-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

In critical power systems, including UPS-backed distribution, industrial inverters, and motor control centers, contactors are small components with outsized consequences. When an ABB contactor becomes obsolete, fails in service, or simply cannot be sourced in time, the question is not just ŌĆ£What fits?ŌĆØ but ŌĆ£What will keep my system reliable for the next decade?ŌĆØ As a power system specialist focused on reliability, I have seen both wellŌĆæplanned replacements that quietly run for years and rushed substitutions that buzz, overheat, or fail at the worst possible moment.

This article walks through how to think about ABB contactor replacement, which technical parameters you must match, and how alternative suppliers such as Schneider Electric, Siemens, Eaton, and costŌĆæoptimized brands can fit into a robust strategy. The goal is not to promote one brand over another, but to help you make disciplined, engineeringŌĆæsound decisions backed by field experience and reputable references.

A contactor is an electrically controlled switch designed to handle high current, typically for motors, large lighting loads, heating, and other industrial circuits. Sources such as C3Controls and Kentstore describe contactors as highŌĆæpower cousins of relays, able to carry currents from a few amperes up to thousands of amperes and withstand millions of mechanical operations. ABBŌĆÖs portfolio, highlighted in market overviews by VIOX Electric, includes AF series contactors that cover threeŌĆæ and fourŌĆæpole designs up to about 2,700 A and motor duties up to roughly 1,150 hp, in NEMA sizes from 00 to 8. In other words, ABB gear spans everything from modest HVAC loads to very large industrial drives.

In practice, ABB contactors end up on a replacement list for a handful of recurring reasons. The first is straightforward endŌĆæofŌĆælife failure: pitted or welded contacts, buzzing coils, or devices that no longer pull in reliably. C3Controls notes that welded or sticking contacts are the most common failure mode, driven by high inrush currents, unstable control voltages, and contamination. The second reason is obsolescence or supplyŌĆæchain pressure. A contactor that was commonplace fifteen years ago may now be discontinued or simply hard to get on the schedule your plant requires.

The third driver is system upgrade. As contactor technology evolves toward higher efficiency and more intelligence, some operators intentionally move away from older generations. VIOX Electric cites modular contactors as part of a global market worth about $442 million in 2023 and projected to reach approximately $827 million by 2030, with smart, energyŌĆæefficient designs cutting operating costs by up to around 30 percent. In this landscape, users sometimes replace ABB devices not because they have failed, but because they want better energy performance or richer diagnostics.

Whatever the motive, successful replacement starts with a nonŌĆænegotiable engineering truth: whatever brand you choose, certain parameters must match.

The first requirement is aligning the new contactorŌĆÖs power side ratings with your load. Motor load contactors, as described by Contactor Depot, must be rated above the motorŌĆÖs maximum current if they are to survive long term, especially in heavyŌĆæduty industrial and HVAC applications. This means you cannot simply match nameplate fullŌĆæload amps; you must account for starting inrush and the duty cycle.

IEC utilization categories such as ACŌĆæ1 and ACŌĆæ3, cited in guides from Kentstore and C3Controls, exist for exactly this reason. ACŌĆæ1 covers primarily resistive loads, where current is relatively steady and arcing is mild. ACŌĆæ3 is intended for squirrelŌĆæcage motor starting, where inrush and associated arcing are severe. If the original ABB contactor was ACŌĆæ3 rated, downgrading to an ACŌĆæ1ŌĆæoriented replacement from any brand is asking for contact erosion and early failure.

Voltage rating must also be checked both for insulation strength and for the system in which the contactor operates. Industrial guides consistently emphasize matching the maximum switching voltage to the highest voltage present on the circuit. In a UPS bypass panel or motor control center, this may be several hundred volts AC; in DC systems, specialized DC contactors or vacuum contactors may be required, as Kentstore notes, because DC arcs are harder to extinguish.

Coil voltage is where many ABB replacement projects go off the rails. Contactor Depot stresses that the coil voltage must match the control circuit, not the load voltage. The coil is connected at dedicated terminals (typically labeled A1 and A2) and only needs enough voltage to energize the electromagnet. The power contacts, connected between L1/L2/L3 and T1/T2/T3, carry the main circuit voltage and current.

A contactor may, for example, control a 240 V motor while using a 24 V AC coil fed from a thermostat or control transformer. The coil and the load are separate circuits and must be treated as such. Contactor Depot details what happens when you get this wrong. A 24 V coil subjected to 120 V burns out almost instantly. A 120 V coil fed with 24 V never pulls in. Undervoltage leads to chattering, buzzing, and failed starts; overvoltage can cause overheating and even internal fire risk.

