-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

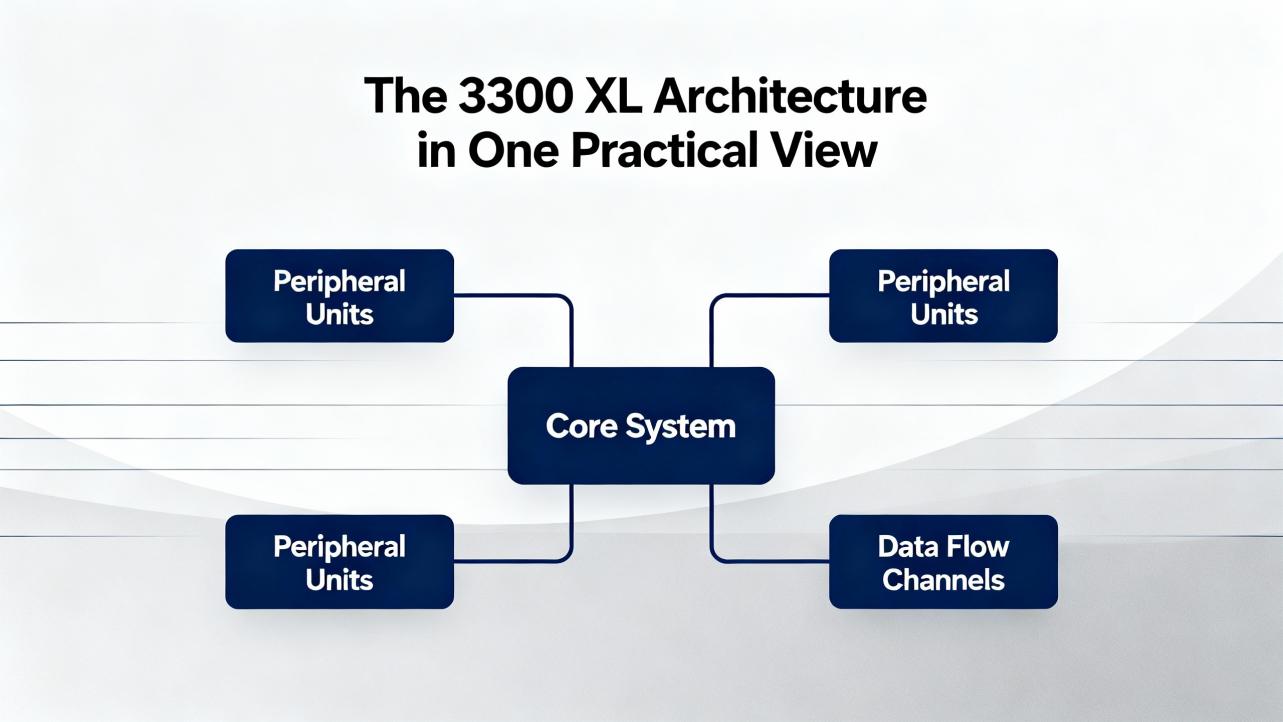

The Bently Nevada 3300 XL family remains a cornerstone of machine protection on turbines, compressors, and generator trains that underpin plant power reliability. In power-critical environmentsŌĆöespecially where large drives feed switchgear, UPS inputs, and essential loadsŌĆökeeping these proximity transducer systems healthy is nonŌĆænegotiable. As a power system specialist and reliability advisor, IŌĆÖve spent years specifying, installing, and troubleshooting 3300 XL components. This article distills what actually matters when you must source replacements, keep compatibility intact, and restore signal integrity without introducing new risk.

The fastest way to put a turbineŌĆægenerator unit, an MV drive, or a process compressor out of service is to lose trusted machine protection. The 3300 XL proximity transducer system measures both static position and dynamic vibration at the shaft or target, enabling APIŌĆæstyle protection decisions before faults cascade into trips that jeopardize power continuity. The reliability of those signals hinges on a tightly matched trio: the probe at the machine, the extension cable routing that signal, and the Proximitor sensor that conditions it. When any one of those elements fails or is mismatched, you can see intermittent channels, spurious alarms, or a blind protection systemŌĆöexactly the scenarios that lead to unplanned outages and painful starts on backup power.

