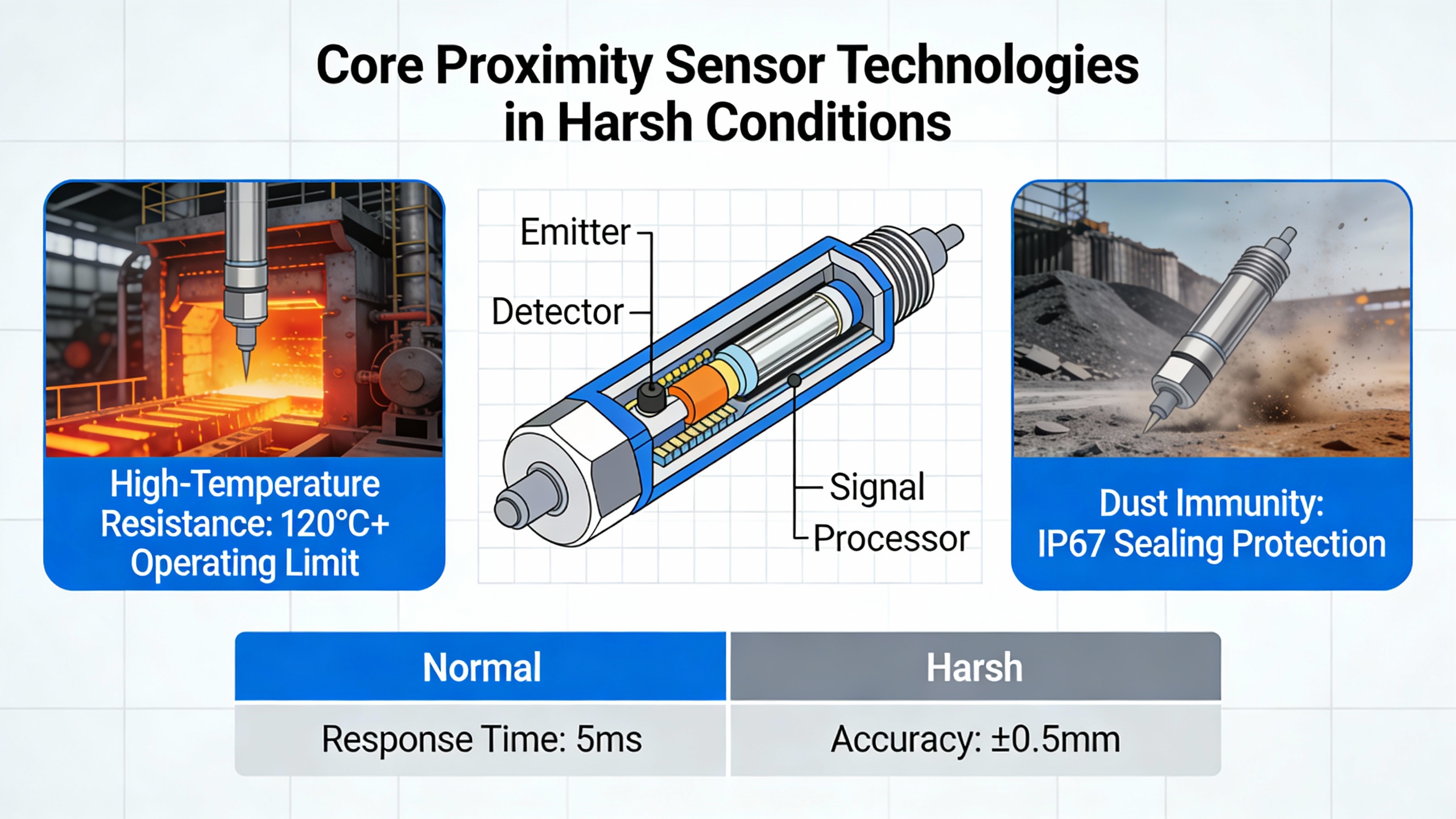

Temperature is usually the first constraint. UnseenEra notes that typical industrial sensors work from about minus 4 to 176┬░F, while specialized high-performance devices can handle temperatures approaching roughly 1,832┬░F in extreme applications such as steel manufacturing. RikasensorŌĆÖs survey of humidity sensors for harsh environments describes models that operate up to about 356┬░F, demonstrating what is possible when sensors are purpose-built for high temperatures. A proximity sensor used near hot bus bars or in a turbine enclosure might not see those peak temperatures, but the same principle applies: verify the specified temperature range against the worst credible case, not the average.

