-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

When a Bently Nevada monitor goes down on a turbine, compressor, or large motor, the real risk is not a nuisance alarm on the HMI. The risk is that a critical protection layer has just become uncertain. In power plants, refineries, and large industrial facilities, Bently Nevada 3300 and 3500 systems sit between rotating machinery and the trip system, and they also feed condition data into DCS, PLC, or safety systems.

I have seen more than one outage where a ŌĆ£monitor faultŌĆØ triggered a scramble: maintenance blames the instrument rack, operations blames the machine, and nobody is sure whether to keep running. Fixing these situations reliably demands structured module-level diagnostics, clear separation of sensor versus monitor versus network problems, and a realistic view of when to repair, when to replace, and when to plan a full upgrade.

The procedures below draw on vendor material from Baker HughesŌĆÖ Bently Nevada organization, independent module guides, and security advisories from agencies such as CISA, combined with field-proven reliability practice.

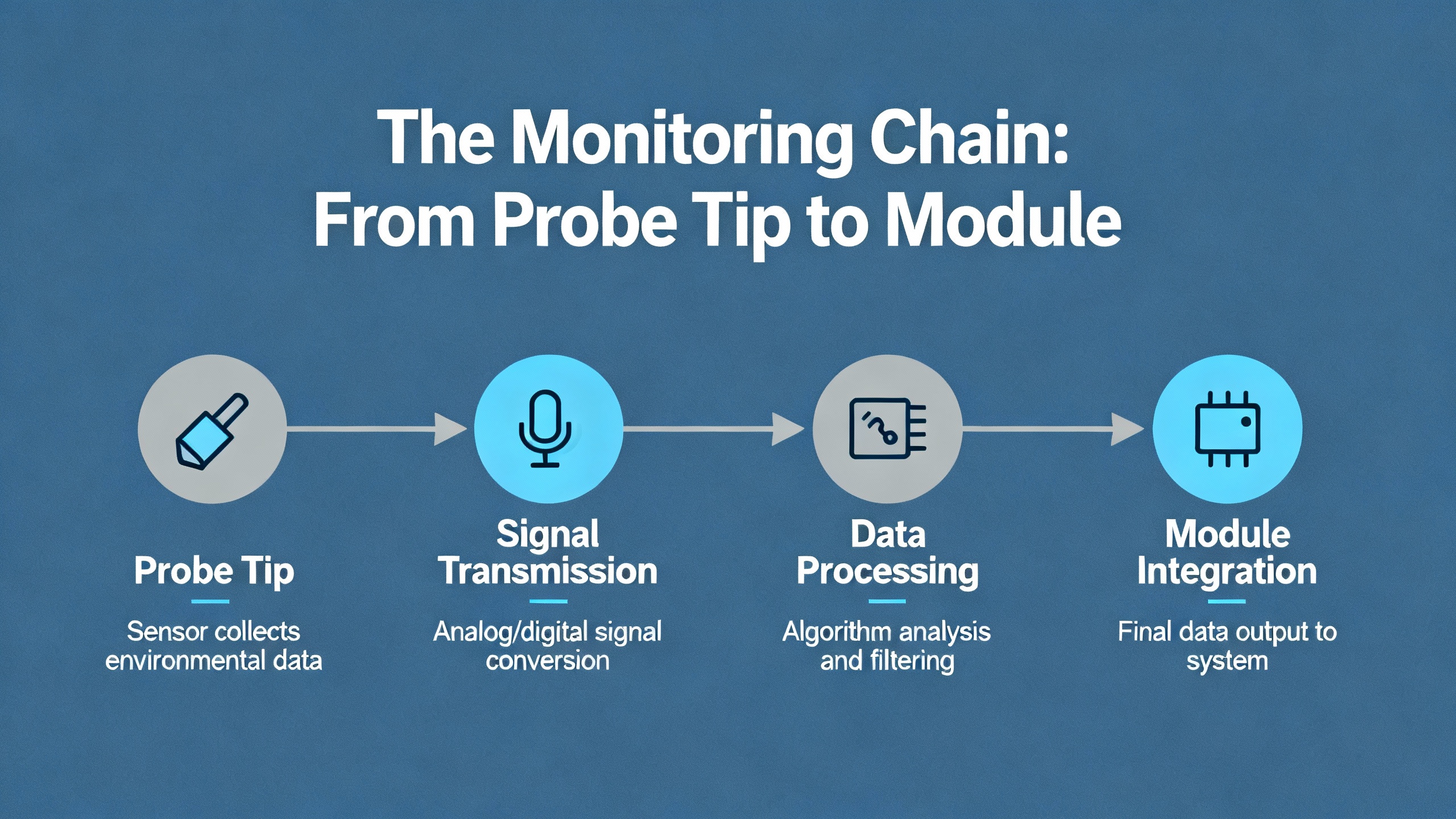

Before you can repair a ŌĆ£failed monitor,ŌĆØ it helps to see where that monitor sits in the chain.

