-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

When an ABB motor refuses to start, keeps tripping, or runs erratically, the instinct on many factory floors is to immediately blame the motor. In practice, especially with ABB equipment, most ŌĆ£motor not workingŌĆØ situations are system problems that sit at the intersection of the motor, the drive or soft starter, the power supply, and the mechanical load.

From field audits and root-cause investigations across plants, pumping stations, and commercial HVAC systems, a consistent picture emerges. ABB motors and drives are built to be robust and efficient, but they are unforgiving of poor wiring, weak power quality, bad parameters, or neglected maintenance. The upside is that most failures are preventable and, with a structured diagnostic approach, you can usually get back online without guesswork.

This article walks through how to diagnose an ABB motor that is not working, grounded in practices highlighted by ABBŌĆÖs own guidance and by experienced service organizations such as Delta Automation, IBT Industrial Solutions, Megger, and others. The focus is practical: what to check, how to interpret symptoms, and how to avoid repeat failures.

ABB electric motors are widely used because they are reliable, efficient, and designed for long service life. Their portfolio spans induction motors for general industrial duties, synchronous motors for precise speed and position control, and servo motors for high-accuracy applications. In industrial and commercial buildings they drive pumps, fans, compressors, conveyors, and process machinery, often under harsh conditions.

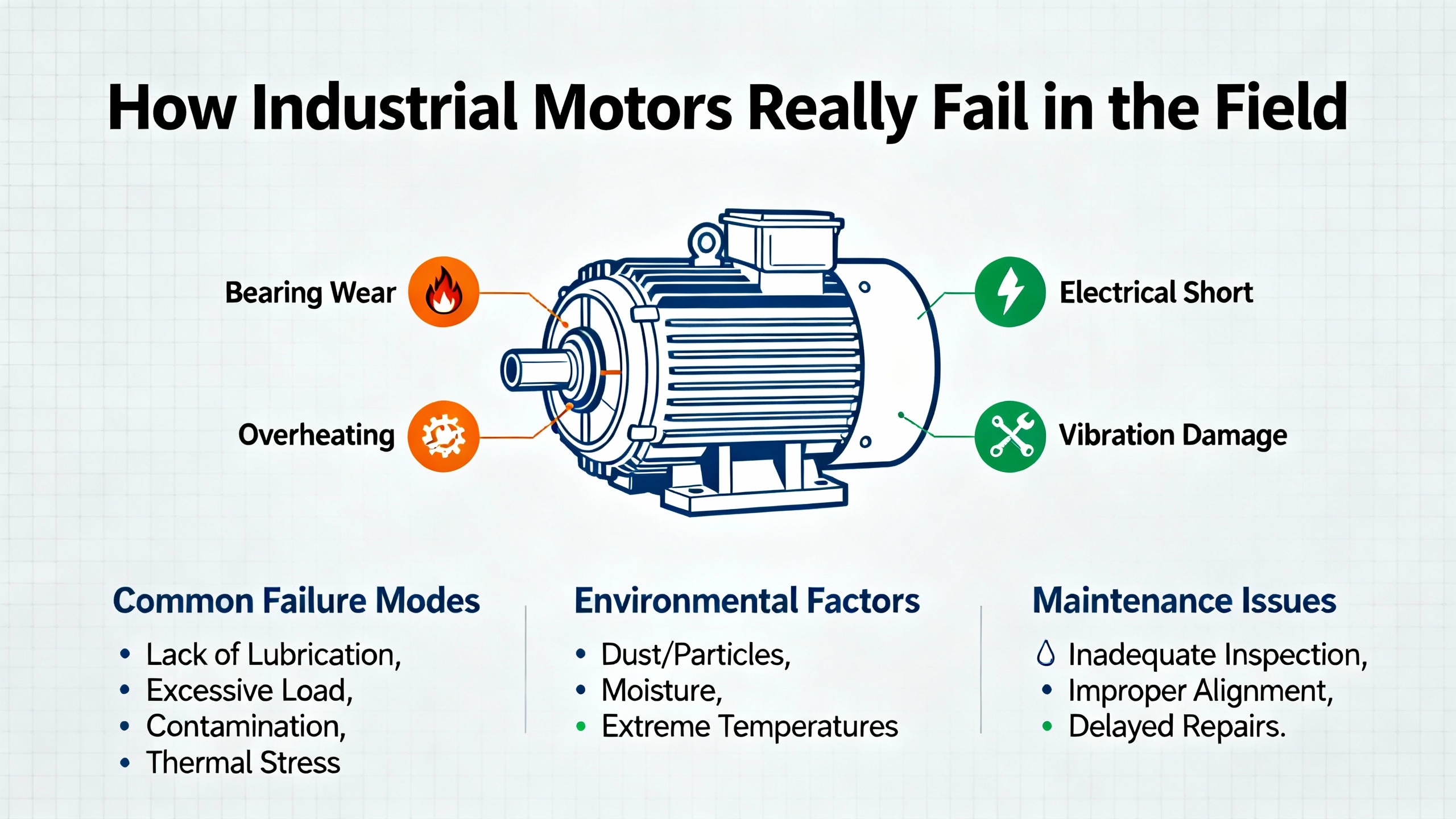

Several independent sources converge on the same reality. Large proportions of electric motor failures are preventable if early warning signs are taken seriously. IBT Industrial Solutions notes that nearly 80 percent of motor failures can be avoided by acting when the first symptoms appear instead of waiting for catastrophic failure. Duke Electric emphasizes that bearing failure alone accounts for about 51 percent of motor failures, but that bearings usually fail because something else in the system is wrong. Motion Drives highlights that overheating is particularly destructive, with around 55 percent of insulation failures driven by excessive temperature and every increase of roughly 18┬░F cutting insulation life roughly in half. Fluke points out that about 30 percent of failures are related to overloading and around 13 percent are directly attributed to bearing problems, which in turn represent more than 60 percent of mechanical failures in many facilities.

