-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Industrial contactors are part of the nervous system of every serious power and automation installation. In motor control centers, UPS plants, switchboards, and process skids, a failed contactor often means a stopped line, a hot motor, or a tripped UPS when you can least afford it. In many facilities ABB has become the default choice for contactors and starters, thanks to a broad product range and strong performance in harsh environments. Yet there are situations where you need reliable alternatives: lead times spike, budgets tighten, or you are working inside a pre-standardized ecosystem built around another brand.

From a power system reliability standpoint, the question is not simply ŌĆ£What can I buy instead of ABB?ŌĆØ The real question is ŌĆ£How do I maintain or improve reliability, safety, and uptime when I specify another manufacturer?ŌĆØ This article looks at ABBŌĆÖs contactor positioning, then maps out credible alternative suppliers and sourcing channels, anchored in what matters most to industrial and commercial power systems.

ABBŌĆÖs contactor and starter portfolio is broad enough that many engineers treat it as a de facto reference catalog. The company offers AF technology as standard across many 3ŌĆæpole and 4ŌĆæpole contactors, designed to improve reliability, secure uptime, and reduce the amount of stock a plant needs to carry. AF motor contactors cover motor starting and power switching applications up to roughly 1,650ŌĆō2,650 A, which is enough to span everything from typical process pumps to highŌĆæpower industrial drives. For safetyŌĆæcritical machine applications, ABBŌĆÖs AFS safety contactors come with factoryŌĆæmounted contact blocks that provide mechanically linked and mirror contacts, allowing dependable safety feedback and interlocking.

ABB also addresses a wide range of specialized needs. Mini contactors and mini contactor relays in the M range are compact devices engineered for limited panel space while still maintaining robustness in demanding environments. For DC switching up to about 1,500 V, ABBŌĆÖs GF, GAF, and GA contactors target applications such as solar plants, battery storage, and DC drives. On the building side, humŌĆæfree installation contactors rated around 16ŌĆō100 A provide quiet operation for infrastructure loads, and dedicated DP and CR360L lighting contactors cover roughly 30ŌĆō300 A for large lighting circuits in commercial buildings. ABB also supplies fullŌĆævoltage nonŌĆæreversing, reversing, and multiŌĆæspeed starters, in both NEMA and IEC styles, along with electronic compact starters that integrate directŌĆæonŌĆæline and reverse starting, overload protection, and emergency stop functions in one unit.

This breadth, coupled with ABBŌĆÖs motor management systems such as UMC100.3 with modular analog and digital I/O and multiple fieldbus options, explains why so many engineers standardize on ABB. When you move away from ABB, the safest approach is to treat ABBŌĆÖs device as your technical specification baseline and then evaluate alternative suppliers with the same discipline you applied when you first approved ABB.

