-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

When you are responsible for industrial and commercial power supply systems, your UPS, inverters, and power protection equipment are only as reliable as the measurements feeding their controls. Flow sensors watching cooling water, pressure and level transmitters on fuel and dielectric systems, temperature probes on transformer rooms, and vibration sensors on rotating equipment all form the early-warning network that keeps downtime away from your switchgear lineup.

IFM sensors sit right in the middle of that picture. The brand is known for robust industrial sensing and automation hardware, and, crucially for reliability engineers, it is supported by a mature global supply chain. The practical question is not whether IFM sensors can do the job; it is where to buy them so you can get the right part quickly, with confidence in quality and support.

This article walks through the main options for buying IFM sensors fast, using published information from ifm, authorized distributors, and specialized stocking partners, and frames it in the context of power and industrial measurement reliability.

IFMŌĆÖs portfolio spans the measurement points that matter in power and process environments. Their own product taxonomy highlights sensors, condition monitoring, image processing and identification, safety technology, industrial communication and IO-Link, systems for mobile machines, IIoT solutions, connection technology, voltage supply, and accessories. In other words, they do not just supply point sensors; they provide the ecosystem around them.

Position and object detection are covered by inductive, capacitive, photoelectric, cylinder, and magnetic sensors, as described by Automation24. Inductive sensors detect metal targets without contact, which is standard practice for limit detection on breaker mechanisms, motor couplings, and mechanical interlocks. Capacitive sensors extend detection to bulk materials and liquids, including through non-metallic tank walls, where ifmŌĆÖs own application notes describe minimum level, leakage, and overflow detection in industries such as wood, paper, glass, plastic, food, chemical, and semiconductor. In a power context, that same approach can be applied to non-metallic day tanks, chemical feed tanks for cooling water treatment, or dielectric fluid reservoirs.

Process sensors from IFM, summarized by Automation24 and ifmŌĆÖs portfolio pages, include flow meters, pressure sensors, resistance thermometers, temperature sensors, level and point-level devices, and volumetric flow meters. These are media-contact devices with high resistance to pressure, vibration, and shock, designed for demanding environments. They are exactly the kind of instrumentation used to protect UPS cooling circuits, monitor transformer oil or cooling water flow, and supervise fuel delivery for generator sets.

Condition monitoring equipment from IFM focuses on vibration and diagnostic tools. According to Automation24, vibration and motion sensors support drive monitoring and help avoid premature machine failures. When you tie that into UPS fans, pump motors, or auxiliary drives in your power plant, these sensors become the front line for predictive maintenance.

On top of the sensing layer, IFM invests heavily in IO-Link and other industrial communication solutions. Both Automation24 and Advantage Electric Supply emphasize IO-Link as a flexible, fieldbus-independent digital interface that exposes sensor parameters and diagnostics to the control system. In practical terms, that means you can remotely parameterize an IFM sensor, read its internal status, and feed that data into your IIoT or reliability analytics platform without sending a technician with a screwdriver to every device.

Finally, IFMŌĆÖs IIoT solutions and mobile systems categories, as described on their own site and by Cross Company, tie these sensors and controllers into digital architectures for both fixed and mobile equipment. For mobile power assets such as utility trucks or generator trailers, Cross Company has used IFM mobile controls and sensors for more than 15 years, integrating them as complete control systems programmed in Codesys.

Taken together, IFMŌĆÖs range covers position, process, motion, safety, and communication layers. For a power-system-focused reliability engineer, that means you can standardize many of your key measurement points on a single brand, then decide where to purchase based primarily on availability, quality assurance, and support rather than on whether the needed product exists.

