-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Migrating a distributed control system from an established ABB platform to a Yokogawa platform is one of the most consequential changes you can make in a plant. From a power systems and reliability perspective, it is the equivalent of openŌĆæheart surgery on the brain and nervous system that keeps your processes, UPS-backed loads, and critical auxiliaries running. Done well, you come out with higher availability, better cybersecurity, cleaner power integration, and a control architecture that can support the next decade of operational improvement. Done poorly, you increase the risk of extended outages, unsafe conditions, and years of ŌĆ£technical debtŌĆØ embedded in the new system.

Drawing on guidance from ISA, NIST, major automation vendors, and migration specialists such as MAVERICK Technologies, Rockwell Automation, and others referenced in the research notes, this guide walks through a practical, experience-backed approach to moving from ABB to Yokogawa with minimal pain and maximum long-term benefit.

Legacy DCS owners often stay with the status quo out of fear of change. As ISA authors note, the result is a slow drift into higher risk rather than stability. Multiple sources in the research converge on the same drivers that typically force action.

First, obsolescence and supportability become unacceptable. As Rockwell Automation and MAVERICK Technologies point out, many plants now depend on platforms that vendors have consolidated or discontinued. Spare parts become hard to find, and operators resort to what several articles call the ŌĆ£eBay and prayŌĆØ strategy for sourcing critical components. With an ABB system that is beyond its support horizon, a move to a stillŌĆæsupported Yokogawa platform can be less risky than trying to keep an aging system alive.

Second, knowledge is disappearing. Several papers highlight a growing shortage of engineers and technicians who truly understand older DCS generations. As they retire, the cost and risk of keeping a legacy platform increases. Migration is not just about new features; it is about securing a maintainable platform for the next generation of staff.

Third, cybersecurity pressure is rising. Guidance from NIST, the U.S. Department of Homeland Security, and HoneywellŌĆÖs migration white paper all emphasize that older ŌĆ£airŌĆægappedŌĆØ assumptions no longer hold. Many ABB systems in the field were designed for a world without todayŌĆÖs connectivity, while modern Yokogawa platforms can be designed from the start for defenseŌĆæinŌĆædepth, secure remote access, and better patch management.

Finally, there is a business case beyond avoiding disaster. Schneider Electric and Honeywell analyses underline that a modern DCS is one of the few investments that directly touches throughput, quality, energy use, and maintenance efficiency. Migration is a strategic, lifecycle-driven capital project, not just a technology refresh.

Before you debate I/O cards or marshalling panels, you need a crisp justification and clear objectives. TechWEMŌĆÖs planning guidance and HoneywellŌĆÖs white paper both stress that ŌĆ£whyŌĆØ must come before ŌĆ£how.ŌĆØ

Clarify your primary drivers. For an ABB to Yokogawa migration these often fall into a mix of obsolescence risk, cybersecurity gaps, lack of scalable capacity, and the need to support new units or optimization projects. Quantify the risk where possible using your own maintenance history, unplanned downtime events, and near misses. Several sources emphasize that you should compare the expected cost of continued breakdowns, emergency overtime, poor information visibility, and security exposure against the capital and project cost of migration.

Next, convert those drivers into measurable objectives. Drawing on TechWEMŌĆÖs SMART goal approach and ISA guidance, typical objectives include reducing unplanned process downtime by a defined percentage, achieving a given ISA or IEC cybersecurity level, consolidating multiple legacy consoles into a smaller number of Yokogawa operator stations, or enabling high-performance HMI that shortens abnormal situation response. Control Engineering reports that plants with modern HMIs on a modern DCS resolve abnormal events significantly faster and can reclaim several percent of lost capacity; those are the types of improvements that belong in your business case.

Finally, define the boundaries of this migration. Are you moving all ABB units to Yokogawa, or only certain process areas? Will safety instrumented systems remain on their current platform? How will power-related controls such as generator synchronization, load shedding, and UPS monitoring be handled? An honest scope definition becomes the anchor for later cost, schedule, and risk estimates.

