-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

In every serious power-protection project I work onŌĆöwhether it is a UPS-backed data hall, a process plant with ride-through inverters, or a hospital with complex transfer schemesŌĆöthe humble contactor is one of the most consequential components in the single-line diagram. It is also one of the most underestimated. A contactor that is poorly specified, installed, or supported by the wrong supplier can quietly undermine the reliability of a multiŌĆæmillionŌĆædollar power system.

This article looks at industrial contactor suppliers through the lens of power reliability. Drawing on manufacturer guidance from sources such as c3controls, Kent Store, Proax (ABB), Schneider Electric distributors, Schaltbau, Chint, and Contactor Depot, it explains what you are really buying when you choose a contactor, how to match the technology and ratings to your loads, and what to expect from a competent supplier over the lifecycle of your equipment.

Before you judge a supplier, it helps to be clear about the component itself.

A contactor is an electrically controlled, highŌĆæcurrent switch that uses an electromagnetic coil to pull in heavyŌĆæduty power contacts inside an insulated enclosure. Manufacturer briefs from Kent Store and c3controls describe the core elements the same way. There is a coil or electromagnet that produces the force, one or more main contacts that carry the load current, auxiliary contacts for signaling and interlocks, and an enclosure with an arc chute to manage the arc every time the circuit opens.