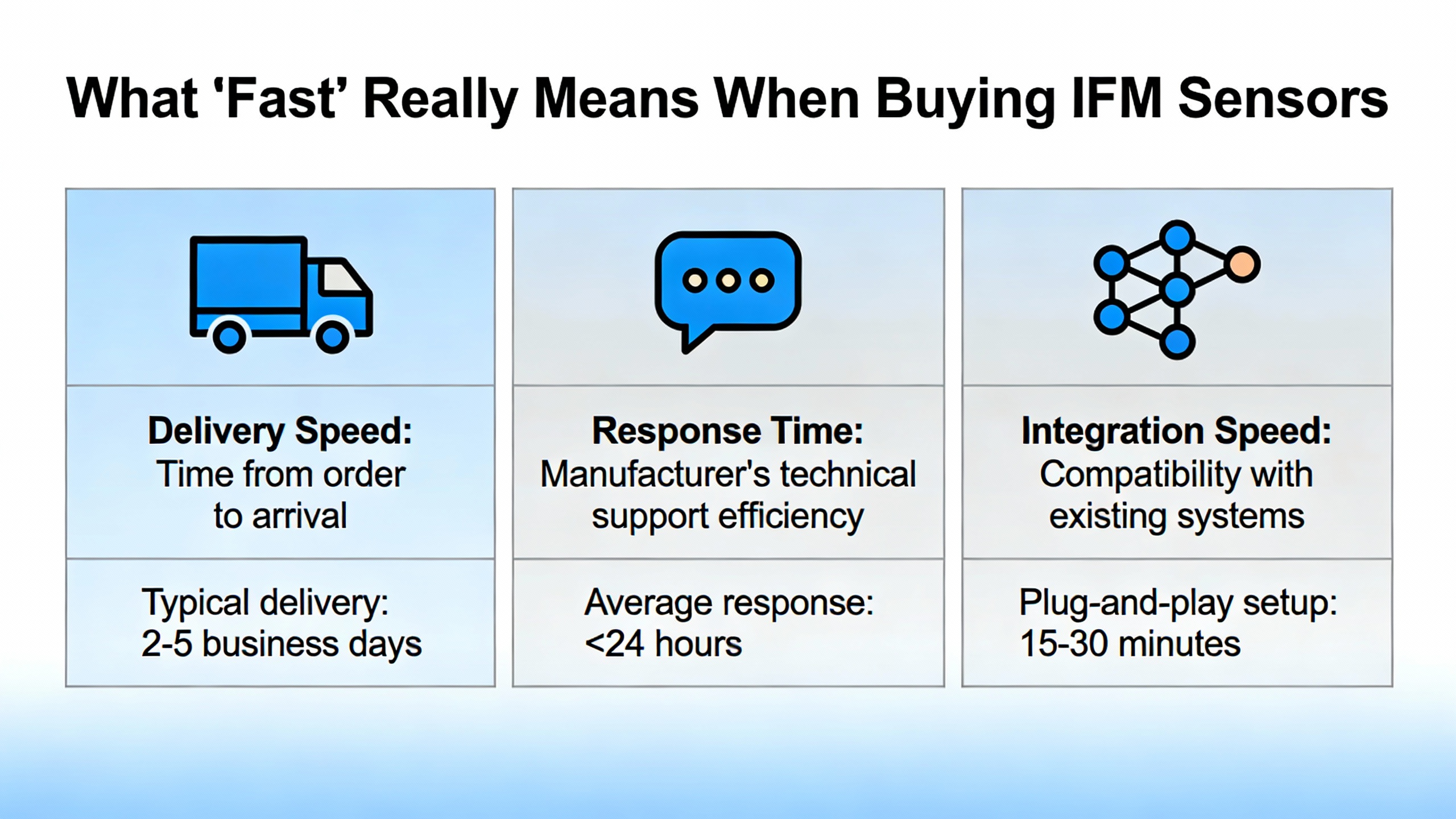

ŌĆ£FastŌĆØ is not just how quickly a supplier can ship a box. From an uptime perspective, speed has at least three dimensions: fulfillment speed, decision speed, and recovery speed.

On fulfillment speed, IFMŌĆÖs own data is unusually specific. The company describes a build-to-stock manufacturing model, with products made for inventory rather than only on demand. They report that roughly 90% of orders ship within 24 hours. In North America that capability is supported by a 53,000-square-foot stocking and distribution facility in Downingtown, Pennsylvania. According to IFM, this warehouse holds around 4,354 unique part numbers and approximately 389,000 individual products, ships more than 1,400 small parcels per workday, and maintains two to three months of inventory on hand. Production lead times are described as being measured in hours, not weeks.

For a reliability engineer, those numbers are important. If a level sensor in a generator day tank fails, and your plant loses redundancy on fuel delivery, the cost of waiting two weeks for a part may dwarf the premium of buying from a supplier that can ship overnight. Imagine a facility where a critical line produces $50,000.00 of value per hour. An eight-hour outage caused by a missing flow or pressure sensor would roughly translate to $400,000.00 in lost value, before cleanup and recovery costs. In that light, choosing a channel that can typically ship within a day is effectively a risk-control decision, not a purchasing convenience.