Once you know why you are migrating, you need to decide how aggressive the redesign will be. The research repeatedly contrasts two main strategies that apply directly to ABB to Yokogawa projects.

Hargrove Engineers and several other sources describe a oneŌĆæforŌĆæone migration strategy. In that approach, every loop, piece of logic, and HMI element from the ABB system is recreated as closely as possible in Yokogawa. IEB Media and others call this replication. The primary benefit is familiarity and reduced upŌĆæfront engineering effort, especially for simple loops and basic PID control. Many legacy schemes can be autoŌĆæconverted by tools, which speeds configuration.

The downside, documented by Hargrove and Rockwell Automation, is that this ŌĆ£freezes the clock.ŌĆØ You carry decades of design decisions and workarounds straight into the new system, including structured text where the target platform offers cleaner function blocks, and large amounts of disabled or obsolete ŌĆ£dead code.ŌĆØ That inflates controller loading, complicates troubleshooting, and often ignores builtŌĆæin Yokogawa functions that could simplify control and improve reliability. As IEB Media notes, replication tends to be cheaper initially but more expensive across the full lifecycle because it gives up the advantages of a modern platform.

The alternative is a fromŌĆæscratch or innovationŌĆæfocused approach. HargroveŌĆÖs field experience shows that redesigning control strategies for the new platform can reduce logic from roughly one hundred blocks to around ten for the same function, with leaner code that is easier to maintain. The IEB Media article on modernization emphasizes that innovation allows you to adopt smarter I/O, advanced control, and better HMIs that lead to higher throughput, fewer safety incidents, and reduced unplanned downtime. MAVERICK Technologies and Honeywell both argue that this approach is where most of the long-term ROI lies.

For an ABB to Yokogawa migration, many plants adopt a hybrid. They replicate straightforward loops while redesigning complex schemes and operator interfaces. The key is to make this a deliberate, documented choice rather than defaulting to oneŌĆæforŌĆæone out of fear.

A concise way to view the tradeoff is captured below.

| Strategy type | Impact on ABB to Yokogawa migration | Strengths | Weaknesses |

|---|---|---|---|

| OneŌĆæforŌĆæone replication | Recreate ABB logic and graphics as closely as possible in Yokogawa | Faster for simple loops, easier for operators to recognize | Carries old design flaws, keeps dead code, misses modern features |

| FromŌĆæscratch redesign | Rebuild control narratives and HMIs to fit Yokogawa capabilities | Leaner code, better long-term maintainability, easier troubleshooting | Higher upŌĆæfront engineering effort, more change for operators |

| Hybrid | Replicate simple, redesign complex and critical areas | Balances risk and innovation | Requires strong governance to avoid inconsistent decisions |

The right mix depends on process complexity, the age and quality of your ABB configuration, and your risk posture.

Several research sources, including ISAŌĆÖs FEL guidance, MAVERICKŌĆÖs DCSNext methodology, and Control EngineeringŌĆÖs planning advice, all insist on the same discipline: successful DCS migrations are frontŌĆæloaded with engineering and planning.

FrontŌĆæend loading is a structured, phased process that moves from concept to detailed plan. Control Engineering describes three FEL phases with progressively tighter cost accuracy and scope definition. Even if you do not label them FEL1 through FEL3, the idea is the same. You evaluate whether an ABB to Yokogawa move is the right answer, define the future architecture and vendor strategy, then lock down scope, cost, and schedule before major spending begins.

Proper FEL for migration means you create subŌĆæplans early. The MAVERICK and ISA material call out project execution plans, commissioning plans, cutover plans, and even control room optimization plans that start in the business justification phase, not at the end. These documents formalize who is responsible for what, how changes will be managed, and how risks will be tracked.

The FEL process also forces stakeholder alignment. Multiple sources stress involving operations, maintenance, engineering, IT or OT security, and corporate management from the start. Without that, you risk friction later over automation levels, alarm philosophies, or power systems interactions such as automatic transfer schemes and generator control, which are critical to a power supply specialist.

