-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Natural gas treatment used to be a craft dominated by panel boards, analog gauges, and a few seasoned operators who could ŌĆ£hearŌĆØ when a plant was unhappy. Today, the plants I walk into look very different. Screens outnumber gauges, control rooms are quieter, and the reliability conversations start not with pumps or compressors, but with the control system and the electrical backbone that keeps it alive.

If you are standardizing on Emerson control systems for a gas treatment facility, you are not just buying software and I/O. You are selecting the nervous system of the plant and, by extension, defining how power quality, automation, and business processes will interact for the next two decades. This article walks through how to think about that decision, using evidence from recent automation projects across the oil and gas sector and layering in hard-earned lessons from power and reliability engineering.

Gas treatment facilities sit at the crossroads of production growth and environmental pressure. Industry forecasts summarized by Blackthorn Vision, citing the International Energy Agency, projected U.S. natural gas marketed production reaching record levels in 2023, while global oil demand was set to increase by around 1.7 million barrels per day. That kind of growth pushes more gas through amine contactors, dehydration trains, and NGL recovery systems, often without the luxury of building entirely new plants.

At the same time, processing itself is getting more complex. Reset Energy highlights how modern plants now integrate advanced membrane separation, hybrid carbon capture schemes, and modular process units to meet tighter specifications and sustainability targets. Each new technology brings more control loops, more analyzers, and more potential failure modes.

From a reliability advisorŌĆÖs standpoint, that complexity changes the risk profile. Historically, a single pump trip might cost a few hours of downtime. In an automated, tightly integrated gas plant, a bad instrument calibration or a control power disturbance can ripple across units, tripping dehydration, upsetting fractionation, and blowing through emissions limits in a matter of minutes.

In one plant review I led, a single miscalibrated moisture analyzer in the dehydration system quietly forced operators to over-dry the gas. The result was higher regeneration duty, unnecessary fuel use, and a few percentage points of lost margin that only became visible once we scrutinized the energy balances. ImubitŌĆÖs work on self-optimizing plants documents similar patterns, noting how something as mundane as an uncalibrated water vapor probe can distort hydrate predictions and chip away at both safety and profitability.

Across upstream, midstream, and downstream operations, the picture is clear: automation is no longer an add-on, it is core infrastructure.

FlowForma, referencing Deloitte research, notes that roughly sixty percent of oil and gas companies already have digital transformation initiatives around human-centric processes, yet much of the automation potential remains untapped. Other sources converge on the same theme:

Blackthorn Vision shows how business process automation improves regulatory compliance, environmental risk management, supply chain coordination, and cost control, using centralized data, analytics, and digital twins.

Axis Technical Group highlights that end-to-end automation of logistics and fleet management can cut total production costs by about ten to fifteen percent, and cites McKinsey estimates of around twenty percent lower delivery vehicle service costs and roughly two percent lower materials costs when digital tools and automation are applied.

Proceso App points out that global demand for natural gas could rise on the order of thirty percent by 2040, arguing that AI-infused automation will be essential to keep up with operational complexity, workforce constraints, and environmental obligations.

