-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

In modern plants, the reliability of your power protection systems is no longer determined only by transformer sizing, UPS runtime, or inverter topology. The Ethernet and wireless networks that connect your PLCs, SCADA servers, power meters, UPS SNMP cards, and remote I/O now sit squarely in the critical path. When those networks are misconfigured, you do not just lose visibility; you erode your safety margins and your ability to respond to disturbances.

Guidance from NIST Special Publication 800-82 emphasizes that industrial control systems must balance security with performance, reliability, and safety. That document, along with ISA/IEC 62443, treats the network as a safety-relevant subsystem, not just a convenience. Vendors such as Siemens, Cisco, Rockwell Automation, and others have responded by building structured training and certification programs focused specifically on industrial Ethernet and WiŌĆæFi configuration.

From a power systems perspective, these certifications are not mere badges. They codify the skills needed to keep power quality meters online during disturbances, ensure UPS alarms reach control rooms and security operations centers, and maintain deterministic communication to switchgear and protective relays. In my work with industrial and commercial facilities, every prolonged power incident that ŌĆ£should have been handled by the UPSŌĆØ but was not, eventually traces back to a configuration issue: an unmanaged switch replaced in a hurry, a misconfigured VLAN that isolates alarms, or a wireless link that was never hardened. Certification does not magically prevent such problems, but it raises the floor on how those networks are designed and maintained.