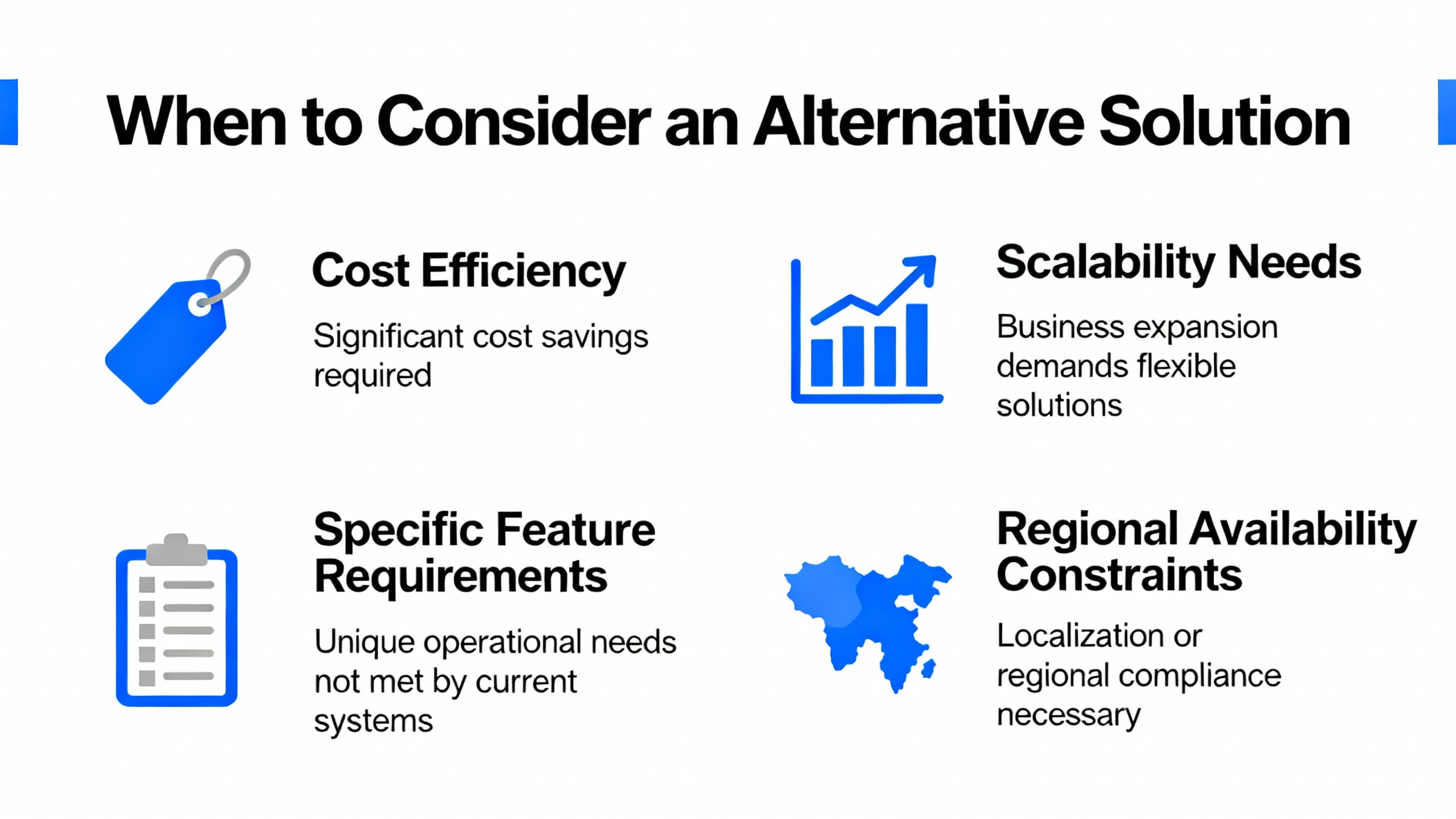

In real projects, there are several practical reasons to look beyond ABB even if you are comfortable with its performance. Procurement teams may run into extended lead times on certain AF frames or specialized DC contactors during peak demand. Global projects sometimes inherit regional standards where Schneider Electric, Siemens, or Eaton are the entrenched brands, and keeping a homogeneous installed base simplifies spares, training, and diagnostics. Cost pressure on nonŌĆæcritical loads can also drive a search for more costŌĆæeffective options, provided they still meet ratings and certification requirements.

HighŌĆægrowth sectors such as electric vehicles, energy storage, and smart buildings add another twist. A report by Elehub on highŌĆævoltage contactor manufacturers highlights that EVs, energy storage systems, and utilityŌĆæscale renewables are pushing toward higher voltages and tougher duty cycles. In these spaces, specialized suppliers that focus on highŌĆævoltage DC contactors or modular, IoTŌĆæready devices sometimes move faster than the traditional generalŌĆæpurpose players. Similarly, a market analysis by VIOX Electric notes that the modular contactor market was about $442 million in 2023 and is projected to reach roughly $827 million by 2030, driven by smart buildings and renewable integration. That level of growth tends to attract niche suppliers that can be worth considering alongside ABB.

The key point is that moving to an ABB alternative is not inherently a downgrade or an upgrade. It is a design decision. You must first match the contactorŌĆÖs technical role and stress profile, then choose a manufacturer and channel that are credible for that role.

Before comparing suppliers, make sure you are absolutely clear about what the contactor has to do. If you only match a catalog amp rating and frame size, you are taking unnecessary reliability risk.

Multiple sources, including guides from industrial distributors and white papers by C3Controls, agree on a basic definition. A contactor is an electrically controlled switch designed to make and break highŌĆæcurrent circuits repeatedly. Its electromagnetic coil uses a lowŌĆæpower control signal to pull in an armature that closes robust main contacts. Those contacts carry the motor, heater, or lighting load; when the coil is deŌĆæenergized, spring force opens the contacts and interrupts power.