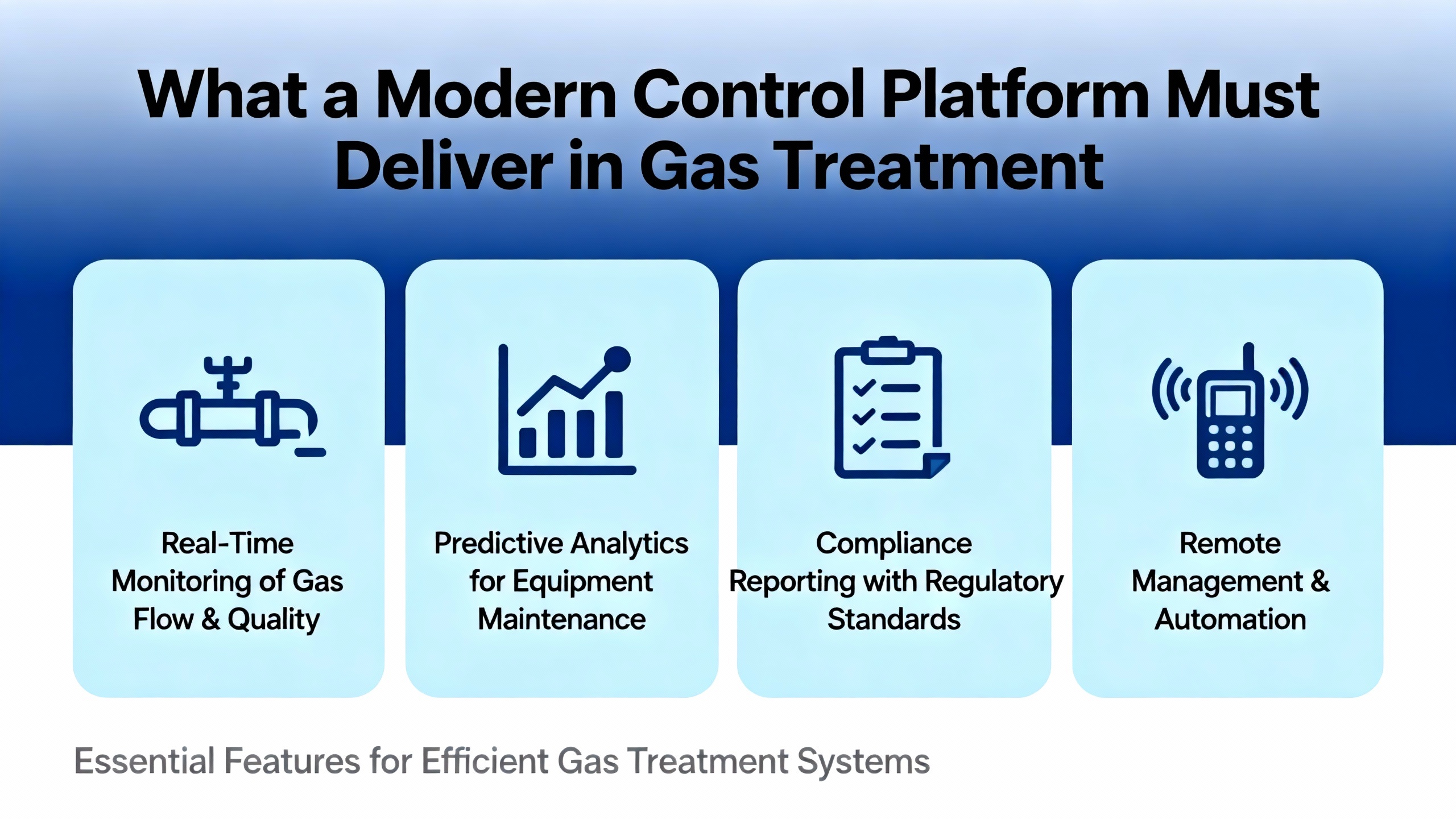

In gas treatment specifically, Damien T. DulŌĆÖs discussion of automation in gas plant workflows underscores the central role of distributed control systems, real-time monitoring, predictive maintenance, and centralized dashboards in running high-performance plants safely.

Taken together, the evidence says that your Emerson control platform will not live in isolation. It will sit in the middle of sensors, analyzers, business systems, and workforce tools, and its success will depend as much on data quality, power integrity, and workflows as on PID tuning.

When I assess a proposed Emerson-centered architecture for a gas plant, I mentally break it into three layers: core process control, optimization and analytics, and business process automation. All three matter, and all three draw directly on the automation patterns described in the recent literature.

ImubitŌĆÖs six-phase roadmap for self-optimizing gas plants starts with something unglamorous: data and instrumentation. Before you think about advanced control or AI, your Emerson-based system needs accurate sensors, disciplined calibration, and clean historian data. That includes analyzers for COŌéé and HŌééS in the amine system, moisture measurements in dehydration, and composition data for NGL recovery.

Imubit emphasizes synchronized timestamps, tag audits, and data validation as non-negotiable. The practical reason is simple. If your amine regenerator temperature transmitters drift high, the control system will happily ŌĆ£optimizeŌĆØ toward a false target, burning fuel and shortening equipment life. If the gas chromatograph feeding your NGL recovery model is not maintained, your advanced process control layer will either push the plant into unsafe regions or leave margin on the table because operators stop trusting its recommendations.

Once the measurements are right, the next job for the Emerson DCS is to stabilize the plant using well-tuned loops. Damien T. DulŌĆÖs treatment of gas plant automation underlines how distributed control systems, with carefully tuned PID loops, create the steady operating environment that higher layers rely on. Imubit suggests using quantitative metrics, like integral absolute error and integral squared error, to find poorly performing loops and fix issues such as valve stiction before layering advanced control on top.

A simple example from a dehydration train illustrates the point. Suppose your contactor tower pressure loop hunts by a few pounds per square inch because of sticky control valves and aggressive tuning. That oscillation may not trip the plant, but it constantly disturbs downstream fractionation, makes compositional control harder, and forces operators to run conservatively. Cleaning up that loop is a low-cost, high-impact reliability improvement that your Emerson controls can deliver before you write a single advanced control block.

Once the base layer is stable, advanced process control and AI-based optimization can start to justify their reputation. Imubit describes a typical transformation where plants that complete the full optimization journey see around twenty-five cents of added margin per barrel of product from distillate system optimization, along with fifteen to thirty percent reductions in natural gas consumption for certain operations.

For a gas plant processing the equivalent of 100,000 barrels per day of liquids, even a fraction of that improvement is material. At twenty-five cents of additional margin per barrel, you are looking at about twenty-five thousand dollars per day, which is on the order of several million dollars per year if you sustain it. The practical levers include tighter control of amine circulation rates, better reflux management in cryogenic units, and dynamic adjustments of refrigerant compressor setpoints based on real-time economics.