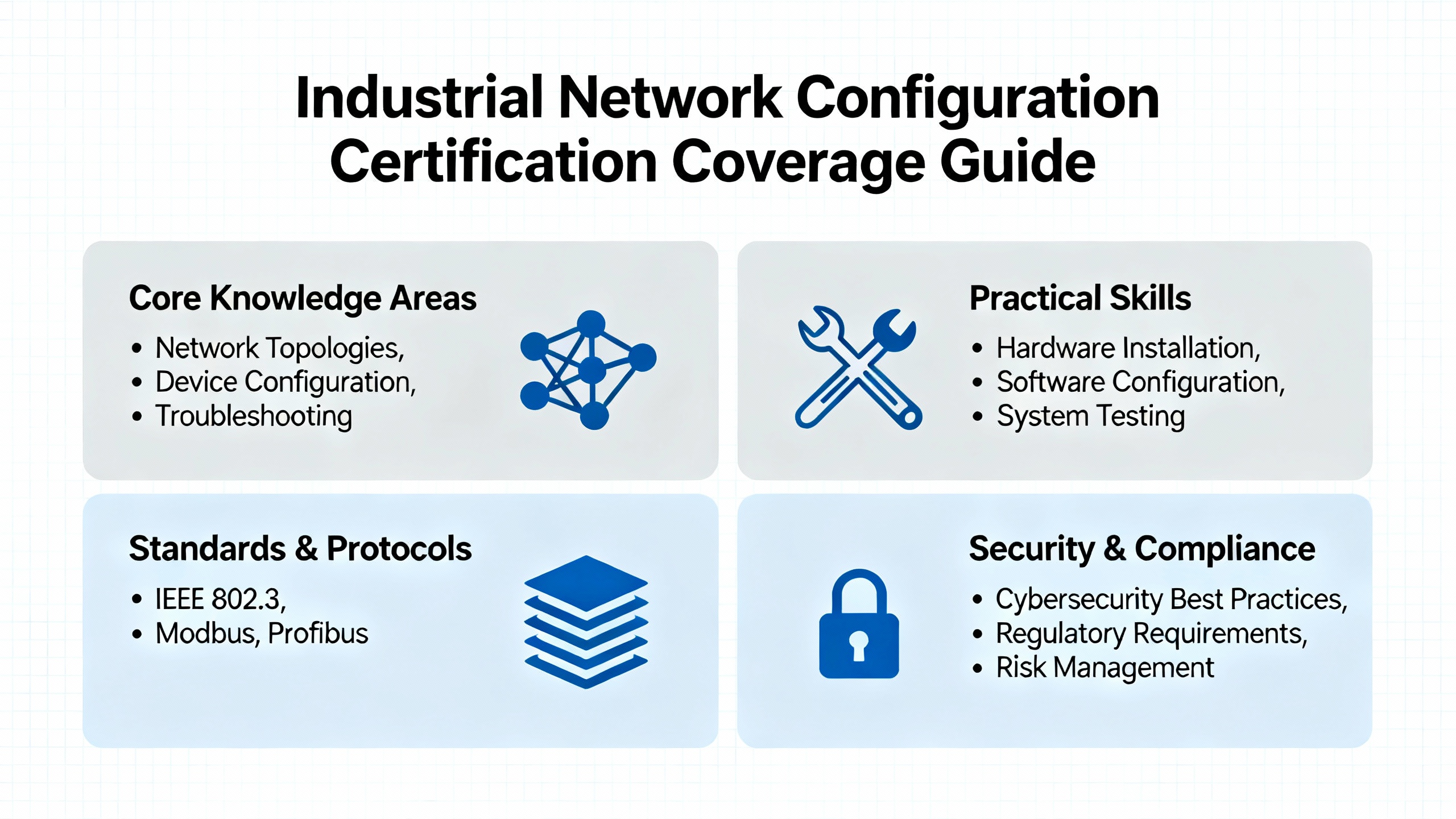

Most industrial network configuration certifications are grounded in the day-to-day tasks of OT engineers, plant network admins, and IT staff who operate in harsh, availability-focused environments. The Cisco 200ŌĆæ401 blueprint for industrial networking, CiscoŌĆÖs Industrial Networking Specialist certification, Siemens Industrial Networks Education programs, and lab-intensive courses such as IMINS2024 and specialist four-day offerings from providers like SolutionsPT have very similar building blocks.

They begin with the basics: understanding ruggedized end devices and infrastructure devices, correctly installing and replacing them, and validating their configuration. For an end device, that means far more than plugging in a cable. Candidates are expected to confirm IP addressing, subnet masks, default gateways, port settings, and connectivity, and to do so in an industrial context where bandwidth, real-time behavior, and deterministic performance matter. Exam objectives explicitly include safe physical installation using terminal block diagrams and schematics, acknowledging that miswiring in a high-energy panel can be as dangerous as a software bug.

Infrastructure devices receive even more emphasis. Certifications require familiarity with industrial protocols such as EtherNet/IP and IEC 61850, as well as command-line or graphical configuration of switches and routers. Candidates learn how to position these devices correctly in the topology, how to design for network resiliency, and how to validate that the complete network aligns with design diagrams and asset inventories. Security is embedded at each step: CiscoŌĆÖs objective blueprint, for example, expects candidates to understand safety and security risks using models such as the Purdue architecture and to apply hardening techniques such as disabling unused ports and preferring encrypted management protocols.

Troubleshooting is typically the single largest domain. CiscoŌĆÖs 200ŌĆæ401 exam dedicates roughly one third of its weighting to multi-layer troubleshooting from cabling to routing and application performance. That reflects reality. In a live plant, the person who can systematically diagnose a duplex mismatch, a spanning-tree loop, or a duplicate IP address is the person who can keep production and critical power systems online.

Industrial Ethernet is the backbone of contemporary OT environments. Renesas describes how factories are shifting from serial buses to industrial Ethernet to meet real-time requirements, support higher bandwidth, and tolerate noise and harsh environments. Certifications pick up those requirements and translate them into concrete configuration skills.

Candidates learn to design and implement topologies such as star, ring, and mixed architectures. Guidance from industrial network design experts emphasizes that star topologies simplify management but can introduce single points of failure at central switches, while ring topologies with fast redundancy mechanisms improve availability for drives, protection panels, and controllers. Training content from IQNetX and others reinforces that selecting the right topology is inseparable from understanding the plantŌĆÖs latency, determinism, and reliability targets.