Ingress of dust and fluids is another key issue. Affiliated Control emphasizes checking ingress protection ratings such as IP65 through IP69K. UnseenEra explains that IP67 is dust-tight and resists immersion, IP68 allows prolonged underwater operation, and IP69K is intended for high-pressure, high-temperature washdown in food and beverage environments. ContrinexŌĆÖs EXTREME inductive sensors, for example, are rated to IP68 and IP69K and are built from a single piece of stainless steel with a hermetically sealed cable entry, allowing them to survive continuous immersion and aggressive washdown.

Chemicals and mechanical stress further complicate things. UnseenEra points out that stainless steel or titanium bodies, ceramic coatings, and polymer seals can help sensors survive high pressure, mechanical stress, and corrosive chemicals. Contrinex specifies that its EXTREME inductive sensors resist corrosion, are impervious to oil, and withstand pressure up to about one thousand four hundred fifty psi. For vibration and shock, UnseenEra recommends looking for compliance with IEC 60068ŌĆæ2ŌĆæ6 and IEC 60068ŌĆæ2ŌĆæ27, which indicate a sensor has been tested against defined vibration and shock profiles.

A simple mental checklist based on SiliconExpertŌĆÖs hazardous-environment guidance can help define ŌĆ£harshŌĆØ for a given application. Ask what is being sensed, what the environmental conditions are (temperature, pressure, chemicals, mechanical shock, vibration), what range is required, what the target is made of, and what special requirements apply such as hazardous area certifications or extreme EMC immunity. If any of those answers are extreme, you are in the ŌĆ£harshŌĆØ category and should select sensor families accordingly.

Effective sensor selection in harsh environments starts with the application, not the catalog. Affiliated Control recommends beginning with the measured variable and its range, then layering on mounting, response time, power, and output type. SiliconExpert adds criteria such as environmental conditions, control interface, resolution, repeatability, and form factor. For proximity sensors, several specific factors determine whether your choice will be durable and accurate under stress.

The target material and nearby clutter often dictate the sensing technology. Newark and Misumi both stress that inductive sensors are ideal when the target is metal and the environment is dirty or oily, because non-metal dirt and moisture have little effect on the electromagnetic field. If you need to see both metal and non-metal materials, capacitive or photoelectric sensors may be better, provided you account for their environmental sensitivities.

Newark cautions that target size and material strongly influence inductive and capacitive sensor range, especially for non-ferrous metals. The Eaton-based summary of inductive sensor selection reinforces that non-ferrous materials reduce effective sensing distance compared with steel and that manufacturers provide correction factors on datasheets. If your process includes stainless steel, aluminum, and mild steel parts, it is good practice to design for the worst-case correction factor and verify it in tests.

A simple example highlights this. Suppose a compact inductive sensor has a nominal range of one inch for a standard steel target. If the datasheet indicates that stainless reduces range to sixty percent, you should assume only about 0.6 inch of usable range for stainless parts and apply the safety margin discussed next.

Engineers frequently make the mistake of designing around the nominal sensing distance printed in a datasheet as if it were a hard guarantee. Guidance summarized from OMCHŌĆÖs proximity range discussion differentiates between nominal sensing distance, usable operating distance, and guaranteed sensing distance. The practical recommendation is to treat only about seventy to eighty percent of the nominal range as safe in real machines.

Consider a sensor with a nominal range of 0.6 inch. Following a seventy percent rule, you would design your target so that detection occurs at about 0.4 inch. The remaining 0.2 inch accounts for temperature swings, supply voltage variation, aging, and mechanical tolerances. If your minimum target distance ever gets beyond 0.4 inch, you risk missed detections under worst-case conditions.

The same guidance emphasizes hysteresis, the difference between the turn-on and turn-off distances. Adequate hysteresis prevents chattering when the target hovers near the threshold. When testing, you should move the real target slowly toward and away from the sensor, documenting where it actually turns on and off under hot, cold, and contaminated conditions. OMCH suggests performing these bench tests at worst-case conditions and repeating them after some hours of operation to expose drift.