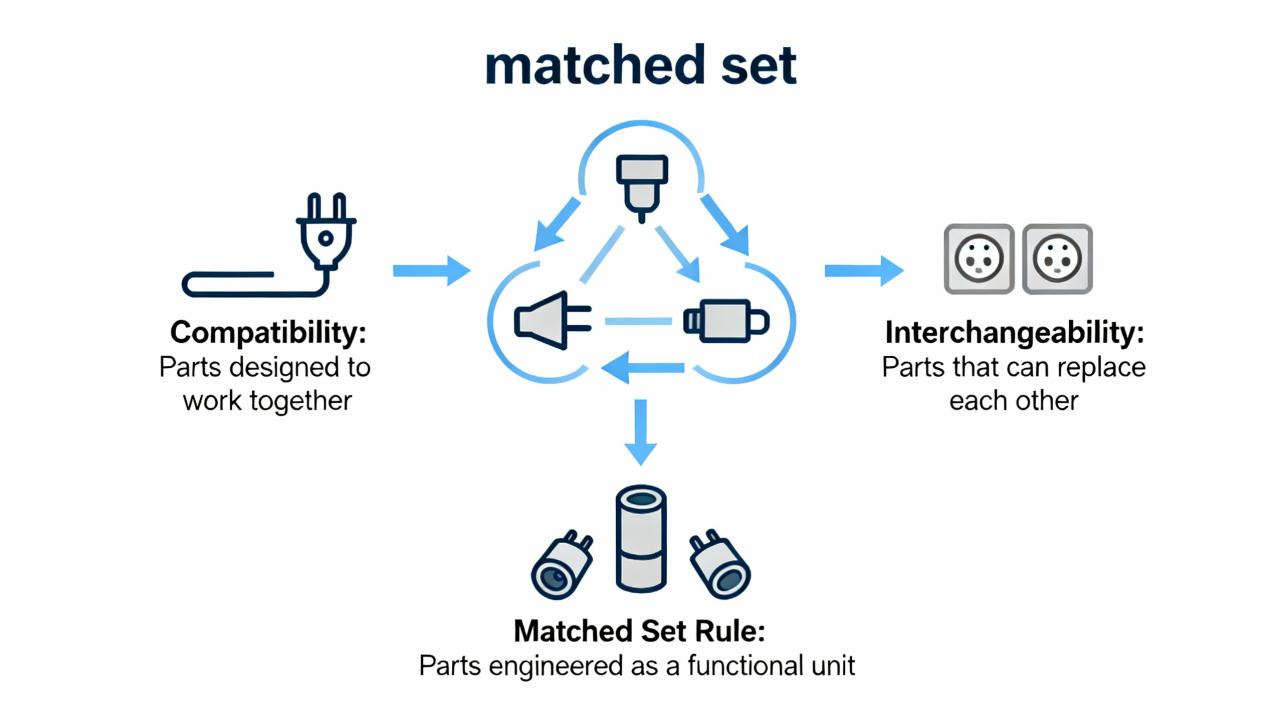

Every 3300 XL channel is a calibrated chain consisting of a proximity probe at the machine face, an extension cable, and a Proximitor sensor. Together they form a nonŌĆæcontact eddyŌĆæcurrent system that outputs a DC voltage proportional to gap along with an AC component representing vibration. The chain behaves as a matched set with a total calibrated length and specific scale factor. Replace one piece with the wrong dash code or length, and you alter the calibration enough to skew your bias (gap) and dynamic readings. There are also specialized channels such as Keyphasor, which provide a onceŌĆæperŌĆærevolution phase reference used for angleŌĆæbased diagnostics and speed.