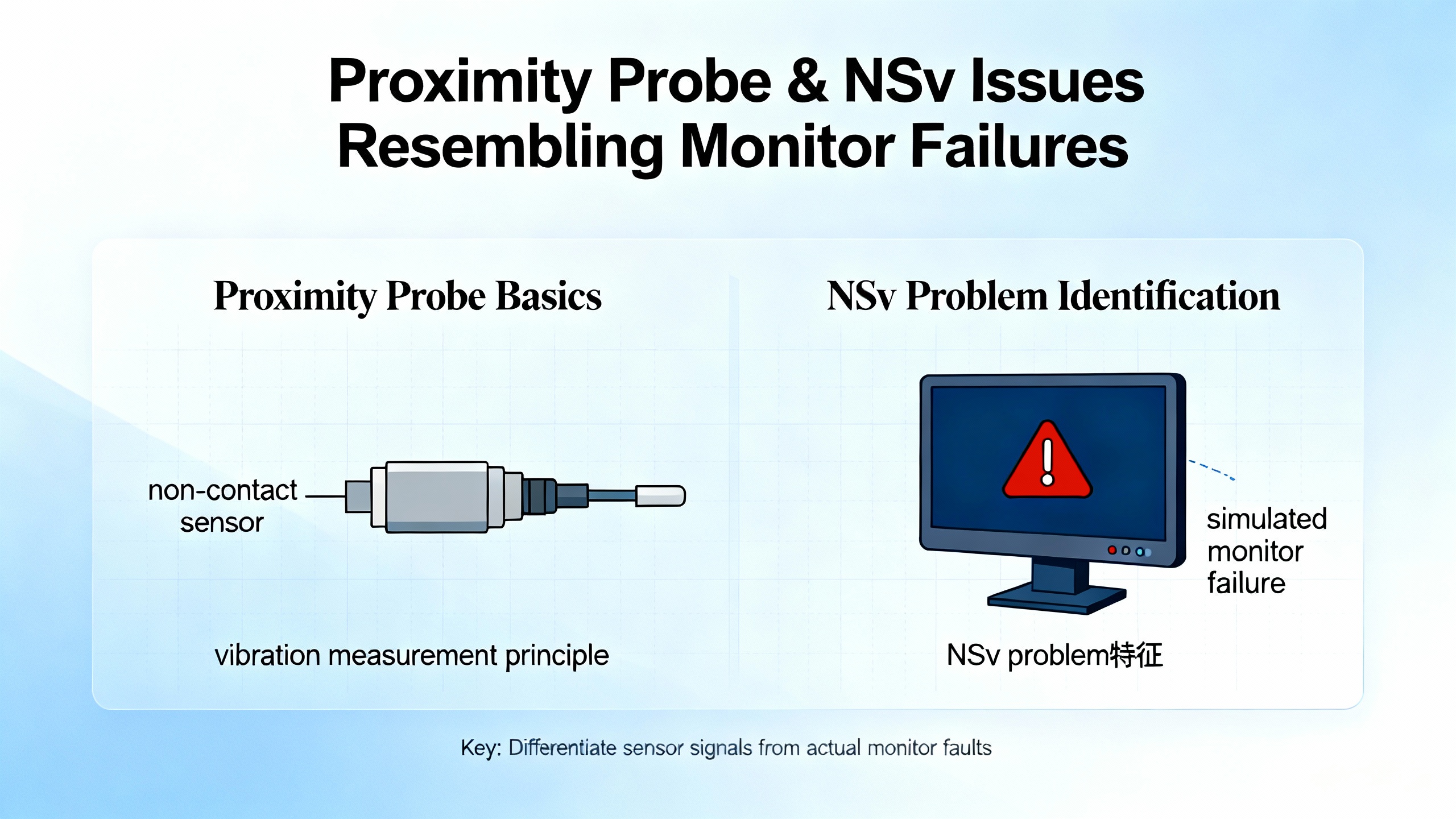

At the machine, Bently Nevada proximity and seismic probes measure shaft vibration, position, and housing motion. The 3300 NSv probes, for example, are compact, non-contact sensors designed for tight clearances and shaft position monitoring. Their health is heavily dependent on clean probe tips, intact cabling, and correct mechanical gap.

Those raw signals flow through an extension cable into a Proximitor-style driver such as the 330525ŌĆæ02 proximity transducer system. This driver converts the eddy-current probe signal into a usable voltage output that the rack can interpret. Correct matching of probe, extension cable, and driver part numbers is critical, as the Baker Hughes Orbit article on proximity probe system interchangeability emphasizes.

At the rack, vibration monitor modules such as the Bently 135473ŌĆæ01 in a 3500 system process these signals. The 135473ŌĆæ01 is a four-channel vibration monitoring module that accepts proximitor and seismic inputs, with a frequency response roughly from 0.5 to 10,000 Hz, a minimum dynamic range of about 80 dB, and independent 4ŌĆō20 mA outputs per channel. It runs from a 24 V DC supply (about 18ŌĆō30 V range), draws around 8 W, offers continuous self-diagnostics and automatic calibration, and is designed to operate roughly from ŌłÆ22┬░F to 158┬░F with storage ratings down to about ŌłÆ40┬░F and up to about 185┬░F, according to the supplier guide.