Finally, FEL is where you map the migration strategy to your plantŌĆÖs outage windows. The DCS migration articles consistently caution that you must understand unit turnaround cycles, partial shutdown opportunities, and interactions between units so that ABB to Yokogawa cutovers line up with realistic maintenance opportunities.

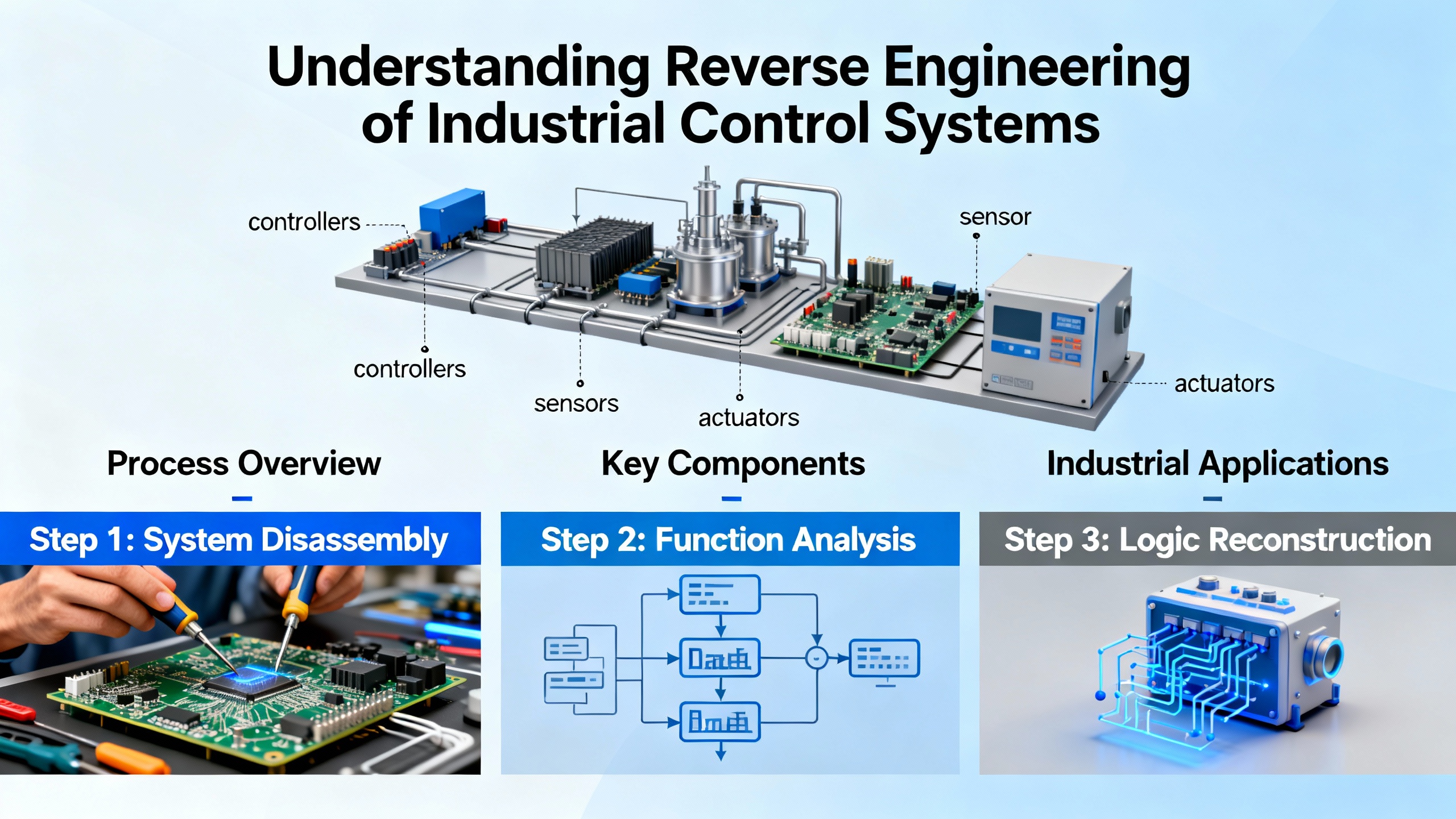

Regardless of your eventual strategy, the first technical task in any ABB to Yokogawa migration is deep reverse engineering of the existing ABB platform. Hargrove, Control Engineering, and multiple other sources make this clear.