Decision speed is the time from detecting a problem to placing a correct order. If you waste three days chasing the wrong part number, debating sensor technology, or waiting for a quotation, a fast warehouse does not help. This is where transparency of product data and access to competent support become part of what ŌĆ£fastŌĆØ means. Authorized distributors like Advantage Electric Supply emphasize expert teams that help specify inductive, capacitive, photoelectric, ultrasonic, and process instrumentation devices for particular applications. Automation24 similarly offers parameterization services for IFM encoders and temperature sensors, which can remove a configuration step during commissioning. These capabilities shorten the decision window by turning vague problem descriptions into concrete parts lists.

Recovery speed is everything after the box arrives: installation, configuration, and validation. Sensors that use IO-Link and have clear parameter sets, as IFM promotes across its IO-Link range, allow remote configuration and diagnostics. Application notes on capacitive level sensors, for example, describe how parameters can be set via onboard buttons or via IO-Link, and how variants with automatic load detection simplify commissioning with different evaluation systems. The faster you can swap a device, configure it correctly, and verify operation, the smaller your downtime window.

With that understanding of speed, you can compare the main categories of suppliers for IFM sensors.

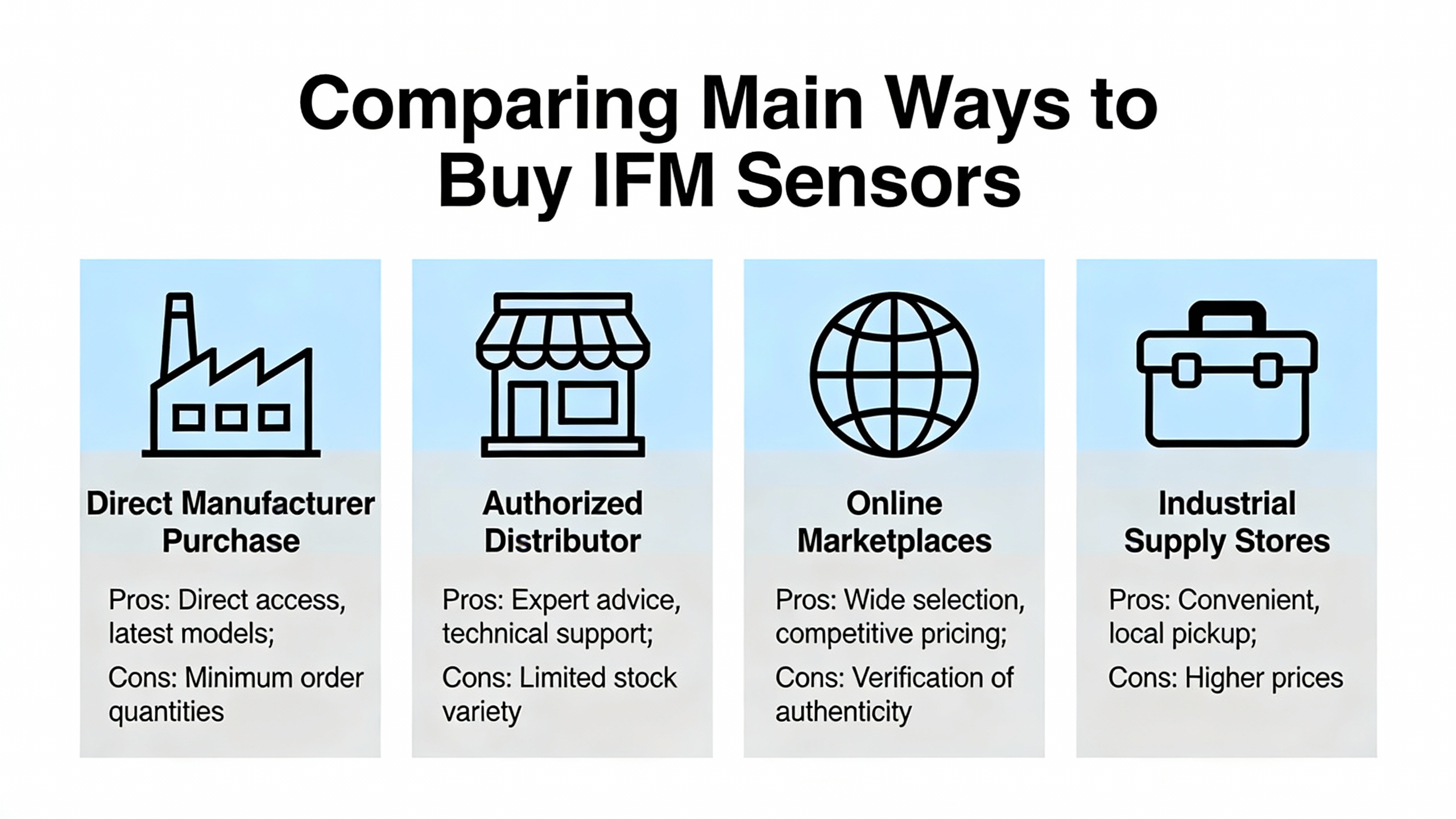

The industrial market offers several distinct channels for IFM sensors. Each has different strengths in speed, engineering support, and quality control.

| Source type | Example providers (from research) | Primary strengths for speed and reliability | Typical use cases in power and measurement |

|---|---|---|---|

| Manufacturer direct | ifm efector (ifm US) | Build-to-stock, about 90% of orders ship in 24 hours, deep product expertise | Standard sensors, new designs, IIoT projects, broad standardization |

| Authorized electrical/automation distributor | Advantage Electric Supply, Industrial Electrical Warehouse | Stock breadth, local relationships, technical support, promotions | Multi-vendor projects, plant-wide upgrades, mixed technologies |

| Online automation specialist | Automation24 | Focused IFM assortment, parameterization services, online convenience | Fast replacement of common sensors, standardized SKUs, remote buying |

| System integrator and solution partner | Cross Company | Custom systems, Codesys programming, long-term engineering support | Mobile power equipment, OEM platforms, complex control architectures |

