-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Industrial automation has moved from ŌĆ£nice to haveŌĆØ to ŌĆ£nonŌĆænegotiableŌĆØ for competitive plants. Robotics, advanced control systems, and dataŌĆædriven optimization are now intertwined with something far less glamorous but absolutely critical: stable, protected power. As a power system specialist, I see the same pattern again and again. Plants invest heavily in PLCs, robots, and software, yet overlook the basics of power quality, backup power, and protection. The result is an automation stack that looks sophisticated on paper but behaves unpredictably in real life.

A wellŌĆædesigned Industrial Automation Fundamentals course should correct that imbalance. It needs to build core competencies in control, safety, reliability, and power systems from day one, so engineers learn to think of the power system and automation stack as one integrated reliability platform. Drawing on best practices from leading integrators, engineering associations, and power system specialists, this article outlines what that fundamentals course should cover and why it matters.

Industrial automation replaces repetitive, timeŌĆæconsuming manual tasks with interconnected systems of machines, sensors, and software that can run around the clock with high consistency. Advantech describes this as integrating machines, control systems, sensors, and software so production tasks can be executed with minimal human intervention and high repeatability. Pacific Blue Engineering extends that concept into warehousing, where automation spans robots, conveyors, automated storage and retrieval systems, and the software that coordinates them.

Across these environments, automation is not just about speed. It is about uptime, product quality, and predictable cost. CNCTech emphasizes that reliability in automation directly protects uptime and product quality while lowering operating costs by avoiding emergency repairs and schedule slips. JHFoster highlights that poor or unstable power can cause equipment failures, unplanned downtime, corrupted data, and safety hazards, particularly as plants add more robotics and IoTŌĆæbased equipment.

The fundamentals course is where future automation professionals learn to connect these dots. They must understand that every elegant PLC program, every DCS strategy, and every robot cell rests on three pillars: robust control architectures, clean and resilient power, and disciplined safety and reliability practices.

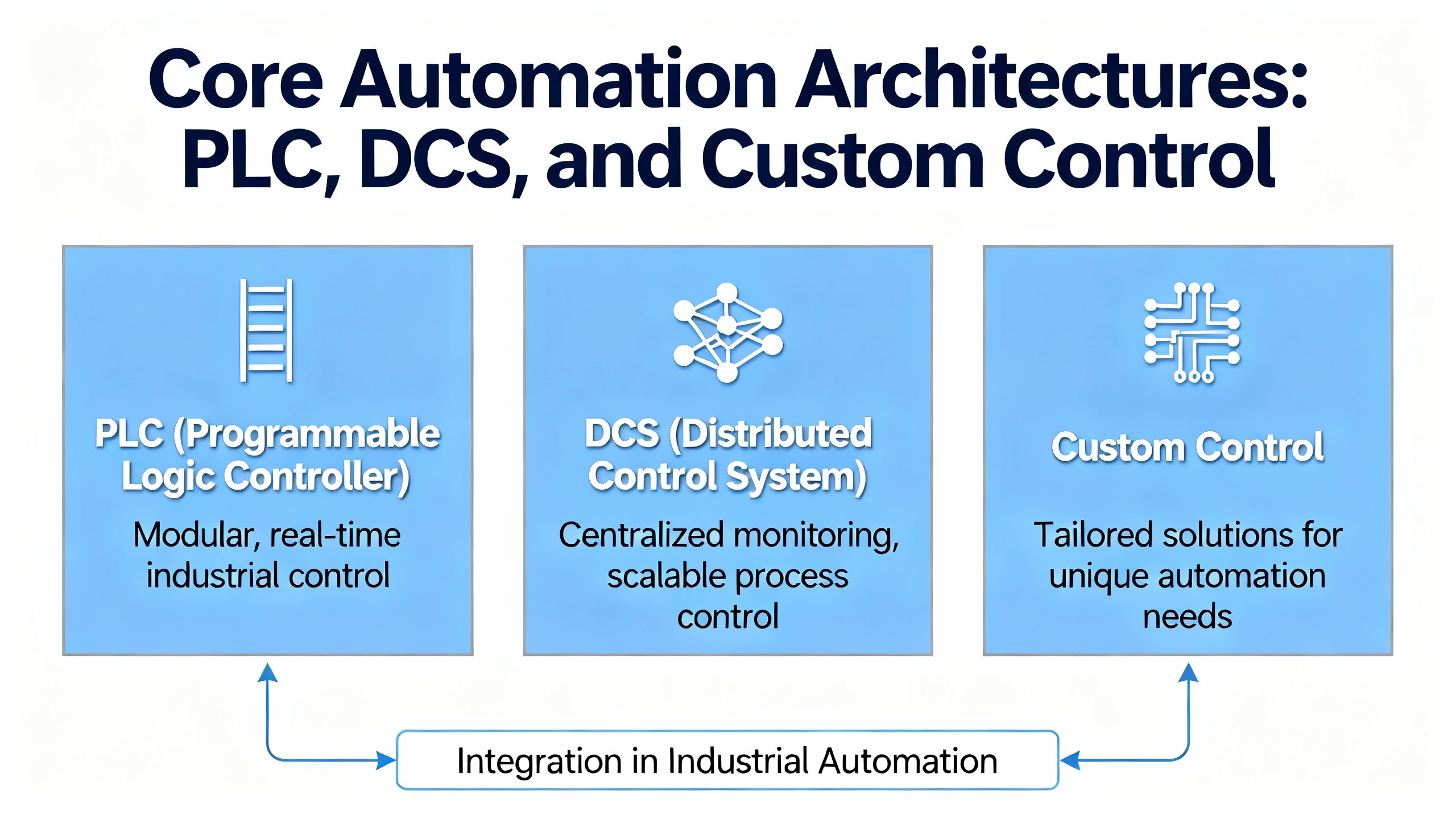

A solid course starts by demystifying how control architectures are structured and why they are chosen.