Start with documentation. Collect and validate piping and instrumentation diagrams, loop sheets, panel and rack drawings, cable and conduit schedules, network diagrams, control narratives, alarm philosophies, and maintenance logs. Several authors note that many plants discover that what is in the cabinet no longer matches the drawing, and what is in the drawing does not reflect decades of incremental changes. This reconciliation is tedious, but every inconsistency you fix here saves you time and risk later.

Next, mine the ABB configuration database. You need to identify control modules, sequences, interlocks, batch logic, and interfaces to subsystems such as electrical protection relays, UPS and inverter monitoring, and packaged units. HargroveŌĆÖs guidance on ŌĆ£dead codeŌĆØ is particularly important: legacy systems are often full of unused or obsolete logic left behind from previous projects. Best practice, according to their experience, is to document that code and leave it out of the new configuration, then use structured testing to prove that what remains still does what you need.

In parallel, study graphics and alarm behavior on the ABB HMIs. Operators are usually very clear about which screens work and which do not. Multiple sources, including ASM-based HMI case studies, show that modern high-performance graphics and rationalized alarms can significantly improve situation awareness and reduce operator error. Capture current pain points and good practices so that the Yokogawa design does not start from a blank sheet psychologically.

Finally, talk to people. The research on common pitfalls emphasizes that failing to include operators and maintenance staff in early scoping leads to missed requirements and resistance to change. Interviews reveal undocumented workarounds, informal operating modes, and tribal knowledge around power system behavior during black starts, load shedding events, or UPS transfers. That knowledge needs to be reflected in the control narrative and not left in a few peopleŌĆÖs heads.

Once you understand the ABB system, you design the Yokogawa architecture and configuration. Several sources, including a Control Engineering case study, recommend building a formal functional design specification or control narrative as an independent reference. Rather than copying ABB logic, you define how the process should behave, then implement that behavior on the Yokogawa platform.

Architecture decisions should be driven by both process and power reliability. Research from BBa Consultants and others highlights the importance of modernizing control networks and server infrastructure. This is the moment to ensure your Yokogawa controllers, servers, and engineering workstations are supplied from redundant UPS systems and clean feeders, with clear segregation between control power and highŌĆæenergy process loads. A modern OT network, typically Ethernet based, becomes the nervous system that ties Yokogawa, electrical protection, and auxiliary systems together; if you leave this on antiquated cabling and unmanaged switches, you undermine the value of the new DCS.

On the application side, modern DCS platforms, as discussed by Plant Engineering and Rockwell Automation, make it easier to incorporate advanced control strategies, windup protection, better initialization, and even model predictive control where appropriate. Even if you are not implementing advanced algorithms on day one, you should design control modules and Yokogawa templates so that they can accommodate future enhancements without major rework.

High-performance HMI deserves special attention. ISA and ASM-aligned guidance, along with quantitative data cited by Control Engineering, show that operators resolve abnormal conditions much faster with thoughtfully designed modern graphics and rationalized alarms. When migrating from ABBŌĆÖs HMI to YokogawaŌĆÖs, use this as a chance to standardize layouts, color conventions, and alarm priorities. For power-system related graphics, that means clear depictions of oneŌĆæline diagrams, breaker status, UPS states, and load shedding schemes without clutter.

Finally, plan integration with other systems early. Multiple articles highlight the importance of connecting the DCS to historians, asset management systems, and business platforms. If your Yokogawa system will collect detailed data on power quality from UPSs and switchgear, or will participate in energy management schemes, design those interfaces up front, not as an afterthought.