Material and construction make or break durability in harsh environments. UnseenEra highlights stainless steel or titanium bodies, ceramic coatings, and polymer seals as ways to cope with high pressure and mechanical stress. SemeqŌĆÖs discussion of heavy-duty temperature sensors makes a similar point, noting that high-grade stainless housings are chosen for corrosion resistance and survival under high pressures and mechanical stress in industries such as oil and gas, power generation, and chemical processing.

ContrinexŌĆÖs EXTREME inductive sensors embody these principles. They use a single-piece stainless steel housing with a hermetically sealed cable entry, making them highly resistant to mechanical damage, corrosion, and ingress. Those sensors not only achieve IP68 and IP69K ratings but also withstand pressures around one thousand four hundred fifty psi. The result is a ŌĆ£fit and forgetŌĆØ product in washdown or oil-soaked environments where conventional plastic-faced sensors fail early.

EatonŌĆÖs E57 family offers a more general illustration. The E57 metal-face inductive sensors replace the usual plastic sensing face with stainless steel, significantly improving resistance to abrasion, particulate impact, corrosion, and chemical attack. Eaton describes them as easy drop-in replacements for damaged standard sensors because they retain common diameters, voltages, and wiring styles. For applications where moving parts or debris may strike the sensor face, this kind of metal-face construction greatly extends service life.

Mounting style also matters. The Eaton-based selection guidance distinguishes flush (shielded) sensors, which can be embedded level with surrounding metal but have shorter ranges, from non-flush (unshielded) sensors, which require a clear field and some metal-free clearance around the face but offer longer reach. Newark echoes that shielded sensors typically trade range for embeddability. In cramped switchgear or machine cubicles, flush mounting may be the only safe option, even if it costs some range.

Ingress protection and environmental ratings translate marketing claims into actionable data. Affiliated Control encourages buyers to check operating temperature, vibration and shock resistance, chemical compatibility, and IP rating to ensure sensors survive washdown, dust, and outdoor or hazardous-area use. UnseenEra elaborates that IP67 is dust-tight and resists immersion, IP68 supports prolonged underwater operation, and IP69K tolerates high-pressure, hot and cold washdown.

ContrinexŌĆÖs EXTREME sensors show what a top-end IP68/IP69K sensor looks like in practice: stainless steel construction, sealed entry, corrosion resistance, oil resistance, and pressure capability. For food and beverage plants or outdoor equipment in harsh weather, that level of sealing and robustness justifies its premium.

Where chemicals are present, UnseenEra recommends looking for chemical-resistant body seals such as PTFE and special internal coatings to prevent degradation from acids and aggressive substances. Similar considerations apply in wastewater plants and chemical processing, where humidity and aggressive condensates can attack cable jackets, seals, and housings.

The sensorŌĆÖs electrical behavior must match both the control system and the environment. Affiliated Control notes that industrial sensors typically provide discrete PNP or NPN switching signals, analog 4ŌĆō20 mA or 0ŌĆō10 V outputs, or digital IO-Link and fieldbus interfaces, simplifying integration with PLCs and drives. Misumi adds that two-wire sensors can directly drive loads at higher currents and are sometimes used in simple, controller-less setups, while three-wire sensors are tailored for PLC inputs with lower currents and standard connectors such as M8.

The Eaton and Newark summaries emphasize choices among PNP and NPN, normally open or normally closed, and two-wire versus three-wire configurations. For safety-related signals like door interlocks, normally closed circuits can provide fail-safe behavior by alarming when a wire breaks or a sensor loses power. For non-safety indicators, normally open may simplify wiring.

EatonŌĆÖs performance-oriented E57P sensors are described as having high noise immunity and short-circuit protection, designed to withstand harsh electrical environments and mechanical impacts. In inverter rooms, UPS systems, and motor-control centers, strong electromagnetic fields and switching transients are common. Choosing sensor families with documented EMC robustness, surge protection, and short-circuit tolerance reduces mysterious intermittent faults.

Finally, diagnostics and connectivity can enhance reliability. RS Components notes that IO-Link versions of photoelectric and laser sensors expose measurements, diagnostics, and parameters such as excess gain or distance values. OMCH highlights modern features such as LED status indicators, teach-in or auto-set functions, adjustable sensitivity, and smart diagnostics, all of which help fine-tune sensing range and simplify maintenance and troubleshooting. For a power system engineer trying to minimize truck rolls, being able to interrogate a sensor over IO-Link or a fieldbus to see its health status is as valuable as remote UPS monitoring.