Around these monitors sit communication and interface modules. Examples include the 3500/92 Ethernet Global Data (EGD) communication gateway that feeds vibration data into Mark VIe turbine controls, and the 3500/22M TDI (Turbine Diagnostic Interface) that exposes rack data over serial or USB. These modules often sit at the center of ŌĆ£monitoring system errorŌĆØ complaints because they bridge to HMIs and DCS, even when the underlying vibration channels are actually healthy.

The table below summarizes these elements and where failures typically present.

| Element | Primary role | Typical failure symptoms at site level |

|---|---|---|

| 3300 NSv proximity probe | Shaft vibration/position sensing | Zero or unstable signal, noisy trends, gap voltage out of range |

| 330525ŌĆæ02 Proximitor driver | Converts probe signal to usable voltage | Incorrect scaling, noisy or drifting readings |

| 135473ŌĆæ01 vibration monitor | Four-channel vibration measurement and alarming | Channel or module ŌĆ£Not OK,ŌĆØ stuck outputs, false alarms |

| 3500/92 EGD gateway | Sends vibration data to Mark VIe HMIs over Ethernet | Vibration missing on HMI while rack channels look normal |

| 3500/22M TDI | Rack data interface via serial or USB | Communication loss, security alerts, unexplained access issues |

| 3300 rack | Legacy machinery protection rack | Increasing false trips or missed trips, rising maintenance load |

Understanding where you are in this chain is the first step toward an effective repair strategy.

In practice, many ŌĆ£monitor failuresŌĆØ turn out to be problems elsewhere. Preventing unnecessary module replacements starts with good symptom analysis.