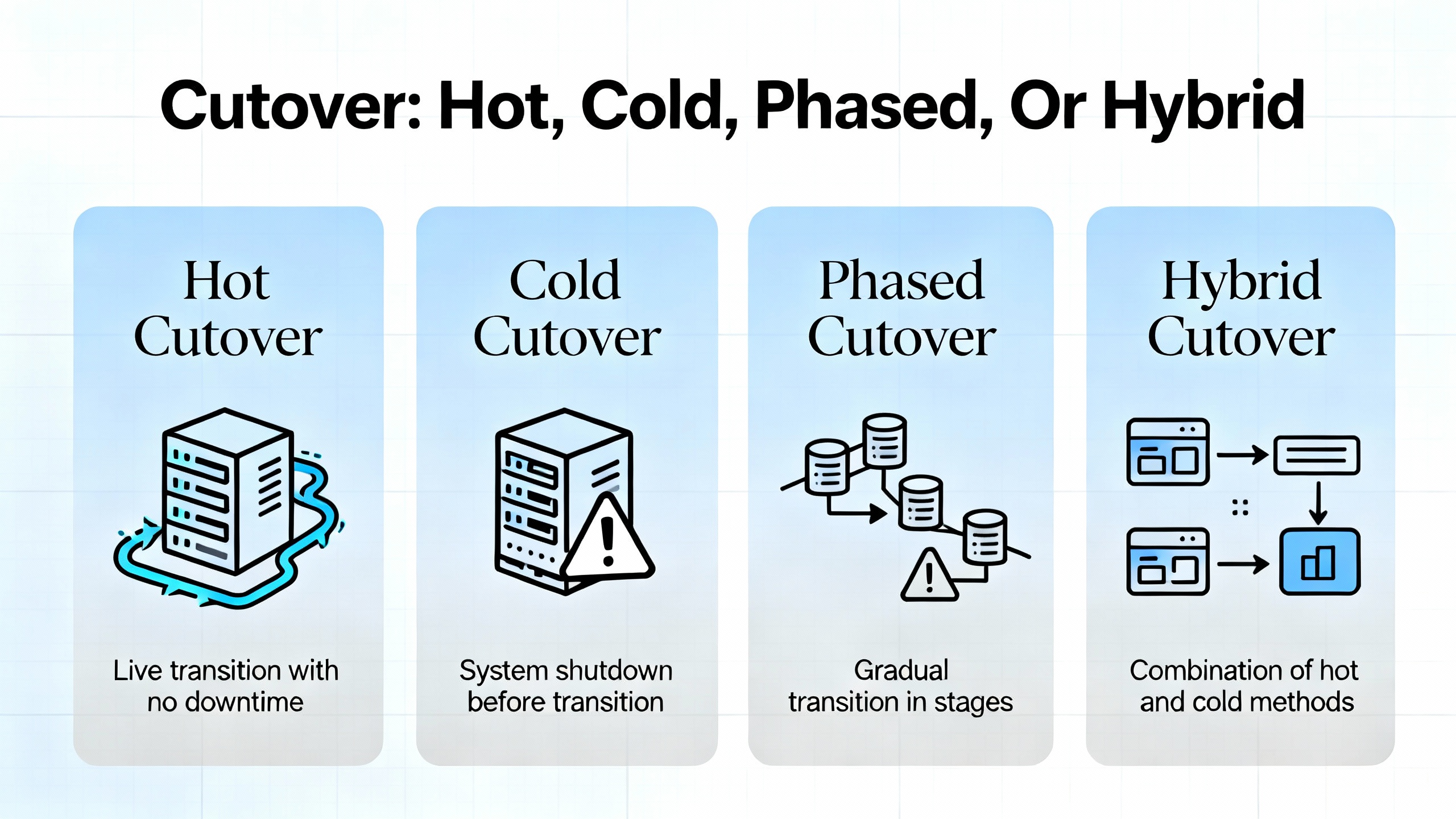

The highest risk period in any DCS migration is the cutover, when control moves from ABB to Yokogawa and field wiring or I/O assignments change. ISA and several migration best-practice articles are very explicit about this.