Lafayette Engineering describes PLC controls as the backbone of modern automation. PLCs act as rugged industrial computers that monitor inputs, process programmed logic, and drive outputs such as motors, valves, and heaters. They thrive in discrete manufacturing, material handling, and many process applications because they are robust, scalable, and well understood.

Distributed Control Systems (DCS), highlighted by Norwalt and Tessy Automation, connect multiple controllers and access points across a plant to allow centralized, coordinated monitoring and control. Modern DCS solutions are recommended over older, rigid systems because they integrate more easily with other platforms, support scalable growth, and provide plantŌĆæwide visibility.

Custom machine control systems, as described by Automation Services Inc. (ASI), take this further by tailoring control solutions to specific machines or production lines. These solutions use advanced PLCs or DCS controllers, extensive sensor networks, and userŌĆæfriendly interfaces to manage and optimize equipment with precision. ASI stresses that custom systems are designed to attack bottlenecks, downtime, and inconsistent quality directly, while being scalable, compatible with legacy gear, and upgradeable as technologies evolve.

From a teaching perspective, students should understand where each architecture shines and how they relate:

| Architecture Type | Typical Use Cases | Key Course Concepts |

|---|---|---|

| PLCŌĆæbased cells | Discrete manufacturing, material handling, packaging lines | Ladder logic basics, I/O mapping, interlocks, startup/shutdown sequences |

| DCS | Process plants, utilities, large continuous operations | Function blocks, control loops, plantŌĆæwide coordination, alarm philosophy |

| Custom control systems | OEM machines, specialized lines | Requirements gathering, integration with legacy systems, userŌĆæcentric HMI design |

A fundamentals course should not turn students into fullŌĆætime programmers in the first week. Instead, it should use small, realistic examples to show how PLC logic, DCS strategies, and machineŌĆælevel controllers fit into an overall control architecture, including how they respond to power loss, abnormal conditions, and human intervention.