Switch configuration is another core theme. Courses and certification blueprints require the ability to configure VLANs, trunks, and interŌĆæVLAN routing, and to understand unicast, multicast, and broadcast traffic. SolutionsPTŌĆÖs four-day industrial networking course explicitly walks through the OSI model, spanning tree, VLAN fundamentals, and associated practical labs. VernetzenŌĆÖs Industrial Network Fundamentals course similarly trains participants to implement and validate VLANs and trunks, then troubleshoot IPv4 addressing and switched-network issues. Translating that to reliability, these skills allow you to separate protection systems from less critical loads, constrain broadcast domains, and keep monitoring traffic from starving real-time control flows.

Quality of Service and precise timing come into play where time-sensitive loads or coordinated motion control are present. While not every certification drills deeply into Time-Sensitive Networking, the broader ecosystem, as described by Renesas, is clearly moving toward deterministic Ethernet with features such as time synchronization, traffic shaping, and frame preemption. When you dispatch a command to transfer a critical load to an alternate feeder, the timing and predictability of that packetŌĆÖs journey through the network can matter as much as the mechanical response of the breaker.

Configuration tasks also extend down to the physical layer. Exam objectives for industrial networking certifications include selecting appropriate cables for high EMI environments, installing and documenting them correctly, and validating them with proper test tools. Standards such as TIAŌĆæ1005 and TIAŌĆæ568 are referenced to reinforce best practices for grounding, bonding, and shielding. In power rooms, where high-current equipment can generate significant electromagnetic noise, this is not academic. Poor cable selection or installation can turn a control packet into a random event.

The common threads across these Ethernet topics can be summarized succinctly.

| Focus Area | What Certification Teaches | Reliability Impact for Power and OT Systems |

|---|---|---|

| Topology and redundancy | Choosing and configuring star, ring, and redundant paths | Limits single points of failure for UPS, switchgear, and control communications |

| VLANs and segmentation | Creating and routing between logical zones | Confines faults and cyber incidents, keeps protection and monitoring isolated |

| QoS and timing | Prioritizing and shaping traffic based on criticality | Ensures time-critical trips and alarms are delivered even under network stress |

| Physical media and installation | Selecting cable types, managing EMI, validating installations | Reduces intermittent faults and communication noise in high-energy environments |

Ethernet will remain the workhorse for protection and control, but wireless is now entrenched for mobile HMIs, remote diagnostics, AGVs, and instruments in locations where pulling cable is impractical. Certifications and training paths are increasingly reflecting this.

A specialized article on robust industrial WiŌĆæFi highlights several configuration strategies that you see echoed in advanced courses. It starts with a thorough site survey, using heat maps to visualize signal strength and interference before any access point goes on the wall. In heavy manufacturing, large metal structures, moving cranes, and high-power drives create dead zones and reflections that office WiŌĆæFi planners rarely encounter. Learning to interpret survey data is not just a technical curiosity; it is how you avoid losing connectivity to a mobile maintenance terminal in front of a live switchboard.

Hardware selection is another focus. Providers recommend industrial-grade, weatherproof access points paired with highŌĆæperformance switches and routers, often with highŌĆægain antennas to overcome difficult propagation paths. Certifications and courses do not turn candidates into RF engineers, but they do teach the tradeoffs between channel reuse, transmit power, and antenna placement in dense or noisy environments.

On the configuration side, industrial WiŌĆæFi training emphasizes nonŌĆæoverlapping channel plans, bandwidth management, and Quality of Service, so that mission-critical control and monitoring traffic is prioritized over less important data. For example, prioritizing telemetry from a remote power house over background file transfers can be the difference between a controlled generator shutdown and an unexpected trip.

Security is deeply embedded in these wireless modules. The Eoxs industrial WiŌĆæFi article recommends modern encryption such as WPA3, multi-factor authentication, strong segmentation between wireless user networks and critical OT segments, and continuous firmware updates. These are very much aligned with broader industrial security design guidance from Cisco, NIST, and CISA, which insist that wireless should never be a direct bridge into control system zones. Certifications that include wireless components therefore focus on integrating secure WiŌĆæFi into the wider zone-and-conduit architecture rather than treating it as a standalone system.

