-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

As a power system specialist, I tend to look at distributed control system decisions through the lens of one harsh reality: your DCS is the nervous system of the plant, and your power infrastructure, UPS, and inverters are the heartbeat that keeps it alive. When the DCS is a legacy Honeywell platform that has quietly run for decades, the temptation is to leave it alone. Yet the combination of aging hardware, shrinking expertise, and rising cyber and power-quality risks means that ŌĆ£do nothingŌĆØ is usually the riskiest option on the table.

This article looks at Honeywell DCS replacement and migration options in detail, grounded in HoneywellŌĆÖs own guidance and in broader best practice from industry bodies and other vendors. The focus is practical: how to build a credible business case, how to exploit HoneywellŌĆÖs investment protection strategy, and when to consider alternatives to staying on Honeywell, all while protecting process uptime and power reliability.

HoneywellŌĆÖs own white paper on migrating legacy control systems is blunt: every DCS will eventually require upgrading to maintain reliable operation and leverage modern automation capabilities. The paper stresses that migration projects are hard to justify unless they offer a clearly superior business value proposition, not just a like-for-like technology refresh.

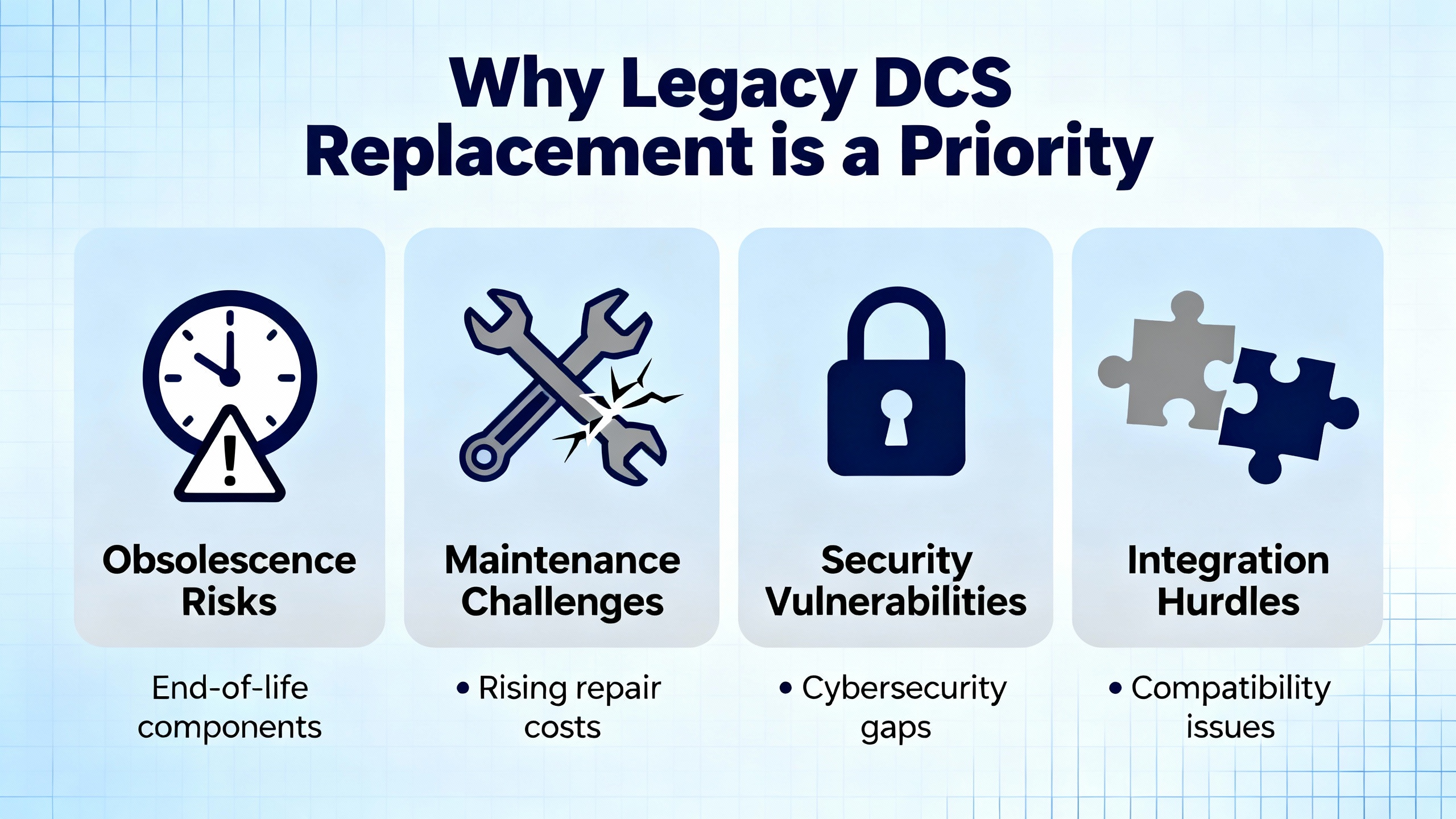

In practice, three flavors of obsolescence tend to converge on older Honeywell platforms. Technical obsolescence shows up as missed performance or yield because the control strategy or platform cannot fully exploit todayŌĆÖs instrumentation or optimization tools. Functional obsolescence appears as missing capabilities such as advanced control, asset management, or seamless data sharing with business systems. Supply obsolescence is the most visible day-to-day: electronic components reach the end of their useful life, spare parts become scarce and expensive, and the pool of people who can troubleshoot and repair the older system shrinks as experienced staff retire. Honeywell itself acknowledges that difficulty sourcing spares, combined with rising failure rates and lack of qualified personnel, drives up the risk and cost of downtime.

Independent research reinforces this picture. Analysts cited by Western States Controls point to roughly sixty-five billion dollars of installed DCSs nearing end of life, many more than twenty-five years old. Hargrove Controls & Automation describes plants still operating legacy systems that have been in place for thirty years or more, with spare components sometimes sourced through what they call ŌĆ£eBay and pray.ŌĆØ In other words, the apparent stability of the legacy Honeywell DCS often masks a growing exposure to unplanned outages and expensive last-minute workarounds.