Most plants maintain spares across four categories because these are the parts that fail in the field or are damaged during mechanical work. Proximity probes are the machineŌĆæmounted sensors and come in commonly used tip sizes named in the product family, which practitioners typically translate to imperial dimensions during selection. The 8 mm family is the familiar workhorse for radial measurements with a tip close to 0.31 in in diameter. The 11 mm family with a tip near 0.43 in is preferred wherever longer linear range is needed, such as thrust position and differential expansion. The 25 mm family, close to 0.98 in, supports largeŌĆæshaft applications with the longest linear range in this series. Proximitor sensors convert the probeŌĆÖs eddyŌĆæcurrent response into a conditioned voltage and are available in compact housings for DIN rail or panel mounts with builtŌĆæin electrical isolation. Extension cables complete the calibrated length and demand particular attention to armor type, connector type, and length formatting. Accessories round out the system: mounting hardware, protective housings, junction boxes, cable protectors and conduits, and test kits for validation and calibration checks. In addition, the 3300 XL NSv variants provide improved chemical resistance and sideŌĆæview behavior in compressor services compared with older RAM designs.

Bently Nevada designed 3300 XL components to be interchangeable within their approved families, but interchangeability is not the same as random mixing. The matched set rule governs most successful repairs: the probe, extension cable, and Proximitor must correspond to the same series and maintain the specified total calibrated length. In practice, that means keeping likeŌĆæforŌĆælike dash codes for length and connectors, and sticking to the intended system family and output scale factor. The 3300 XL 11 mm system is known for replacing older 7200ŌĆæseries 11 mm and 14 mm systems; however, that crossover requires replacing every component in the chain, not just the probe or cable, and updating the monitor configuration accordingly. In my experience, failing to update the 3500 configuration or using a monitor firmware that predates the 3300 XL 11 mm option is one of the most common reasons an upgraded channel refuses to behave despite new hardware.

Baker Hughes Bently Nevada datasheets and reputable distributors provide practical anchors for selection. The 11 mm 3300 XL systemŌĆÖs output sensitivity is 100 mV per mil of displacement and its larger tip enables a longer linear range than the 8 mm system. The 8 mm variant is widely applied for radial vibration and is commonly quoted at approximately 200 mV per mil; based on field experience and vendor literature, that figure is a reasonable planning assumption, though always confirm on the specific datasheet for your order. This inference is stated with medium confidence and should be verified before procurement. Storage and handling ranges for 3300 XL probes reach up to 351┬░F on the upper end, with cold storage limits down to roughly ŌłÆ60┬░F. Pull strength and cable integrity features such as CableLoc rated around 75 lb have proven reliable when cables are properly strainŌĆærelieved, and TipLoc molding has demonstrably reduced tip loosening over repeated thermal cycles. Optional FluidLoc is a pragmatic upgrade for oilŌĆærich machine bays because it minimizes wicking through cable interiorsŌĆöa subtle but real cause of signal degradation in compressors and turbines. On the Proximitor side, SpringLoc terminals simplify panel work by eliminating screw clamps and the modern housings meet CE immunity without forcing metallic conduit, which reduces installed cost and makes retrofits cleaner.

Most plants standardize on one or two probe families to keep spares simple. A proven pattern is an 8 mm family for radial channels and 11 mm for thrust and differential expansion or where the target area or clearance demands a longer linear span. Where shafts are very large or standoff must be generous, the 25 mm family is sensible. Do not oversize just because a larger tip exists. Larger tips increase standoff and linear range but change geometry, mounting envelope, and may alter signalŌĆætoŌĆænoise in tight sideŌĆæview spaces. When replacing, maintain the same family and length codes you already have unless a design change is explicitly part of an engineered upgrade.

| Family (tip nominal) | Approx. tip size (in) | Typical output sensitivity | Typical use case summary |

|---|---|---|---|

| 8 mm | 0.31 in | Commonly referenced around 200 mV/mil; inference with medium confidence, verify datasheet for your dash code | Radial vibration and position on fluidŌĆæfilm bearings in standard applications |

| 11 mm | 0.43 in | 100 mV/mil per vendor literature | Thrust position, differential expansion, rod position/rod drop, tach/zeroŌĆæspeed, Keyphasor where longer linear range helps |

| 25 mm | 0.98 in | Scale factor varies by set; consult the specific datasheet | LargeŌĆæshaft radial clearance and position on major rotating machines requiring extended linear range |

The output values listed are intended as a selection aid, not a substitute for your exact dash code datasheet. Confirm with the manufacturer documentation or your distributor before ordering.

