-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Summary: Real-time stock checks for motion controller parts turn spare-part planning from guesswork into a controlled reliability tool, cutting downtime and protecting critical power systems from avoidable outages.

In UPS, inverter, and power protection environments, a down machine often comes back to one missing part: a motion controller board, drive module, or feedback encoder sitting ŌĆ£somewhereŌĆØ in the network but not where maintenance needs it.

From reliability audits IŌĆÖve done in power-heavy plants, the pattern is consistent: great maintenance plans on paper, but no live view of where critical motion parts actually are. A lost controller or actuator kit can extend an outage from hours to days and put SLAs for hospitals, data centers, or industrial campuses at risk.

Inventory research from NetSuite and Interlake Mecalux shows that real-time stock control reduces stockouts, improves service levels, and frees working capital. For motion hardware, that translates directly into lower mean time to repair (MTTR) and fewer ŌĆ£line downŌĆØ events when power systems are under maintenance or being built.

The business case is simple: treat motion controller parts as reliability assets, not just purchasing line items, and you need live, accurate availability data to manage them.

Real-time availability starts with perpetual inventory: every movement of a controller, drive, or linear stage is recorded as it happens, not days later during a physical count. Sources like inFlow Inventory and Erplain emphasize that this is nearly impossible to sustain with spreadsheets.

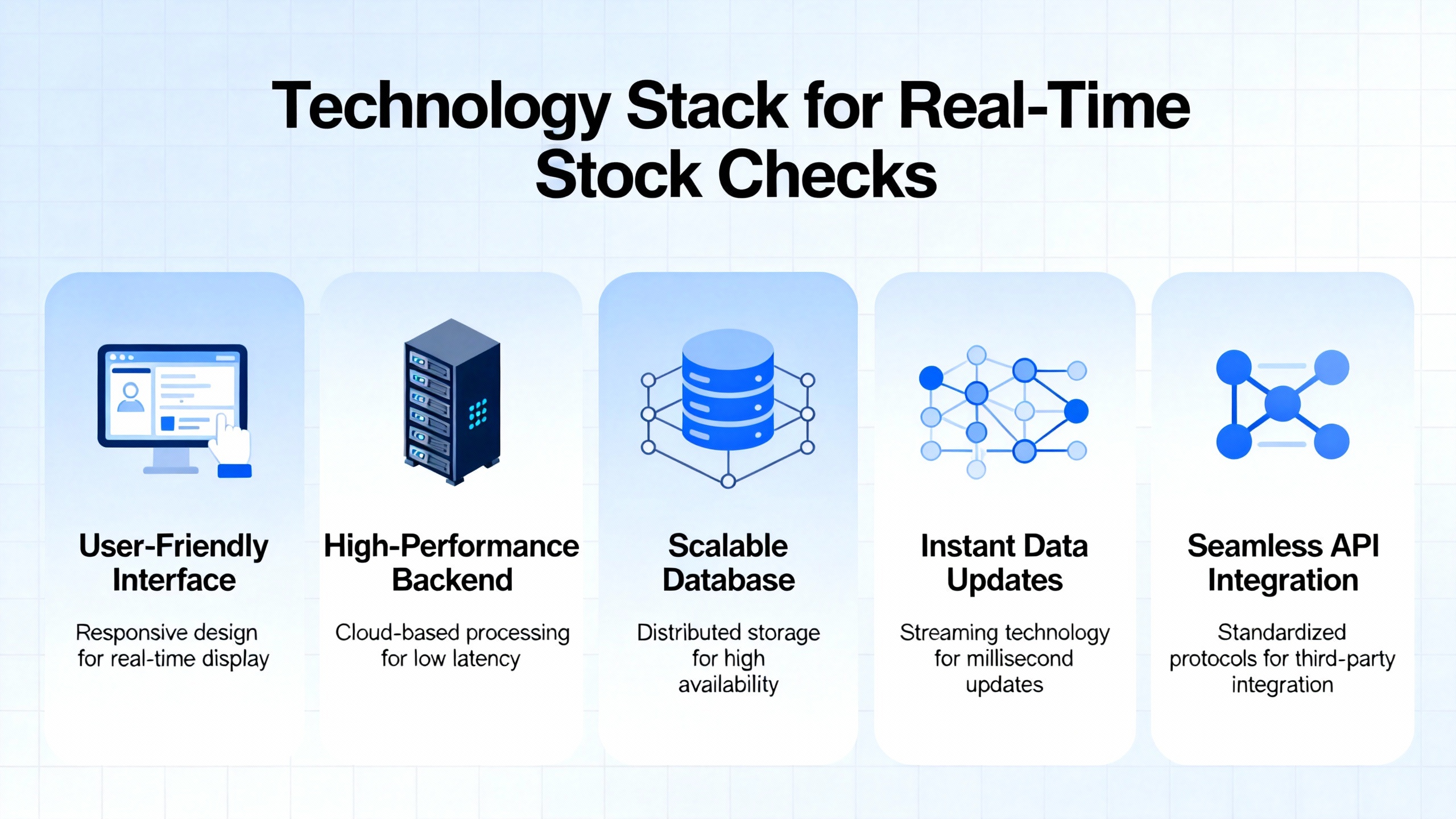

Core enablers include:

One nuance: vendors use ŌĆ£real-timeŌĆØ loosely; some systems batch-sync every few minutes, which may be fine for slow-moving spares but not for fast-paced maintenance windows. Make the update interval explicit in your requirements.

Technology without a control plan simply produces prettier dashboards. For motion parts that protect your power availability, you need clear policies, thresholds, and KPIs.