From a power reliability perspective, this is especially concerning. A DCS outage does not just take down PID loops; it can trigger emergency trips, affect breaker coordination, and force manual operation of power distribution systems. If the control room UPS and inverter backbone were sized for the original architecture, unplanned workarounds or added servers can also erode ride-through margins. That is why forward-looking plants are reassessing Honeywell legacy systems well before catastrophic failure.

Honeywell frames DCS justification explicitly in total cost of ownership terms. The question is not simply whether the system is still running, but whether the combined cost of maintaining the legacy platform, procuring scarce spares, carrying downtime risk, and living with performance and security limitations outweighs the cost and benefit of migration.

The white paper distinguishes between the visible maintenance cost and the less visible impact of poor control on quality, energy consumption, and throughput. If processes cannot be held close to setpoints due to limitations of the old platform, product quality, energy usage, and capacity are affected. Other sources, such as Plant Engineering and Rockwell Automation, similarly emphasize that aging DCSs are a relatively small fraction of plant capital expenditure but have a disproportionate impact on profitability and safety.

Several common drivers repeatedly show up across Honeywell and third-party guidance.

| Driver category | Typical Honeywell and industry concerns |

|---|---|

| Obsolescence and lifecycle | Rising support costs, end-of-service components, risk of critical failures due to supply obsolescence |

| Performance and flexibility | Inability to support new units, advanced control, or cross-unit closed-loop strategies on the legacy platform |

| Workforce and support | Loss of experienced engineers, reliance on external support, difficulty maintaining obsolete platforms |

| Cybersecurity | Legacy DCS and embedded software not designed for connected environments, leading to a false sense of security |

| Business integration | Need for secure, timely process data at the desktop and across the enterprise to enable better decisions |

Honeywell highlights that obsolescence alone is often not enough to justify capital expenditure unless it materially increases the probability of a failure that can shut down a critical process. What usually tips the balance is when obsolescence interacts with business opportunity. For example, a plant might need to add a new unit, integrate with enterprise production management, or support modern asset management tools, and finds that the legacy Honeywell platform cannot do so economically or securely.