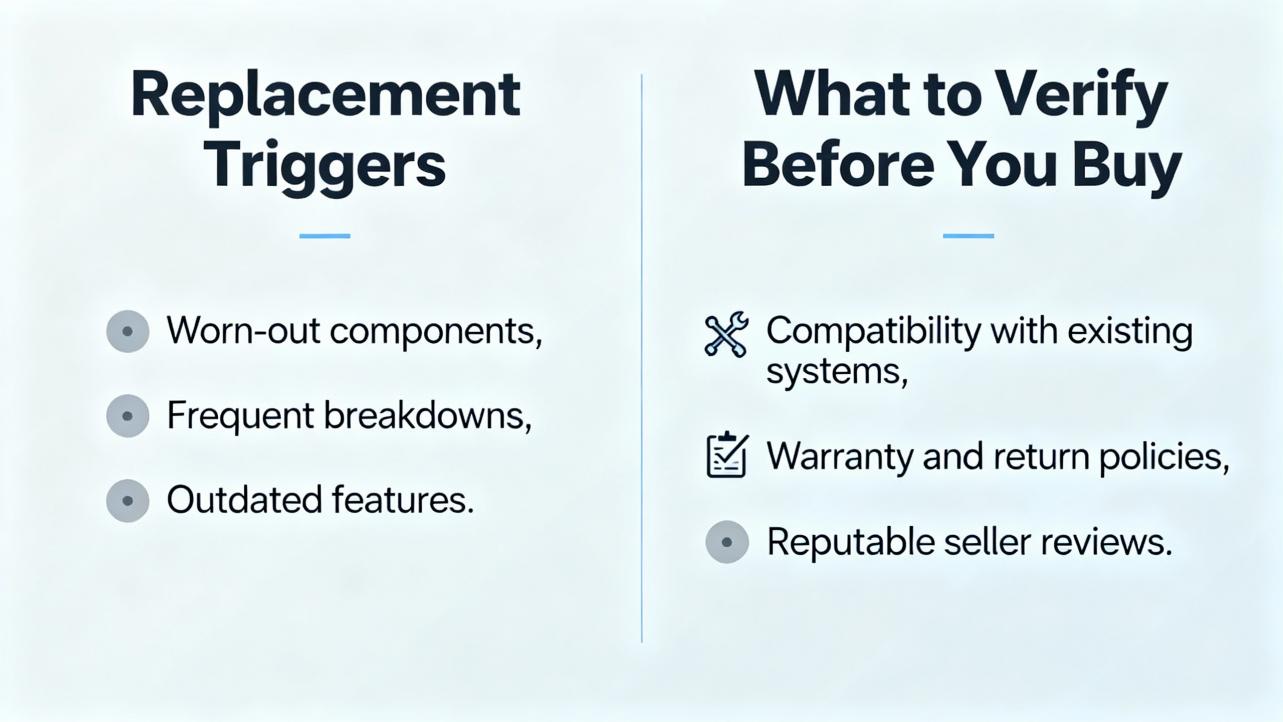

Most replacements are triggered by obvious damage, recurring signal dropout, or persistent bias voltage that will not sit within the expected range after proper gapping. Less obvious triggers include moisture ingress in cable armor, prolonged exposure to oil mist without FluidLoc, and EMI corruption because of new VFD cabling routed too close to transducer runs. Before you place an order, document the asŌĆæfound configuration including probe family, length codes, connectors, extension cable coding, and Proximitor model. Verify the target material and finishŌĆömany proximity sets are calibrated on steels similar to 4140 and deviating surfaces can skew the scale factor if not accounted for. Confirm hazardous area approvals where relevant and ensure your monitor configuration supports the replacement, particularly when moving to the 11 mm 3300 XL from older 7200ŌĆæseries sets. Plants that have standardized panel layouts will appreciate the ProximitorŌĆÖs consistent mounting footprint and builtŌĆæin isolation; it usually means the new sensor will drop into an existing fourŌĆæhole pattern without extra isolation plates.