The different proximity-sensor families and ruggedized offerings can be compared at a high level in terms of how they handle harsh environments. The table below uses information from Misumi, Newark, Eaton, Contrinex, and UnseenEra.

| Sensor type or family | Typical target | Strengths in harsh environments | Key limitations or cautions |

|---|---|---|---|

| Inductive (standard) | Metal | Immune to non-metal dirt and moisture, short range but very robust, good for oily or dusty zones | Limited to short ranges around 0.05 to 1.6 inches, only sees metal, reduced distance for non-ferrous metals |

| Inductive EXTREME (Contrinex Full Inox) | Metal (ferrous and non-ferrous Factor 1) | Single-piece stainless housing, hermetic sealing, IP68/IP69K, pressure around one thousand four hundred fifty psi, long ranges up to about 1.6 inches | Higher upfront cost, limited to target metals, installation must respect clearances |

| Inductive metal-face (Eaton E57 metal) | Metal | Stainless sensing face withstands abrasion, impact, corrosion, chemicals; easy retrofit of damaged plastic-face units | Range similar to standard inductive; still limited by metal-only detection and mounting geometry |

| Capacitive | Metal and non-metal (plastics, liquids, bulk solids) | Versatile detection, useful for level sensing or non-metal presence | Highly sensitive to moisture, temperature, dust; requires careful adjustment and cleaning in harsh conditions |

| Ultrasonic | Any object with sound-reflecting surface | Longer range (inches to several feet), works through fog, dust, vapor where optics fail | Affected by acoustic noise and temperature; foam or turbulent liquids can confuse readings |

| Photoelectric (background-suppression, retroreflective, through-beam) | Various solids | Long range, very fast, immune to sound and largely to temperature; background-suppression modes ignore clutter | Vulnerable to lens contamination and ambient light; requires clean optical path and mechanical protection |

| Magnetic, reed, Hall | Magnet-equipped targets | Works through non-metal barriers, highly sealed, immune to many contaminants | Requires magnets on targets; detection range and alignment can be more constrained |

When you map these strengths and limitations to your environment, a pattern usually emerges. Harsh mechanical and chemical conditions push you toward fully metal inductive or magnetic solutions with robust sealing, while high-speed optical verification in clean but washdown-heavy lines may favor photoelectric sensors with IP69K and stainless housings.