In my own field work, whenever I consider substituting an ABB contactor with another brand, I start with three simple checks. I read the coil rating on the original ABB device, I verify the actual control voltage with a meter, and I refuse to use any replacement whose coil voltage and frequency do not exactly match those values. Contactor Depot and Peerless Electronics both reinforce this mindset: match the coil to the control circuit, and do not ŌĆ£make doŌĆØ with whatever coil happens to be on the shelf.

A replacement contactor must fit not only electrically, but also within the standards and certification envelope of your equipment. C3Controls explains the practical differences between NEMA and IEC contactors. NEMA devices, common in North America, are intentionally oversized and organized in frame sizes 00 through 9 with builtŌĆæin safety margins. IEC contactors, which dominate globally, are more compact and tightly aligned to specific applications.

ABBŌĆÖs range covers both IEC and NEMA styles. If the original ABB contactor was a NEMA device, substituting an undersized IEC unit from any other vendor without carefully checking ratings and certifications can compromise safety. Peerless Electronics recommends replacing AC contactors with units that meet appropriate standards such as UL 508A for use in certified panels. VIOX Electric underlines that leading manufacturers test to IEC 60947 and UL 489 and operate under ISO 9001 quality systems.

When you move away from ABB, you must confirm that the replacement carries equivalent IEC and UL markings and that your panel, especially if it is part of a listed assembly, remains compliant.

Modern contactors are highly durable when correctly applied. Kentstore notes that industrial contactors can exceed ten million mechanical operations, and definiteŌĆæpurpose contactors for HVAC commonly reach about 250,000 electrical operations and around one million mechanical operations. That said, this durability assumes that ambient temperature, humidity, contamination, and duty cycle are within the manufacturerŌĆÖs expectations.

Articles from Kentstore and Chint emphasize that environmental conditions and duty cycle (continuous versus intermittent, heavy cycling versus occasional switching) must inform selection. In UPS and inverter applications where transfer operations may be infrequent but critical, it is tempting to disregard cycling ratings. However, if a bypass contactor is also used to sequence loads or support maintenance operations, it may accumulate more operations than you expect, making mechanical life a real concern.

Staying within the ABB ecosystem is often the easiest path. The AF series offers wide current coverage, up to about 2,700 A and roughly 1,150 hp motor duty according to VIOX Electric, with threeŌĆæ and fourŌĆæpole configurations and NEMA sizes from 00 to 8. ABB also provides installation contactors designed to match other modular DINŌĆærail components, as well as compact B/BC series units and AS/ASL devices for highŌĆævolume applications.

Remaining with ABB has several advantages. Mechanical interchangeability is more likely, particularly within the same series. Accessory compatibility, such as overload relays, auxiliary contacts, and mechanical interlocks, remains straightforward. Global support and documentation are consistent. Industry discussions summarized in research on contactor manufacturer choices show that many panel builders deliberately standardize on one or two major brands like ABB, Schneider, or Siemens, precisely to simplify spares and training.

The limitations of staying with ABB are usually logistical or strategic. In some regions or industries, ABB parts may have longer lead times than competitors. In other cases, the plantŌĆÖs strategic direction may favor another automation ecosystem, such as Siemens or Rockwell Automation, for deeper integration into control architectures. There is also the issue of modernization: while ABB certainly offers advanced products, other vendors may align more closely with specific smartŌĆæcontactor roadmaps or sustainability targets that your corporate standards emphasize.

When an ABB contactor is unavailable or when your longŌĆæterm strategy favors another platform, crossŌĆæbrand replacement can be a strong choice as long as you adhere to the fundamental matching principles described earlier.

Multiple sources, including Balaji Switchgears and slides on industrial automation contactors, position Schneider Electric as a global leader in energy management and automation. SchneiderŌĆÖs contactors are repeatedly described as durable, energyŌĆæefficient, and compliant with international standards. The TeSys family, highlighted by VIOX Electric and other technical briefings, includes compact TeSys D contactors up to about 150 A, TeSys Deca lines with motor applications up to roughly 100 hp at 480 V, and TeSys GC modular series aimed at DINŌĆærail installations.