Across the industrial networking landscape, a few certification and training families stand out for Ethernet and wireless configuration in OT environments. Each caters to slightly different roles and vendor ecosystems, but the overlap is substantial.

Siemens Industrial Networks Education programs provide a structured pathway focused on planning, deploying, operating, and securing industrial Ethernet-based communication networks. According to SiemensŌĆÖ own descriptions, these programs target automation engineers, plant network planners, commissioning engineers, system integrators, and OT-aligned IT staff. The program typically offers several certification levels and technology tracks covering fundamentals, switching and routing, wireless, and security. Courses combine theory on Ethernet, TCP/IP, PROFINET, and industrial communication standards with intensive handsŌĆæon labs using Siemens networking hardware and diagnostic tools. The exams test both theory and practical configuration and troubleshooting.

CiscoŌĆÖs Industrial Networking Specialist certification concentrates on designing, implementing, and troubleshooting industrial networks in manufacturing and process environments. It builds on core networking fundamentalsŌĆöIP addressing, VLANs, subnetting, wirelessŌĆöand extends into industrial protocols such as Modbus and Profibus, industrial firewalls, and redundancy mechanisms. Candidates must pass the Cisco 200ŌĆæ401 exam, which evaluates endŌĆædevice lifecycle management, infrastructure device deployment, cabling, multi-layer troubleshooting, and maintenance practices. Cisco recommends a dedicated training course, Implementing and Operating Cisco Industrial Network Core Technologies, to prepare.

The IMINS2024 course ŌĆ£Managing Industrial Networking for IoT with Cisco TechnologiesŌĆØ is a lab-intensive offering that develops skills in configuring, maintaining, and troubleshooting industry-standard protocols, wireless technologies, and security features. It is explicitly targeted at plant administrators, control system engineers, and network engineers working on ITŌĆōOT convergence in manufacturing, process control, and oil and gas. Completion of IMINS2024 earns thirty Cisco Continuing Education credits, which can be applied toward maintaining certain Cisco certifications.

Outside those major vendor ecosystems, there is a growing ecosystem of vendor-neutral training that still aligns with the same configuration practices. SolutionsPT runs a four-day Industrial Networking course covering fundamentals such as the OSI model, IP addressing, VLANs, spanning tree, and troubleshooting, followed by focused days on switching, security, and secure remote and cloud connectivity. Labs use both Cisco and Hirschmann devices, and the course includes practical exercises on mitigating attacks like DHCP spoofing and ARP poisoning and deploying industrial firewalls.

VernetzenŌĆÖs Industrial Network Fundamentals course offers a two-day, lab-rich introduction to IPv4 and OT networks targeted at OT career starters and experienced technicians in industries such as mining. Participants learn to install, configure, and validate switches, VLANs, wireless basics, Quality of Service, and Power over Ethernet budgeting, and they receive a course completion certificate with the option to sit a formal exam.

Other training providers, such as RealPars and Industrial Networking Solutions, emphasize practical, example-based courses taught by practicing engineers. Their programs cover Ethernet and IP networking fundamentals for OT, integration of SCADA and PLCs, and cybersecurity awareness for critical infrastructure, all with the goal of enabling engineers and technicians to troubleshoot and adapt industrial networks safely.

For organizations that want group training, Siemens also offers private industrial networks certification classes at customer sites, optimized for companies with around half a dozen or more staff needing the same education. This model minimizes travel and allows training to be tightly aligned with the specific plant environment.