Put simply, ABB motors generally do not fail ŌĆ£out of the blue.ŌĆØ They fail because something upstream or downstream has been stressing them for a long time: poor power quality, misapplied drives, bad alignment, contamination, or weak maintenance practices.

Before you dive into detailed electrical testing, take the time to interpret what the system is telling you. Leading maintenance providers and motor specialists describe a consistent set of early warning signs.

Overheating is the silent motor killer. IBT describes motors that are hot to the touch, discolored paint on the housing, and fans choked with dust or debris. An increase of around 18┬░F, even briefly, can damage winding insulation and dramatically shorten motor life. Overheating often reflects blocked cooling paths, incorrect voltage, poor power quality, an overloaded motor, or a fan that is not moving air.

Vibration and unusual noises are another primary red flag. Grinding, rattling, or humming sounds from an ABB motor, especially when combined with noticeable vibration, almost always point to mechanical problems such as worn bearings, misalignment, shaft imbalance, loose mounting feet, or unbalanced magnetic forces. IBT and Motion Drives both stress that vibration accelerates wear across the system and must be addressed early.

Frequent tripping of circuit breakers or blowing fuses indicates deeper electrical issues. This behavior can signal excessive current draw, short circuits, or winding problems. Northend Electric and Fluke both highlight the importance of determining whether you are dealing with a genuine overload, a short, or a power quality issue such as phase loss or voltage imbalance.

Decreased performance and efficiency show up as slower speed, lost torque, or sagging process throughput. This typically reflects internal damage, misalignment, or deteriorated insulation. IBT notes that motors nearing failure often consume more energy than usual for the same load, quietly inflating energy bills.

Irregular motor operation, such as sudden stops, intermittent running, or difficulty starting, must never be ignored. These symptoms can result from electrical faults, control problems, or mechanical binding. IBT warns against repeated restart attempts in such cases. Short cycling, where operators keep trying to start a motor that will not run, adds enormous thermal stress and can turn a repairable issue into a destroyed machine.

The key is to capture these symptoms carefully. Many service organizations encourage technicians to maintain baseline data for motors, including nameplate information, ambient conditions, vibration levels, temperatures, and power consumption, then compare current readings against that baseline. IBT, Fluke, and Megger all emphasize this data-driven approach as the backbone of effective reliability programs.