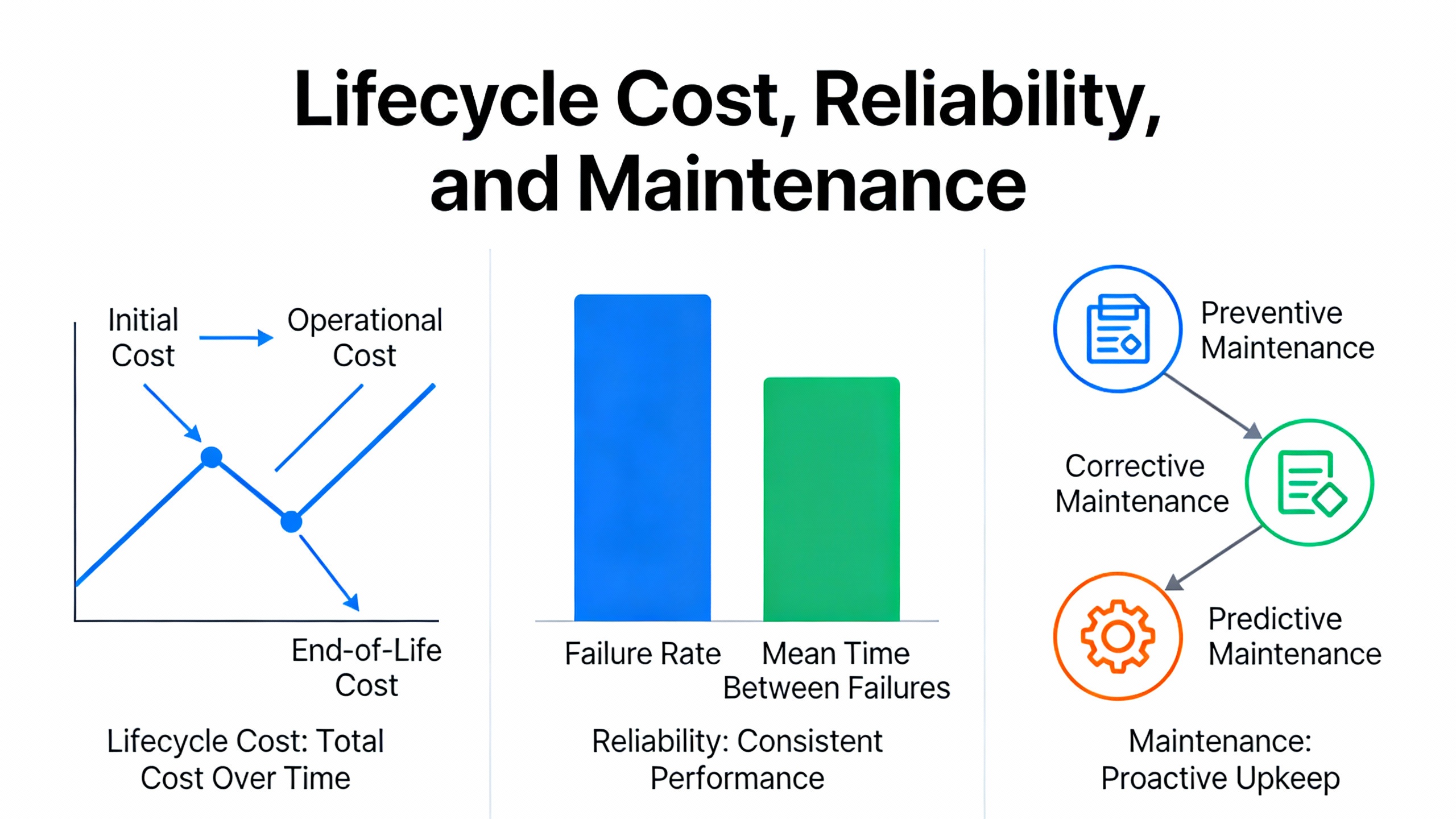

Total cost of ownership is more important than unit price. Affiliated Control explicitly warns that cheap sensors may fail more often, increasing downtime and labor, while robust designs with stainless or metal housings can lower lifetime costs despite higher upfront cost. Contrinex positions its EXTREME inductive sensors as an ŌĆ£insurance policyŌĆØ for demanding industries, where their durability and precision reduce unplanned downtime and maintenance.

Heavy-duty temperature and humidity sensor discussions reinforce this. Semeq notes that heavy-duty temperature sensors made from high-grade materials provide long-term reliability in harsh environments such as oil and gas, power generation, and chemical processing. Rikasensor describes top-tier industrial humidity sensors that combine accuracy, fast response, wide operating range, and durability, including models built for high temperatures and resistant to contamination. While these are not proximity sensors, the design philosophy is the same: invest in sensors whose construction, sealing, and stability match your worst-case conditions.

Maintenance practices are another major lever. Affiliated Control recommends planning for calibration and cleaning intervals, maintaining spares for critical points, documenting sensor locations and settings, and periodically reviewing performance data to catch drift or early failures. UnseenEra adds that regular maintenance should include cleaning sensor surfaces, seals, and connectors and checking mounting and wiring roughly every six to twelve months.

For a power-system application, that might mean placing all critical proximity sensors for breaker position and safety interlocks on a periodic inspection route, and keeping at least one spare of each type in inventory. For sensors connected through M8 or M12 connectors, a visual inspection of seals and tightening torque can prevent water ingress that would not show up until the next storm or washdown event.

Redundancy and data integrity also matter. UnseenEra suggests backup sensors and continuous data validation as a way to ensure trustworthy readings, particularly in extremely harsh environments. In a critical transfer switch or generator control panel, dual redundant proximity sensors on a key position could be justified when the cost of a false reading is higher than the extra hardware and logic.