For power-intensive sites, there is another dimension. When you modernize DCS platforms, you typically centralize compute resources, increase reliance on Ethernet, and add analytics, all of which depend on stable, clean power. If your UPS and inverter systems are undersized or aging, the project can either expose a hidden weakness or create one. Including power system upgrades in the business case is not a luxury; it is often what protects the promised return on investment.

One of HoneywellŌĆÖs differentiators, according to its own white paper, is that it continues to support control systems more than thirty years old and offers migration paths that avoid ripping out entire legacy hardware and software stacks. The overarching idea is investment protection: retain as much of the existing wiring, cabinets, and intellectual property as is sensible, while introducing modern capabilities through Experion-based solutions.

Honeywell summarizes its strategy in terms of technology evolution, control-level integration, HMI replacement, supervisory control migration, virtualization, and migration kits. While the exact product names and model numbers are outside the scope of the notes, the categories are clear enough to plan against.

Instead of insisting on a single-step replacement, Honeywell promotes coexistence. Its approach allows legacy systems to continue operating and being fully supported while new technologies are phased in. The company emphasizes that transitions to new controllers and applications can be executed with practically no change to physical wiring and with preservation of the existing control database and strategies.

This is achieved through migration mechanisms that let multiple generations of controllers share a common network. From an engineering standpoint, this means existing loops and interlocks can be ported or integrated progressively rather than all at once. From a power system standpoint, it means you do not have to rework field wiring, marshalling cabinets, or motor control centers purely to accommodate the new control platform, avoiding unnecessary outages on critical feeders.

Third-party sources describing multistage DCS migrations, such as NovaTech Automation and BBA Consultants, reinforce this philosophy. They recommend stabilizing and documenting the existing system, introducing new engineering and HMI environments in parallel, then migrating controllers and I/O by unit or area while retaining marshalling cabinets and field terminations. HoneywellŌĆÖs investment protection approach slots neatly into that pattern.

Many Honeywell users are still running HMI and SCADA components on outdated operating systems, sometimes more than a decade old, as noted by automation guidance from GCG and other integrators. HoneywellŌĆÖs white paper and the broader literature both stress that HMI migration should not be treated as a simple version upgrade. It is a chance to rethink alarm philosophy, operator graphics, and information flow.

Schneider ElectricŌĆÖs DCS migration material, for example, highlights improvements in operator effectiveness and alarm handling when moving to modern HMI and alarm management tools. Control Engineering reports that operators using legacy interfaces may take about forty-one percent longer to respond to abnormal situations than those using high-performance graphics, with typical plants losing more than five percent of capacity annually due to poor alarm response. Although these figures are not specific to Honeywell, they illustrate the scale of opportunity when you modernize the supervisory layer.

HoneywellŌĆÖs approach includes HMI replacement and supervisory control migration as explicit elements, often combined with virtualization and server consolidation. In practice, I see three practical impacts. First, the number of servers and operator workstations can often be reduced through centralization and virtual machines. Second, alarm and event handling can be aligned with current ISA and MESA guidance, not just replicated as-is. Third, the new environment is much easier to protect with UPS, inverters, and power quality monitoring because the load is centralized and more predictable.

At some point, controllers and I/O hardware have to be modernized. Industry data cited by Control Engineering suggest typical life expectations around fifteen years for controllers, twenty years for I/O and termination panels, and around forty years for wiring. That is why most staged DCS migration strategies aim to replace controllers and I/O while keeping field wiring intact.

HoneywellŌĆÖs migration kits are designed with this in mind. The white paper describes solutions that provide access to up-to-date technology without ripping and replacing the entire system, and emphasizes that the transition can occur with practically no changes to physical wiring. Other vendors offer similar ŌĆ£plug-inŌĆØ approaches, such as Schneider ElectricŌĆÖs EcoStruxure Foxboro DCS migrations that reuse existing wiring and enable hot cutovers, but HoneywellŌĆÖs differentiator is that it can do this while also continuing to support the legacy installed base.