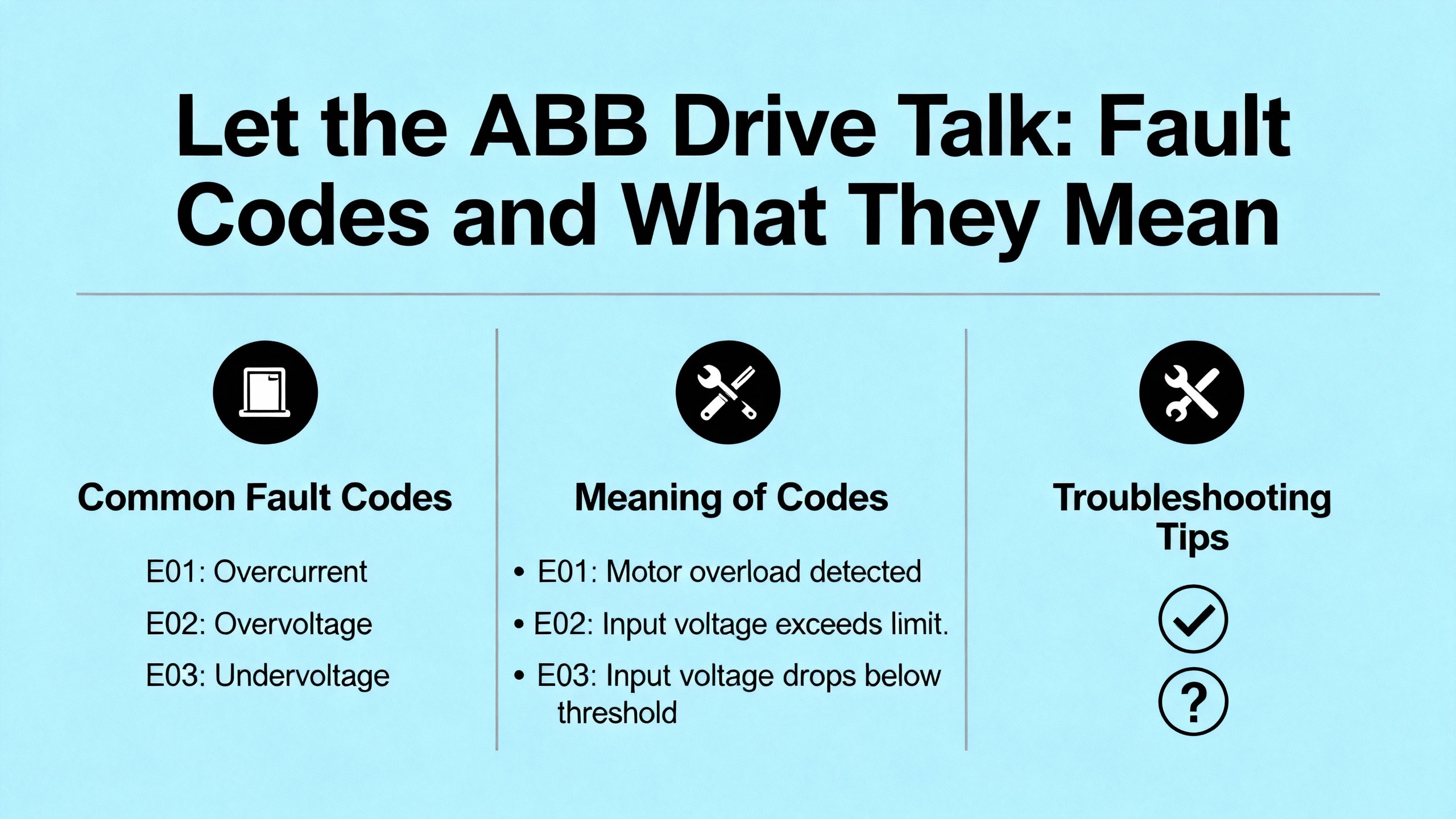

In many ABB installations the motor is controlled by a variable frequency drive such as the ACS355, ACS580, or ACS880 family, or by a soft starter from series like PSTX, PSR, or PSE. These devices exist not just to control speed and torque, but also to protect the motor and themselves. When something abnormal occurs, they trip on fault rather than silently letting the motor burn.

Delta Automation, which specializes in ABB drives, stresses that efficient troubleshooting starts by reading the fault code and reviewing event history, including timestamps and operating state. ABB drives present clear fault codes on the local keypad, and higher-end models also log events accessible through the keypad or ABBŌĆÖs Drive Composer software.