If a shaft channel reads essentially zero when the machine is clearly running, the root cause is often outside the rack. Power Gear XŌĆÖs description of zero-output faults for 3300 NSv metric probes highlights classic suspects: loss of driver power, open or shorted probe or extension cables, mismatched probeŌĆōcableŌĆōdriver combinations, or an excessive probe-to-target gap. In that situation, a four-channel vibration monitor like the 135473ŌĆæ01 may only be relaying bad input.

Conversely, if several channels in a module simultaneously show ŌĆ£Not OKŌĆØ or produce obviously inconsistent readings compared to independent instruments, and the sensor wiring checks out, suspicion should shift to the module or its rack slot. The 135473ŌĆæ01ŌĆÖs own self-diagnostics and automatic calibration are designed to flag internal problems, which can then be confirmed by comparing 4ŌĆō20 mA outputs and rack event logs.

There is also a third category: communication path problems that masquerade as monitor failures. A good example comes from a Mark VIe turbine control integration where four gas turbine units experienced frequent communication loss between Mark VIe HMIs and their Bently Nevada 3500 systems. During these events, turbine and process parameters remained visible, but vibration data disappeared from the HMIs. Field checks showed that the 3500 racks themselves were healthy, yet the 3500/92 EGD communication gateway on one unit had its communication LED off and its OK LED flickering while other unitsŌĆÖ gateways showed communication LEDs on and steady green OK LEDs. In the Bently Nevada rack configuration utility, all vibration channels were OK but the 3500/92 gateway module reported ŌĆ£Not OK.ŌĆØ That is a classic signature of a communication interface module problem rather than a sensor or monitor-channel issue.

Distinguishing among sensor, monitor, and communication faults is essential before deciding what and how to ŌĆ£repair.ŌĆØ

When a Bently Nevada monitor appears to fail, the worst response is adŌĆæhoc tinkering. A disciplined workflow shortens troubleshooting, preserves evidence, and reduces the chance of creating new problems.

Start by documenting the symptoms. Note which racks, modules, and channels are affected, whether the issue is continuous or intermittent, and which alarms or trips were generated. If your DCS or condition monitoring software such as System 1 is logging alarm and event histories, take screenshots or exports before making changes. The NexGen-PLC brief on diagnosing 3500 monitoring system errors stresses capturing rack event logs before altering configuration or hardware.

Next, inspect the rack in the cabinet. Look for obvious issues: missing power, tripped breakers, overheated enclosures, heavy dust accumulation, or moisture. On the rack front, check the Power, System OK, and individual Module OK LEDs. Persistent red or flashing patterns on a specific module or slot are invaluable clues that help you decide whether you are dealing with a single-channel issue, a module issue, or a rack-level power or backplane issue.

Power verification comes next. The 3500 troubleshooting guidance from Ubest Automation calls out power supply problems as a common root cause of unexplained rack behavior. Confirm that rack input power is within specification, that redundant power supply modules (if fitted) are both operational, and that no fuses are blown. Intermittent voltage dip at the rack can produce seemingly random module OK faults and communication glitches.

With power confirmed, move to configuration and communications. Use the official 3500 configuration software to check that channel types, scaling, alarm setpoints, and voting logic match the mechanical design and protection philosophy. Misconfigured channels often appear as ŌĆ£monitor failuresŌĆØ when in fact they are doing exactly what the configuration told them to do. For communication-related complaints, verify basic network parameters: IP addresses, subnet masks, and protocol settings for interfaces such as the 3500/92 gateway or the 3500/22M TDI. UbestŌĆÖs case study of repeated communication drops between a 3500 system and an AllenŌĆæBradley PLC was ultimately resolved by replacing a faulty network switch and updating firmware, not by replacing monitors.

Only after sensors, power, configuration, and basic networking have been checked should you start isolating hardware. A standard technique recommended in multiple guides is crossŌĆæswapping suspected modules or I/O channels with knownŌĆægood spares. Swapping a vibration monitor like a 135473ŌĆæ01 into a different slot, or moving a suspect sensor cable to a known-good channel, can quickly reveal whether the fault follows the hardware or stays with the rack position. If it follows the module, you now have strong evidence for a genuine monitor failure.