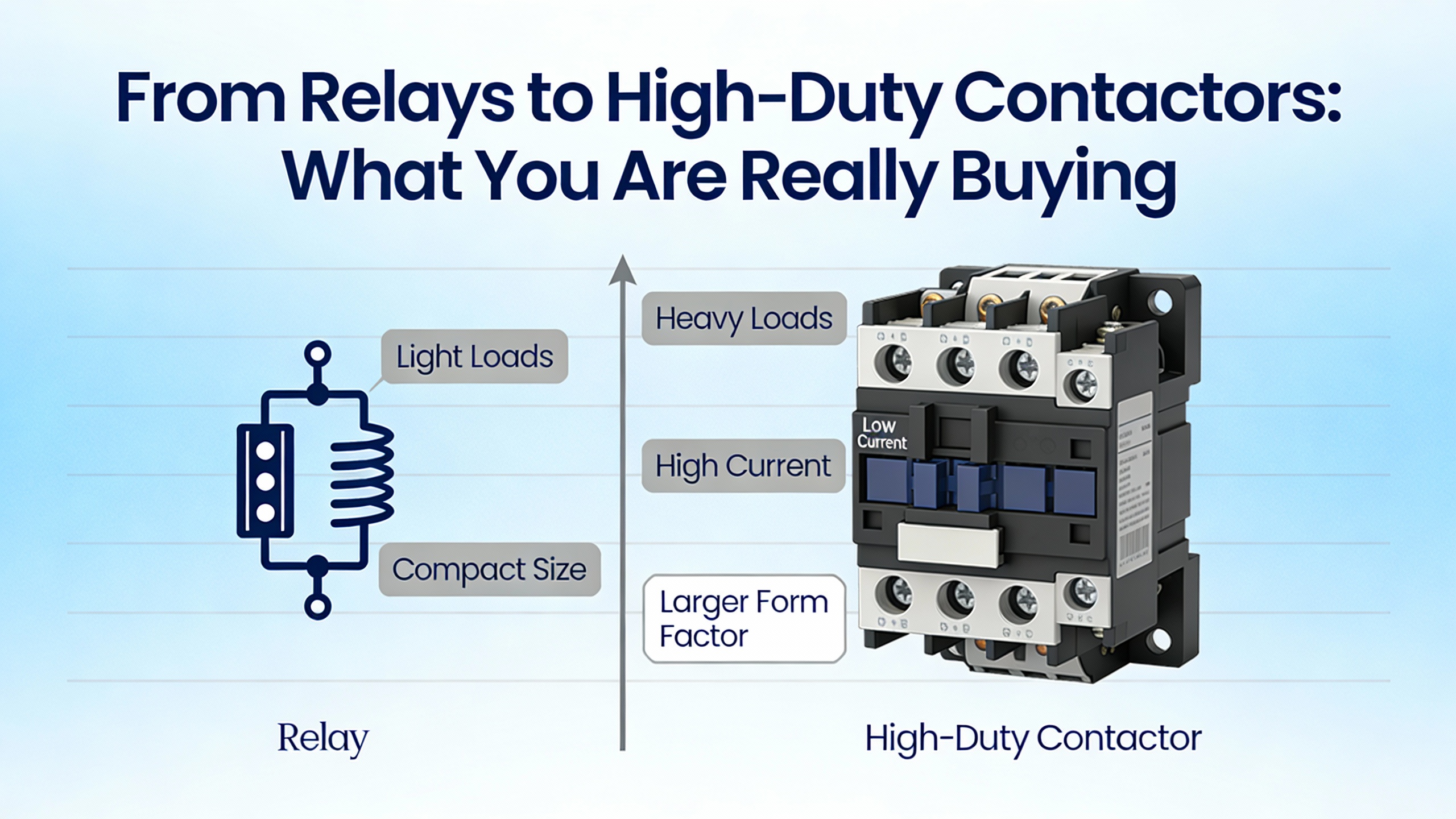

Compared with relays, which typically handle low currents in the range of roughly 5 to 15 amperes, c3controls notes that contactors cover everything from a few amperes up to well over 5,000 amperes and more than 100 kilowatts at voltages from 24 VDC into the thousands of volts. That makes them the right tool for motors, large lighting banks, heavy heating loads, and the feeders that power your UPS, inverters, and distribution gear. Kent Store highlights that modern industrial contactors, as of 2025, can reach more than ten million mechanical operations, which is exactly what you need in applications with frequent switching.

It is also important to separate contactors from motor starters. A motor starter is essentially a contactor bundled with overload protection and control elements. Kent Store and c3controls both emphasize that a bare contactor on its own does not provide motor overload protection; that duty belongs to separate overload relays or electronic protection units that must be specified and coordinated.

From a reliability perspective, you are not just buying copper and plastic. You are buying a tested mechanism for repeatedly making and breaking highŌĆæenergy circuits at distance, on command, in a controlled way. The quality of that mechanism, its contact materials, its arc control, and its thermal design are what differentiate commodity devices from industrialŌĆægrade solutions.

Almost all industrial contactors in the field today are magnetic contactors. As RS and Kent Store explain, they operate entirely via electromagnetism and require only a small control power to open and close, enabling remote operation without manual intervention. This basic design has proven efficient and reliable over decades.

However, it is not the only option. Kent Store and RS outline several important variants:

| Contactor type | How it works and where it fits | Key pros | Key considerations |

|---|---|---|---|

| Electromagnetic (mechanical) | Coil pulls a mechanical armature that closes metal contacts; standard for motors, heating, and lighting. | Very high current capacity, low onŌĆæstate resistance, relatively low cost, well understood. | Contacts wear over time from arcing; requires periodic inspection, cleaning, and replacement. |

| SolidŌĆæstate | Uses semiconductor devices to switch the load instead of mechanical contacts. | Fast, silent, no contact wear, long switching life, good for precision control and inaccessible locations. | Higher voltage drop and heat, higher initial cost, temperatureŌĆæsensitive; needs careful thermal management. |

| Vacuum | Arc is contained in a sealed vacuum chamber. | Very effective arc suppression, suitable for demanding highŌĆævoltage or capacitor switching applications. | More specialized and typically higher cost; must be matched carefully to application. |

| Latching (bistable) | Holds its state mechanically and only needs power for state changes. | Very low holding energy; useful where control power is limited or energy efficiency is a priority. | Control logic is more complex; must ensure safe behavior after power loss. |

| DefiniteŌĆæpurpose | Compact units tailored for HVAC, refrigeration, and pump or compressor duty. | SpaceŌĆæefficient, accessoryŌĆæready, optimized for specific load types. | Ratings and life are tuned to a narrow duty profile; less flexible outside intended applications. |