There are two main dimensions of cutover strategy described across the research. The first is ripŌĆæandŌĆæreplace versus phased migration. A ripŌĆæandŌĆæreplace approach swaps the entire ABB system for Yokogawa in one outage. This often minimizes the total number of outages and can simplify some engineering, but it demands a long, continuous shutdown and leaves little room for learning. A phased approach breaks the work into multiple windows, often unit by unit or layer by layer, spreading cost and risk while keeping more of the plant online.

The second dimension is hot versus cold cutover. In a cold cutover, the ABB system is shut down and the Yokogawa system takes over in one step, with no overlap. In a hot cutover, some or all of the ABB and Yokogawa systems run in parallel for a period. IEB Media and Rockwell Automation both report that most plants prefer hot cutover where feasible because each loop or subsystem can be moved individually, and control can fall back to ABB if Yokogawa behavior is not yet correct.

For an ABB to Yokogawa migration in a process that cannot easily stop, a phased, hot cutover is often the safest. HargroveŌĆÖs example of running new DCS I/O in parallel with the old system until commissioning is complete illustrates how this can work. That approach does require additional rack room space, temporary power supply arrangements, and careful management of instrument terminations and power to avoid confusion.

From a power systems standpoint, cutover is especially sensitive. Many control loops related to generators, transformers, UPS systems, and critical feeders may have low tolerance for misbehavior. Early in planning, classify which of those must be migrated only during full outages, and which can tolerate loopŌĆæbyŌĆæloop hot cutover under close supervision. Ensure that backup power arrangements for the control room itself are robust enough to handle an extended hot cutover window without risking brownouts to the very systems you are commissioning.