Compared with relays, which often switch up to about 10 A, contactors can handle currents from a few amperes up to thousands of amperes and power levels beyond 100 kW. They are built for frequent switching, with mechanical lives that can reach tens of millions of operations in correctly specified industrial designs. As a result, contactors are central to safe, automated control of motors, compressors, pumps, conveyors, HVAC equipment, and highŌĆæcapacity lighting.

Voltage and current ratings are the first gate. Articles from Contactordepot, RSŌĆæbranded technical guides, and several manufacturer FAQs all emphasize that the contactorŌĆÖs operational voltage must match or exceed the system voltage, whether that is a typical threeŌĆæphase 400 V industrial supply, a 110 V utility service, or a higherŌĆævoltage system up to around 690 V in heavy industry. Using a contactor whose contact voltage rating is below the system voltage risks overheating, insulation breakdown, and early failure.

Current is more subtle. For motors, the relevant rating is not just the nominal current but the utilization category, such as ACŌĆæ3 for squirrelŌĆæcage motors, which incorporates the inrush at start. As one motorŌĆæselection article notes, motor starting currents can reach about six to eight times the running current. That means a contactor sized only to the nameplate fullŌĆæload current without regard to utilization category may be underspecified, leading to contact welding or nuisance trips. For resistive heating elements or some lighting loads, ACŌĆæ1 ratings apply and the contactor can be smaller for the same steady current because the switching stress is lower.

Coil voltage is equally important. Resources from RS Components, RSP Supply, and others point out that the coil (control) voltage does not have to match the load voltage. You might energize a 24 V DC coil from a PLC output to switch a 480 V AC motor circuit, for example. The critical rule is that the coil voltage must match the control circuit and that any controlŌĆæside transients are managed by surge suppression so the coil is not overŌĆæ or underŌĆædriven.

How often the contactor operates and where it lives mechanically are major life drivers. Articles from SpringŌĆæbranded control specialists and Contactordepot stress that equipment which starts and stops many times per hour needs contactors rated for high duty cycles and rapid switching. These devices deal with more mechanical wear and thermal cycling than contactors that close once for many hours of continuous duty.

Environmental factors are just as critical. Industrial guidance from Contactordepot and Long Beach Breeze notes that heat, dust, humidity, altitude, and corrosive atmospheres can all degrade contactor performance, forcing derating or requiring special materials and enclosures. In manufacturing plants, dust and metal filings can accumulate; in outdoor pump stations or substations, wide temperature swings and moisture are common. Not all contactors that match a voltage and current rating are suitable for these environments.

HighŌĆæquality contactors are usually certified to standards such as UL and IEC contactor standards, as recommended in Contactordepot and multiple manufacturer FAQs. A white paper on contactors from C3Controls explains that contactors themselves generally do not provide full shortŌĆæcircuit protection, which is why they are coordinated with upstream breakers and often paired with overload relays. In motor circuits, a soŌĆæcalled magnetic switch combines the contactor with a thermal relay, adding overload protection but still relying on breakers for major shortŌĆæcircuit events.

Industry best practice, as described by Schneider ElectricŌĆÖs selection guidance and others, is to define the load type and utilization category, determine operational current and voltage, and then select a contactor that meets these values with appropriate certification. When you substitute another brand for ABB, you must make sure the new contactor carries equivalent approvals and that its rated breaking capacities are adequate for the fault levels in your system.

Several global manufacturers offer contactor portfolios that can credibly substitute for ABB in many applications. Evaluations from Handelespd, KentŌĆæbranded contactor guides, Elehub, and VIOX Electric highlight the strengths of these suppliers.