Finally, compare Bently Nevada readings with independent instruments wherever possible. For vibration and speed, portable analyzers and calibrated tachometers provide reality checks. Large discrepancies may point to scaling problems, failing sensors, or internal module faults.

Throughout this process, treat configuration and hardware changes as formal management-of-change activities. Document asŌĆæfound and asŌĆæleft states, obtain approvals where required, and reŌĆævalidate alarms and trips before returning the machine to service.

Once you are confident that a vibration monitor module is the culprit, the ŌĆ£repairŌĆØ process is not about component-level soldering in the cabinet. For most industrial users, repair means cleanly removing, validating, and either replacing or factoryŌĆæservicing the module.

For modules such as the 135473ŌĆæ01, use the builtŌĆæin diagnostics and selfŌĆætest information from the 3500 system as your starting point. If the rack and power supplies are healthy yet one 135473ŌĆæ01 reports channel faults across all four inputs, fails to produce valid 4ŌĆō20 mA outputs, or repeatedly shows ŌĆ£Not OKŌĆØ despite known-good sensors and wiring, treat it as a defective module. The recommended field procedure, reflected in the troubleshooting advice from Ubest Automation and NexGen-PLC, is to swap the suspect module with an identical, knownŌĆægood spare. If the problem moves with the module, you have confirmed the fault and can send the failed unit for factory repair or replace it outright.

During replacement, ensure that the configuration for the module is backed up and restored correctly. Channel parameters such as sensor type (proximitor versus seismic), scaling, and alarm thresholds must be reloaded or re-entered exactly; otherwise, you may inadvertently change protection behavior. After installation, perform a basic functional verification: confirm that each channel shows plausible vibration or position values, that Alert and Danger setpoints trigger as expected in controlled tests, and that 4ŌĆō20 mA outputs and relay contacts drive the DCS or trip relays correctly.

Given the safetyŌĆæcritical role of these modules, I strongly recommend leaving component-level board repair to qualified shops or the OEM. Electrolytic capacitors, relays, and other wearŌĆæout components do fail, especially as the equipment approaches a couple of decades in service, but adŌĆæhoc repairs without proper calibration rigs and test procedures can quietly degrade the accuracy and reliability of the monitor.

Communication modules deserve their own playbook, because failures here often look like lost monitoring, even when all protection functions are intact.

The Mark VIe gasŌĆæturbine example shows a classic 3500/92 EGD gateway failure pattern. In that case, all four turbine trains had Bently Nevada 3500 racks, each connected to Mark VIe HMIs via a 3500/92 EGD gateway. During failures, vibration data vanished from the HMIs, yet turbine and process parameters remained, indicating a vibration communication issue rather than a control-system collapse. The Bently Nevada rack configurator showed that all vibration channels were healthy and online, but reported the 3500/92 EGD communication gateway as ŌĆ£Not OKŌĆØ for the affected unit. On the front panel, the gatewayŌĆÖs communication LED was off and its OK LED flickered, while the other three unitsŌĆÖ gateways had steady green OK and communication LEDs on. Network tools showed the EGD server services on the workstation were running and that Ethernet cables appeared healthy.

The proper module repair procedure in that scenario starts with confirming network basics and then treating the 3500/92 as a replaceable unit. Verify that the Mark VIe EGD server is configured correctly, doubleŌĆæcheck cabling and switch ports, and use your network team to rule out VLAN and firewall issues. Once external causes are excluded and the 3500/92 still reports ŌĆ£Not OK,ŌĆØ replace it with a properly configured spare and confirm restored vibration data flow to all HMIs.

The 3500/22M TDI adds another dimension: cybersecurity. A CISA advisory documents a critical improper authorization vulnerability in 3500/22M devices, with a CVSS v3 base score of 10.0, where open ports could allow unauthorized remote access with elevated privileges. The affected products include the 3500/22M USB version with firmware prior to Version 5.0, and all versions of the 3500/22M serial version. CISA notes that the vulnerability is remotely exploitable over a network and that even a lowŌĆæskill attacker could abuse it.