ImubitŌĆÖs description of their phased approach maps well to what you would expect from a mature Emerson-based architecture:

First, a distributed control system layer that keeps key variables within safe and stable limits.

Next, advanced process control that can manipulate multiple variables simultaneously to keep the plant at its economic sweet spot while respecting hydrate and phase-envelope constraints.

Then, AI in advisory mode that uses historical and real-time data to propose setpoint changes, with transparent dashboards showing expected profit deltas and the drivers behind each recommendation.

Finally, closed-loop AI optimization, where validated AI recommendations are allowed to write setpoints directly back to the control system under tightly governed conditions.

To make that last step work, Imubit stresses that you need strong data governance, regular model retraining, and a culture in which operators understand and trust the recommendations. In my own projects, I have seen the trust issue derail technically sound solutions. Operators will not hand over control to a ŌĆ£black boxŌĆØ unless they can see what it is doing and they know they can override it safely at any time.

Control systems for gas treatment are not just about stable temperatures and pressures. They are also the front line for safety and compliance workflows that extend into the back office.

FlowForma notes that human error accounts for roughly sixty to eighty percent of failures and errors in common oil and gas tasks. Automation can drastically reduce those errors by standardizing workflows, validating data, and embedding audit trails. COPAS describes how automated workflows that handle notifications, approvals, and interdepartmental handoffs reduce forgotten actions and preserve institutional knowledge, particularly important in regulated environments.

PakEnergy goes further into compliance management with its description of Corrective and Preventive Actions, or CAPA. They outline a closed-loop process consisting of problem identification, root cause analysis, corrective and preventive action planning, implementation and verification, and ongoing documentation and improvement. Embedding CAPA into automation platforms means that when your Emerson system logs, for example, a high HŌééS event or an amine regenerator off-spec condition, that event can automatically trigger an investigation and follow-up actions that are tracked to closure.

In one mid-sized upstream case quoted by PakEnergy, replacing spreadsheets and disconnected systems with an integrated automation platform cut administrative overhead by around thirty percent within six months, and reduced financial reporting times from days to hours. While that specific case centers on a different software platform, the principle carries into an Emerson environment: data coming out of your control system and historian needs to feed automated compliance, maintenance, and financial workflows, or you leave value on the table.