One notable point from VIOX Electric is that TeSys Deca Green contactors use electronic coils that can cut energy use by up to about 91 percent compared with traditional coils, delivering immediate reductions in control circuit consumption and associated COŌéé emissions. Balaji Switchgears further notes that Schneider contactors are strong in smart integration and Industry 4.0 environments, offering seamless compatibility with advanced automation.

Compared with ABB, Schneider is described in that same Balaji analysis as having an edge in ease of integration with existing systems and smart technologies, with userŌĆæfriendly interfaces and a strong sustainability focus. The tradeŌĆæoff is that Schneider often carries a higher purchase price than some competitors such as Eaton. However, the literature argues that longŌĆæterm value is favorable due to durability, lower maintenance, and scalability.

In ABB replacement scenarios, Schneider is well suited when your plant prioritizes integration into Schneider automation platforms, wants to leverage energyŌĆæsaving coils, or has corporate sustainability metrics that favor demonstrably efficient components.

Siemens appears repeatedly in industry comparisons as a reference vendor for demanding industrial and automationŌĆæcentric applications. Slideshare material on industrial contactors cites the Sirius 3RT line as thermally stable, modular, and tightly integrated with Siemens automation controllers. VIOX Electric notes Siemens SIRIUS 3RT2 and 3RT6 contactors, including solidŌĆæstate options, and emphasizes advanced diagnostic capabilities and predictive maintenance.

Market analysts on platforms like LinkedIn recommend Siemens for heavy industrial sites where deep integration with a Siemens automation stack is a priority. In the context of ABB replacement, Siemens is attractive when you are already standardizing on Siemens PLCs and drives or want builtŌĆæin diagnostics that support predictive maintenance strategies.

Balaji Switchgears mentions AllenŌĆæBradley (Rockwell Automation) as a premium brand that often commands higher pricing than Schneider, with Schneider positioned as a more costŌĆæeffective alternative for similar functionality. Analysts following lowŌĆævoltage contactor markets also highlight Rockwell and Siemens as leading choices for automationŌĆæcentric environments.

For ABB replacement, AllenŌĆæBradley contactors tend to make sense when your site already uses Rockwell PLCs, drives, and HMIs and you want a tightly integrated, singleŌĆævendor control ecosystem. The main drawback, explicitly noted in BalajiŌĆÖs comparison, is cost: you may pay a premium relative to Schneider or Eaton, which can be justified in missionŌĆæcritical applications but should be weighed against budget and lifecycle expectations.

Eaton is frequently positioned as a costŌĆæeffective yet reputable alternative. Balaji Switchgears suggests that although Schneider contactors may cost more upfront, they deliver better longŌĆæterm value compared with Eaton through superior durability and scalability. Conversely, LinkedIn market commentary on lowŌĆævoltage contactors lists Eaton as a costŌĆæeffective option for priceŌĆæsensitive projects and emerging markets.

VIOX Electric describes EatonŌĆÖs ZŌĆæSCH modular contactors with capacities around 25 to 63 A, compact footprints, and emphasis on energy efficiency. For ABB replacement, Eaton suits applications where you want a brand with global reach and decent reliability but must control capex more tightly than a full Schneider or Rockwell migration might allow.

VIOX Electric profiles several European manufacturers whose strengths lie in building automation and modular panel solutions. Legrand offers connected contactors that integrate with smart building platforms, including IoTŌĆæenabled units such as CX┬│ with Netatmo. Hager focuses on compact, energyŌĆæefficient modular contactors, including lowŌĆænoise versions suited to noiseŌĆæsensitive environments. Finder produces modular contactors across the 25 to 63 A range with strong quality assurance, and Lovato Electric provides compact threeŌĆæ and fourŌĆæpole designs optimized for panel space.

If the ABB contactor you are replacing is part of a building services or small power distribution application rather than a large motor starter, these brands may offer dropŌĆæin modular options with strong smartŌĆæbuilding integration, especially in EuropeanŌĆæstyle panels.

For some projects, especially in costŌĆæconstrained markets or nonŌĆæcritical loads, valueŌĆæoriented brands are part of the conversation. The key is to ensure that lower price does not come at the cost of safety or reliability.

Analysts reviewing lowŌĆævoltage contactor markets describe Chint as a costŌĆæeffective choice with acceptable reliability in priceŌĆæsensitive projects. CNC Electric, in a technical overview of contactor types, highlights its broad product range covering AC, DC, magnetic, thermal, vacuum, and solidŌĆæstate contactors. That same material points out that CNC products carry certifications such as CE, UL, and RoHS and are typically about 15 to 30 percent cheaper than major brands like Siemens and ABB.