Common ABB drive fault codes are particularly informative. Delta Automation highlights several examples:

| ABB fault code | Meaning | Typical underlying issues | Key checks and actions |

|---|---|---|---|

| F0001 | Overcurrent | Sudden load increase, short circuit, too-rapid acceleration | Look for mechanical binding, jams, or seized pump impellers; extend acceleration time; inspect motor cables for shorts. |

| F0002 | Overvoltage | Excessive input voltage, aggressive deceleration without braking | Verify supply voltage; inspect or add dynamic braking resistors; increase deceleration time. |

| F0003 | Undervoltage | Input dips, missing phase, weak upstream supply or UPS/inverter issues | Confirm stable three-phase power; check for loose conductors, blown fuses, and upstream power problems. |

| F0005 | Device overtemperature | High ambient temperature, blocked airflow, dirty cooling paths | Clean filters and heatsinks; ensure adequate clearance; consider external cooling in severe environments. |

| F0010 | Motor stalled | Load too heavy, motor cannot reach speed, mechanical jam | Inspect driven machine for jamming; confirm motor sizing and torque limits; test windings for damage. |

| F0022 | Earth fault (ground fault) | Ground fault in motor or output cables | Use an insulation tester on motor leads; inspect cable insulation and terminations. |

| F0023 | Internal fault (control or firmware) | Control-board failure, firmware corruption, deep hardware problem | Power-cycle the drive; if recurring, involve qualified service or consider drive repair or replacement. |

CM Industry Supply Automation notes that many ABB drive issues are rooted in human error: incorrect wiring, wrong parameters, or poor matching between drive and motor. Critical settings such as motor full-load amps, base speed, and control mode must be correctly programmed from the motor nameplate. The drive type must also match the load profile, for example using constant-torque drives where high starting torque is required.

As a reliability advisor, I recommend making the drive keypad or HMI the first diagnostic stop. Confirm the active fault code, review the last several events, and write down or photograph the values before clearing anything. This simple practice, championed by Delta Automation and others, can save hours of guesswork.

Once you have captured the symptoms and drive fault information, you can move into a structured diagnostic workflow. Several technical sources and service providers describe broadly similar steps, which align well with practical field experience.

IBT Industrial Solutions and Fluke both emphasize the value of baseline data. Before you start disconnecting components, record the motorŌĆÖs nameplate data, including voltage, current, power rating, and speed. If possible, note the serial number and keep a photo of the nameplate. This helps confirm that the drive settings match the motor and that the motor is correctly sized for the application.

Record ambient temperature, humidity, and any obvious environmental factors such as dust, corrosive vapors, or exposure to weather. Document how the system was running when the fault occurred: startup, ramping, steady load, or deceleration. This context is invaluable when interpreting drive events and test results.

Many ABB motor issues can be spotted with nothing more advanced than eyes, ears, and hands. ABB and partners like Equipmake and HMFT repeatedly stress basic inspections and housekeeping.

Start by examining the motor exterior and surrounding area. Look for darkened paint, burn marks, cracked terminal boxes, oil or grease leakage, and evidence of overheating. Inspect the cooling fan and vents for dust, debris, or damaged blades. Several drive repair articles warn against using compressed air, which can push contaminants deeper; instead they recommend vacuuming and carefully wiping surfaces.

Check for loose mounting bolts and uneven feet. Fluke and other experts describe ŌĆ£soft foot,ŌĆØ where an uneven base or foot casting causes the frame to distort when the bolts are tightened. Soft foot does more than cause vibration; it can introduce misalignment and stress that drive repeated failures.

Rotate the shaft manually (with the system safely de-energized and locked out). Feel for roughness, tight spots, or grinding that suggest bearing damage. Listen for noise during normal operation as well. Sources such as IBT, Motion Drives, and HMFT all highlight bearing wear as one of the most common and preventable failure modes.

If the motor drives a pump, fan, or gearbox, check coupling alignment, belt tension, and the driven equipment itself. Misalignment and mechanical binding are frequent root causes of drive trips blamed on ŌĆ£electrical faults.ŌĆØ HMFTŌĆÖs pump-focused experience shows that small misalignments between motor and pump shafts can quickly escalate into vibration, seal failures, and bearing damage.

With mechanical checks underway or completed, verify that the motor is supplied by clean, stable power. FlukeŌĆÖs discussion of motor failures places power-quality issues near the top of the list. Voltage imbalance, transient overvoltages, and harmonics all drive extra heating and stress.

At the supply side, inspect terminals, lugs, and bus bars for looseness, corrosion, and discoloration. Smart Elemech notes that loose connections and aging components are frequent culprits in ABB power supply problems. Use a multimeter or power quality meter to confirm that three-phase line voltages are within the motorŌĆÖs rating and reasonably balanced between phases. Undervoltage can cause overcurrent, and persistent imbalance leads to overheating, particularly in one phase.