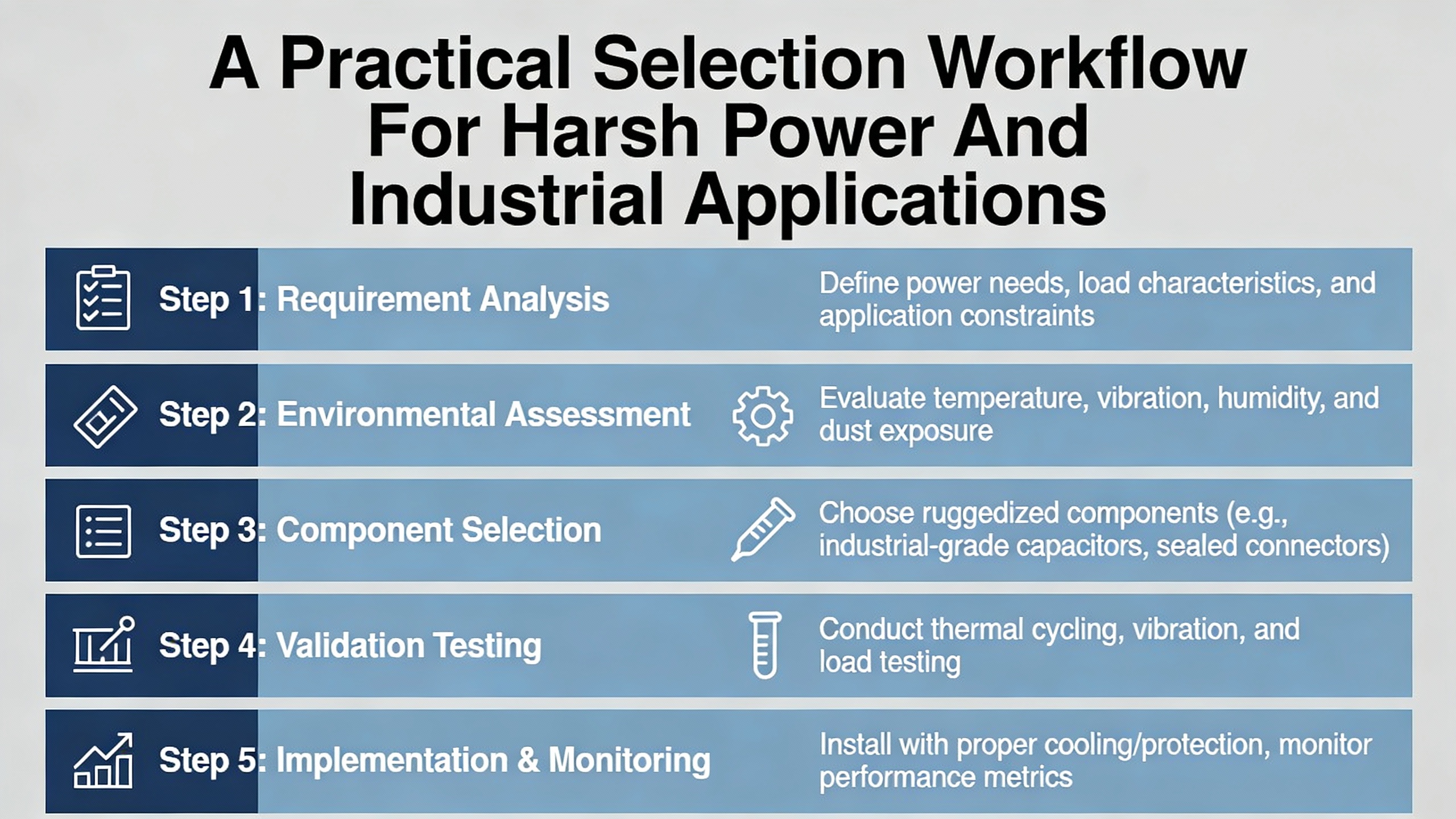

Bringing together the above criteria, the selection process for proximity sensors in harsh environments can follow a structured path.

The starting point is the functional requirement. Define clearly what you are sensing: presence or absence of a metal component, position of a mechanical element, level in a vessel, or the state of a door or cover. Identify the targetŌĆÖs material, size, and motion profile. This aligns with SiliconExpertŌĆÖs recommendation to begin with what is being sensed and the measurement range.

Next, characterize the environment. Document minimum and maximum temperatures, the presence of water, oil, coolants, or chemicals, the likelihood of high-pressure washdown, and expected vibration and mechanical shock. Use UnseenEraŌĆÖs ranges as a rough benchmark: if your conditions exceed roughly minus 4 to 176┬░F or include significant chemicals, vibration, or immersion, treat the environment as harsh and rule out general-purpose, lightly sealed devices.