In practice, this means Chint and CNC can be viable ABB replacement options when budgets are tight and when you carefully verify ratings and certifications. They are particularly applicable in secondary or nonŌĆælifeŌĆæsafety loads where some risk is acceptable as long as standards are met. Even then, the same sizing discipline applies: coil voltage, current rating, utilization category, and environmental ratings must all be matched.

VIOX Electric itself acts as an OEM partner, offering AC and DC modular contactors with OEMŌĆæfriendly customization, flexible minimum order quantities, and full testing to IEC and UL standards. For panel builders who previously standardized on ABB but want more control over branding or cost, working with an OEM like this can be appealing.

The tradeŌĆæoff is that longŌĆæterm ecosystem support and global stocking may not match what ABB or Schneider can offer. For missionŌĆæcritical UPS, inverter, and protection equipment, I generally advise keeping OEM or privateŌĆælabel contactors to nonŌĆæcritical circuits or using them only when the supplierŌĆÖs longŌĆæterm support model is well understood.

Regardless of the brand you choose as a replacement, adopting a disciplined workflow greatly reduces the risk of misapplication.

In the field, I begin by taking the system safely offline. Peerless Electronics and Chint both stress that all power must be shut off and verified with a meter before you touch a contactor. That means locking out the upstream breaker, testing for absence of voltage, and not proceeding until every terminal is confirmed deŌĆæenergized.

Next, I document the existing wiring. Peerless recommends photographing the contactor before removal and carefully labeling line and load terminals. Many devices use standard designations such as L1, L2, L3 for line and T1, T2, T3 for load, but over the years I have seen enough creative wiring to never assume labeling is accurate. For ABB replacements with a different brand, this photographic record is invaluable because terminal layouts and auxiliary contact positions may change.

Once the system is safe and documented, I remove the old contactor and read its nameplate carefully. From Contactor DepotŌĆÖs guidance, coil voltage and frequency are nonŌĆænegotiable. If the ABB coil is marked 24 V AC, 60 Hz, the new unitŌĆÖs coil must match that exactly. Likewise, I confirm main contact voltage rating, current, and utilization category. Where there is any ambiguity about control voltage, I measure the control circuit under operating conditions to confirm.

Selection of the new contactor then becomes an exercise in matching or exceeding every relevant parameter. C3Controls recommends first determining load voltage, current, and duty, then verifying that the contactorŌĆÖs power ratings meet or exceed those requirements. For motors, Contactor Depot advises choosing a contactor with a current rating above the expected load and using ACŌĆæ3 or equivalent motorŌĆæduty ratings. I also confirm that any auxiliary contacts required for interlocking or status are present and appropriately rated.

Installation reverses the removal process. Peerless outlines good practice: mount and secure the new contactor, clean the mounting area with appropriate electrical cleaners, reconnect wires to their corresponding terminals rather than to approximate positions, and tighten screws to manufacturer torque recommendations. Once everything is reassembled, power is restored and the control circuit is tested to ensure that coil operation, contact closure, and load behavior are all correct.

Throughout, UL or IEC certifications matter. Contactor Depot and Chint recommend choosing coils and contactors that are UL and IEC certified. This is especially important when swapping ABB for lesserŌĆæknown brands; certification provides some assurance that breaking capacity, distances, and insulation have been tested.