The following table summarizes key characteristics mentioned in those sources.

| Brand | What sources highlight | Typical fit based on sources |

|---|---|---|

| ABB | Broad 3ŌĆæ and 4ŌĆæpole AF contactors up to roughly 1,650ŌĆō2,650 A, safety contactors (AFS), DC contactors to about 1,500 V, humŌĆæfree installation and lighting contactors, plus electronic compact starters and UMC100.3 motor management systems with modular communication. | General industrial motor control, safety circuits, DC renewables and storage, and building lighting where uptime and flexible integration are priorities. |

| Schneider Electric | Market reports and supplier profiles emphasize strong energy management and automation focus, smartŌĆægrid integration, and sustainability; product families such as TeSys contactors can control motors up to about 800 A (around 450 kW at 400 V) and switch lines up to roughly 1,100 A, with IoTŌĆæready options. | Utility and industrial automation projects where digital energy management and global service networks matter, and where plants already standardize on Schneider platforms. |

| Siemens | Industry guides describe Siemens as a major OEM with a complete lowŌĆæ to highŌĆævoltage portfolio and tight integration between contactors, protection, and automation systems. | Large process plants and factories, particularly where Siemens PLCs and drives dominate and integrated diagnostics are valuable. |

| Eaton | Reviews of top contactor manufacturers point out applicationŌĆæspecific contactors, highŌĆæbreaking capacity for large systems, strong safety features for overŌĆæcurrent and shortŌĆæcircuit events, and a focus on training and technical support. | Heavy industrial loads, highŌĆæfaultŌĆælevel systems, and applications where engineering support and safety margin are primary concerns. |

| Mitsubishi Electric | Analyses of global players highlight MitsubishiŌĆÖs precise manufacturing of contact gaps and contact pressure, lowŌĆæloss coil technology to reduce power and heat, and wide adoption in robotics and industrial drives. | AutomationŌĆæintensive plants and OEM equipment that already use Mitsubishi drives and controls, and where compact yet robust contactors are needed. |

| Fuji Electric | Industry rankings note FujiŌĆÖs emphasis on thermal management through heatŌĆæsink materials and ventilation, plus highŌĆæspeed switching for fast control. FujiŌĆÖs UPS maintenance guidance also underscores attention to cleanliness and torque control for longŌĆæterm reliability. | Motor control and UPS or power electronics environments where thermal performance and fast, clean switching are critical. |

These companies are not ŌĆ£dropŌĆæin ABB replacementsŌĆØ in every frame size or accessory combination. Instead, they represent robust ecosystems. For a given ABB AF frame, you can usually find a Schneider TeSys, Siemens Sirius, or Eaton equivalent that matches voltage, current, utilization category, and certification. The selection process should start from your operating requirements and then use each manufacturerŌĆÖs tables or configurators to pick the right part, rather than forcing oneŌĆætoŌĆæone part number crossŌĆæreferences.

Beyond the generalŌĆæpurpose motor and power contactor space, several specialized manufacturers offer alternatives that may actually be better suited than ABB for certain niches.

ElehubŌĆÖs review of top highŌĆævoltage contactor manufacturers underscores how demanding EV, energy storage, and renewable systems can be. Sensata Technologies, which expanded into highŌĆævoltage contactors through its GIGAVAC acquisition, focuses on EVs, aerospace, and renewable energy with designs aimed at extreme conditions and high reliability. Schaltbau, based in Germany, is known for contactors that tolerate high mechanical and electrical stress, particularly in rail and heavy industrial environments. TE Connectivity supplies highŌĆævoltage contactors used extensively in EV battery disconnect units, combining strong coil designs with wide temperature operating ranges.

Other highŌĆævoltage providers in that analysis include Panasonic, whose HV contactors feature compact footprints and low coil power consumption that make them attractive for EV battery systems and spaceŌĆæconstrained installations, and LS Electric, whose HV contactors appear in power plants and infrastructure projects across Asia. Mitsubishi Electric and Delphi Technologies bring deep automotive and driveŌĆæsystem experience to highŌĆævoltage contactors for industrial robots and EV propulsion systems, while YM Tech offers flexible manufacturing of HV contactors for EV battery systems, energy storage, and advanced automation.

When ABBŌĆÖs GF, GAF, or GA DC contactors do not align with your voltage window, footprint, or automotive standards, these specialized suppliers are logical alternatives. The same selection rules apply: match voltage, current, switching frequency, environment, and certifications such as UL, IEC, ISO 9001, and automotive standards like IATF 16949 where required.