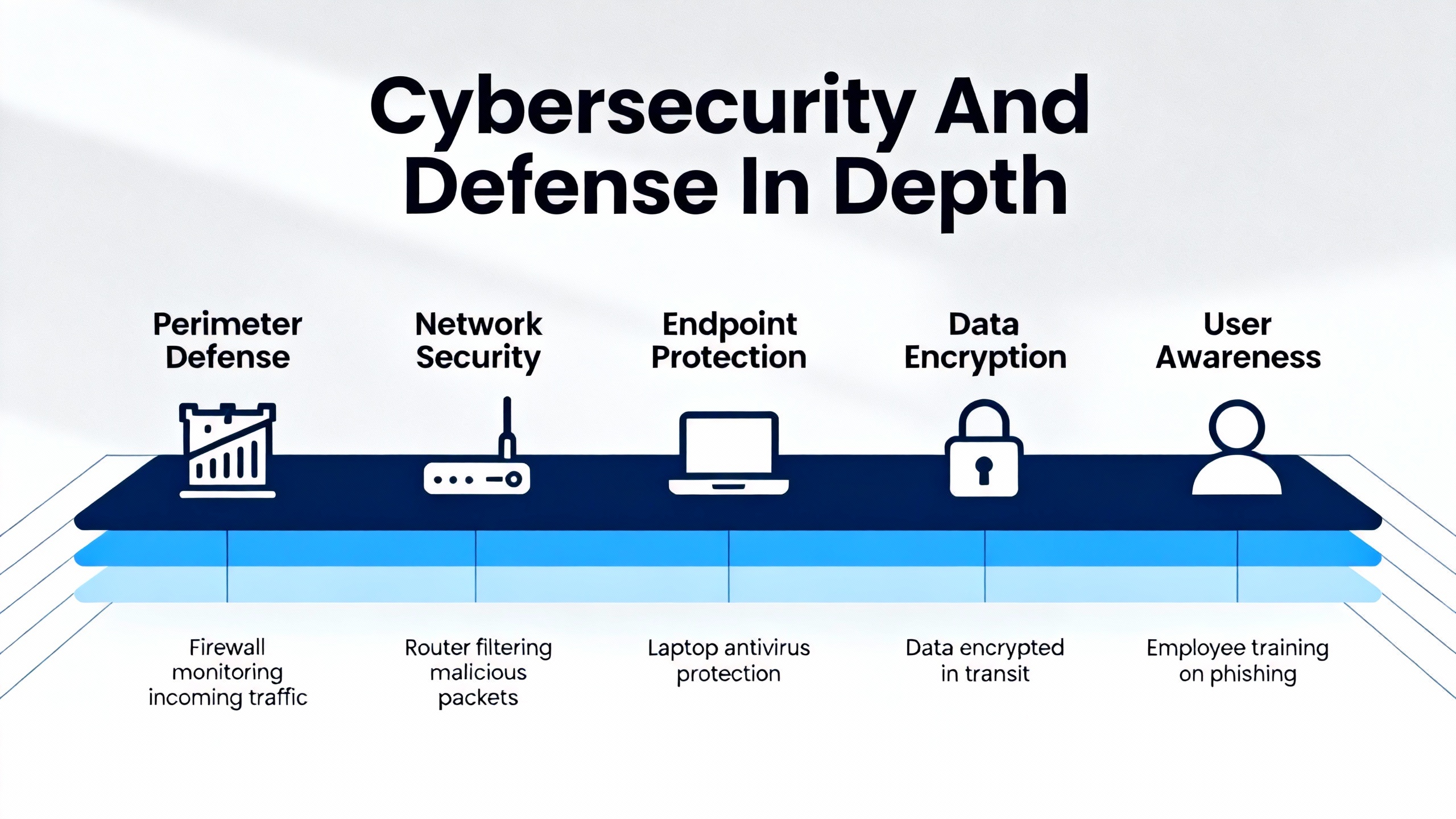

Migration is the time to redesign cybersecurity, not just replicate ABB network rules in a Yokogawa configuration. Research from GCG, Honeywell, and NIST-aligned guidance all converge on treating cybersecurity as a core design requirement.

HoneywellŌĆÖs white paper emphasizes a defenseŌĆæinŌĆædepth strategy in which control systems, safety systems, and networks are independent enough to avoid commonŌĆæcause failures or unintended access paths. When designing the Yokogawa environment, that means segmenting networks, deploying firewalls between plant and business domains, and aligning user authentication with corporate identity management where appropriate.

Older ABB implementations often lacked regular patching or security monitoring. Several sources note that industrial control systems tend to miss routine updates, making them attractive cyber targets. As you migrate, define a realistic patch and update policy for Yokogawa that balances uptime with security, and build in monitoring so that unusual activity is detected rather than assumed away.

Cybersecurity also intersects with power reliability. If your Yokogawa system will participate in load shedding, breaker control, or generator dispatch, then a cyber compromise can have immediate power system consequences. Treat these functions as critical from both a security and power-protection standpoint.

Every migration case study and best-practice article in the research set stresses testing, simulation, and validation. ISA and IEB Media call out both factory acceptance tests and site acceptance tests as nonŌĆænegotiable.

Factory acceptance testing should occur at the system integrator or vendor site before any Yokogawa equipment ships. Based on guidance from TechWEM and others, you want to simulate the ABB environment as closely as is practical. That includes controller logic, HMI graphics, alarm behavior, and representative I/O signals. Investing in controller simulation, as several sources recommend, is especially valuable because logic errors are far harder to correct during live commissioning than HMI cosmetic issues.

Site acceptance testing verifies that the installed Yokogawa system is wired correctly, communicates properly with field devices, and behaves as intended in the real process environment. It should include loop checks, function tests, and where possible, dry runs of startup or shutdown sequences. For power and UPS-related controls, this might include simulated transfer scenarios, breaker interlock checks, and validation that load shedding logic does not trip the wrong feeders.

Across the sources, a common theme is that accurate simulation is worth the cost. Rushed goŌĆælives without full functional, performance, and security testing are repeatedly cited as root causes of early production failures.