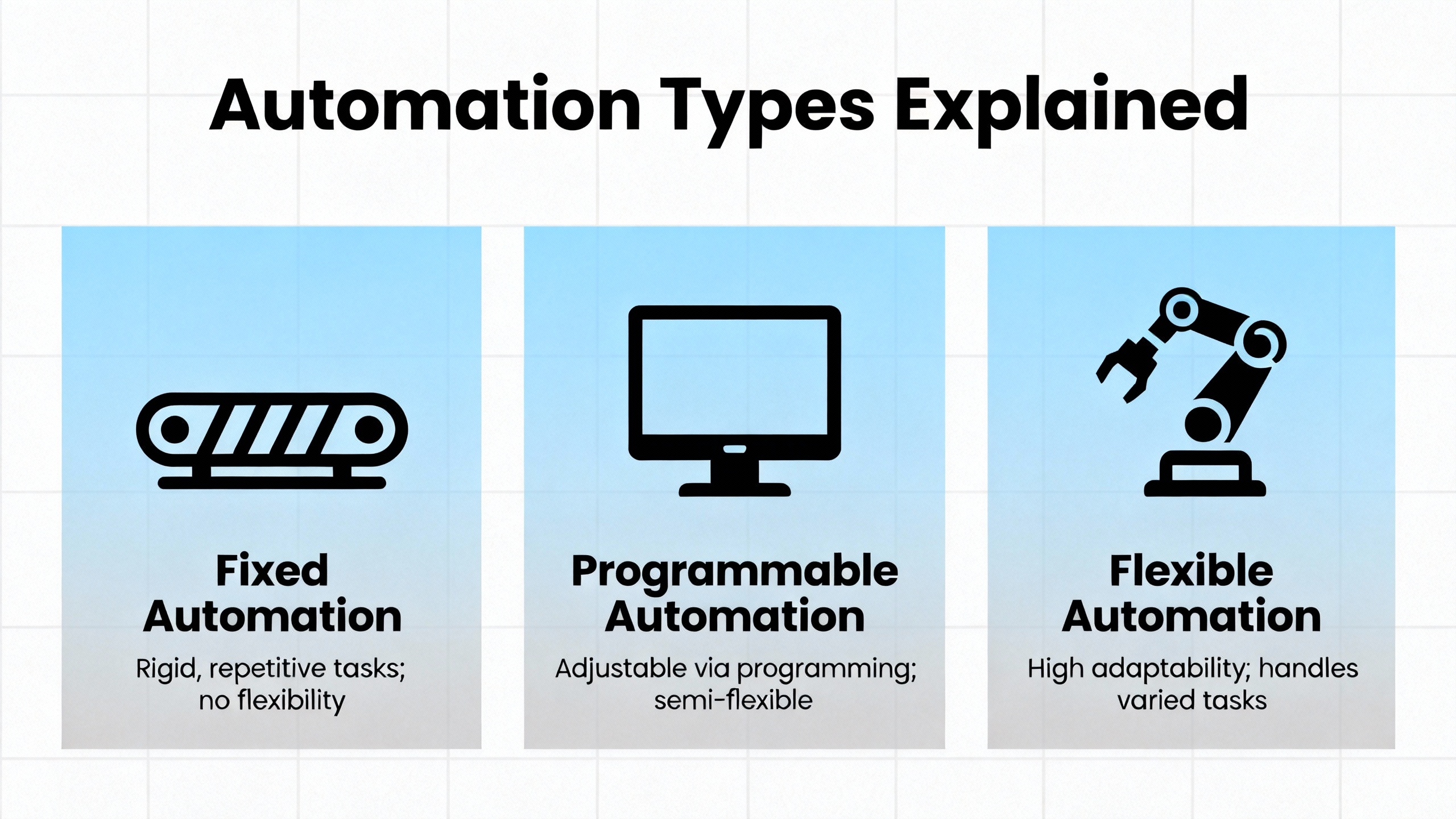

Pacific Blue Engineering and Advantech highlight three broad categories of automation that every learner should recognize.

Fixed automation suits highŌĆævolume, unchanging tasks. Once installed, it runs very efficiently but is hard to reconfigure. Programmable automation supports batchŌĆæstyle changes, such as reconfiguring an AGV route or a robotic pick pattern between product runs. Flexible automation, often AIŌĆæenabled, adapts rapidly to changing orders or product mixes.

For students, the important competency is not memorizing labels but understanding tradeoffs. Fixed automation can be costŌĆæeffective for stable, highŌĆævolume products but becomes a liability if the product mix changes. Flexible automation offers agility but increases complexity in integration, power demand profiles, and maintenance.

When power reliability is weak, highly flexible automation with many intelligent devices can actually be more fragile than simpler fixed systems. That is exactly why power quality and protection must be woven into the fundamentals course rather than treated as an afterthought.