Inspect breakers, fuses, and protective relays. Northend Electric and IBT both point out that frequent breaker trips signal genuine issues that must be addressed rather than simply resetting devices. Confirm trip settings relative to motor full-load current. Consider whether upstream UPS systems, inverters, or generators are correctly sized and configured; MeggerŌĆÖs guidance on generators notes that degraded insulation or poor maintenance can undermine backup power exactly when it is most needed.

If the motor is fed by an ABB soft starter, review starter fault codes and settings. ABBŌĆÖs soft starters, as described by Synchronics and ABB channel partners, use SCR modules, thermal protection, and current balancing to limit inrush and protect motors. Soft starter faults related to phase loss, overtemperature, or overcurrent frequently trace back to supply issues or load conditions rather than to the motor itself.

Once safety has been verified and lockout procedures are in place, more advanced electrical tests can confirm the health of the ABB motor. Megger, Motion Drives, Repairwise, and DP Brown all stress insulating and winding tests as fundamental.

Insulation resistance testing is the first line of defense. Using an insulation tester (often referred to as a megohmmeter), measure resistance between each phase and ground, and between phases where applicable. MeggerŌĆÖs application notes recommend insulation resistance and polarization index tests to detect early-stage insulation wear, moisture ingress, or contamination. IBT and Motion Drives both highlight that insulation breakdown is a leading cause of winding failure.

ABB drive repair specialists caution against performing insulation tests through the drive electronics. CM Industry Supply Automation specifically recommends disconnecting motor leads from the VFD and testing only on the motor and cables to avoid damage to drive components.

Low resistance winding tests complement insulation measurements. Motion Drives describes low resistance between windings as a common failure mode when insulation breaks down between turns or phases. Using an ohmmeter or dedicated low-resistance tester, compare winding resistances. Significant imbalance between phases suggests winding damage or poor connections.

Surge testing, as described by Megger and Repairwise, can reveal weak insulation and turn-to-turn faults not visible in standard resistance tests. Surge tests apply high-voltage pulses to the windings and analyze the response. Because surge testing involves elevated voltages and interpretation of waveforms, it is typically handled by specialized service shops or in-house teams trained for the task.

Taken together, these tests paint a clear picture of electric health. If insulation resistance is low, polarization index is poor, and surge tests show weaknesses, motor rewinding or replacement is almost always more cost effective than repeated in-service failures.

ABB has published detailed guidance on bearing currents in drive systems, particularly in variable speed drive applications. In some installations, induced voltages on the shaft discharge through the bearings, causing electric discharge machining of races and rolling elements. The result is distinctive fluting, increased noise and vibration, and ultimately early bearing failure, sometimes within only a few months.

Historically, inductive circulating currents were mainly an issue in larger motors. ABB notes that for motors at or above typical IEC 280 or comparable NEMA frame sizes, the solution has long been to use an insulated bearing to break the current path. More recently, ABB engineers have documented capacitive induced bearing currents in smaller motors up to roughly 55 kilowatts in some variable speed drive applications. These problems are closely tied to installation details and common mode voltage patterns in the drive system. Their data suggests that grounded networks present higher risk than floating networks, although the sample size remains limited.

Bearing current issues often manifest first as increased noise and vibration, much like more conventional mechanical failures. ABB recommends measuring shaft-to-frame voltage during commissioning when there is any concern, though there is no single universal threshold for acceptable voltage. If problematic bearing currents are confirmed in a correctly installed system, ABB suggests several mitigations. One approach is to use insulated bearings at both drive and non-drive ends, or to adopt hybrid bearings with ceramic rolling elements that provide electrical insulation as well as reduced friction and longer relubrication intervals. When both bearings are insulated but the motor is rigidly coupled to a grounded gearbox or load, currents can migrate into that equipment. In such cases ABB proposes installing insulating couplings or shaft grounding brushes to divert currents safely to ground.

Long motor cable runs amplify these concerns. An ElectricianTalk discussion of an ABB ACS800 experiencing intermittent overcurrent trips on a remote motor underscores issues related to long cables, reflections, and the need for load reactors. The experienced responder in that discussion also cautions against overlooking mechanical issues, reminding readers that hot or dry bearings can elevate load enough to cause trips, then appear normal after cooling.