| Obsolete and hard-to-find specialist | 4 Star Electronics, Industrial Parts R Us, Zancot | Obsolete parts, rigorous anti-counterfeit QA, quote-based sourcing | Legacy UPS and process systems, last-time buys, like-for-like replacements |

The rest of this article explores how and when each channel is the fastest and most reliable option, viewed through the lens of industrial measurement and power protection.

IFMŌĆÖs own North American operation combines manufacturing, inventory, and logistics to offer short lead times. Their build-to-stock model and statistics such as roughly 90% of orders shipping within 24 hours, thousands of stocked part numbers, and several hundred thousand units on hand indicate that for many catalog items, the manufacturer itself is essentially a high-speed warehouse.

From a power-system standpoint, buying direct makes particular sense when you are:

Working on a standardized design or fleet program. If you are rolling out a common UPS, inverter, or switchgear platform across multiple sites, standardizing on IFM sensors directly from the manufacturer can simplify part number management and reduce the risk of substitutions. IFMŌĆÖs broad portfolio, which includes position sensors, process instruments, condition monitoring, IO-Link modules, and connection technology, supports a consistent design language.

Leaning into IIoT and advanced diagnostics. IFM promotes an IIoT-focused portfolio: IO-Link-enabled sensors, smart connectivity, and solutions that tie field devices into analytics platforms. When you need deep support on how, for instance, a vibration sensorŌĆÖs IO-Link diagnostics map into your condition monitoring system, manufacturer-level application support is often the fastest path.

Requiring predictable ongoing availability. With two to three months of inventory in a regional warehouse and build-to-stock manufacturing, IFM positions itself as a reliable long-term source. That matters if you want assurance that a specific flow, pressure, or distance sensor will be available on short notice for years, not just for the current project.

A practical example is a chilled-water cooling loop serving a large inverter or UPS bank. Suppose that loop relies on IFM flow sensors and pressure transmitters. Standardizing those measurement points using part numbers that IFM stocks heavily, and aligning your plantŌĆÖs spares strategy with IFMŌĆÖs own inventory levels, reduces the chance that a sensor failure will leave you waiting weeks for a replacement.

The main limitation of buying direct is that it focuses on IFMŌĆÖs own catalog. If you are building a system that mixes multiple brands, or if you need on-site visits and multi-vendor coordination, an authorized distributor or integrator may provide a more convenient one-stop experience.