Accessories from the same vendor ecosystem are more than convenience items; they protect signal integrity in harsh bays. Protective housings and junction boxes reduce connector exposure and make field isolation and swap tests faster. Mounting brackets and clamps help maintain minimum bend radius and prevent longŌĆæterm cable stress. Conduit and cable protectors avoid abrasion and crush damage on runs near access ways. Test kits enable quick validation and calibration checks so technicians can distinguish a machine fault from an instrumentation fault before a restart. Baker Hughes offers these accessory classes as part of a single portfolio, and in my experience, having a few standardized kits and brackets in the spares cabinet pays back quickly in both MTTR reduction and technician confidence.

When uptime is at risk, you do not have days to debate channel sources. OEM and authorized distributors offer the cleanest path on warranty, traceability, and the latest revisions. Reputable industrial distributors such as Instrumart routinely list part families and can help decode dash codes during a quote process. Specialized stockists likewise maintain deep catalogs of Bently Nevada replacement parts and can support buyŌĆærepairŌĆæexchange flows when you need a fast stopgap. The secondary market has expandedŌĆöfrom surplus dealers to legitimate eŌĆæcommerce listingsŌĆöwhich means both opportunity and risk. NewŌĆæoldŌĆæstock and refurbished parts can be a lifeline; they can also be mismarked in length or dash code or be out of spec without an easy recourse. When evaluating a nonŌĆæOEM listing, insist on clear photos of labels, full dash codes, and a test verification summary. Ask about return windows and whether label costs are deducted from refunds. For critical machines, my recommendation is to keep one channelŌĆÖs worth of full matched spares on the shelf and use secondary sources only to replenish nonŌĆæurgent inventory after you have a verified, running replacement installed.

Availability is a function of part popularity, regional stock, and revision churn. The 8 mm family moves fastest and is commonly available in popular lengths. The 11 mm family is broadly available, but longer lengths and less common connectors may have longer lead times. Proximitor sensors with DINŌĆærail housings and SpringLoc terminals are widely stocked. Accessories like cable protectors and mounting brackets are usually available off the shelf, while specialized housings may require a short lead. Manual repositories maintained by reputable third parties are useful for part identification and revision checks when your internal records are thin. In general, plan for standard lead on uncommon lengths and niche accessories, and keep enough inŌĆæhouse spares so that a single machine upset does not put you into an emergency buy on a unique dash code.