In practice, when dealing with long cable runs, high carrier frequencies, or sensitive bearings, it is wise to involve drive specialists or ABB support to evaluate cable selection, grounding strategy, and the potential need for filters, reactors, or shaft grounding devices.

Replacing a failed bearing or rewinding a motor fixes the symptom, not necessarily the underlying cause. Duke ElectricŌĆÖs ŌĆ£essential guideŌĆØ to motor failure makes this point clearly. If fifty-one percent of motor failures are classified as bearing failures but those bearings fail due to misalignment, high ambient temperature, moisture, shaft voltage, or overload, then the real cause lies elsewhere.

Root cause failure analysis (RCFA) provides a structured way to uncover that underlying chain. Duke Electric recommends using techniques such as the ŌĆ£5 Whys,ŌĆØ where investigators repeatedly ask why a component failed, then why that condition existed, and so on, until they reach a correctable root cause. Some failures can be understood with fewer questions; more complex faults may require more iterations.

This discipline is especially important in ABB systems, where motors, drives, soft starters, and power supplies are tightly integrated. For example, a recurring drive overcurrent fault might be traced to a misaligned pump that periodically binds, rather than to a problem with the drive. Replacing the drive without fixing the alignment merely resets the failure clock.

As a power system specialist, I recommend documenting every significant failure using at least a basic RCFA template: failed component, observable symptoms, test results, upstream causes, and corrective actions. Over time, these records will reveal patterns in power quality, environmental control, alignment practices, or maintenance gaps that can be addressed at the system level.