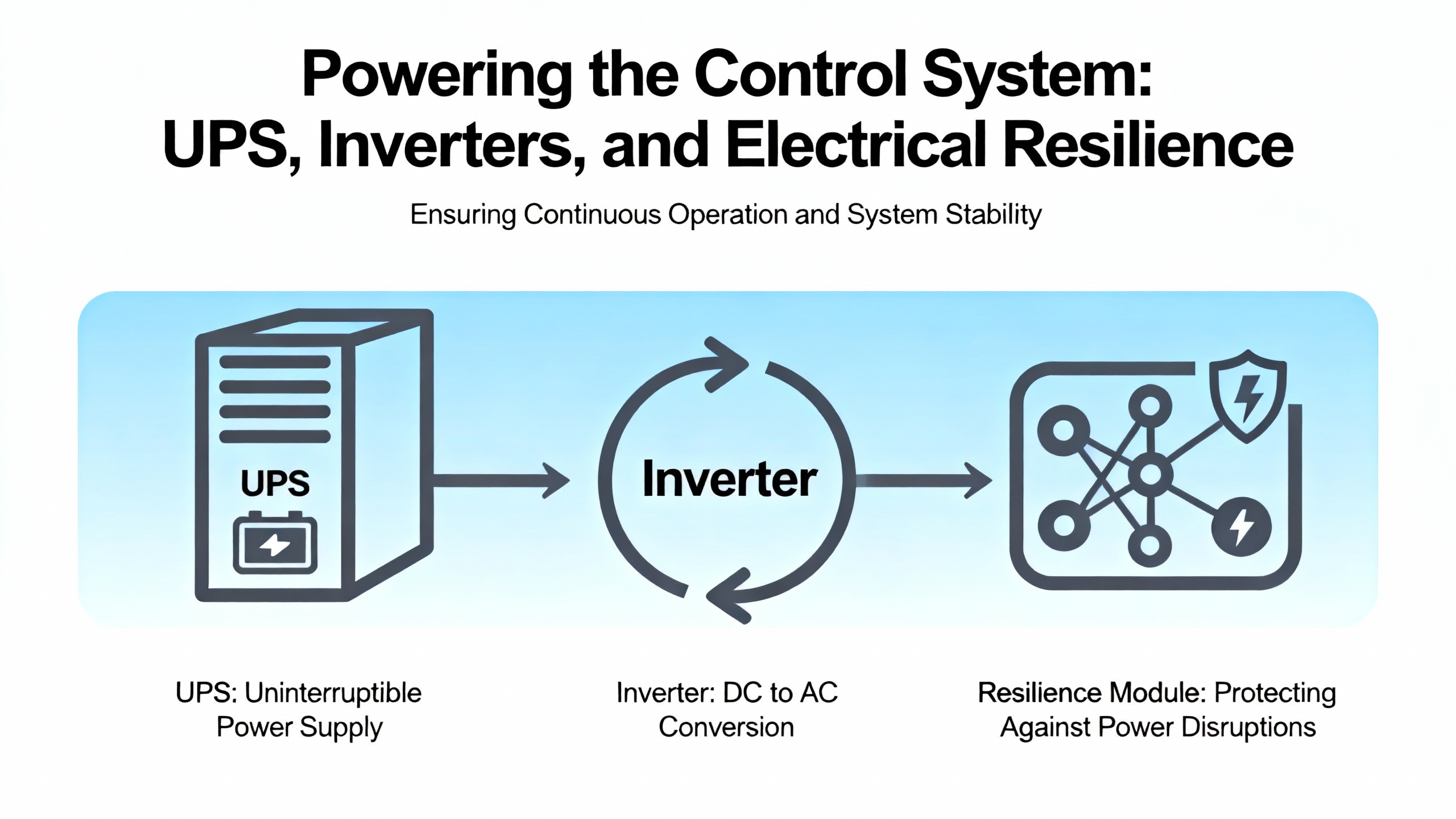

From my vantage point as a power systems specialist, the most fragile part of many gas plants is not the big rotating equipment. It is the chain that runs from utility feeds and generators, through switchgear and transformers, into UPS systems and finally into the control hardware. The most sophisticated Emerson installation is only as reliable as the volts and frequency at its terminals.

A sensible way to think about power for an Emerson-based gas control system is to classify loads into tiers.

The highest tier includes safety instrumented systems, emergency shutdown logic, key process controllers, historian and engineering servers, network switches and firewalls, and essential operator workstations. These are the loads that must ride through outages, voltage sags, and generator transitions without dropping. In most plants I have worked on, that means double-conversion UPS systems feeding dedicated power distribution to control rooms and marshalling panels, often backed by batteries and sometimes by DC systems with inverters for critical field panels.

The next tier includes analyzers, auxiliary instrumentation, and communications equipment that should stay up through short disturbances but may not need the same autonomy as core safety systems. These may be fed from separate UPS segments or shorter-runtime systems, with careful discrimination so that a fault on an analyzer circuit does not knock out the entire control backbone.

The third tier is everything that can safely trip on power failure and restart under control: non-critical HVAC, general lighting, and some local loads. These may still be backed by generators but do not typically require UPS.

Getting that segmentation right is essential. A common problem I encounter on site audits is that control cabinets share upstream feeders with noisy loads such as large motor drives or welding outlets. The result is nuisance trips, strange control system resets during maintenance activities, and unexplained bit errors in fieldbus networks. In a plant where human error already accounts for a large fraction of failures, according to FlowFormaŌĆÖs summary of industry data, it is unnecessary to add more risk through poor power segregation.

Once you know what must stay energized, you can sensibly size UPS and inverter systems. The math is straightforward but often overlooked.

Imagine your total critical control load, including Emerson controllers, safety PLCs, servers, and networking, is around 15 kilowatts. If your design basis calls for thirty minutes of ride-through time to cover short generator outages and allow for a controlled shutdown, you need storage on the order of 7.5 kilowatt-hours before accounting for inverter and battery inefficiencies. After you include realistic efficiency and aging margins, you will likely specify something closer to 9 or 10 kilowatt-hours of installed battery capacity.

The exact numbers will vary, but the reliability principle is constant. If the UPS cannot support a controlled shutdown of your gas treatment trains in the event of a generator failure or upstream disturbance, then your Emerson control system is being asked to perform a job it is not electrically equipped for. In every gas plant I have commissioned, we have treated control-room UPS as non-negotiable infrastructure, not as an optional add-on.

PetrotechŌĆÖs discussion of automation for turbomachinery adds another angle. They emphasize integrated control solutions for gas and steam turbines, generators, compressors, and pumps. From a power perspective, this integration only works if your control power supply is at least as robust as the machinery it supervises. That means considering redundant UPS systems, separate feeds to critical cabinets, and careful coordination of transfer schemes to avoid dropping control loads when switching between power sources.

Power issues in gas plants are not limited to full outages. Brownouts, harmonic distortion, and short-duration voltage sags can all destabilize control hardware and instrumentation. I have seen plants where a momentary sag during motor starts caused field input modules to reset, leading to spurious alarms and occasionally to unnecessary trips.

Modern UPS systems and power conditioners can mitigate many of these issues, but only if they are sized and configured correctly. For example, the inrush current of Emerson controller power supplies, network switches, and monitors must be considered when specifying UPS output capabilities. Similarly, harmonic filters and careful grounding schemes help prevent noise from variable-frequency drives and large motor loads from coupling into sensitive control circuits.

Automation literature on gas plants, such as the work by Damien T. Dul, also highlights cybersecurity as an aspect of reliability. From a power systems viewpoint, segmented and well-protected control networks often share infrastructure with power distribution, including uninterruptible power supplies and networked switchgear controllers. Designing those systems with both electrical resilience and cyber segmentation in mind is now part of standard practice.