Kent Store also points to emerging research into lowŌĆæ or zeroŌĆæholdingŌĆæenergy magnetic designs that dramatically cut controlŌĆæcircuit power once the contactor is closed. In large UPS, inverter, or EVŌĆæcharging installations with thousands of coils energized, this can translate into material efficiency gains over the system life.

When you evaluate a supplier, one practical question is whether they can cover all of these technologiesŌĆöespecially if your site mixes classic motor loads with highŌĆæduty cycling, lowŌĆænoise building services, and energyŌĆæstorage DC strings. Suppliers aligned with large portfolios from brands such as Schneider Electric, ABB, Eaton, and Siemens are often better positioned to do that.

For a powerŌĆæprotection project, the heart of the specification exercise is matching the architecture of the contactor to the load: AC versus DC, singleŌĆæphase versus threeŌĆæphase, pole count, and ratings.

Kent Store and RS both emphasize that contactors are always designed for one power type: AC or DC. AC contactors use AC coils and rely on the natural voltage zeroŌĆæcrossings of alternating current to help extinguish arcs. They dominate applications like standard motors, lighting, and resistance heaters.

By contrast, DC contactors use DC coils and require much stronger arc suppression, with features like magnetic blowŌĆæouts and specialized arc chutes. Kent Store and Proax note that DC contactors are favored in battery systems, EV charging, DC drives, PV arrays, and DCŌĆæcoupled energy storage. Proax specifically highlights ABBŌĆÖs GF, GAF, and GA families, engineered for switching DC circuits up to about 1,500 volts, and explicitly aimed at systems such as PV solar, EV charging, UPS, and storage.

Power system architecture also determines whether you need singleŌĆæphase or threeŌĆæphase devices. RS describes singleŌĆæphase contactors for smaller, singleŌĆæphase installations, usually switching the live conductor while leaving the neutral intact. ThreeŌĆæphase contactors, with three main contact sets, are the industrial workhorses for large motors, heavy machinery, and any highŌĆæpower equipment in typical plant and data center environments. In practice, that means most UPS input and bypass paths, as well as many inverter feeders, will be managed through threeŌĆæphase contactors.

Once you know the phases, the next decision is how many poles you actually need. Standard motor contactors are usually threeŌĆæ or fourŌĆæpole devices. However, Contactor DepotŌĆÖs guidance on sixŌĆæ and eightŌĆæpole designs is particularly relevant for complex facilities.

SixŌĆæpole contactors are designed for applications where several moderateŌĆæload circuits, such as multiple motors, HVAC units, or lighting groups, can be controlled from a single point. EightŌĆæpole units extend that concept further, offering additional connection points and greater flexibility for large, powerŌĆæheavy installations. Contactor Depot points to sectors like manufacturing automation, data centers, transportation infrastructure, power plants, and healthcare facilities with critical and backup power as typical users.

Space in your panels matters as well. SixŌĆæpole devices can be a compact way to aggregate multiple circuits where you might otherwise install several smaller contactors. EightŌĆæpole models consume more space but allow more circuits and, importantly, leave room for future connection of added motors or loads. As Contactor Depot suggests, choosing an eightŌĆæpole contactor with spare poles up front can significantly reduce future rewiring and associated downtime when you expand.

A simple example illustrates the point. Imagine a chilledŌĆæwater system with four pumps today and likely expansion to six pumps as load grows. A single eightŌĆæpole contactor with six poles reserved for the pumps and two for auxiliaries can centralize control, simplify interlocking, and avoid adding a second contactor and field wiring when the extra pumps are installed later. Over the life of the plant, that design decision and the supplierŌĆÖs ability to support it will often matter more than a small upfront price difference.