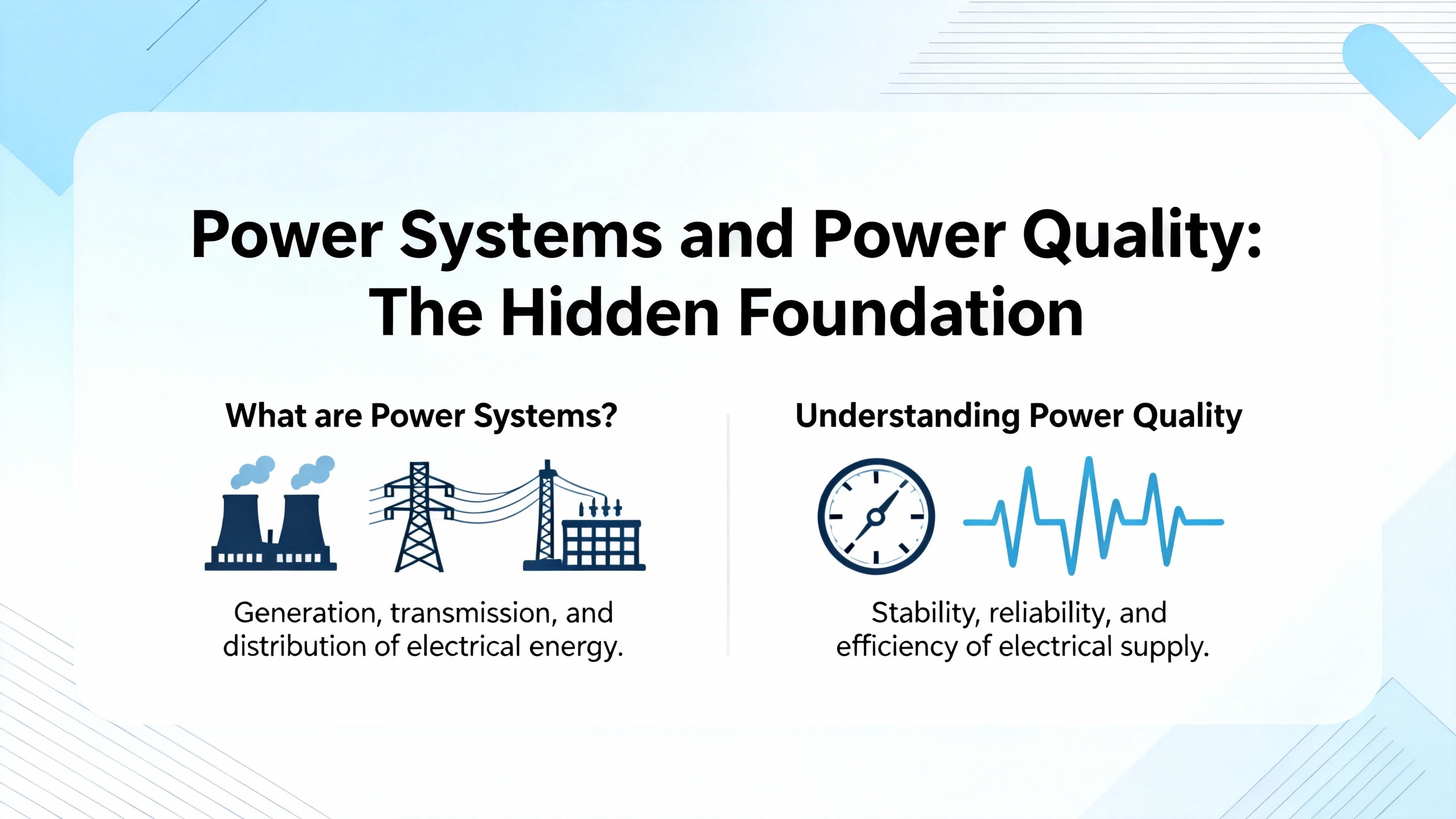

JHFosterŌĆÖs work on industrial power systems makes a point that aligns closely with what I see in the field: automation is only as robust as the power feeding it. Power quality is defined there as having a stable, appropriately rated voltage supply that meets or exceeds equipment requirements without harmful fluctuations or interruptions. Poor power quality leads to failures, downtime, and corrupted data, particularly in automationŌĆæheavy plants.

A fundamentals course should treat power as a firstŌĆæclass topic alongside PLCs and networks. Engineers should be comfortable discussing:

Clean, continuous power and its impact. Maintaining clean, continuous power minimizes sudden stops of robots and control systems, extends equipment life by reducing stress from frequent voltage fluctuations, and improves data integrity in IoTŌĆæbased control systems. This is particularly critical in regulated sectors like pharmaceutical and medical device manufacturing, where JHFoster notes that data integrity underpins compliance.

Backup power and UPS. JHFoster recommends installing backup power using uninterruptible power supplies to provide immediate power during outages, allowing controlled shutdowns that protect equipment and preserve critical data. In practice, this means teaching students how UPS systems interface with control panels and servers, how they signal lowŌĆæbattery conditions to the control system, and how automation logic should behave when running on backup power.

Surge protection and protective coordination. SurgeŌĆæprotective devices shield sensitive automation equipment from voltage spikes. JHFoster points out that these devices reduce downtime, maintenance, and premature failures. For learners, the key is understanding where surge protection belongs in the electrical hierarchy and how it protects PLCs, HMIs, drives, and network infrastructure.

Power system sizing and scalability. JHFoster recommends starting with a thorough assessment of facility loads, voltage levels, and critical systems to size and specify appropriate power equipment for current and future automation. That mindset belongs in the classroom. When students calculate power requirements for an automation cell, they should also consider inrush currents for drives, critical vs. noncritical loads, and how future robotics or AI servers might change the power profile.

Without these competencies, it is easy to design a sophisticated control system that collapses the first time a voltage sag coincides with a production surge.

Automation that is fast and powerful but unsafe is not an asset; it is a liability. Automation Electric & Controls stresses that safety and compliance must be top priorities in industrial environments, not only for worker protection but also for efficiency and product quality.

A fundamentals course should embed several safety and standards topics early.

UL508A and control panel safety. UL508A is described by Automation Electric & Controls as the industry standard for control panels operating at or under 1,000 V, recognized by both the National Electrical Code in the United States and the Canadian Electrical Code. Panels earn this certification only after passing tests for overcurrent protection, general safety, and reliability across all components, including motor drives, switches, contactors, terminal blocks, and transformers. Teaching students what UL508A covers, how to read a UL panel label, and why specifying ULŌĆælisted components improves safety and reliability is foundational.

Risk assessment and mitigation. The same source highlights proactive risk assessment of workstations, equipment, and procedures to identify potential problems. With modern analytics and predictive maintenance tools, risk detection is easier, but they emphasize not abandoning traditional walkŌĆæthroughs. Students should learn basic hazard identification methods and how to link them to automation design decisions, such as adding interlocks, eŌĆæstops, or safetyŌĆærated controllers.

Compliance checks, training, and continuous monitoring. Regular compliance audits, structured checklists, and OSHAŌĆæstyle guidance for PPE are presented as effective ways to keep safety practices aligned with standards. Automation Electric & Controls stresses that safety training is not a oneŌĆætime event but an ongoing obligation with refresher courses and drills. The course should mirror that philosophy by repeatedly connecting theory to safe work practices around panels, UPS systems, and live testing.

Standards and integrator best practices. The Control System Integrators Association (CSIA) has updated its Best Practices Manual to align with modern cybersecurity standards such as ISO 27001 and the NIST Cybersecurity Framework. ISA is also highlighted as a key source of standards for automation, cybersecurity, alarm management, and manufacturing data models such as ISAŌĆæ95. Introducing students to CSIA and ISA as authoritative bodies, and explaining why integrators lean on their frameworks, builds a realistic perspective on how safety and security are enforced in practice.