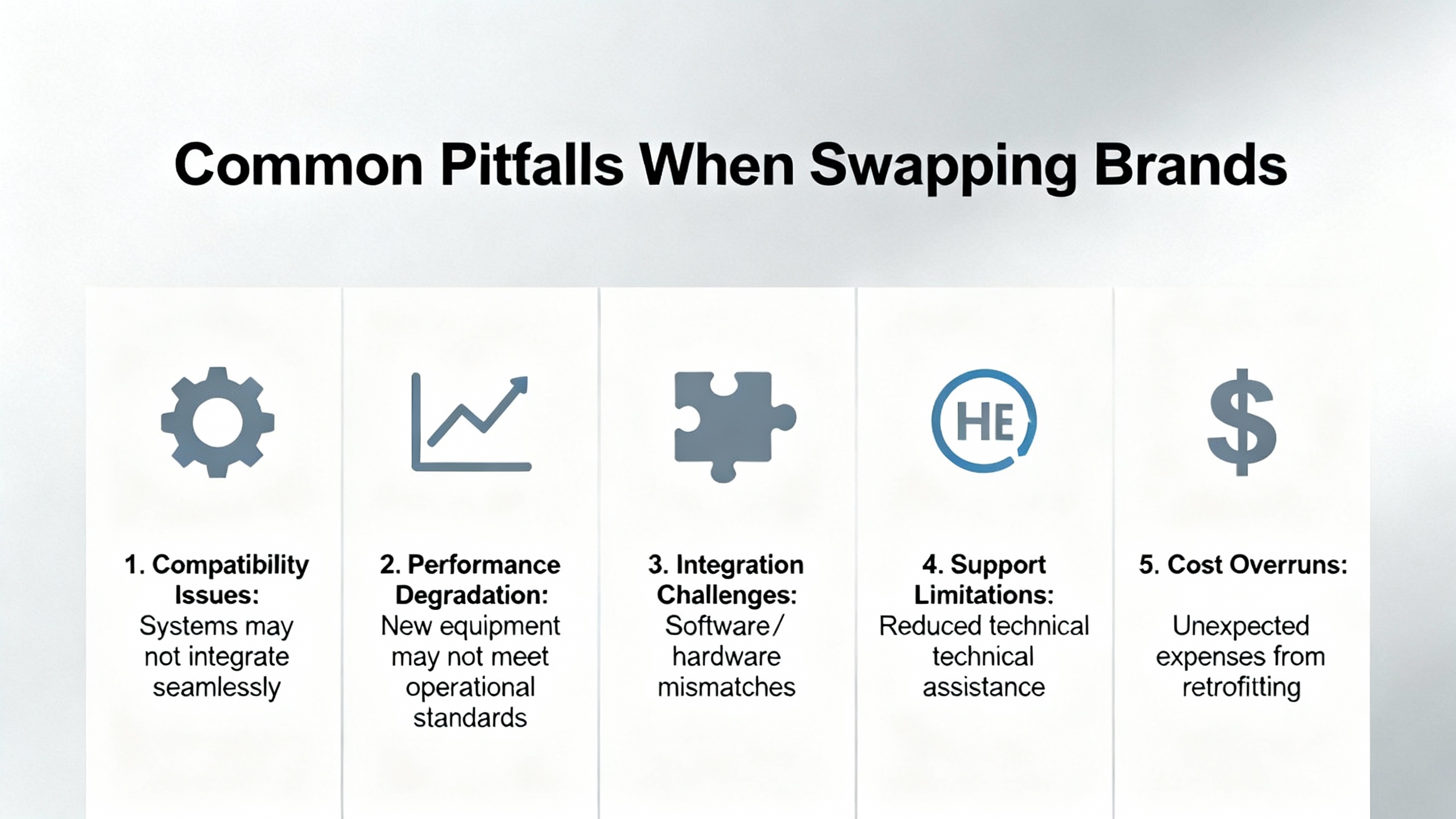

In ABB replacement projects, I see the same mistakes again and again, and they are all avoidable.

The first is coil mismatching, already discussed but worth underscoring. Contactor Depot gives concrete examples of a 24 V coil subjected to 120 V burning out immediately and a 120 V coil fed with 24 V never energizing. UnderŌĆævoltage creates chatter and buzzing; overŌĆævoltage creates heat and fire risk. In UPSŌĆæbacked systems where the contactor may be called on during a utility outage, a coil that has been weakened by chronic overŌĆæ or underŌĆævoltage may fail exactly when you need it most.

The second pitfall is using the wrong type of device. A story from the Mike Holt community recounts a grocery store project where large motor starters were installed in place of lighting contactors because the buyer had ordered the wrong equipment and insisted the installer ŌĆ£make it work.ŌĆØ The installer tried to fit larger overloads to compensate, and the system ran for only a week or two before burning up. This illustrates that motor starters and lighting contactors are not interchangeable; they are engineered for different load profiles and duty cycles. The same logic applies when substituting ABB motor contactors with devices designed primarily for resistive loads.

A third recurring issue is misjudging environment and duty cycle. Kentstore and Chint both highlight that ambient temperature, humidity, vibration, and contamination affect contactor performance. Installing a compact IEC contactor from a different brand into a hot, dusty enclosure where an ABB device previously had more thermal headroom can shorten life dramatically.