NovaTech and IEB Media recommend using adaptable I/O bases that allow new modules to connect to existing terminations, preserving loop integrity and reducing commissioning time. In Honeywell environments, this approach aligns with keeping field devices, marshaling cabinets, and most control-room power circuits untouched while focusing outage time on panel-level work and software cutover.

Honeywell explicitly calls out virtualization as part of its migration strategy. BBA Consultants and other system integrators stress similar benefits. Moving application servers and engineering workstations into a virtualized environment allows operating system images to be standardized and backed up centrally, simplifies patching, and makes it easier to restore service if a hardware server fails or is retired.

From a power reliability viewpoint, virtualization changes the power profile. Instead of many scattered desktop-class machines drawing from various panelboards, you now concentrate critical workloads in a smaller number of robust servers in the rack room. This is a perfect match for modern UPS architectures: you can provide higher-quality power, better surge protection, and longer ride-through for fewer, more critical loads. During Honeywell migration planning, I typically recommend treating the new virtual host cluster and storage as a separate critical load, backed by double-conversion UPS and appropriate static transfer switches, sized for at least the longest likely DCS restart time plus a safety margin.

Staying with Honeywell and leveraging its investment protection strategy is not the only path. Depending on business and technical priorities, some facilities choose to migrate toward other DCS vendors or to more open architectures built around PLCs, SCADA, and open process automation concepts. The research notes offer a useful comparison of these options.

| Path | Description | Typical advantages | Typical concerns |

|---|---|---|---|

| Honeywell-to-Honeywell migration | Phased migration to Experion-based architecture while preserving existing wiring and control strategies | Strong investment protection, continued support for legacy systems, minimized rewiring, high continuity of operator experience | Potential dependence on single vendorŌĆÖs roadmap, risk of underusing the opportunity for broader innovation |

| Migration to another DCS vendor | Transition to platforms such as Schneider ElectricŌĆÖs Foxboro DCS or Rockwell Automation solutions, often in stages | Access to alternative technologies, migration programs with plug-in hardware and hot cutover, ability to choose vendor best aligned with future digital strategy | Need to translate Honeywell-specific IP, higher learning curve, interface complexity during coexistence |

| Hybrid PLC/SCADA or open architectures | Replacing parts of the Honeywell DCS with PLCs, modern SCADA, or open process automation components as described in Control Engineering | High flexibility, potential for modular, open standards-based solutions, easier integration with IIoT and analytics | More integration responsibility, need for strong internal or third-party system architecture expertise, risk of fragmented lifecycle support |

Schneider Electric emphasizes in its DCS upgrade guidance that a future-proof design, cost-efficient staged migration, limited downtime through plug-in solutions and hot cutovers, and extensive reuse of wiring can make switching vendors viable where the business case is strong. Rockwell AutomationŌĆÖs LifecycleIQ material frames DCS migration as an opportunity to clean up inconsistent standards and abandoned logic and to adopt modern engineering environments that support advanced control, digital twins, and IIoT.

Control EngineeringŌĆÖs discussion of open process automation adds a longer-term angle. Open standards and modular, plug-and-play architectures can improve interoperability and allow incremental improvements without full plant shutdowns. This is especially attractive for process units with expected life far beyond the fifteen-year control system horizon. For Honeywell users considering such a shift, the key is honest assessment of in-house capabilities. If your team has limited exposure to OPA concepts, a vendor-agnostic partner with proven experience becomes almost mandatory.

Regardless of which path you choose, successful Honeywell DCS replacement depends less on brand names and more on disciplined planning, risk management, and respect for the power and control interplay in your plant.

ISA, Control Engineering, and multiple integrators converge on one message: front-end loading is critical. That means doing as much planning and preliminary engineering as practical before committing to hardware or booking outages. HoneywellŌĆÖs own white paper recommends understanding risks and rewards, developing a project vision, doing the homework on options, choosing the best methodology, and selecting the right partner before moving forward.