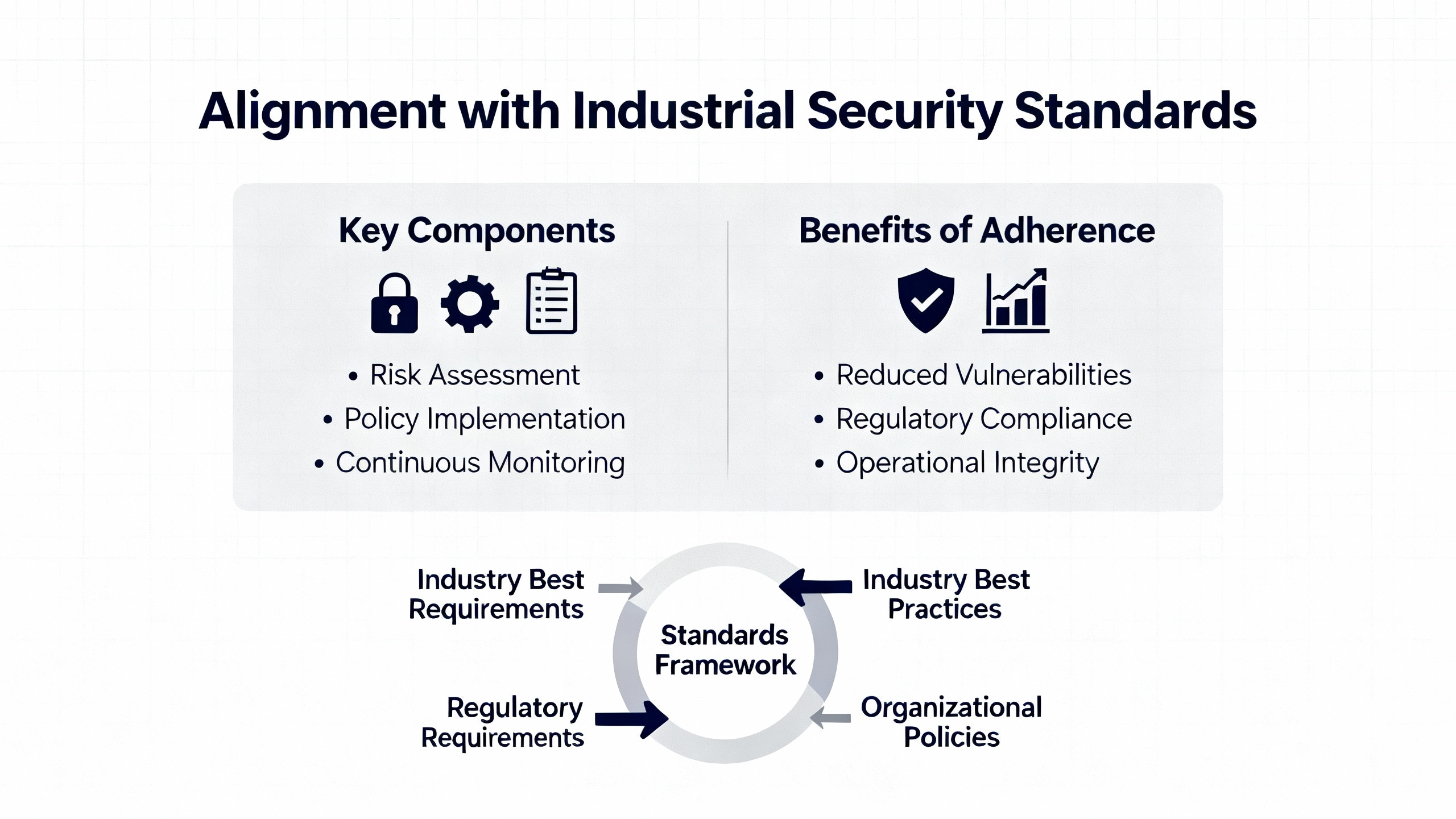

While exam blueprints and course outlines vary in wording, there is a tight alignment between reputable industrial networking certifications and established OT security frameworks.