In practical terms, good design means that a localized power issue should not propagate into a plant-wide loss of visibility or control. That usually requires redundant Emerson controllers on separate UPS segments, redundant network paths, and a philosophy that refuses to single-feed any device whose failure would trip the plant.

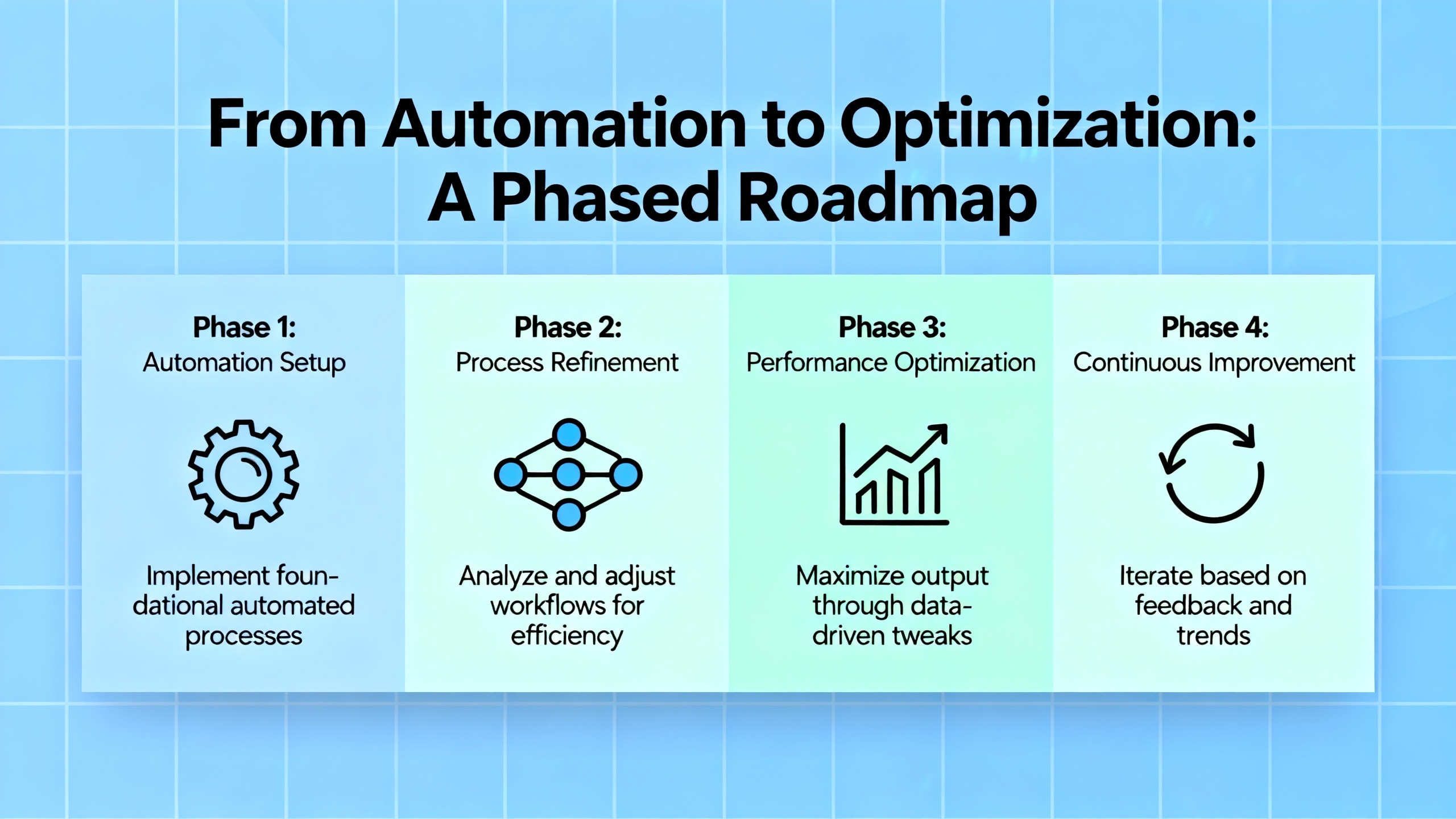

One of the most helpful insights from ImubitŌĆÖs work on self-optimizing gas plants is that automation maturity is a journey, not a switch you flip. That perspective aligns with what Blackthorn Vision, PakEnergy, COPAS, and others describe in the business process automation realm.

As already noted, Imubit starts with instrumentation and data governance before moving to control loop performance. Blackthorn Vision reinforces this, describing how analytics can only deliver value if the inputs from sensors, machines, and production systems are accurate and well-structured. They argue for using business analysts or similar roles to examine processes, identify bottlenecks, and ensure that the automation effort targets real problems.

From a plant perspective, this phase is where you pair your Emerson system engineers with process engineers, instrument technicians, and power engineers. The goal is to fix the basics: calibrate analyzers on a disciplined schedule, resolve noise issues, consolidate tag naming conventions, and stabilize loops. It is tedious work, but it pays back quickly in fewer nuisance alarms, smoother operations, and fewer midnight callouts.