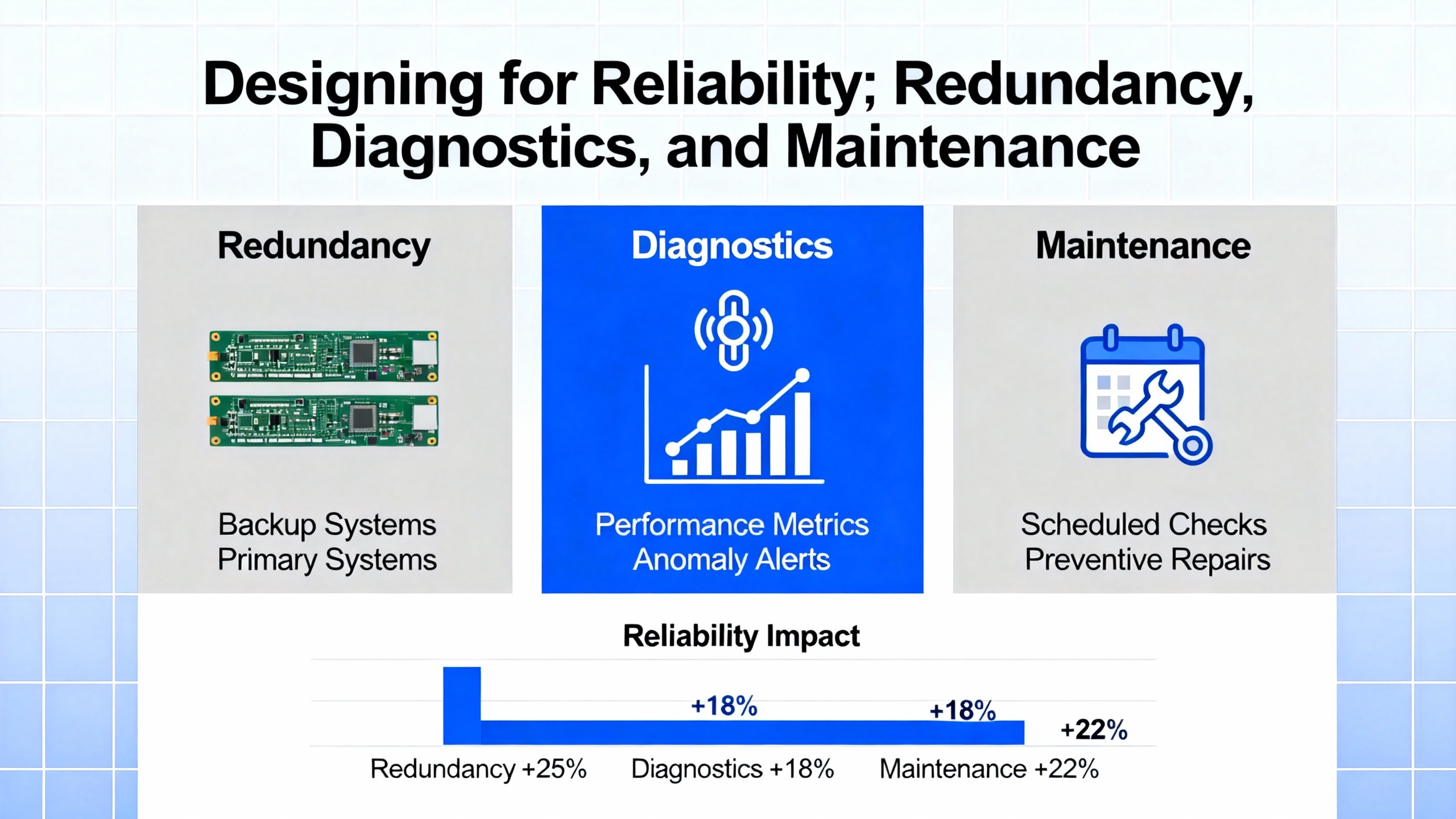

Reliability engineering is often treated as an advanced topic, but CNCTech makes it clear that reliability planning should start early. They define reliability as the discipline that protects uptime and product quality while avoiding emergency repairs and elevated defect rates.

Key concepts that belong in a fundamentals course include faultŌĆætolerant design, redundancy, diagnostics, and maintenance strategy.

FaultŌĆætolerant and redundant design. CNCTech describes fault tolerance as designing systems that anticipate failures and keep operating, often at reduced capacity, through redundancy and graceful degradation rather than complete shutdown. They recommend starting redundancy with critical sensors, controllers, and power paths, then extending to drives and network interfaces, often in N+1 configurations. Distributed control, where intelligence is spread across multiple nodes, helps avoid single points of failure when paired with clear data paths and synchronization.

Diagnostics and telemetry. CNCTech emphasizes continuous selfŌĆædiagnostics and telemetry feeding a centralized dashboard with actionable alerts and responseŌĆætime targets. Center Diesel MachineŌĆÖs discussion of automated process control systems adds that realŌĆætime data analytics can detect bottlenecks early, optimize setpoints, and produce productivity gains of up to 20 percent while reducing unplanned downtime, citing studies from McKinsey. Together, these sources point to the need for students to understand not just how to control processes, but how to monitor and diagnose them.

Maintenance strategies and planning. CNCTech and Tessy Automation both highlight preventative maintenance as critical: fixing small issues early reduces the risk of major repairs that require taking systems offline. Maintenance strategies should align with production schedules, define preventive maintenance intervals based on field data, and ensure critical spares are stocked. For a fundamentals course, it is enough to teach the principles of preventive vs. reactive maintenance, how to interpret basic diagnostic data, and how to design control sequences that support safe maintenance conditions.

Modern automation is inseparable from data. Pacific Blue Engineering notes that automated warehouse systems integrate hardware such as robots and conveyors with software such as WMS, WES, and WCS to deliver faster task execution, higher accuracy, and easy scalability. McKinsey research cited there indicates automated picking can improve cycle time and fulfillment speed by up to 300 percent, while other studies report operational cost reductions of 20 to 30 percent from automation and smarter control.