Organizations such as Advantage Electric Supply and Industrial Electrical Warehouse occupy the middle ground between manufacturers and online-only stores. Advantage Electric Supply explicitly positions itself as an authorized distributor of IFM Electronic, combining IFMŌĆÖs engineering with a broad distribution network. Industrial Electrical Warehouse highlights IFM sensors and automation products alongside promotions and deal-driven collections.

Authorized distributors add value in several ways that influence speed:

They stock a curated portfolio of IFM sensors. Advantage Electric Supply describes offerings that include inductive, capacitive, photoelectric, and ultrasonic sensors, as well as pressure, flow, and temperature instruments, IO-Link technology, fieldbus systems, and controllers. That breadth allows a plant engineer to source most of the required measurement and communication hardware from a single purchase order.

They provide application-level guidance. Both Advantage Electric Supply and Industrial Electrical Warehouse emphasize expert support and tailored recommendations. For power-related measurement, that might mean aligning the pressure ranges of sensors with pump curves, confirming that inductive sensors used on breaker mechanisms are correctly rated for the available DC supply, or choosing between analog and IO-Link outputs for integration with your existing PLCs.

They often align with existing purchasing workflows. Many industrial and commercial facilities already buy breakers, cable, and panel hardware through their electrical distributor. Folding IFM sensors into those arrangements can simplify credit terms, logistics, and documentation.

Imagine a plant upgrading the power monitoring and condition monitoring across a medium-voltage switchgear room. The project includes IFM inductive sensors on mechanical interlocks, temperature sensors near bus ducts, flow and pressure transmitters on auxiliary cooling systems, and IO-Link masters to bring these points into a central controller. An authorized distributor that stocks IFM and related connection technology can build a complete, compatible bill of materials and ship it as a consolidated order, reducing both lead time and the risk of mismatched parts.

Industrial Electrical Warehouse also markets monthly deal collections, best sellers, and limited-time promotions. While the research notes do not include specific prices, this kind of structure can make it easier to source common IFM sensors at competitive cost without sacrificing lead time.

Automation-focused online stores such as Automation24 specialize in a narrow but deep industrial automation range, including IFM sensors, control, signaling, and connection technology. Automation24ŌĆÖs overview of IFM products emphasizes complete system monitoring and optimization, with position, process, and motion sensors plus IO-Link and high-quality sensor cabling.

The speed advantages here are mostly about convenience and configuration:

Products are organized by function and technology. For example, Automation24 categorizes IFM position sensors into inductive, capacitive, photoelectric, cylinder, and magnetic types, and process sensors into flow, temperature, volumetric flow, pressure, level, and point-level devices. That structure helps engineers quickly filter to the right sensor type and form factor, especially if you are replicating an existing design from another site.

Parameterization services reduce commissioning time. Automation24 notes that they can pre-parameterize IFM encoders and temperature sensors on request. In a power or industrial measurement context, having a temperature sensor arrive with ranges already set to match your PLC scaling can save valuable time during a planned outage.

Connection technology is treated as a first-class product. They highlight robust M12 sensor and connection cables and circular connectors, which are essential for reliable operation in high-vibration environments such as motor control centers and generator rooms. Ensuring that the correct cable assemblies are on the same order as the sensors removes a common source of last-minute delays.

Typical use cases for an online specialist include fast replacement of standard inductive proximity sensors, temperature transmitters, or IO-Link distance sensors where the part number is known and the mechanical layout is fixed. For example, replacing an IFM precision distance sensor used for position feedback on a bus transfer mechanism benefits from the detailed product listings and selection recommendations Automation24 provides, while leveraging their logistics to get the device onsite quickly.

Online specialists are strongest when you know exactly what you need and want to minimize friction between identifying the part and checking out. For more complex problems where you are still deciding on measurement principles or communication architectures, manufacturer or distributor application support is usually more efficient.