Every reputable manufacturer and distributor in the notes gives the same fundamental advice: start with the load. Kent Store, c3controls, LongŌĆæterm industrial guides, and Proax all recommend that you first determine the type of load, its voltage, its running current, and the inrush or starting current, as well as the duty cycle. Then you select a contactor whose ratings meet or exceed those requirements.

c3controls highlights that power ratings represent the maximum voltage and current the contactor can safely switch. Kent Store adds that you must align three parameters: the contactorŌĆÖs voltage rating (the maximum line voltage that can be safely interrupted), the current rating under the relevant utilization category, and the coil voltage that matches your control supply. Kent Store and RS both stress that the coil voltage does not need to match the load voltage; you can, for example, use a 24 VDC coil to switch a highŌĆævoltage AC motor, which is standard practice in UPS and PLCŌĆæbased control panels.

Utilization categories are another subtle but important dimension. Kent Store references common IEC categories such as ACŌĆæ1 for resistive loads and ACŌĆæ3 for motor starting. LongŌĆæduration resistive loads like heating elements impose relatively gentle electrical stress; inductive loads like motors generate high inrush and strong arcs when switching. c3controls advises that for inductive loads you should ensure the contactorŌĆÖs inductive rating accounts for both the starting surge and the steady running current.

A simple calculation makes the reason obvious. LongBeachŌĆæstyle guidance notes that motor inrush can be roughly six to eight times the running current. If a motor nameplate shows 80 amperes fullŌĆæload current and your application involves frequent starting, the contactor may see 480 to 640 amperes during each start. It would be a mistake to size the contactor purely on the 80ŌĆæampere running current. Instead, you need a contactor whose ACŌĆæ3 rating and mechanical endurance are appropriate for that level of stress.

As system voltages climb, these choices become more critical. ABB contactors presented by Proax, for example, span motor ratings from about 9 to 800 amperes and installation contactors from about 16 to 100 amperes, while ChintŌĆÖs NC1 and NC2 contactors are rated up to about 690 volts AC with currents up to around 800 amperes. At DC, ABBŌĆÖs GF, GAF, and GA contactors reach about 1,500 volts. Combining these capabilities intelligently for your UPS feeders, inverter outputs, and DC strings is precisely where a knowledgeable supplier earns their keep.

DC contactors deserve special attention in powerŌĆæprotection work because they often sit between highŌĆæenergy battery strings and the rest of the system. SchaltbauŌĆÖs guidance on DC contactor selection is particularly explicit and aligns well with best practice.

The two starting parameters are the rated insulation voltage and the rated operational current, which Schaltbau calls the thermal continuous current. The thermal current determines how hot the contactor runs in normal service; it depends heavily on the resistance of the main contacts, which in turn is driven by the contact material and contact force. Manufacturers specify this rating under very specific environmental and installation conditions. If your cabinet differs in ventilation, ambient temperature, or mounting, the actual safe current may change.

Schaltbau notes that in some practical cases, a certain overload above the rated operational current is permissible, citing an example of about twentyŌĆæfive percent overcurrent in a wellŌĆæventilated control cabinet. For instance, a DC contactor with a 200ŌĆæampere rated operational current might tolerate 250 amperes in those favorable conditions. However, Schaltbau is clear that any planned overload or deviation from ratings must be explicitly clarified and agreed with the manufacturer. That is exactly the kind of coordination an experienced supplier should facilitate.

Crucially, DC contactors must be able to interrupt not just continuous current but also transient peak currents. Many applications show shortŌĆæterm peaks at specific operating points; from a purely thermal perspective these may be harmless, but from a switching and safety standpoint they can be decisive. Schaltbau recommends that engineering assessments consider worstŌĆæcase fault scenarios and that system developers work closely with contactor manufacturers to interpret ratings against real application conditions.