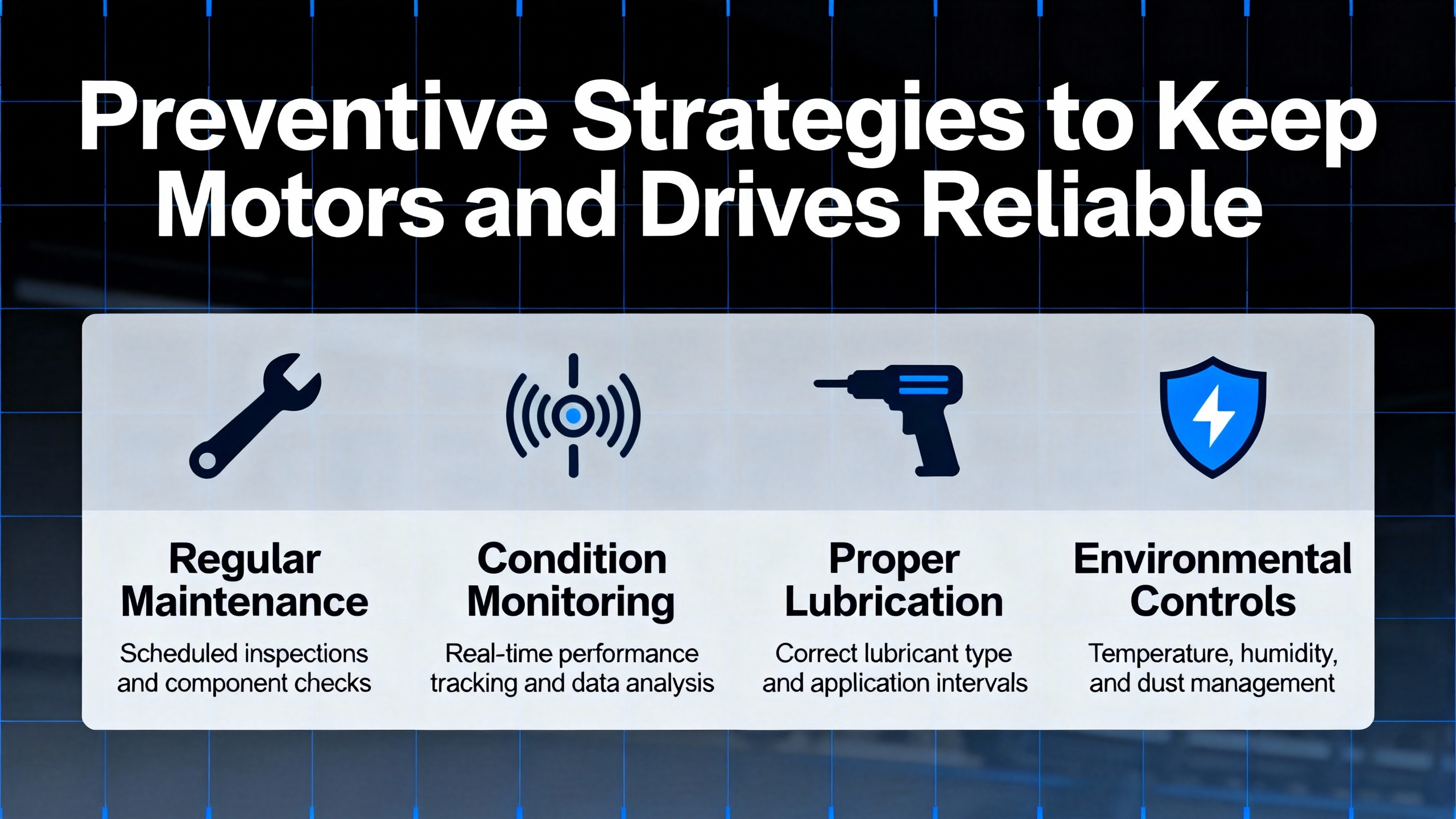

Diagnosis is only half the battle. The most cost-effective plants treat failures as lessons to refine preventive maintenance and condition monitoring. ABB, Delta Automation, DP Brown, IBT, HMFT, Megger, and others all promote proactive programs over reactive repairs.

Both ABB and third-party service providers emphasize the importance of clean cooling. For ABB drives, Delta Automation provides specific guidance. Cooling fans typically last around 50,000 operating hours, and they recommend replacing them proactively every five to seven years to avoid nuisance trips from overheating. Electrolytic DC bus capacitors typically have a five to ten year service life; mid-life testing of capacitance and equivalent series resistance, followed by planned replacement, can prevent costly, catastrophic failures.

For ABB motors themselves, Equipmake and HMFT highlight basic housekeeping: keep housings and fans free of dust, ensure ventilation openings are unobstructed, and avoid installing motors in dead-air pockets with high ambient heat unless additional cooling is provided. Overheating is not merely about comfort; it drives insulation breakdown, lubricating grease degradation, and recurring drive trips.

IBT and Motion Drives both underscore the relationship between temperature and insulation life. Even modest, sustained temperature rises can halve expected insulation life. Maintenance teams should treat elevated temperature as a core reliability metric and respond quickly when hot spots appear.

Routine lubrication and precise alignment are absolutely central to ABB motor longevity. HMFTŌĆÖs experience with motor-pump assemblies shows that proper lubrication minimizes friction and wear, while misalignment between motor and pump shafts is a leading cause of vibration and premature bearing and seal failure.

DP Brown recommends structured lubrication management: selecting the correct lubricant based on manufacturer guidance, monitoring lubricant condition and contamination, and following a consistent lubrication schedule. Over-lubrication can be almost as damaging as under-lubrication, so adherence to ABB recommendations is important.

Alignment services, using laser tools where possible, should be part of the regular preventive maintenance program. Misalignment not only generates vibration but also increases energy consumption and masks itself as ŌĆ£electrical problemsŌĆØ when in fact the motor is simply fighting unnecessary mechanical load.

Environmental control is another recurring theme across technical guidance. DP Brown, Smart Elemech, and Motion Drives all emphasize that dirt, chemicals, moisture, and temperature extremes are major contributors to failure.

Practical measures include locating motors away from heavy contamination sources such as grinding stations, implementing appropriate enclosures where dust or moisture is unavoidable, and ensuring adequate ventilation or climate control in motor rooms and drive cabinets. Smart ElemechŌĆÖs troubleshooting guide for ABB parts stresses keeping terminals and control panels clean, checking for corrosion, and using surge protection in areas prone to lightning or switching transients.

For ABB drives in particular, Delta Automation recommends periodic cleaning of filters and vents, especially in Type 12 enclosures, and inspection of terminal blocks and connectors in high-vibration environments to identify loose or corroded connections before they cause faults or arcing.

Condition monitoring moves maintenance from reactive and time-based actions to data-driven decisions. DP Brown describes how vibration analysis and thermal imaging can detect problems before they escalate. Megger expands this view with a portfolio of static, dynamic, and condition-based tests, including partial discharge monitoring for high-voltage equipment.