Control Engineering describes three front-end stages with progressively tighter cost and scope estimates, and notes that the ability to influence outcomes is highest and costs are lowest early in the process. During these early stages, risk analysis should explicitly cover safety, expected downtime, cybersecurity, network traffic, data integrity, resource availability, and, in my experience, power-system implications such as UPS loading, breaker coordination, and generator capacity in islanded operation.

IEB Media, TechWem, and other sources stress that the highest-risk period in any DCS migration is installation and cutover. The transition point where field devices and I/O connections move from the old to the new system is where production can be either protected or seriously harmed.

Cold cutover involves shutting down the legacy DCS and starting the new system in one outage. This approach minimizes project complexity and can reduce engineering cost, but requires long continuous downtime. Hot cutover runs legacy and new systems in parallel, transferring control loop by loop with the ability to fall back if problems arise. It typically results in lower operational risk and less production downtime, but increases temporary complexity and requires more space and careful coordination.

Most plants, according to IEB Media and Plant Engineering, favor phased migration and hot cutover because once you include the cost of lost production and startup risk, the total cost of ownership is usually lower than a big-bang replacement. HoneywellŌĆÖs coexistence and migration kits align well with this approach, enabling hot or staged cutovers while preserving wiring.

From a power reliability viewpoint, hot cutover is also easier to protect. UPS-backed control rooms can support both old and new systems during overlap if loads are carefully measured and staged. For cold cutover, you must be sure your UPS and backup power can support extended outage-related testing and commissioning without compromising other critical loads.

HoneywellŌĆÖs investment protection strategy is not just about wiring; it is also about preserving intellectual property. Western States Controls emphasizes that existing control processes, algorithms, and workflows embody years of operational experience and are valuable. HoneywellŌĆÖs migration messaging similarly highlights the ability to transition to new technology while keeping the existing control database and schemes intact.

In practical terms, this means that reverse engineering and documentation should be treated as a core workstream, not an afterthought. Loop lists, interlock narratives, alarm configurations, and custom logic need to be backed up, reviewed, and cleaned up before any automated conversion tools are used. Vendors including Honeywell and others offer configuration and graphics conversion utilities, but TechWem cautions that these tools should be treated as aids only; expert review is still required to avoid replicating obsolete practices or introducing subtle errors.

Legacy Honeywell systems were designed in an era when air gaps were normal and cyber threats were limited. HoneywellŌĆÖs white paper warns that keeping an old DCS purely for perceived security can create a false sense of safety, because obsolete software inside the system remains vulnerable. The paper advocates a defense-in-depth strategy in line with IEC 61511, requiring clear independence between protection layers and robust controls against unintentional access and common-cause failures.

AFS and BBA Consultants expand on what that looks like architecturally. They recommend clear segregation between corporate IT and operations technology, using an industrial DMZ that hosts services such as Windows update servers, antivirus signature distribution, secure file transfer, backup systems, and intermediate data historians. The industrial OT network below the DMZ should host controllers, HMIs, and other critical systems, with carefully defined roles and responsibilities.

When migrating Honeywell DCS, you should treat network architecture changes as first-class project scope. Modern platforms, whether Honeywell Experion or alternatives, are more connected by design, meaning security and network segmentation must be designed in, not bolted on. NIST, the Department of Homeland Security, the Department of Energy, and NERC all publish guidance on industrial cybersecurity, and Honeywell emphasizes aligning with such frameworks.

Finally, a point that often receives less attention than it deserves: power quality and backup. As migrations move HMIs and servers into centralized, often virtualized environments, the control systemŌĆÖs dependency on clean, continuous power becomes even more acute. BBA Consultants describe virtual machines as simplifying recovery when physical servers fail or become obsolete. That benefit only materializes if the underlying power path is robust.

Before committing to a Honeywell DCS migration, I recommend a combined power and control audit that covers existing UPS capacity and age, inverter topology, battery autonomy, grounding, and distribution to control panels and rack rooms. Increasing server density or adding high-performance engineering workstations can change harmonic profiles and inrush behavior, with implications for static transfer switches and generator stability.