With a stable base layer, advanced process control becomes viable. Imubit describes deploying APC on units like LPG extraction, fractionation, and condensate stabilization to keep them near their economic optimum while avoiding hydrate or phase boundary violations. In a gas plant context, that translates to controlling reflux flows, tower temperatures, compressor loading, and recycle streams in a coordinated way.

AI in advisory mode is a natural extension. ImubitŌĆÖs model is to have reinforcement learning systems trained on historical data propose setpoint changes and show, in dashboards, the expected profit and risk impacts. Operators remain in the loop, accepting or rejecting each recommendation. COPAS and FlowForma both stress how highly visible, well-documented workflows improve adoption and auditability, which is exactly what you want when AI starts influencing process conditions.

In plants I have helped evaluate, advisory systems often deliver two benefits long before full closed-loop control is allowed. First, they help operators see patterns that were previously buried in data, such as the subtle interactions between amine strength, circulation rate, and energy usage. Second, they create a shared language for discussing trade-offs between energy, throughput, and emissions.

The final step in ImubitŌĆÖs roadmap is closed-loop AI optimization, where the AI engine writes setpoints directly back to the control system under supervision. They report that this step can yield significant additional energy savings and margin uplift, provided the plant has already demonstrated reliable gains in advisory mode.

Imubit suggests a readiness checklist that includes operators routinely accepting recommendations, models remaining stable under changing feed conditions, and clear financial benefits being tracked. Risks such as data latency, cybersecurity, and cultural resistance are managed with redundant sensors, strict network segmentation, and frequent feedback sessions.

What matters for an Emerson-based gas plant is not only the technology but the culture. Triax TechnologiesŌĆÖ work on IIoT and workforce tools emphasizes that analytics and automation succeed only when workers are equipped and willing to use them. FlowForma highlights the usefulness of no-code automation and user-friendly interfaces in overcoming resistance among long-tenured staff. Proceso App reminds us that an aging workforce and harsh working conditions make automation attractive, but also mean you need strong training and change management to bring people along.

In practice, that culture shows up in small ways. It means operators using Emerson screens not just as alarm ack panels but as tools to explore ŌĆ£what ifŌĆØ scenarios. It means maintenance planners trusting equipment health data coming from sensors and predictive maintenance systems described by Blackthorn Vision. And it means leadership measuring and rewarding behavior that leverages automation rather than bypassing it.

To make the discussion concrete, the table below contrasts a traditional, largely manual gas treatment facility with one built around a modern control system and integrated automation stack.

| Aspect | Traditional Gas Treatment Facility | Automated Gas Treatment Facility with Modern Control Systems |

|---|---|---|

| Process control | Local panels, manual setpoint changes, limited trending | Centralized DCS, stable loops, real-time trending and remote access |

| Optimization | Operator intuition, periodic studies | Advanced process control and AI advisory optimizing continuously |

| Compliance and reporting | Paper logs, spreadsheets, manual compilation | Automated event capture, CAPA workflows, digital audit trails |

| Power and reliability | Mixed feeds, limited UPS coverage, frequent nuisance trips | Segmented UPS-backed control power, designed ride-through capability |

| Workforce and workflows | Tribal knowledge, slow onboarding, high manual data entry | Standardized digital workflows, faster training, reduced manual entry |

This is not a theoretical distinction. Axis Technical Group and COPAS both document how automated logistics and workflow systems can cut costs and reduce errors. PakEnergyŌĆÖs case study shows administrative overhead reductions of about thirty percent with integrated automation. Imubit demonstrates substantial energy and margin gains from advanced control and AI. Those are the kinds of differences you should be targeting when you deploy an Emerson control platform in a gas treating context.