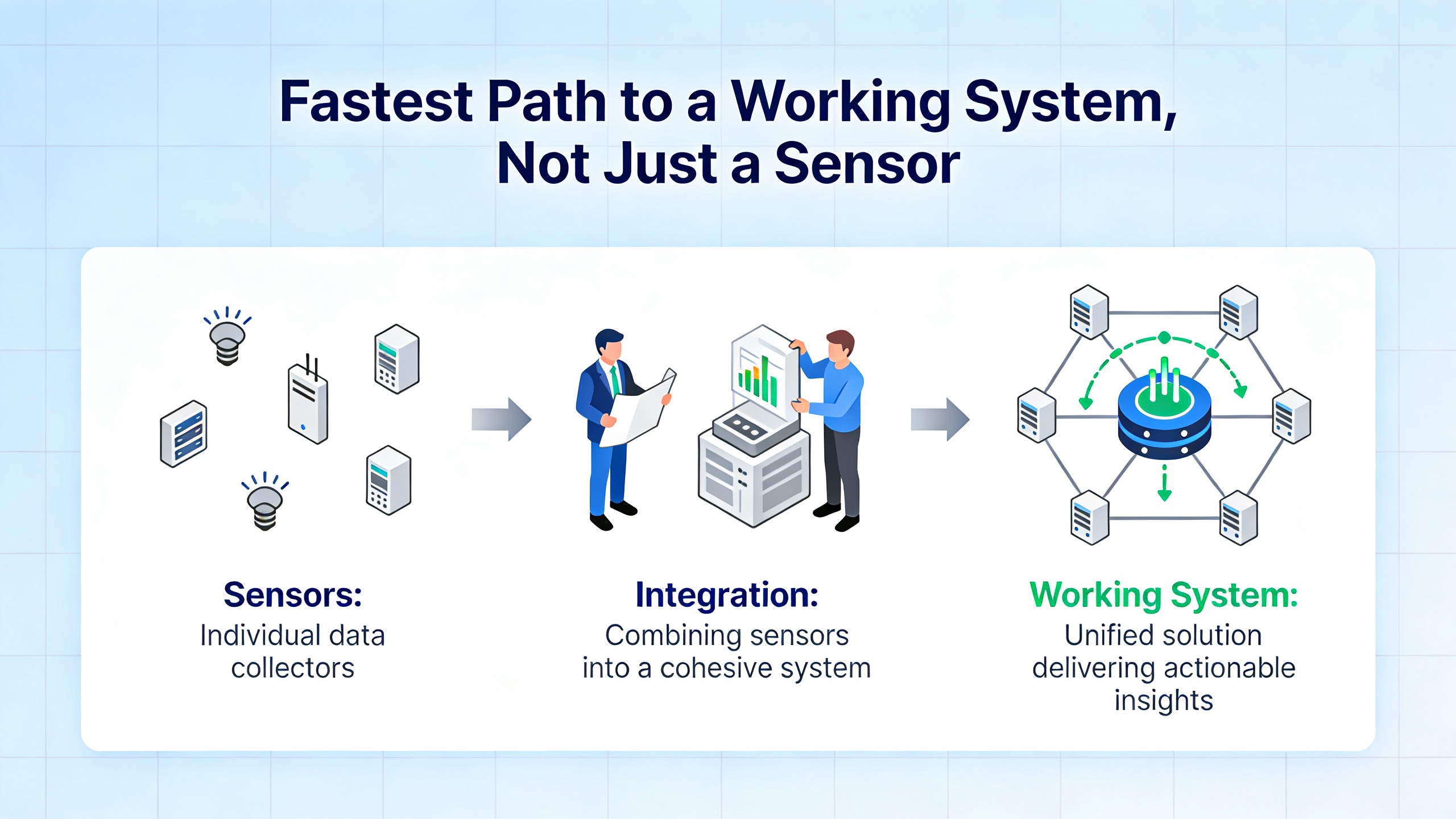

In some projects, the bottleneck is not sensor delivery; it is engineering bandwidth. If you are developing a mobile power solution, such as a utility work truck or a generator-based airport support vehicle, you might need a complete control and measurement architecture rather than a handful of discrete sensors.

Cross Company illustrates this role. They have used IFM mobile control products and sensors for more than 15 years, acting as a system integrator and solution provider rather than a pure distributor. Cross organizes IFM-based mobile solutions around controllers, displays, and sensors, and their engineers custom program these systems using Codesys.