In many plants, the most cost-effective reliability upgrade is not only a modern DCS, but a coordinated enhancement of UPS, inverter, and distribution design for the control environment. That might mean migrating from offline or line-interactive UPS units scattered under desks to a centralized double-conversion UPS with proper bypass arrangements and maintenance plans, synchronized with the DCS migration timeline.

When I guide teams through Honeywell DCS replacement decisions, the most successful projects tend to follow a common narrative, even if the details differ by site. The first step is to clarify business and operational objectives in concrete, measurable terms. TechWem recommends SMART goals such as targeted reductions in unplanned downtime, specific gains in operator efficiency, or compliance with defined cybersecurity levels. HoneywellŌĆÖs own justification framework also stresses clear vision and measurable value.

Next, teams perform a thorough ŌĆ£as-isŌĆØ assessment. This includes verifying and updating P&IDs, loop sheets, panel drawings, cabling schedules, and backups, as described by ISA, TechWem, and Control Engineering. Hardware and software configurations are audited, control network performance and security are assessed, and operators and maintenance staff are interviewed about real-world pain points and workarounds that documents rarely capture.

With this foundation, you can define a realistic ŌĆ£to-beŌĆØ architecture and shortlist options: staying with Honeywell using its migration kits and Experion platform, moving to another DCS vendorŌĆÖs migration program, or adopting a hybrid or open approach. Requests for proposals can then be framed around critical-to-quality factors such as lifecycle support, scalability, high-performance HMI capability, migration path, installed base, and readiness for IIoT and analytics, as recommended by Rockwell and Plant Engineering.

Pilot projects or proof-of-concept implementations on less critical units are particularly valuable. They allow you to validate vendor claims, test conversion tools, tune cutover procedures, and refine UPS and power design with minimal risk. Once confidence is built, a detailed, multi-year migration plan can be approved, aligned with maintenance outages, and supported by solid total installed cost and total cost of ownership estimates.

Throughout, it is essential to treat training, documentation, and change management as integral parts of the plan. Operators who are comfortable with legacy Honeywell consoles may be understandably cautious about new interfaces. Hands-on training with simulated process graphics, coupled with clearly explained benefits and realistic transition support, goes a long way toward securing buy-in.

Multiple industry sources note systems still running after twenty-five to thirty years, and Honeywell itself continues to support platforms more than thirty years old. However, that does not mean it is safe to run indefinitely. As spare parts become harder to find, experienced personnel retire, and cybersecurity expectations tighten, the risk of a failure with no quick recovery path rises sharply. A structured risk assessment that quantifies the probability and impact of unplanned shutdowns, along with clear obsolescence indicators, is a better guide than calendar age alone.

Sticking with Honeywell and using its investment protection strategy is often the lowest-disruption approach, particularly when your team is familiar with Honeywell tools and you want to reuse existing control strategies and wiring. However, it is not automatically the lowest-risk or highest-value path. Other vendors, such as Schneider Electric and Rockwell Automation, offer robust migration programs with their own strengths, and open or hybrid architectures can be attractive when interoperability and modularity are top priorities. The right answer depends on your critical-to-quality requirements, your appetite for architectural change, and the level of vendor and integrator expertise available to you.

UPS and power systems should be treated as core elements of the migration, not background infrastructure. As you consolidate HMIs, servers, and controllers onto modern platforms and virtualized environments, you change the critical load profile of your control system. Assessing UPS capacity, inverter health, distribution, and generator interactions should happen at the same time as FEL and network design. Aligning DCS migration milestones with UPS upgrades, battery replacements, and any needed redistribution of critical loads is one of the most effective ways to ensure that the reliability gains promised by a modern control system are actually delivered in day-to-day operation.

In the end, Honeywell DCS replacement is less about swapping hardware and more about reengineering the way your plant manages risk, information, and power. If you build your strategy on clear business objectives, disciplined engineering, and a holistic view of power and control reliability, you can turn an inevitable modernization into a long-term competitive advantage.

Leave Your Comment