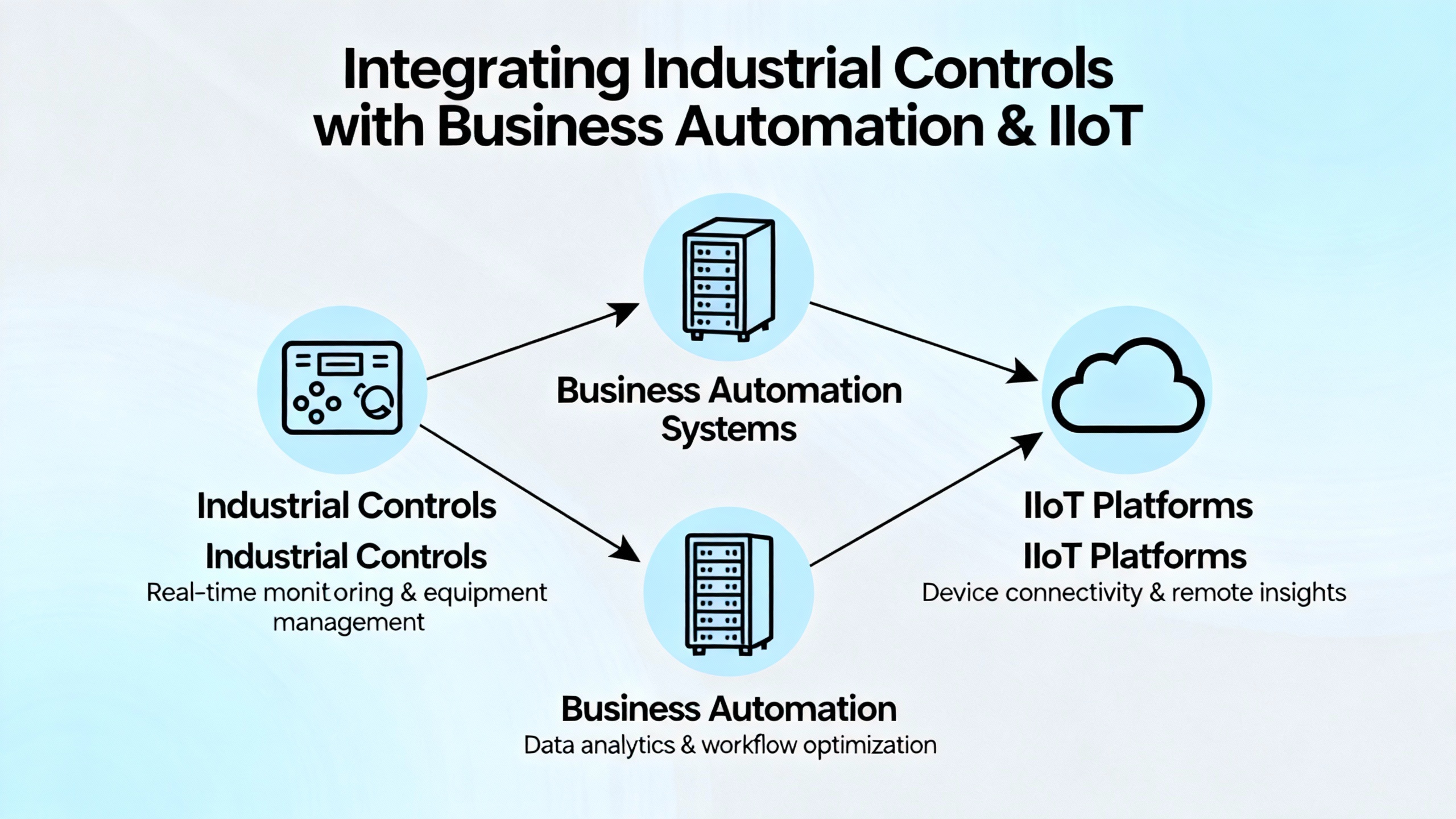

A modern Emerson installation in a gas treatment facility is not just a plant-level control layer. It is a data engine feeding business process automation, supply chain systems, and IIoT platforms.

PakEnergyŌĆÖs description of end-to-end business automation shows how field data capture, asset health monitoring, and financial reporting can be stitched together so that data flows seamlessly from the field to the finance department. COPAS details how having a single area of record that feeds accounting, production, and forecasting systems, plus automated alerts for manual journal entries, reduces redundancy and improves timeliness. DOCUmation notes that reporting is often the first function to be automated in oil and gas, giving teams better visibility into inventory and forecasting.

FlowForma and Petro Ledger stress that automating repetitive data collection and logging lets staff focus on higher-value tasks, while real-time data updates reduce the need for field trips and shorten feedback loops. Enverus, in its guide on business process automation for source-to-pay, shows how specialized procurement tools can increase spend visibility and control without burdening operations.

In a gas treating plant anchored on Emerson controls, this means that process events, maintenance data, and production metrics should not die in the historian. They should trigger workflows: CAPA investigations, maintenance work orders, procurement actions, and financial postings. The technical path runs from Emerson controllers to historians and OPC servers, then into business automation platforms and industry-specific toolsets. The organizational path runs from control engineers and operators to maintenance planners, compliance officers, and accountants.

Triax TechnologiesŌĆÖ work on IIoT and worker safety adds an important dimension. By equipping field staff with wearables and linking equipment and sites through IIoT platforms, they show how real-time data can improve safety, turnaround management, and operating costs. When those data streams are integrated with Emerson system alarms and historian trends, you get a more complete picture of what is happening in the plant, both in the process units and in the field.

The decision to standardize on Emerson control systems is often made for corporate reasons, but how you implement those systems in a gas treatment facility is where reliability and value are actually won or lost. Three themes consistently make the difference in projects I have seen up close.

Automation vendors and internal champions often promise the world. The literature is full of potential benefits: ImubitŌĆÖs margin improvements and energy savings, Axis Technical GroupŌĆÖs ten to fifteen percent cost reductions in logistics, PakEnergyŌĆÖs thirty percent administrative overhead reduction, COPASŌĆÖs faster audits, and FlowFormaŌĆÖs claim that no-code tools can accelerate digitalization several-fold.