In that context, ŌĆ£fastŌĆØ means getting from concept to reliable operation quickly. Instead of internally designing the logic for, say, monitoring generator voltage, engine parameters, hydraulic pressures, and safety interlocks on a mobile platform, you can work with an integrator that already has experience applying IFM equipment in sectors such as utility/work trucks, construction, and material handling.

For stationary power-system projects, system integrators become relevant when you are deploying new architectures, such as combining IFM IIoT sensors with cloud-based analytics, or integrating IFM condition monitoring into existing DCS or SCADA platforms. The speed advantage comes from proven design patterns and reusable software, not just from component availability.

Legacy power and process equipment often relies on sensor models that are no longer in current catalogs. When a twenty-year-old UPS, chiller plant, or process tool fails on a specific IFM sensor, the fastest way back to service may be to find the exact part rather than redesign the measurement point.

This is where specialized distributors of obsolete or hard-to-find IFM components enter the picture.

4 Star Electronics describes itself as an industry-leading stocking distributor for obsolete IFM Efector parts. They highlight an ISO 9001:2015 certified quality management system and a multi-stage inspection process for incoming and outgoing parts. Their documentation mentions an IDEA-ICE-3000 seventy-two-point visual inspection performed by three independent inspectors, data sheet cross-checking, acetone swab testing on sample pieces, macro zoom microscope inspection at 200x magnification, and digital photography of all outgoing parts. Supplier risk is controlled via a strict Approved Vendor List, and all parts are handled in a facility certified to ANSI/ESD-S20.20.

The obvious relevance to reliability is counterfeit risk. When you are buying discontinued sensors on the secondary market, rigorous inspection and vendor control are essential to avoid substandard or fake components being installed in critical measurement loops. 4 StarŌĆÖs stated goal of 100% order accuracy, backed by multiple quality checks, is designed to address that risk.

Industrial Parts R Us focuses on current and legacy industrial automation components, with specific listings such as the IFM Efector IFS204 inductive proximity sensor (model IFB3004BBPKG/M/US). Their documentation notes that this sensor operates from a 10ŌĆō36 V DC supply and provides a positive-switching, normally open output for metal detection. They also emphasize the importance of confirming wiring diagrams and I/O types in the full IFM datasheet before integration. From a reliability perspective, this kind of detail helps avoid miswiring and electrical incompatibility, which can be just as harmful as using the wrong sensing principle.

Zancot provides another angle, hosting a dedicated category for IFM sensors, controllers, and automation parts and explicitly stating that many models may be available even if they are not listed online. Their approach is quote-based: if you cannot find a particular model, you provide product details and they commit to sending a price quotation. This is often the fastest path to sourcing uncommon variants or replacements for older designs, especially when combined with manufacturer part numbers pulled from your documentation.

For a power system, consider a legacy automatic transfer switch where an IFM inductive proximity sensor confirms the position of a main breaker. If that sensor fails and the part is obsolete, redesigning the mechanical mounting and re-verifying clearances for a different sensor family may require significant downtime. A supplier that can rapidly deliver the same model, backed by strong anti-counterfeit checks, can restore redundancy far more quickly.