For a UPS battery or DCŌĆæcoupled storage project, a strong supplier will therefore do more than pull a catalog part. They will help you interpret the ABB or Schaltbau curves, confirm that insulation voltage and breaking capacity cover your highest normal and faultŌĆælevel voltages, and, where needed, engage the manufacturer to validate any overload or derating assumptions.

Once the technical fundamentals are clear, the question becomes: what makes a supplier a true reliability partner rather than just an orderŌĆætaker?

A first marker is the breadth and depth of the supplierŌĆÖs portfolio and its alignment with recognized standards. Kent Store points to major brands such as Schneider Electric, ABB, Eaton, and Siemens as examples of manufacturers with broad contactor families, international certifications, and global support networks. Distributors aligned with those ecosystems typically offer better coverage across AC and DC, generalŌĆæpurpose, definiteŌĆæpurpose, safety, and specialized contactors.

Proax, for example, acts as an ABB authorized distributor and highlights a wide range of contactors: standard threeŌĆæphase motor contactors from roughly 9 to 800 amperes, installation contactors optimized for lowŌĆænoise building services, specialized capacitorŌĆæswitching contactors with damping resistors to manage high inrush, lighting contactors in electrically held and mechanically held variants, definiteŌĆæpurpose contactors for compressors and resistive heating, and highŌĆævoltage DC contactors for PV, EV, UPS, and storage.

c3controls underlines another aspect, the choice between NEMA and IEC designs. NEMA contactors, used largely in North America, are organized into standardized frame sizes such as 00, 0, 1, and higher, and are deliberately oversized with safety margins that can be around twentyŌĆæfive percent. IEC contactors, by contrast, are more compact, fineŌĆætuned to specific application ratings, and often incorporate ŌĆ£fingerŌĆæsafeŌĆØ terminal designs and faster response to overloads. A supplier that understands both standards and can steer you between them based on load certainty, space, and maintenance philosophy provides clear value.

Certifications are nonŌĆænegotiable. Contactor Depot explicitly recommends UL or IECŌĆæcertified products engineered for industrial use, and Proax stresses CSA and UL compliance for their ABB solutions. In a power system that must meet codes and insurance requirements, working with a supplier that treats certifications as table stakes, not an afterthought, is essential.

The second differentiator is engineering depth. In practice, many of the failure modes that c3controls and Chint describeŌĆöwelded contacts from high inrush, coils burned by overŌĆæ or undervoltage, excessive heating from poor ventilationŌĆöare rooted in misapplication more than inherent product flaws.

Proax highlights that its inŌĆæhouse engineers across numerous locations in Canada support customers in selecting, installing, and maintaining ABB contactors. Contactor Depot positions its free technical support as a resource for installation and maintenance questions. Balaji Switchgears, focusing on Schneider contactors, emphasizes the value of working with authorized suppliers for standardsŌĆæcompliant service and technician training. KINO Electrical underscores its ability to support selection and supply of replacement and applicationŌĆæspecific AC contactors.

SchaltbauŌĆÖs recommendation for early, collaborative definition of DC contactor requirements and explicit manufacturer signŌĆæoff on any overload or nonstandard condition is a good benchmark. A supplier that habitually involves the manufacturerŌĆÖs engineering team, rather than guessing at derating, will help you avoid unpleasant surprises later in factory acceptance testing or commissioning.

Contactor Depot introduces another angle that system owners sometimes overlook: logistics as a reliability strategy. They emphasize nextŌĆæday shipping for urgent replacements in industrial settings and free shipping across the United States, backed by a quality guarantee and industrialŌĆærated, certified products. The message is that rapid component availability is as much a part of reliability as the nameplate on the device.

Modern contactors may have mechanical lives in the millions of operations, as Kent Store notes, but actual electrical life depends heavily on load type and duty cycle. In a plant where a motor contactor cycles once per minute around the clock, even a tenŌĆæmillionŌĆæoperation mechanical rating can be consumed over years rather than decades. Thoughtful suppliers help you plan strategic spares based on your switching profile and the consequences of failure, not just on the procurement budget.