VIOX ElectricŌĆÖs market study on modular contactors shows that modular devices for lighting, HVAC, and building loads are a growth area, with AC modular contactors commonly covering roughly 120ŌĆō690 V AC at about 16ŌĆō125 A and DC variants around 12ŌĆō250 V DC. ABB offers humŌĆæfree installation contactors and dedicated lighting contactors for similar current ranges. Competing modular contactor suppliers highlighted in that study include Schneider Electric with its TeSys and energyŌĆæefficient ŌĆ£Deca GreenŌĆØ contactors that use electronic coils to cut energy use by up to roughly 91 percent, ABB with AFŌĆæbased modular solutions, Eaton with compact DINŌĆærail designs, and Siemens with Sirius modular contactors that incorporate diagnostics and IoT readiness.

Additional brands such as Legrand, Hager, Finder, ETI, and Lovato Electric specialize in lowŌĆænoise, multiŌĆævoltage, renewableŌĆæready, and spaceŌĆæsaving modular contactors for smart buildings and compact control panels. In many commercial and institutional projects, the decision between ABB and these alternatives comes down to the building management system ecosystem, the need for IoT integration, and the level of energyŌĆæefficiency regulation the project must meet.

In materials handling equipment, the duty cycle, vibration, and DC arcing behavior are different from standard fixedŌĆæplant motor loads. Albright, for example, designs and manufactures DC contactors specifically for counterbalance forklifts, warehouse trucks, pallet trucks, power steering pumps, lift pumps, and reversing systems. Its SW80, SW180, and SW200 series address common duty and configuration needs, while changeover and motorŌĆæreversing variants extend the family. Newer RW and RU series are optimized as line contactors with reduced silver content for costŌĆæeffective battery connection duties, and Albright also offers dedicated emergency disconnect and combined disconnectŌĆæcontactor units.

If you are considering ABB contactors in batteryŌĆæpowered materialsŌĆæhandling vehicles, it is worth comparing them to specialists like Albright. Those specialists provide tailored mechanical designs, custom options, and a full range of spare parts and service kits, which can significantly simplify lifeŌĆæcycle maintenance in large forklift or AGV fleets.

Once you know which type of contactor you need, the next decision is where to purchase it. Multiple sources emphasize that supplier quality directly affects product quality, authenticity, and availability.

Guidance from Balaji Switchgears on choosing Schneider contactor suppliers makes several points that apply equally when sourcing ABB alternatives. Authorized distributors are preferred because the manufacturer has vetted them and they have direct access to genuine inventory. This reduces the risk of counterfeit or used products entering your system. Pricing that appears far below typical list levels is a red flag; reputable suppliers tend to cluster around similar price bands, allowing for promotions and negotiated discounts but not unrealistically low prices.

Stock and lead time are also crucial. BalajiŌĆÖs advice is to favor suppliers with sufficient onŌĆæhand inventory rather than living on backŌĆæorders that might stretch lead times into weeks or months. For missionŌĆæcritical projects, that guidance is particularly important when ABB lead times are already stressed and you are switching brands primarily to meet a delivery window.

A broader view of industrial automation supply chains from OMCH distinguishes between OEM channels, authorized distributors, costŌĆæeffective alternative manufacturers, and surplus or obsolete parts specialists. OEMs like Siemens, ABB, Rockwell, and Mitsubishi Electric are well suited to greenfield projects and standardized global platforms, providing deep architectural support but often with higher prices and longer lead times. Authorized distributors bridge OEMs and end users with multiŌĆæbrand catalogs and faster shipping, which is ideal for maintenance and highŌĆæmix, lowŌĆævolume ordering. CostŌĆæeffective alternatives such as Delta, Autonics, or OMCH itself supply components at lower cost for nonŌĆæcritical applications. Surplus specialists such as Radwell focus on endŌĆæofŌĆælife and hardŌĆætoŌĆæfind parts.

Articles by Simplybuy on AC contactor suppliers add another layer: product authenticity and quality assurance are the first screening filter. Reliable suppliers can demonstrate certification, traceability, and inŌĆæhouse testing, and many back their contactors with at least a oneŌĆæyear warranty and structured return policies. Simplybuy, for instance, positions itself as a channel that only ships authentic products from major brands like ABB, Schneider, and Siemens, supported by multiŌĆælanguage service teams and warehouses in multiple regions to improve logistics.

ElehubŌĆÖs manufacturer ranking and the AC contactor supplier guidance from Simplybuy also emphasize afterŌĆæsales capabilities. Suppliers that can help interpret specifications, troubleshoot installation problems, and process warranty claims promptly tend to reduce total risk even if their unit prices are slightly higher. This is especially important when you are standardizing a nonŌĆæABB brand across multiple sites and need consistent technical support.