ISA/IEC 62443 places strong emphasis on defense-in-depth and configuration management. It calls for clear zoning and conduits, robust access control, rigorous change management, and detailed documentation of who changed what, when, and why. Articles discussing configuration management in the context of IEC 62443 highlight how legacy platforms cannot always be patched easily, so organizations rely on virtual patching, strict segmentation, and careful scheduling of changes during maintenance windows. Effective programs maintain role-based access control, conduct regular access audits, and log configuration changes to create the audit trails necessary for compliance and incident investigation.

Training programs mirror this by teaching structured change processes, configuration backups, and the importance of keeping firmware and configuration baselines current. CiscoŌĆÖs 200ŌĆæ401 objectives explicitly include ensuring reliable backups, verifying appropriate firmware, and maintaining accurate asset inventories. NSAŌĆÖs Network Infrastructure Security Guide reinforces the need for standardized secure baselines, controlled change processes, and periodic configuration audits for routers, switches, and firewalls.

NIST SP 800ŌĆæ82 provides ICS-specific security guidance and stresses that connectivity to enterprise networks increases exposure. It recommends risk assessments, network segmentation, secure remote access, and continuous monitoring. The Cisco Industrial Security design guidance, as summarized in industry briefs, adopts Purdue-style reference architectures with demilitarized zones, internal segmentation firewalls, industrially hardened switches, and intrusion detection tuned for industrial protocols. Certifications that focus on architecture and configuration prepare practitioners to implement those patterns rather than leaving them as theoretical diagrams.

Remote access is a recurring theme where configuration errors routinely undermine otherwise solid designs. CISAŌĆÖs recommended practice on managing remote access for industrial control systems defines remote access as a high-risk function and strongly discourages any direct connectivity from the internet to control assets. Instead, it recommends terminating VPNs in a demilitarized zone, using jump hosts, enforcing strong identity and access management, and logging and monitoring every session. This guidance is reflected in practical courses that teach secure VPN configuration, remote desktop gateways, and jump host usage as part of day four content on secure connectivity to cloud or remote sites.

Finally, security assessment methodologies for industrial networks, such as those described by ICS security specialists, emphasize asset discovery, segmentation analysis, vulnerability mapping, and risk-based hardening roadmaps. When people trained and certified in industrial network configuration design Ethernet and wireless architectures with those assessment outcomes in mind, plants move toward resilient, standards-aligned networks rather than piecemeal patchwork.

The value of industrial network configuration certification is ultimately measured in fewer unplanned outages, safer maintenance, and better visibility into the health of your power and process systems. To achieve that, the concepts learned in Ethernet and wireless certification programs must be translated into daily practice around your power infrastructure.

One practical step is to treat every networked power device as a first-class OT asset. UPS monitoring interfaces, networked relays, power quality analyzers, generator controllers, and static transfer switches should appear in your asset inventory with IP addresses, firmware levels, and configuration owners. Network design should explicitly place these devices into suitable security zones, often alongside related control assets, with well-defined conduits for monitoring and control traffic. This is completely in line with IEC 62443 zoning principles and prevents ad hoc connections that expose power devices directly to less-trusted segments.

Next, apply the segmentation, VLAN, and QoS skills from certification training to ensure these power systems retain communication priority during disturbances. That means placing protection and monitoring traffic in high-priority classes, limiting broadcast domains, and ensuring redundant paths exist between power devices, control rooms, and central monitoring or security centers. Industrial networking design guides, especially those from Cisco and Rockwell Automation, describe converged plantwide Ethernet architectures precisely to support this kind of high-availability, segmented design.

Remote access for power systems requires particularly disciplined configuration. Vendors often need remote access to UPS units, battery management systems, or generator controllers for diagnostics and firmware upgrades. CISAŌĆÖs guidance makes it clear that such access should never be via direct inbound connections. Instead, terminate vendor VPNs or remote desktop sessions in a demilitarized zone, use jump hosts, enforce multi-factor authentication, restrict access windows, and log sessions. Incorporating these patterns into your network configuration standards transforms certification knowledge into reduced risk.