ABB offers its own digital tools, such as the ABB Ability Smart Sensor, which converts traditional motors into wirelessly connected devices. As described by DP Brown, these sensors monitor parameters like vibration and temperature and feed data into analytics platforms that flag trends and anomalies. This allows maintenance teams to plan interventions during scheduled downtime rather than during unplanned outages.

Fluke advocates a similar strategy: document operating conditions and specifications at installation, capture and archive critical measurements after maintenance, and regularly compare new data to baseline trends. This approach supports predictive maintenance and better prioritizes limited maintenance resources.

Delta Automation provides a concrete model for structured maintenance on ABB drives that can be adapted for motor systems:

| Time frame | Typical focus areas for ABB drives and motor systems |

|---|---|

| Monthly | Visual inspections, alarm and event log review, quick checks for overheating or noise. |

| Quarterly | Fan and filter inspection and cleaning, review of operating logs, basic vibration checks. |

| Annually | Detailed connector and terminal inspections, internal cleaning, capacitor and insulation testing, alignment verification. |

| Every five years | Fan replacement, capacitor renewal or testing, solder joint inspection, firmware updates or deeper diagnostics. |

While this table is drive-focused, the rhythm translates well for motors. Monthly, technicians should walk routes, listening for unusual noises and feeling for hot housings. Quarterly, they should confirm lubrication, alignment, and cleanliness. Annually, they should perform deeper electrical, vibration, and thermal assessments. Every several years, a more thorough overhaul or replacement plan should be considered for critical units, especially in high-duty-cycle applications.

Even the best diagnostic tools are ineffective without trained people using them. DP Brown and Smart Elemech emphasize training maintenance personnel in proper handling, inspection, and troubleshooting techniques for ABB equipment. This includes understanding drive fault codes, interpreting vibration and thermal images, and appreciating the difference between symptoms and root causes.

Several sources also draw a clear line between what can reasonably be handled in-house and what should be outsourced. CM Industry Supply Automation and Northend Electric both suggest that basic cleaning, tightening, and simple component replacements can be appropriate for in-house teams. However, persistent overheating, repeated drive trips, insulation degradation, complex internal faults, or rewind decisions should involve specialists. Synchronics, Delta Automation, HMFT, IBT, and others all position their professional services around component-level diagnostics, reverse engineering, and controlled testing that most plants cannot replicate.

From a reliability standpoint, this division of labor is essential. It is far safer and more cost-effective to have a professional perform high-voltage surge testing or control-board repairs than to risk improvised fixes on critical ABB assets.

Start by reading the ABB drive or soft starter fault codes and reviewing the event history. Faults such as overvoltage, undervoltage, or internal control-board errors often point toward the drive or upstream power supply. Faults like motor stalled, earth fault, or repeated overcurrent during acceleration require you to examine both the drive and the motor, including mechanical load and wiring. If insulation resistance and winding tests on the motor are healthy but internal drive faults persist, the drive or soft starter is likely the primary issue. Conversely, poor insulation readings, high vibration, or mechanical binding point more strongly to the motor and driven equipment.

If you have repeated faults after addressing obvious issues, if drive fault codes persist as internal errors, if insulation tests show degraded values, or if you see clear signs of severe overheating, arcing, or physical damage, it is time to involve a qualified service provider. High-voltage surge testing, rewinding, bearing current mitigation, and control-board repairs require specialized tools and experience. Many ABB-focused service companies offer remote support as well as in-shop diagnostics, and their involvement often shortens downtime and prevents unsafe repairs.

Soft starters and VFDs greatly reduce inrush current and mechanical stress, and they add valuable protection and diagnostics. However, they do not eliminate the need for good power quality. Fluke and Smart Elemech both stress that voltage imbalance, transients, and harmonics still affect the driveŌĆÖs input stage and can lead to DC bus stress, nuisance trips, and component wear. Drives and soft starters should be seen as part of an integrated power system that includes proper grounding, surge protection, appropriately sized UPS or inverter systems where needed, and good utility or generator practices.

As a power system specialist and reliability advisor, my experience with ABB motors and drives is that they reward disciplined engineering and maintenance. When an ABB motor does not work, resist the urge to guess. Let the drive tell its story, listen to the mechanical symptoms, measure what matters, and trace causes back to their roots. Most failures can be prevented, and with a structured diagnostic approach you can keep your motors, drives, and the processes they power running safely and efficiently for many years.

Leave Your Comment