Technical design alone does not make an ABB to Yokogawa migration successful. EurekaŌĆÖs analysis of migration pitfalls and multiple other sources emphasize that change management and training are often neglected and then show up as postŌĆæstartup problems.

Operators and maintenance technicians will live with the new Yokogawa system every day. If they are not part of early planning and reverse engineering, they are more likely to resist new graphics, control philosophies, or alarm behaviors. Conversely, when they help define what is wrong with the ABB system and what the Yokogawa system should improve, buyŌĆæin increases.

Structured training should begin well before cutover. TechWEM recommends handsŌĆæon sessions using the actual system or a simulator. That is particularly important for HMI and alarm changes; highŌĆæperformance graphics can feel unfamiliar at first even though they ultimately improve performance. For power-system and UPS interfaces, training should cover normal operations and abnormal conditions such as loss of utility, generator start, UPS battery discharge, and recovery.

Communication is just as important as formal training. Keeping stakeholders updated on schedule, risks, and expected benefits reduces rumor and fear. When operators see that new Yokogawa graphics will help them spot abnormal situations faster, or that improved diagnostics will reduce nighttime callouts, they are more likely to embrace the change.

Migration does not end at startup. Eureka and several other sources warn that postŌĆæmigration support is frequently underestimated.

In the first weeks and months on Yokogawa, track performance carefully. That includes process metrics, alarm rates, and powerŌĆærelated events such as nuisance trips or UPS alarms. Use this data to fineŌĆætune control loops, alarm settings, and HMI layouts. Many plants plan a formal optimization phase after initial stabilization specifically for this purpose.

You also need a clear long-term support plan. This ties back to earlier research from Schneider Electric, Honeywell, and others about evaluating vendor support horizons. Clarify with your Yokogawa supplier how long hardware and software will be supported, what the upgrade roadmap looks like, and how often you should expect major version changes. Build ongoing patching, backup, and test procedures into your maintenance program so that the new system does not quietly drift into the same obsolescence trap that drove you off ABB.

From a power systems perspective, revisit your reliability model after migration. Verify that UPS autonomy assumptions are still correct now that you have new servers and network infrastructure. Confirm that single failures in power distribution to the control system cannot take down both redundant Yokogawa paths. Update protection coordination and emergency procedures to match the new reality.

The research emphasizes comparing the risks and lifecycle costs of staying where you are versus migrating. If your ABB platform is fully supported, modern, and aligned with your future needs, there may be no urgency. When support is ending, spare parts are scarce, cybersecurity is weak, or you cannot implement needed improvements, a vendor change becomes easier to justify. You should evaluate both technical and business factors, including the strength of each vendorŌĆÖs support, migration tools, and long-term roadmap.

Many migration case studies describe reusing field instruments and wiring while replacing controllers, I/O, and HMIs. The decision depends on condition, standards, and how easily Yokogawa hardware can interface with existing terminations. Reverse engineering, careful documentation, and sometimes temporary parallel hardware are required to reuse existing infrastructure safely. Network and server infrastructure, particularly older cabling that does not support modern Ethernet, is often a priority for replacement.

For a power supply specialist, the DCS is one of the highest criticality loads on the UPS and auxiliary distribution. Before cutover, verify that both the ABB and Yokogawa systems (during parallel operation) can be supported by existing UPS capacity and distribution. During design, ensure redundant feeds, proper segregation of critical and noncritical loads, and clear documentation of which panels feed which DCS components. After migration, test power failure scenarios in a controlled way to confirm that the new system and its power supplies behave as expected.

A migration from ABB to Yokogawa is demanding, but it is also a onceŌĆæinŌĆæaŌĆæcareer chance to clean up control logic, modernize cybersecurity, tighten power-system integration, and build a platform that will carry your plant forward. With disciplined frontŌĆæend planning, rigorous reverse engineering, careful cutover strategy, and genuine attention to people and power reliability, you can turn a highŌĆærisk project into a longŌĆæterm advantage.

Leave Your Comment