After you have matched ratings and chosen a credible supplier, reliability comes down to how the contactor is applied and maintained.

C3ControlsŌĆÖ white paper on contactors explains that the most common failure mode is welded or sticking contacts. High inrush currents, unstable control voltages, and rapid transitions between peak currents can overheat and weld contact surfaces. Over time, arcing during each operation causes pitting and burning; black oxide deposits can still conduct, but eventually contacts wear enough that replacement is necessary. Properly sized contactors, correct utilization categories, and coil voltage control all reduce this stress.

UPS maintenance guidance from Fuji Electric highlights a less glamorous but very real threat: contamination. In field inspections of UPS systems and auxiliary equipment, typical contaminants include dirt, dust, sawdust, and metal filings, even in rooms that look clean. These particles can accumulate on relay and contactor contacts and on printed circuit boards, causing insulation breakdown, shorts, and erratic behavior. Fuji recommends cleaning UPS equipment at least once a year with careful vacuuming using nonŌĆæconductive hoses, avoiding blowers or compressed air that can force debris deeper into equipment. For heavier deposits, technicians can use lintŌĆæfree rags lightly dampened with nonflammable, fastŌĆædrying solvent and soft brushes around delicate components. All work must be done on deŌĆæenergized equipment, with appropriate personal protective equipment, and copper and lead connectors should be torqued correctly to prevent overheating and arcing. The same principles apply to contactor compartments in MCCs and switchboards.

Advanced contactor designs from major manufacturers incorporate features that reduce energy consumption and support diagnostics. VIOX Electric notes that SchneiderŌĆÖs Deca Green contactors use electronic coils that cut energy use by up to about 91 percent, and that Siemens Sirius contactors add digital diagnostics and IoT readiness. ABBŌĆÖs AF technology also targets improved uptime and reduced stock complexity. In a reliabilityŌĆæfocused plant, these features justify attention because they enable predictive maintenance dashboards, status monitoring via PLCs or DCS, and reduced heat in control panels.

The final piece is protection coordination. As Schneider ElectricŌĆÖs FAQŌĆæstyle guidance points out, a properly chosen contactor sits in a system that includes appropriately rated breakers and overload relays. Overload relays, whether thermal or electronic, must be set for motor service factors and ambient temperature, while breakers must have interruption capacities that exceed available fault currents. This coordination is brandŌĆæagnostic; it applies equally whether your contactor carries an ABB, Schneider, Siemens, or other label.

Not safely on ampere rating alone. Sources such as RSP Supply and SpringŌĆæbranded guides stress that you must match not just the current but also the utilization category, operational voltage, coil voltage, duty cycle, and environmental rating. You must also verify that the alternative contactorŌĆÖs breaking capacity and certifications (UL, IEC, and similar) are appropriate for your system. Once those parameters align, there is no inherent technical reason you must stay with ABB, but skipping this analysis introduces real risk.

It is usually worth paying more when your application relies heavily on ABBŌĆæspecific features or integration. Examples include systems designed around ABBŌĆÖs AF and AFS lines with their specific accessories, safety feedback schemes, or when you are using ABBŌĆÖs UMC100.3 motor management system with a tightly integrated starter package. It can also be worth paying a premium for ABB in harsh environments where you already have field experience with ABB contactor longevity, or in projects where a single manufacturerŌĆÖs ecosystem simplifies design, documentation, and global support.

Selection guidance from Balaji Switchgears and Simplybuy recommends purchasing only from authorized distributors or wellŌĆædocumented industrial suppliers, watching for pricing that is suspiciously low compared to normal market levels, and requiring documentation of origin and certification. Look for suppliers with established quality systems, such as ISO 9001, and clear return and warranty policies. ElehubŌĆÖs analysis also suggests favoring manufacturers and channels that can demonstrate robust testing and customer feedback histories for highŌĆævoltage and safetyŌĆæcritical contactors.

Choosing an ABB alternative does not have to be a compromise. When you start from sound electrical requirements, evaluate manufacturers on documented strengths, and use credible supply channels, you can maintain or even improve system reliability. The most robust power systems are built on disciplined specification and supplier selection, not on any single logo stamped on a contactor faceplate.

Leave Your Comment