Then select the sensing principle. For metal-only targets in dirty or oily areas, inductive sensors, especially ruggedized stainless or metal-face models from families like EatonŌĆÖs E57 or ContrinexŌĆÖs Full Inox series, usually provide the best mix of durability and immunity. For applications involving plastics or liquids under moderate environmental stress, capacitive or ultrasonic devices from suppliers such as Misumi and NewarkŌĆÖs catalog may be appropriate, with the understanding that they need more careful tuning and cleaning. For longer-range, high-speed detection in relatively clean but washdown-prone zones, background-suppression photoelectric sensors or IP69K-rated models are a strong fit.

Once the sensing principle is chosen, work through range and mounting details. Use OMCHŌĆÖs guidance to design with only seventy to eighty percent of nominal sensing range. Decide whether flush or non-flush mounting is acceptable based on space and nearby metal, guided by EatonŌĆÖs explanation of shielded versus unshielded sensors. Ensure that mechanical design respects the clearances and spacing recommended to avoid mutual interference and unintended triggering on nearby structure, as described by Newark and Eaton.

Electrical and control integration comes next. Choose between two-wire and three-wire devices, PNP versus NPN outputs, and normally open versus normally closed logic in line with Affiliated Control, Misumi, and EatonŌĆÖs descriptions. For safety functions, normally closed configurations that go to a known safe state on power loss or wire breakage often improve diagnostic coverage. In high-noise environments such as inverter rooms, favor sensor series like EatonŌĆÖs E57P that emphasize noise immunity and include short-circuit protection.

Finally, validate the chosen sensor under real conditions. OMCH and SiliconExpert both stress the importance of bench testing and field validation. Move the actual target through its range under hot and cold conditions, with representative contamination present, and verify switching distances, hysteresis, and repeatability. In critical applications, perform this validation with the actual PLC or safety controller, checking that signal integrity and timing meet requirements across the control chain.

If the sensor passes this gauntlet, consider standardizing it across similar machines or panels, as Affiliated Control recommends. Standardization reduces inventory, simplifies maintenance, and helps operators and technicians build intuition about how these devices behave over time.

Q: How much sensing margin should I design into a proximity sensor installation in a harsh environment?

A: Guidance summarized from OMCH recommends using only about seventy to eighty percent of the nominal sensing distance shown on the datasheet. For example, if a sensor lists a nominal range of one inch, place your target so that reliable detection occurs at about 0.7 to 0.8 inch under worst-case conditions. This margin absorbs variation from temperature, supply voltage, aging, and contamination. You should confirm the actual ŌĆ£onŌĆØ and ŌĆ£offŌĆØ distances through bench and field testing with the real target and environment.

Q: Which IP rating should I specify for washdown or outdoor-rated equipment?

A: UnseenEra explains that IP67 provides dust tightness and resistance to immersion, IP68 supports prolonged underwater operation, and IP69K is required for high-pressure, high-temperature washdown typical of food and beverage applications. ContrinexŌĆÖs EXTREME inductive sensors, for instance, are rated IP68 and IP69K and are designed to survive continuous immersion and washdown at pressures around one thousand four hundred fifty psi. For power equipment in washdown areas, specifying at least IP67 and often IP69K for exposed proximity sensors is a prudent starting point.

Q: Are inductive sensors always the best choice for harsh industrial environments?

A: Misumi, Newark, Eaton, and Contrinex all highlight inductive sensors as particularly robust in dirty, oily, or dusty industrial settings, especially when targets are metallic. Inductive designs are inherently immune to non-metal contamination and offer fast response at short ranges. However, they only detect metal and their range is limited to roughly 0.05 to 1.6 inches depending on model. If you need to detect plastics, liquids, or very long distances, capacitive, ultrasonic, or photoelectric sensors may be better despite their greater sensitivity to environment. The right choice depends on target material, range, contamination type, and available mechanical protection.

In power and industrial systems, reliable proximity sensing is not a luxury; it is a prerequisite for safe, continuous operation. Treat proximity sensors with the same rigor you apply to specifying UPS modules or protective relays, leverage rugged offerings from reputable manufacturers such as Eaton and Contrinex, and validate performance under your worst credible conditions. Done well, your sensors will become quiet, dependable partners in keeping the power on and the process running.

Leave Your Comment