Mitigation for the USB version involves upgrading firmware to Version 5.0 as provided by GE/Bently Nevada, along with following their hardening document and technical information letters. For the serial version, the recommendation is to upgrade the device to hardware or firmware that is not vulnerable. CISA also stresses classic network hygiene: segment control networks, use DMZs and properly configured firewalls, minimize direct exposure of control hardware, and use secure and maintained VPNs for any remote access.

From an operational standpoint, unexplained or intermittent TDI communication problems should therefore be approached in two ways. One is hardware diagnosis: confirming power, cabling, and configuration, and swapping the TDI with a known-good spare if necessary. The other is security posture: ensuring firmware is at the recommended version, that devices are not directly reachable from untrusted networks, and that any suspected malicious activity is investigated through your incident-response process.

It is easy to blame the rack when trends look wrong, but proximity probe problems often sit upstream of any monitor module alarm.

For 3300 NSv probes, a preventive maintenance guide from PLC and DCS suppliers emphasizes several basics. Regular visual inspection is essential: probe tips should be clean, cables should show no cracks or fraying, and connectors must be tight. Any visible damage is grounds for immediate replacement because compromised insulation or bent probe bodies often lead to intermittent or noisy signals. The correct mechanical gap between probe tip and shaft is crucial. Engineers are advised to check the gap physically, using feeler gauges, and to compare the probeŌĆÖs DC output voltage to the manufacturerŌĆÖs specification. Skipping these gap checks and calibrations directly introduces measurement errors and increases the risk of machine damage, because the monitoring system may not respond correctly to real changes in vibration or position.

Zero-output faults are a particular concern. Power Gear XŌĆÖs discussion of 3300 NSv metric probe issues notes that persistent zero output typically indicates, not a failed vibration monitor, but one of several probe-system conditions: loss of Proximitor driver power, open or shorted probe or extension cables, mismatched probe and cable part numbers, or an excessively large probeŌĆōtarget gap. Standard troubleshooting there focuses on checking supply and bias voltages at the driver, verifying probe and cable continuity and insulation, confirming the mechanical gap, and ensuring all components in the chain are correctly matched.

Baker HughesŌĆÖ Orbit article on proximity-probe-system interchangeability adds a more subtle failure mode: mixing components from different manufacturers into what they call a ŌĆ£Frankenstein system.ŌĆØ Historically, each probeŌĆōcableŌĆōdriver set had to be uniquely tuned, but modern Bently Nevada families such as the 3300XL 8 mm line guarantee interchangeability within the family through tight manufacturing controls and color coding. This allows a probe bought many years ago to work with a current Proximitor driver when paired with a correct extension cable. When users mix drivers from another manufacturer with Bently probes and cables, the electrical characteristics often shift in ways that distort scaling.

In a refinery example, a plant replaced Bently Nevada Proximitors with a competitorŌĆÖs drivers but kept Bently probes and cables. The mixed system caused intermittent turbomachinery trips. Testing showed that some mixed systems underŌĆæreported vibration by roughly a quarter above certain gaps, while others overŌĆæreported, so an indicated 6 mil peakŌĆætoŌĆæpeak vibration could correspond to more than 8 mil peakŌĆætoŌĆæpeak in reality. In thrust protection roles, these scaling errors can undermine safety logic in dual or triple-voted systems and invalidate vendor warranties.

The practical takeaway is straightforward. Before you condemn a vibration monitor module, verify that the probe system is healthy, properly gapped, powered, and comprised of matched components from a single vendor. If you discover a Frankenstein system, the ŌĆ£repairŌĆØ is to standardize on a fully compatible probeŌĆōcableŌĆōdriver family, preferably the one whose behavior your protection setpoints were originally based on.