LongŌĆæterm guidance from businessŌĆæoriented sources stresses evaluating total cost of ownership rather than purchase price alone. That perspective aligns well with what we see in the contactor domain: a slightly more expensive IEC or NEMA contactor from a mainstream industrial brand, backed by fast availability, manufacturer support, and known failure behavior, usually costs less over the life of a UPS, inverter, or plant electrical system than a bargain device that fails unpredictably and is hard to replace.

Specifying the right contactor is only half the reliability story. Keeping it healthy over time demands a maintenance program, and your supplier should be able to support that as well.

Balaji Switchgears, Contactor Depot, KINO, Chint, and other manufacturers converge on a set of preventive actions that significantly extend contactor life. Regular visual inspections are first. Technicians should look for burn marks, discoloration, cracked housings, loose terminals or mounting screws, and dust or debris buildup. Catching these symptoms early allows intervention before they escalate into overheating, short circuits, or outright failure.

Contact surfaces deserve particular attention. Balaji recommends cleaning to remove carbon deposits and dirt caused by arcing, using only soft cloths or manufacturerŌĆæapproved cleaners to avoid damaging conductive surfaces. Contactor DepotŌĆÖs maintenance guidance adds that uneven wear, damaged surfaces, corrosion, or exposed copper are all signs that the contact set should be replaced as a unit to maintain balance and performance.

Coil health is equally important. Balaji and KINO both advise regular checks with a multimeter to verify that coil resistance falls within the manufacturerŌĆÖs specified range. Coils that are open, shorted, or far out of tolerance can cause chattering, failure to close, or overheating. ChintŌĆÖs troubleshooting instructions include tests where technicians measure both coil voltage and contact resistance and interpret outŌĆæofŌĆærange readings as indicators of faulty coils or contacts.

Terminals and mounting hardware must be tightened periodically. Both Balaji and Contactor Depot note that vibration and thermal cycling can loosen connections, increasing contact resistance, creating hot spots, and reducing efficiency. In my experience, many ŌĆ£mysteriousŌĆØ hot contactors in UPS rooms trace back to a terminal that was never properly torqued.

Auxiliary contacts and overload relays, where present, should be inspected and tested. Balaji points out that misaligned or worn auxiliary contacts can disrupt feedback to the control system, while Contactor Depot recommends verifying overload relays by checking torque, matching fullŌĆæload amperage dials to motor ratings, and manually tripping and resetting relays to ensure they operate correctly.

A robust preventive program also uses structured maintenance logs. Balaji encourages tracking inspection dates, observations, repairs, and replacements. With that data, you and your supplier can spot patterns, such as a specific contactor family wearing out faster under certain loads, and adjust product selection or maintenance intervals accordingly.

Even with good maintenance, issues will occur, and your supplierŌĆÖs troubleshooting playbook matters.

ChintŌĆÖs articles on noisy contactors and selection troubleshooting, together with c3controlsŌĆÖ failure analysis, describe several common symptoms. Overheating can result from high ambient temperature, contactors being energized for prolonged periods, overvoltage on the coil, undervoltage that prevents full armature pullŌĆæin, overloading, or poor ventilation. Discoloration of terminals and insulation is an early warning sign. Measuring the actual current and comparing it to the contactorŌĆÖs ratings, as well as checking coil voltage against the nameplate, are the first checks.

Unusual humming or buzzing is another frequent complaint. Chint explains that all AC contactors generate some noise, but a loud or sudden hum often indicates that coil voltage is outside the rated range, loosening the magnetic coupling. Undervoltage, poor connections, or overloaded circuits can cause the magnetic field to pulse unevenly, creating 50 to 60 Hz vibrations. Mechanical wear or misalignment of the armature, as well as dust, oil, or other contaminants on the pole faces, also introduce air gaps that reduce magnetic attraction and encourage vibration. In AC designs that use shading coils to stabilize the magnetic field at zeroŌĆæcrossings, a degraded shading coil can dramatically amplify humming.