Finally, there is the temptation to ŌĆ£upgradeŌĆØ or ŌĆ£oversizeŌĆØ without understanding consequences. DefiniteŌĆæpurpose contactor literature warns that oversizing can sometimes lead to poor performance on light loads, especially where mechanical forces and contact pressures are optimized for particular current ranges. While most engineers are rightly cautious about undersizing, indiscriminate oversizing is not a free lunch.

The landscape of potential ABB alternatives can be summarized at a high level using observations from Balaji Switchgears, VIOX Electric, market analyses, and technical guides:

| Brand or category | Where it tends to fit best as an ABB replacement | Typical cost positioning | Notable traits from referenced sources |

|---|---|---|---|

| ABB (AF and related series) | LikeŌĆæforŌĆælike replacements in existing ABB panels and motor control centers | Varies, generally premium industrial | Very wide current range up to about 2,700 A and around 1,150 hp; strong global support and certifications |

| Schneider Electric (TeSys) | Plants prioritizing energy efficiency and smart integration; Industry 4.0 projects | Often higher than Eaton, argued to be costŌĆæeffective over life | EnergyŌĆæefficient electronic coils with up to about 91 percent energy savings in TeSys Deca Green; strong customization and sustainability focus |

| Siemens (Sirius) | Deep integration with Siemens automation, diagnostics, and predictive maintenance | Premium | Modular 3RT family with advanced diagnostics; solidŌĆæstate options; strong industrial presence |

| Rockwell Automation / AllenŌĆæBradley | North American ecosystems standardized on Rockwell PLCs and drives | Premium, often higher than Schneider | Tight integration with automation architecture; seen as highŌĆæend alternative in Balaji comparison |

| Eaton | PriceŌĆæsensitive yet reliabilityŌĆæconscious projects | More costŌĆæeffective than Schneider in many cases | Compact modular contactors, focus on energy efficiency and space savings |

| Legrand, Hager, Finder, Lovato | Building services, modular DINŌĆærail panels, noiseŌĆæsensitive or spaceŌĆæconstrained installations | MidŌĆærange | Emphasis on compact, lowŌĆænoise, and smartŌĆæbuildingŌĆæready modular contactors |

| Chint, CNC, and similar value brands | CostŌĆæconstrained projects where certifications are verified and loads are well understood | Roughly 15ŌĆō30 percent lower than major brands like ABB and Siemens, according to CNC | Broad product range, CE/UL/RoHS certifications; attractive pricing but dependent on careful application |

| OEM / private label (e.g., VIOX Electric) | Panel builders wanting customized ratings, branding, or pricing | Negotiated | OEM services with full IEC and UL compliance, flexible minimum orders, and tailored engineering |

This table is not a ranking but a mapping. The right ABB replacement is the one that meets your technical requirements and reliability objectives at an acceptable lifecycle cost, not simply the lowest purchase price.

Yes, but only if the new contactor matches or exceeds the ABB unitŌĆÖs critical parameters: load voltage and current, utilization category (for example, ACŌĆæ3 for motors), coil voltage and frequency, pole count, and relevant standards such as IEC and UL certifications. As research on contactor manufacturer choices notes, many engineers standardize on a primary brand for mechanical and accessory consistency, yet selective crossŌĆæbrand replacements are common when done with proper verification and documentation.

Contactor Depot recommends a threeŌĆæstep approach. First, look for any readable markings near the coil terminals, often labeled A1 and A2. Second, verify the control circuit voltage with a meter; remember that this may be 24 V, 120 V, or 240 V and is often different from the main load voltage. Third, order a replacement whose coil voltage and frequency exactly match the measured control circuit. Never substitute a different coil voltage just because it is available.

Field experience shared in the Mike Holt lighting control anecdote suggests this is risky. Motor starters and lighting contactors are designed for different load profiles and duty cycles. While a misapplied device may appear to work briefly, overloads, overheating, and premature failure are likely. When replacing an ABB contactor, choose a device specifically rated for the type of load and duty your circuit experiences, whether that is inductive motor duty, resistive heating, or highŌĆæinrush lighting.

In industrial and commercial power systems, a contactor may be a relatively small component, but the decision to move away from a familiar ABB device to an alternative supplier deserves careful, engineeringŌĆædriven thought. By rigorously matching electrical ratings and coil voltage, respecting load type and environment, and selecting brands whose strengths align with your automation and reliability goals, you can turn an urgent replacement into an opportunity to improve your systemŌĆÖs resilience. As a reliability advisor, my rule of thumb is simple: never let procurement urgency override sound application engineering, especially in the circuits that stand between your critical loads and a blackout.

Leave Your Comment