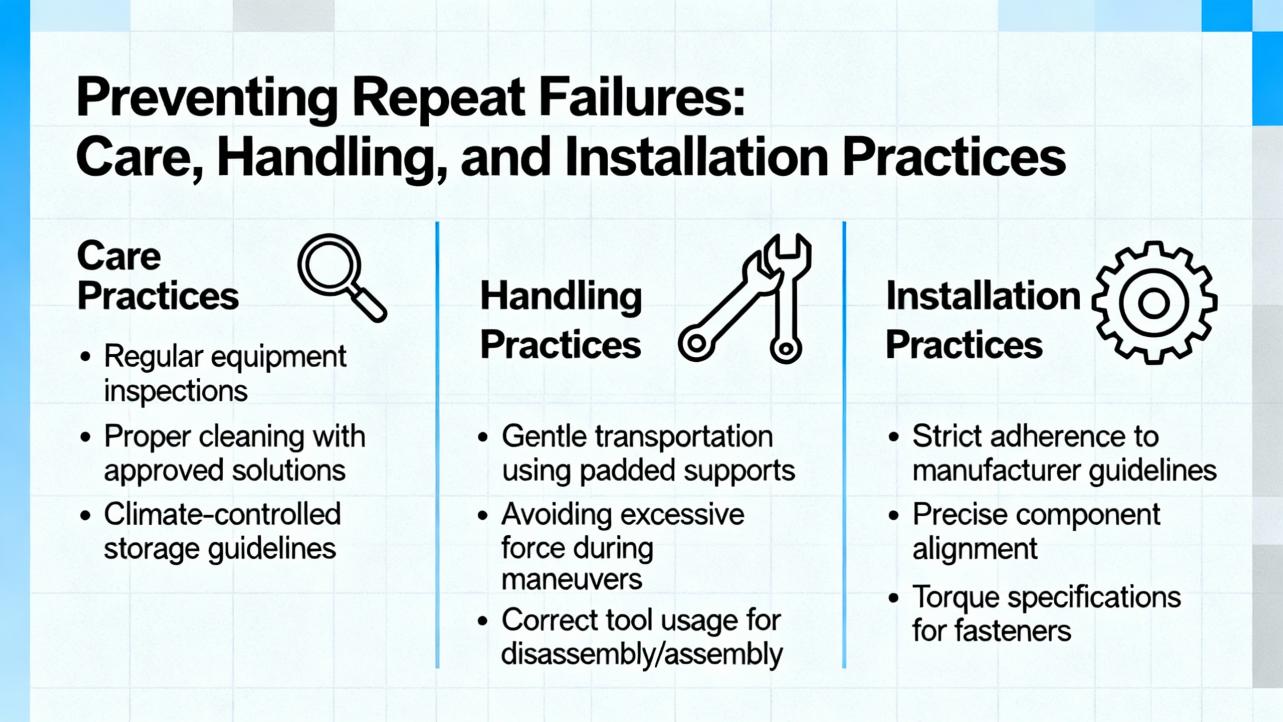

Proximity chains are forgiving in measurement theory and unforgiving in mechanical abuse. Set the mechanical gap near the center of the linear range and lock it. Maintain minimum bend radius and avoid sharp cable turns near probe entries and junctions. Route away from highŌĆæenergy power cables and VFD runs, and maintain continuous shield integrity with singleŌĆæpoint grounding as specified. Use cable protectors in footpaths and near maintenance access. Seal glands on junction boxes and housings to keep oil mist and moisture out; choose FluidLoc options in splashŌĆæprone bays. Torque connectors properly and avoid overŌĆætightening that can crack insulation or deform seals. Record baseline bias voltages and vibration levels after installation and after the first thermal cycle; the second reading often reveals workmanship issues that the first did not.

Field failures repeat themselves. Probe tips get contaminated or dinged during outage work. Cables chafe at turns or get yanked when a ladder clips them. Moisture migrates down a cable interior over weeks, not hours. EMI appears after a new VFD starter is installed in the adjacent cubicle. Electronics in a Proximitor age out and drift. The symptoms are equally repetitive: noisy signals, intermittent channel dropouts after heat soak, clipped waveforms at bias extremes, or channels that suddenly look unlike their twins on sister bearings. The diagnostic recipe is straightforward. Visually inspect everything you can touch safely. Confirm gap and mounting. Check DC bias within the expected range. Verify continuity and shield integrity. Then swap components one at a timeŌĆöprobe, cable, ProximitorŌĆöand see when the symptom follows the part. That singleŌĆævariable swap, paired with good documentation of asŌĆæfound lengths and dash codes, solves the vast majority of recurring issues without guesswork. These steps track well with practitioner guidance and application notes from the vendor community and align with shopŌĆæfloor lessons weŌĆÖve gathered on compressor fleets over many seasons.

| Situation | What to check first | Likely replacement | Ordering note |

|---|---|---|---|

| Bias stuck high or low after proper gapping | Probe standoff and target surface; compare to twin channel | Probe of same family and dash code | Verify family and dash code; maintain total system length |

| Intermittent channel after thermal cycles | Cable strain at turns and gland seals; moisture signs | Extension cable with same length and connectors | Consider FluidLoc and cable protectors; preserve bend radius |

| Persistent noise on otherwise quiet machine | Routing near VFD power; shields and grounds | Reroute and, if needed, replace cable; check Proximitor | Use CEŌĆæcompliant Proximitor housings; avoid metallic conduit when not required |

| Upgrade from 7200ŌĆæseries | Monitor configuration and firmware | Full 3300 XL 11 mm matched set | Replace probe, cable, Proximitor together; update 3500 configuration |

| Frequent tip damage | Access paths and guard design | Probe plus bracket or housing | Add protective hardware; reŌĆæassess mounting geometry |

Buy to the asŌĆæfound dash code and family wherever possible. If you need to deviate, treat it as an engineered change, not a likeŌĆæforŌĆælike swap, and involve your monitoring system configuration owner from the beginning. Ask suppliers for datasheets specific to your dash code and confirm scale factor, total length, temperature rating, and approvals. For secondary market parts, ask for the serial number, date of manufacture, test checks, and a return window in writing. Examine label photos before you pay. On arrival, benchŌĆæcheck with a known target and a reference Proximitor to verify bias and scale before you put technicians in the field. Finally, label every channel with the asŌĆæbuilt configuration so your future self is not reverseŌĆæengineering length codes during a rampŌĆædown.