For many plants, particularly in older power stations and refineries, Bently Nevada 3300 racks are still on the wall. Baker HughesŌĆÖ own lifecycle guidance makes it clear that this platform is well past its prime as a protection system. The 3300 was introduced in 1987 and moved into spare-part-only support around midŌĆæ2009, then into repairs-only status in early 2011, was declared obsolete in March 2014, and even limited repair support ended in 2017. It is no longer recommended for machinery protection.

Key wear-out components in 3300 hardware include electrolytic capacitors, electromechanical relays, front-panel buttons, and EEPROMs, all with typical lifetimes in the 12-to-30ŌĆæyear range depending on environment and usage. Even unused spares age on the shelf. As a result, the probability of false trips or missed trips rises over time, and repair options shrink.

In that context, repeatedly repairing individual monitor modules in a 3300 rack is a short-term tactic at best. Bently Nevada recommends at least annual health checks on 3300 systems, including visual inspections, calibration checks, relay logic tests, and verification of communications to any System 1 or Data Manager installations. Transducer services that assess, remove, and reŌĆæinstall sensors according to best practice can buy some time.

However, the strategic solution is a planned upgrade to newer platforms such as the 3500 Series, which offers higher channel density, advanced vibration variables, better RF immunity, and broad application-specific monitor options; or, in low-point-count or distributed architectures, systems like the 3701 ADAPT platform or other modern monitors that integrate with System 1. Mechanical retrofit is usually manageable, since the 3500 fits standard 19ŌĆæinch cabinets and often reuses existing field wiring.

For a reliability engineer, this means that if you are seeing repeated module failures in a 3300 rack, your module repair procedure should be accompanied by a lifecycle plan to replace the rack before an unrecoverable failure takes down a critical machine.

Modern monitoring systems are as much about networks as they are about hardware. The CISA advisory on the 3500/22M TDI demonstrates how cyber issues can intersect with what looks like simple communication failure.

CISA describes the 3500/22M USB and serial versions as having an improper authorization vulnerability where several open ports allow unauthorized remote access with elevated privileges. The advisory classifies this as a critical issue with a maximum CVSS base score, noting that it is remotely exploitable and could allow an attacker to manipulate or disrupt industrial monitoring operations. While there were no public exploits reported at the time of the advisory, the potential impact on confidentiality, integrity, and availability is high.

From a repair-procedure standpoint, this means that if you are dealing with unexplained TDI communication anomalies, you should not only check the hardware and cabling, but also confirm that firmware is updated to the vendorŌĆÖs recommended version and that network architecture follows hardening guidance. That guidance includes segmenting control networks, using DMZs, limiting exposure to untrusted networks, and implementing defenseŌĆæinŌĆædepth protections such as bumpŌĆæinŌĆætheŌĆæwire security devices. Remote access, if allowed, should be through secure VPNs whose endpoints are themselves hardened and maintained.

Similarly, communication drops between 3500 racks and PLCs, such as the case where a power plant resolved recurring 3500ŌĆōPLC connection loss by replacing a problematic network switch and updating firmware, should be investigated with both network and instrumentation expertise. Treating these as pure monitor failures and repeatedly swapping modules without addressing root network issues simply adds cost without improving reliability.

Once you have repaired or replaced a Bently Nevada monitor module, it is good practice to demonstrate not only that the hardware passes selfŌĆætests, but that the system as a whole behaves correctly in real operating conditions. This is where higher-level analytics in platforms such as Bently NevadaŌĆÖs System 1 with Decision Support become valuable.

Baker Hughes describes Decision Support as an asset-specific algorithm and analytics layer within System 1 that can process highŌĆæresolution vibration, process, and emissions data using firstŌĆæprinciples calculations and logical rules. It can use readyŌĆæmade analytics or custom siteŌĆæspecific insights to detect early signs of mechanical, instrumentation, or process faults.

In one case study, a Naphtha hydrotreater feed filter was causing high maintenance disruption because roughly a third of filter work orders were classified as urgent or emergency, despite filters typically being replaced every 45 to 90 days. Engineers implemented a Decision Support rule that combined pressure measurements across the filter into a virtual differential pressure signal, with staged actions at 6, 9, 15, and 30 PSI for increased monitoring, planned replacement, urgent work orders, and immediate bypass, respectively. Over two years, this simple analytic rule was invoked ten times and enabled ten planned, routine filter replacements without a single urgent/emergency work order.