Center Diesel Machine further emphasizes that realŌĆætime analytics is the backbone of smart manufacturing. By analyzing streaming process data, companies can detect deviations early, reduce variability, and achieve meaningful productivity gains; they cite Deloitte findings that combining automated process control with analytics can reduce operational costs by about 15 percent.

From a learning standpoint, students must grasp a few essentials:

They should recognize the role of sensors and data acquisition in feeding control decisions and reliability analytics. They should understand, at a conceptual level, how predictive maintenance uses historical and live data to identify patterns that precede failures. They should see how dashboards, alarm systems, and even digital twinsŌĆövirtual replicas of plant assets discussed in Control EngineeringŌĆöhelp engineers test operating strategies and responses to abnormal conditions without risking live production.

These are not optional extras. As Rockwell Automation highlights in its commentary on reshoring, manufacturers that can systematically identify suitable processes for automation and optimize them using data will be better positioned to sustain competitive advantage.

Automation does not eliminate the need for skilled human operators; it changes their role. The OnePetro work on automated control systems describes the ŌĆ£automation paradoxŌĆØ: as systems become more automated, effective integration of human contributions becomes even more important. Automated systems clearly improve efficiency, reliability, and safety, but they can erode operatorsŌĆÖ skills and decisionŌĆæmaking ability if humans are rarely engaged.

Researchers at the University of Pittsburgh, as summarized in that source, are exploring how to design control systems that combine the strengths of automation with optimal human performance. Their work with licensed reactor operators in simulators looks at how varying task configuration, level of automation, and override authority affects both human and system performance.

For a fundamentals course, the key message is simple but powerful. Automation professionals must design HMIs, alarms, and procedures that keep operators meaningfully engaged, not just waiting passively for something to go wrong. Lafayette EngineeringŌĆÖs emphasis on HMIs as the visual and interactive layer between operators and machines reinforces this. Students should learn how good HMI design, alarm management based on ISA guidance, and clear operating states can help operators manage more equipment safely, not less.

Bringing these strands together, an effective Fundamentals of Industrial Automation course should explicitly build a set of core competencies that map to real plant needs. The following highŌĆælevel competency map draws on guidance from ASI, CNCTech, JHFoster, Automation Electric & Controls, Lafayette Engineering, Bratney, and others.

| Competency Area | What Learners Should Be Able to Do | Representative Industry References |

|---|---|---|

| Control basics | Explain how PLCs and DCS architectures work, write and read simple logic, and understand how sensors and actuators fit into control loops | Lafayette Engineering, Norwalt, Tessy Automation |

| Power quality and protection | Describe power quality, size basic loads, explain the role of surge protection and UPS, and discuss how power events affect automation | JHFoster |

| Safety and compliance | Interpret UL508AŌĆÖs relevance, outline a basic risk assessment, and describe ongoing safety training and audits | Automation Electric & Controls, CSIA, ISA |

| Reliability and redundancy | Differentiate singleŌĆæpoint vs. redundant designs, explain N+1 concepts, and appreciate the role of diagnostics and preventive maintenance | CNCTech |

| Data and analytics | Understand the purpose of telemetry, dashboards, and predictive maintenance, and relate them to uptime and cost | Pacific Blue Engineering, Center Diesel Machine, Control Engineering |

| Human factors and HMI | Recognize the automation paradox, describe the role of HMIs and alarm management, and explain why operator engagement matters | OnePetro, ISA |

| Implementation and change | Summarize best practices for selecting systems, working with vendors, and training staff for new automation | Bratney, Rockwell Automation, Wolters Kluwer |

In my experience, the most capable automation engineers are those who see these areas as a coherent whole. When they design a panel, they think about UL508A compliance, power quality, diagnostics, human access, and future expansion in one pass. An effective fundamentals course helps students practice that integrated thinking early, before they form siloed habits.