Best-practice inventory guidance from NetSuite and Erplain points to a few essentials: define service-level targets, classify items, and measure performance. For motion control, that means designating A-class partsŌĆöcontroller CPUs, servo drives, feedback encoders, linear actuators, critical cablesŌĆöand guaranteeing zero stockouts within defined lead times.

A practical starting playbook:

Remote inventory guidance from Sortly reinforces the importance of photos and standardized labels. For motion parts, visual documentation (label photos, connector orientation, firmware version on the nameplate) prevents the wrong board from being pulled under time pressure.

Even with perfect internal visibility, your system is only as resilient as your supply chain. OEM Magazine notes that lead times for motion components have stretched from days to weeks or months, forcing tough tradeoffs between cost, customization, and delivery.

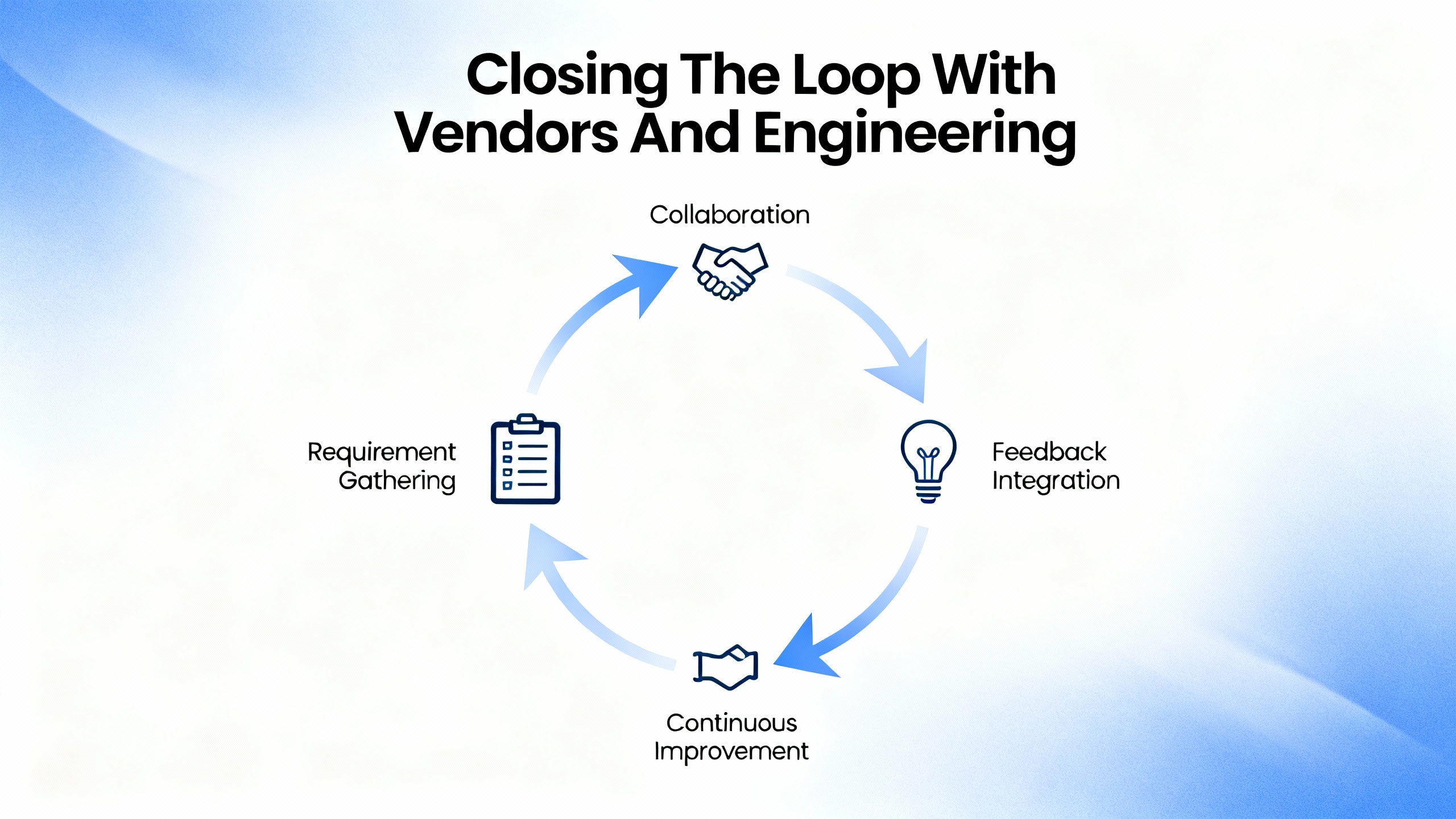

Use your real-time stock data to drive smarter vendor collaboration. Share demand profiles and safety-stock requirements for key controllers and actuators; in return, ask vendors for realistic lead times, ŌĆ£goodŌĆōbetterŌĆōbestŌĆØ options, and pre-approved alternates that wonŌĆÖt compromise motion performance or power quality.

Online collaboration tools many motion vendors now offerŌĆölive CAD reviews, duty-cycle discussions, ŌĆ£good enoughŌĆØ alternate partsŌĆölet engineering, reliability, and procurement jointly decide when to accept a standard, available part rather than wait for a fully customized version. For critical power assets, a slightly oversized, in-stock actuator often beats a perfect but late custom unit.

Finally, implement in phases: start with one high-impact motion family (e.g., servo drives for inverter test stands), digitize its stock control end to end, and prove the MTTR and downtime gains. Then roll the same model across other motion and power-protection components. Over time, your ŌĆ£parts stock checkŌĆØ stops being a scramble and becomes a calm, data-driven confirmation that the system is protected before the next outage or maintenance window hits.

Leave Your Comment