In another case, a custom Decision Support algorithm that analyzed orbit shape, vibration levels, and rate-of-change on a recycle gas compressor allowed earlier detection of imbalance and fouling, improving maintenance scheduling beyond what standard compressor analytics could deliver.

For monitor repair verification, these analytics can be used to confirm that, after a module replacement, measured parameters behave consistently with known machine dynamics. If a repaired vibration monitor module is correctly wired and configured but analytics still show implausible trends relative to process conditions, further investigation of calibration and scaling may be warranted.

Sustainable repair procedures rely on more than individual heroics during a midnight call-out. They require disciplined documentation, training, and reference to trustworthy technical material.

Suppliers of Bently Nevada-compatible modules emphasize maintaining maintenance logs that capture inspection dates, calibration results, replacements, and observed anomalies for probes and monitor modules. Such logs make it easier to identify recurring failure patterns and support reliability-centered maintenance planning.

Training maintenance and operations personnel on correct probe handling, inspection routines, configuration management, and documentation standards is equally important. When technicians understand why negative voltage rails are used in proximitor oscillatorsŌĆöto improve signal integrity, reduce noise, stabilize component behavior, and isolate power supply noise, as one interview-oriented explanation of Bently Nevada proximitor design notesŌĆöthey are better equipped to troubleshoot complex behavior without making unsafe assumptions.

For deeper technical understanding of machinery vibration and monitoring theory, academically oriented resources such as ŌĆ£Machinery Vibration Measurement and AnalysisŌĆØ hosted in curated digital libraries can complement vendor manuals. On the system side, security and architecture guidance from institutions like CISA and technical reports from national laboratories provide context for hardening monitoring systems in modern, connected plants.

The quickest way is to combine basic electrical checks with crossŌĆæswapping. If you see zero output or erratic readings from a channel, check probe gap and cleanliness, confirm driver power, and verify continuity and insulation of probe and extension cables. If those checks look good, move the suspect probe cable to a known-good channel, or move a knownŌĆægood probe to the suspect channel. If the fault follows the probe or cable, the probe system is at fault. If it remains with the monitor channel despite using known-good sensors, suspicion shifts to the monitor module or rack slot.

Baker HughesŌĆÖ own guidance is clear that mixing components into a Frankenstein system is risky. Bently Nevada designs probe, cable, and Proximitor families such as 3300XL to be interchangeable within the family, with tight metrology control and color coding. When users mix drivers from another vendor with Bently probes and cables, tests have shown significant scaling distortion that can either underŌĆæreport or overŌĆæreport vibration, leading to false trips or missed trips. The safest approach is to keep all eddyŌĆæcurrent components in a measurement loop from one vendor, and, if your protection philosophy and setpoints are based on Bently Nevada systems, to use genuine Bently Nevada components.

In a purely functional sense, an older firmware might appear to work, but the CISA advisory on improper authorization for 3500/22M modules makes a strong case for updating. Versions prior to the recommended firmware have open ports that allow unauthorized remote access with elevated privileges, and the vulnerability is rated as critical and remotely exploitable. From a risk perspective, particularly in power and energy sectors where these devices are widely deployed, keeping 3500/22M firmware at the vendor-recommended version and following system-hardening guidance is an essential part of maintaining a reliable and secure monitoring system, not a luxury.

As a reliability advisor, I treat Bently Nevada monitors less as isolated boxes to be ŌĆ£fixedŌĆØ and more as nodes in a protection ecosystem spanning probes, racks, networks, and cybersecurity controls. Effective module repair procedures start with disciplined diagnosis, respect vendor guidance and security advisories, and end with documented verification that the protection system works as intended. If you embed that mindset into your maintenance culture, monitor failures become manageable technical events rather than painful surprises.

Leave Your Comment