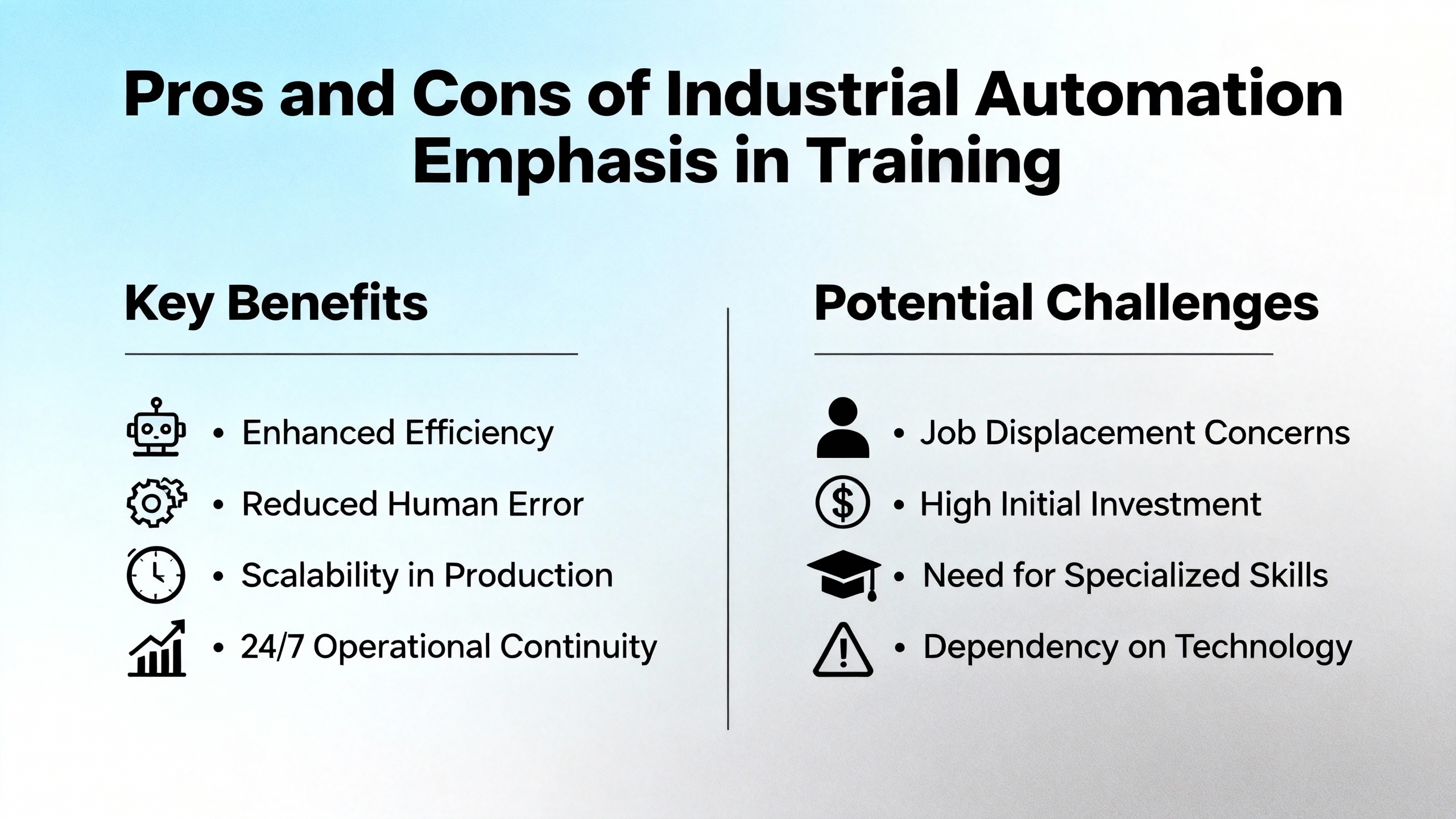

Several sources, including Bratney and Nintex, underline that automation brings both benefits and risks. A balanced course should help learners articulate both sides convincingly.

On the benefit side, industrial automation improves productivity and efficiency, supports consistent product quality, reduces labor costs, and can cut waste and scrap. Pacific Blue Engineering cites studies showing substantial cycleŌĆætime improvements and cost reductions from wellŌĆæimplemented automation. Picomto notes that broader industrial process optimization, reinforced by digital tools, can lead to meaningful reductions in defects and production costs.

OSHAŌĆæaligned safety practices and wellŌĆædesigned automated systems also improve worker safety by removing people from hazardous tasks, a theme echoed across Lafayette Engineering, Automation Electric & Controls, and Bratney. In the power domain, JHFosterŌĆÖs recommendations around surge protection and backup power help reduce failure rates and protect critical data.

On the risk side, Bratney points to high upfront investment, reduced flexibility if systems are poorly specified, risk of costly downtime, and the need for skilled operators and maintenance teams. Nintex adds that integration with legacy systems and organizational change managementŌĆöparticularly employee resistance and skills gapsŌĆöare significant challenges.

For future automation professionals, the lesson is not to be either an automation enthusiast or a skeptic, but a clearŌĆæeyed reliability advisor. They should learn to ask, for each proposed automation change, how it affects power demand and protection, safety compliance, maintainability, data visibility, and human roles. That mindset is a core competency in itself.