The strongest predictor of a painless replacement is documentation. Plants that log asŌĆæbuilt dash codes and keep one full channel spare per critical bearing reduce crisis procurement to routine work. I also keep standardized junction boxes and protective housings in stock; the first time an access ladder clips a cable you will be glad you did. On the technical side, I anchor scale factor and linear range decisions on vendor datasheets and application notes from Baker Hughes Bently Nevada, then crossŌĆæcheck part availability and dash code options with distributor catalogs such as Instrumart. For upgrade paths and legacy crossovers, I consult the vendorŌĆÖs product datasheets and, when necessary, thirdŌĆæparty manual repositories maintained by experienced reliability integrators. When dealing with refurbished parts, I treat returns, test data, and provenance as seriously as I treat the part itself.

What is the minimum I must replace to fix a bad channel on a 3300 XL system? In principle you can replace only the failed element, but the safest and fastest diagnostic approach is to swap one element at a time with a knownŌĆægood spare until the symptom follows the part. Always keep a matched probe, extension cable, and Proximitor on the shelf so you can restore a channel without waiting for deliveries.

Will an 11 mm 3300 XL probe improve a noisy 8 mm radial measurement? Not necessarily. The 11 mm family provides a longer linear range and has a different geometry. It is preferred for thrust position and differential expansion, not as a default fix for noise. Noise is more often solved by routing, shielding, or cable condition. Confirm the root cause before changing families.

How do I know if my monitor supports the 3300 XL 11 mm system? Check your monitor firmware and configuration tool. When upgrading from 7200ŌĆæseries to 3300 XL 11 mm, you must replace the entire transducer chain and update the monitor configuration. If you use a 3500 system, confirm your configuration software lists the 3300 XL 11 mm option.

What are the telltale signs of moisture ingress in extension cables? Intermittent dropouts after heat soak, bias drift over days rather than hours, and sometimes visible staining at cable exits. In oilŌĆærich bays, select cables with FluidLoc and upgrade glands and housings to reduce ingress paths.

Is there a quick way to validate a replacement set before installation? Yes. BenchŌĆætest the matched set with a known conductive target plate. Verify bias voltage at nominal gap and confirm a proportional voltage change with movement consistent with the datasheet sensitivity. This simple shop test catches many shipping or labeling problems before field work starts.

How many spares should a powerŌĆæreliant plant carry for critical trains? At minimum, keep one full matched set per critical bearing typeŌĆöprobe, extension cable, ProximitorŌĆöand a handful of common accessories such as mounting brackets and protectors. Plants with multiple identical trains gain efficiency by standardizing on families and dash codes across lines.

The Bently Nevada 3300 XL line is reliable because it is simple, predictable, and well documented. Replacements are straightforward when you honor the matched set principle, verify dash codes and total length, and treat configuration as part of the job. Spend your effort on routing, shielding, mechanical protection, and documentation, and the channels will give you stable bias and clean vibration signals that protect the assets that keep your power steady. Source OEM or trusted distributors first, keep a complete spare chain onŌĆæhand for every critical bearing, and use the secondary market only with clear verification and return terms. That is the practical path to fewer midŌĆænight outages and fewer emergency runs on backup power.

This guidance references Baker Hughes Bently Nevada datasheets for the 3300 XL families and Proximitor sensors, distributor catalogs and product sets from Instrumart, application and product pages from RMS DCS, and product and program pages from World of Controls. Manual listings and archival references maintained by Reliability Controls provided additional model context. Industry practice insights on failure modes, routing, and diagnostics align with practitioner articles from reputable vendors and service providers.

Leave Your Comment