KINO and Chint both recommend methodical testing with a voltŌĆæohmmeter. With power removed, you label and disconnect wires, then measure contact resistance; a healthy closed contact should read near zero ohms, while higher values indicate contamination or wear. If all contacts appear bad, Chint suggests energizing the coil and confirming with a voltmeter whether the correct voltage is present at each contact; if it is and the contact still fails, the coil itself is suspect.

A specific caution appears in ChintŌĆÖs maintenance tips: avoid blasting the panel with compressed air, which can drive dust and debris directly into contactors. Instead, vacuum around electrical components and clean pole faces and contacts with appropriate tools and solvents.

Suppliers that stock lowŌĆænoise or humŌĆæfree contactors, such as ABBŌĆÖs installation contactors that Proax describes, or ChintŌĆÖs NC2 series engineered for minimal vibration, can sometimes resolve persistent noise problems by design rather than continuous troubleshooting, especially in noiseŌĆæsensitive areas like offices and classrooms fed from central UPS systems.

Contactor Depot points out that robust enclosures and durable construction can reduce cleaning frequency and mitigate loosening from vibration. Kent Store emphasizes that selecting units with appropriate enclosure ratings, highŌĆætemperature coils, and corrosionŌĆæresistant contacts lowers unscheduled downtime and total ownership cost. KINO highlights the importance of correct installation in clean, dry, wellŌĆæventilated areas, proper mounting torque, and adherence to wiring diagrams.

Balaji and KINO both stress technician training, and Balaji links that explicitly to authorized suppliers who can deliver factoryŌĆæaligned guidance. Contactor Depot and Proax supplement this with free or bundled technical support. That ecosystemŌĆömaintainable products, correct application, and support when things go wrongŌĆöis what separates a reliabilityŌĆæfocused contactor supplier from a simple catalog house.

To connect these principles to dayŌĆætoŌĆæday decisions in UPS and powerŌĆæprotection work, it helps to look at a few typical scenarios.

In batteryŌĆæcentric systems, DC contactors sit between highŌĆæenergy DC strings and the rest of the power system. Proax describes ABB DC contactors in the GF, GAF, and GA series engineered to switch DC up to about 1,500 volts in applications such as PV solar fields, EV charging infrastructure, UPS, and storage. These devices are designed specifically to break DC circuits safely, which is more demanding than AC interruption at the same voltage.

SchaltbauŌĆÖs selection criteria push users to treat these devices as engineered components rather than simple catalog items. Rated insulation voltage must exceed the highest DC voltage in your system, including transients. Rated operational current must cover the highest average current under realistic ambient and ventilation conditions. Transient peaks during charge, discharge, and fault must also be within the contactorŌĆÖs breaking capacity at your chosen operating point.

Consider a DCŌĆæcoupled storage rack designed to operate at 1,200 volts and 200 amperes nominal, with shortŌĆæterm peaks to 300 amperes during fault clearing. The supplierŌĆÖs role is to match this profile to an ABB or Schaltbau contactor whose insulation and breaking curve cover that operating window, verify with the manufacturer whether any overload or derating is required, and confirm that mounting and ventilation match the assumptions used in the ratings. That level of support is markedly different from simply providing a ŌĆ£1,500ŌĆævolt DC contactorŌĆØ by part number.

In automation lines and chilledŌĆæwater plants feeding inverterŌĆæbacked loads, you often see multiple motors that must be started, stopped, or transferred together. Contactor DepotŌĆÖs description of sixŌĆæ and eightŌĆæpole contactors shows how these devices can simplify the design.