Those are real, but your plant will not capture all of them. The first practical step is to decide what matters most. For a sour gas treating plant, the emphasis may be on HŌééS compliance, environmental reporting, and avoidance of flaring events. For a cryogenic NGL facility, the emphasis may be on energy per unit of product and maximizing recovery while staying within compressor and column constraints.

Once you settle on priorities, you can choose which Emerson features, which advanced control strategies, and which business workflows to focus on first. You can also define metrics: energy per unit of treated gas, tons of COŌéé per unit of throughput, number of unscheduled trips per quarter, time to close CAPA actions, or days to close the monthly books.

Imubit recommends a simple ROI framing: energy saved plus yield gain plus emissions credit, minus implementation cost. That framework applies just as well to your Emerson-based automation roadmap. It keeps the conversation grounded in numbers rather than buzzwords.

The best technical architecture fails if the people who use it are not ready, or if the power systems behind it are fragile.

Proceso App and FlowForma both point to workforce challenges: an aging workforce, difficulty attracting new talent, and resistance to change, especially where legacy systems are entrenched. Damien T. Dul warns that successful DCS deployment depends on intuitive operator interfaces, robust data analytics, and comprehensive operator training. Triax stresses the importance of workforce development and upskilling to make use of IIoT data and automation insights.

From my perspective, a good Emerson deployment for gas treatment always includes three non-negotiable elements alongside the hardware and software:

First, a training and simulation program that lets operators and engineers practice with realistic scenarios, including power disturbances, equipment failures, and AI recommendations they can accept or reject without risk.

Second, a deliberate change management plan that involves frontline staff early, uses their input to shape screen designs and alarm philosophies, and clearly explains why some long-standing manual practices will be replaced with automated workflows.

Third, a robust power system design that treats control power as a first-class citizen: segregated feeds, appropriately sized UPS and inverters, coordinated protection, and documented testing and maintenance plans.

FlowFormaŌĆÖs examples of using user-friendly interfaces and even simple techniques like QR codes to increase adoption may sound more relevant to office workflows than to gas plants, but the principle is the same. Make new tools easy and obviously useful, and you will get far better outcomes than if you simply drop a sophisticated Emerson system into an unchanged culture.

As automation and connectivity expand, the surface area for cyber and governance risks grows as well. Damien T. Dul calls out cybersecurity as a key concern in modern gas plant automation, and Triax talks about how digital refinery solutions can strengthen both physical and cyber security.

For an Emerson-based gas control system, that means segmenting networks, implementing strict access controls, and monitoring both system health and unusual activity. It also means governance: deciding who can change control logic, who can approve AI moving from advisory to closed-loop modes, and how changes are documented and reviewed.

COPAS notes that automated workflows and centralized digital records make audits faster and more predictable. That benefit does not happen automatically. It requires that Emerson configuration changes, advanced control deployments, and power system modifications all be captured in a way that finance, compliance, and safety teams can understand and trace.

Imubit emphasizes transparent audit trails for AI decisions, including the ability for operators to override recommendations and for analysts to review what the AI did and why. Applying similar discipline to Emerson control changes and power system settings is part of treating automation as a core operational asset rather than a one-off project.

In practice, it is essential. The industry evidence on automation benefits assumes that control systems and instrumentation are available when needed. Without robust, segmented UPS-backed power for Emerson controllers, safety systems, and networking, even short disturbances can cause loss of visibility, spurious trips, or unsafe conditions. The cost of a proper UPS architecture is negligible compared to the margin losses and safety risks of a plant that drops its control backbone whenever the lights flicker.

Both matter, but sequence matters more. The most reliable projects begin with instrumentation, data quality, and basic loop tuning, then layer on advanced process control and AI for the units that most directly affect margin and energy use. Once those are stable, the same data structures can feed business process automation for compliance, maintenance, and finance. That sequence reflects ImubitŌĆÖs phased approach on the process side and the staged automation roadmaps described by Blackthorn Vision, PakEnergy, and COPAS on the business side.

Focus on a small number of clear, evidence-backed value levers. ImubitŌĆÖs reported margin uplift of about twenty-five cents per barrel and energy reductions of fifteen to thirty percent for certain plants, PakEnergyŌĆÖs thirty percent reduction in administrative overhead in six months, and Axis Technical GroupŌĆÖs ten to fifteen percent savings in production costs from logistics automation provide credible reference points. Translate those into your facilityŌĆÖs scale, apply conservative fractions of the cited benefits, and express the result in annual dollars saved. Then set explicit targets and track them, using the ROI frame of energy saved, yield gained, and emissions credit earned, minus implementation cost.

Gas treatment facilities are becoming data-rich, highly automated assets where the control system and the power system that feeds it are as mission-critical as any compressor or tower. Emerson platforms, when combined with disciplined process automation, robust UPS-backed power, and thoughtful business workflows, can turn a conventional gas plant into a self-optimizing, audit-ready, and resilient operation. As a power and reliability advisor, my consistent recommendation is simple: treat automation and electrical resilience as a single integrated design problem, and you will build gas facilities that not only run today, but keep learning and improving for years to come.

Leave Your Comment