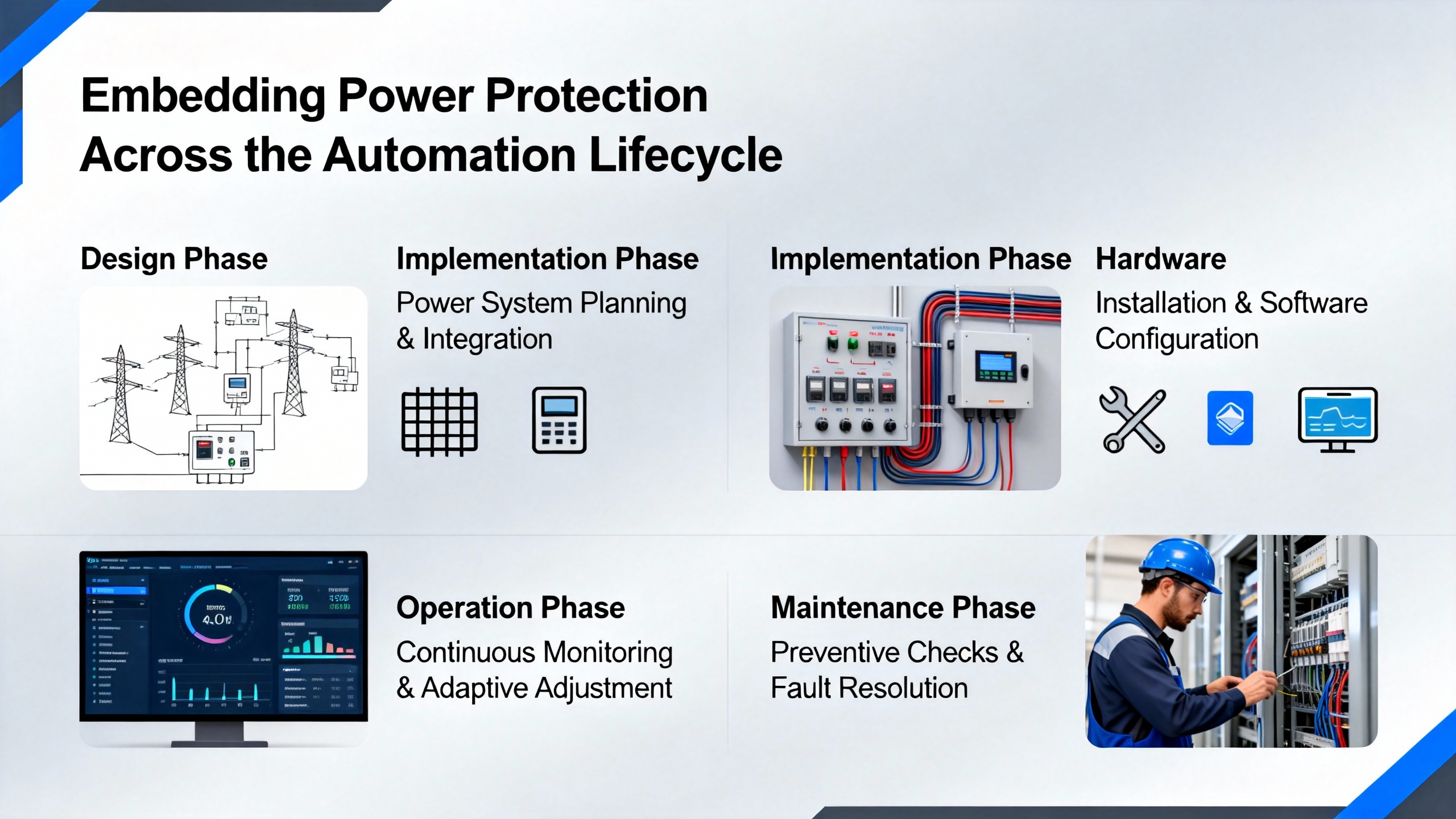

From the vantage point of power systems, the most effective fundamentals course is one that embeds power protection into every phase of the automation lifecycle rather than isolating it in a single lecture.

In the design phase, students should routinely assess whether proposed PLC cabinets, drive panels, and networking racks have adequate surge protection, proper grounding, and clearly identified critical loads that belong on UPS. ASIŌĆÖs emphasis on auditing existing systems before integration aligns well with this approach.

During implementation, they should understand how staged rollouts, as suggested by ASI and CNCTech, can reduce production risk. That includes testing how systems behave under simulated power disturbances, verifying that controlled shutdown sequences actually protect equipment and data, and confirming that compliance requirements such as UL508A are met.

In operation, they should appreciate that realŌĆætime monitoring, predictive maintenance, and periodic compliance audits are not separate disciplines. As Automation Electric & Controls and CNCTech both emphasize, continuous monitoring and adaptation of procedures are essential for safety and reliability. Power quality meters, UPS diagnostics, and breaker monitoring should be seen as part of the same monitoring fabric as process instrumentation.

When a fundamentals course treats power quality, protection, automation architectures, and human factors as intertwined topics, graduates are far better prepared to design and operate resilient systems.

Yes. JHFosterŌĆÖs work on industrial power systems shows that poor or unstable power can cause equipment failures, unplanned downtime, and corrupted data, especially in automationŌĆæheavy plants. Without at least a foundational understanding of power quality, surge protection, and UPS concepts, automation professionals are at a disadvantage when diagnosing realŌĆæworld problems. Even a modest module on power basics dramatically improves their ability to design reliable systems and to communicate effectively with electrical teams.

Automation Electric & Controls, CSIA, and ISA all make it clear that safety and compliance are central, not peripheral, to automation practice. Fundamentals students do not need to become code experts, but they should leave with a working understanding of why UL508A matters, how risk assessments support design decisions, and how ongoing audits and training keep systems safe. That grounding helps them make better technical choices and positions them to collaborate productively with safety and compliance professionals.

It is realistic if the course focuses on concepts rather than depth in every tool. Learners can practice PLC logic on small, focused exercises while also being introduced to how telemetry and analytics support predictive maintenance, using examples from CNCTech, Pacific Blue Engineering, and Center Diesel Machine. The goal is not to turn students into data scientists, but to help them see PLCs, power protection, diagnostics, and analytics as elements of a single reliability ecosystem.

Industrial automation is evolving quickly, but its fundamentals remain rooted in the same essentials: sound control architectures, clean and resilient power, disciplined safety and reliability practices, and thoughtful integration of human operators. A wellŌĆædesigned Industrial Automation Fundamentals course that builds these core competencies does more than teach tools. It forms engineers and technicians who can act as trusted reliability advisors, capable of designing automation that stays online, protects people and equipment, and delivers consistent performance shift after shift.

Leave Your Comment