SixŌĆæpole contactors handle several moderateŌĆæload circuits controlled from a central point. They are well suited for grouped motor control, multiŌĆæzone HVAC, or sectionalized lighting. EightŌĆæpole devices extend that capacity and allow a designer to combine motor control with additional tasks such as bypasses, interlocks, and status circuits.

For example, in a data center mechanical room with multiple CRAH or CRAC units served from a UPSŌĆæbacked bus, a single eightŌĆæpole contactor might be used to shed or transfer several fan and pump motors during certain operating modes, while still reserving poles for feedback and auxiliary functions. The supplierŌĆÖs contribution is to help calculate aggregate current, verify utilization categories, check space and heat dissipation in the panel, and ensure that UL or IEC certifications cover the combined application.

ABBŌĆÖs installation and lighting contactors, as presented by Proax, illustrate another dimension of supplier value for powerŌĆæprotected facilities. NoiseŌĆæoptimized installation contactors with ratings roughly from 16 to 100 amperes can control lighting, heating, ventilation, motors, and pumps in noiseŌĆæsensitive spaces fed from central UPS or generator systems. HumŌĆæfree operation is particularly important in hotels, offices, hospitals, and classrooms.

For heavier lighting loads, Proax describes CRŌĆæseries lighting contactors with modular designs, electrically held and mechanically held variants, and ratings from about 30 to 300 amperes. A supplier that understands how these devices behave with fluorescent, mercury arc, tungsten, and sodium lamp loads, and how they interact with UPS output waveforms and transfer behavior, can help avoid nuisance trips and compatibility issues.

According to c3controls and Kent Store, a contactor is essentially a highŌĆæpower version of a relay. Relays generally handle controlŌĆælevel currents, often around 10 amperes or less, whereas contactors are rated from a few amperes into the thousands, including large motor and feeder currents. Contactors also incorporate arcŌĆæmanagement features, robust mechanical structures, and enclosures designed for repeated highŌĆæenergy switching. In UPS and inverter systems where you are switching feeders, bypass paths, and large motor loads, you need the capabilities of a contactor rather than a relay. Using relays outside their intended current range is a recipe for welded contacts, overheating, and unreliable transfer.

Kent Store and RS note that solidŌĆæstate contactors use semiconductors rather than mechanical contacts, giving them very fast, silent operation and essentially unlimited switching life in terms of mechanical wear. They are particularly attractive in applications that involve extremely frequent switching, where noise is unacceptable, or where equipment is hard to access for maintenance. However, they introduce a higher voltage drop and more continuous heat than electromagnetic contactors and generally cost more. In a UPSŌĆæfed process where a heater bank is being dutyŌĆæcycled many times per minute and is located in a space that is difficult or risky to access, paying extra for a solidŌĆæstate contactor can be justified. For conventional motors and feeders that cycle less often and where periodic maintenance is routine, an electromagnetic contactor is usually more economical and efficient.

Manufacturers and distributors such as Balaji Switchgears, Contactor Depot, KINO, and Chint all recommend regular inspections, but none prescribe a single universal interval, because it depends on duty and environment. In heavily cycled applications, harsh environments, or critical paths in UPS and inverter systems, inspections may need to be performed on a schedule aligned with other preventive maintenance, such as quarterly or semiŌĆæannually. In lighterŌĆæduty, clean environments, annual inspections may suffice. What matters most is that inspections are structured, documented, and include checks of contacts, coils, terminals, mechanical operation, thermal condition, and, where present, overload relays. A good supplier will help you tailor inspection frequency to your operating profile and risk tolerance.

In wellŌĆæengineered power systems, industrial contactors are not commodities; they are safetyŌĆæcritical actuators that stand between your loads and every abnormal condition the grid can throw at you. Partnering with a supplier who understands the nuances of contactor technology, has direct access to major manufacturers, and stays engaged through selection, installation, and maintenance is one of the most costŌĆæeffective reliability investments you can make.

Leave Your Comment