Change management is another area where certification skills directly support reliability. Articles on ISA/IEC 62443 configuration management stress testing changes in advance, scheduling them during maintenance windows, and having rollback plans. Applying the exam-driven discipline around configuration backups, firmware verification, and documentation means that network changes near power systems are transparent, recoverable, and auditable. When a firmware upgrade to an industrial switch supplying multiple UPS cabinets goes wrong, the difference between a five-minute rollback and a multi-hour outage is the rigor of these configuration practices.

Different roles benefit from different starting points in the certification landscape. OT and automation engineers who own both PLC logic and networking will usually gain the most from vendor-neutral fundamentals followed by vendor-specific configuration and security tracks. Courses like VernetzenŌĆÖs Industrial Network Fundamentals and multi-vendor offerings from SolutionsPT or Industrial Networking Solutions build a solid base in Ethernet, VLANs, IP addressing, and wireless concepts in OT environments. After that base, Siemens Industrial Networks Education or CiscoŌĆÖs Industrial Networking Specialist certification provide deeper exposure to specific stacks and diagnostic tools.

Power system specialists responsible for UPS fleets, medium-voltage switchgear, and distributed energy resources often find that industrial networking certifications give them just enough network fluency to participate effectively in design and troubleshooting, without expecting them to become full-time network engineers. For this group, courses emphasizing practical configuration, secure remote access, and network-health monitoring are particularly valuable, because they map directly to tasks such as integrating new UPS systems into SCADA, validating failover paths between substations, or verifying that generator controllers remain reachable under load.

IT network engineers moving into OT benefit from certifications that explicitly address the cultural and technical differences between enterprise and industrial networks. Training providers and thought leaders in Industrial IoT security stress that the OT mindset is defined by safety and uptime, not just data confidentiality. Certifications built around industrial protocols, deterministic behavior, and constrained maintenance windows help IT staff understand why a seemingly harmless change at the network core can have unsafe ripple effects at the plant floor or in power rooms.

Regardless of role, the most effective strategy is to connect certification plans to concrete project roadmaps. If you know that your plant intends to deploy new wireless-connected power panels, prioritize wireless and security-focused modules now. If a converged plantwide Ethernet redesign is on the horizon, invest in architecture-focused certifications that cover CPwE-style segmentation and redundancy patterns.

Vendor-specific certifications from companies such as Cisco and Siemens are not mandatory to run a reliable plant, but they do reflect the configuration models and diagnostic tools you will actually use on their equipment. When most of your installed base comes from one vendor, those certifications often accelerate troubleshooting and reduce the learning curve for new deployments. Vendor-neutral training remains valuable for understanding concepts, but vendor-specific certification closes the gap between theory and the behavior of real devices in your network.

For most industrial and power environments, wired Ethernet remains the foundation. It carries the bulk of control, protection, and monitoring traffic, and it will continue to do so. Certifications that focus on Ethernet topologies, VLANs, redundancy, and security should therefore come first. Once that base is in place, adding wireless-focused training lets you design and secure WiŌĆæFi segments that respect the same zoning and reliability requirements, rather than bolting WiŌĆæFi on as an afterthought.

The research summarized by NIST, NSA, CISA, and industrial security practitioners consistently shows that misconfigurations, flat networks, and insecure remote access are major contributors to industrial cyber incidents and unplanned downtime. Industrial network configuration certifications are designed around exactly those problem areas: segmentation, secure management, troubleshooting, and lifecycle maintenance. When you frame certification as a structured way to reduce the probability and duration of outagesŌĆöin particular outages that interrupt production and test the limits of your power protection systemsŌĆöit becomes much easier to position training and certification as a risk-reduction and reliability investment rather than a discretionary expense.

In the end, every resilient power and automation system rests on a resilient network. Investing in industrial Ethernet and wireless configuration certification is one of the most direct, measurable ways to make that network an asset to reliability rather than a hidden single point of failure.

Leave Your Comment