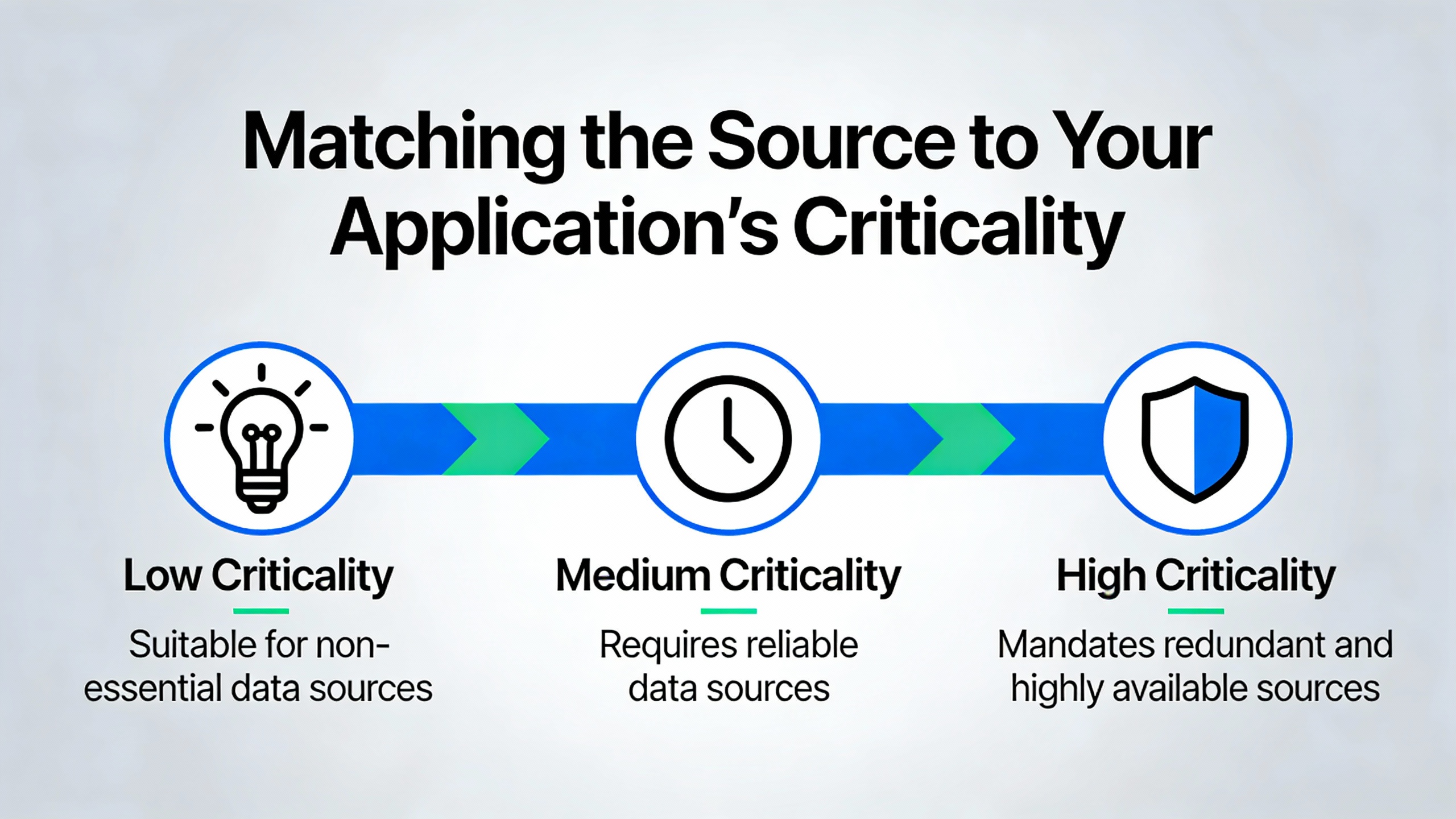

Choosing where to buy IFM sensors is easier when you explicitly weigh application criticality, design status, and engineering needs. Three practical questions help align the source with the requirement.

How critical is the measurement to uptime and safety? For measurements that directly protect major equipment or personnelŌĆöcooling flow to high-power inverters, fuel level in generator day tanks, pressure in gas lines, or vibration on large motorsŌĆöthe primary goals are reliability, traceability, and support. Manufacturer direct and authorized distributors tend to be strongest here. IFMŌĆÖs statistics on fast shipping and deep stock, combined with authorized distributorsŌĆÖ technical support and system knowledge, provide a clear path to high availability.

For example, if you rely on IFM flow sensors to confirm cooling in a 1,000 kVA UPS system, losing that measurement temporarily might force you into conservative operating modes or even shutdown. In such cases, aligning your purchasing with channels that can consistently ship within roughly 24 hours and provide application help when you change setpoints or ranges is worth more than squeezing out small cost differences.

How stable is the design? If you are executing a new design or a major retrofit, you may still be evaluating whether to use capacitive versus guided wave for level, or whether to bring back flow measurements on analog signals or IO-Link. IFMŌĆÖs own application notes on capacitive sensors through non-metallic tank walls, and the DirectIndustry overview of IFM precision distance sensors, both highlight selection considerations such as measurement range, target surface type, required accuracy, output type, and environmental constraints. In this phase, engineers benefit from IFMŌĆÖs technical team and from authorized distributors or integrators who can walk through tradeoffs.

Once the design is stable and the sensor models are standardized, online specialists such as Automation24 or distributors with streamlined web ordering become attractive for fast, repeat purchasing. The parameters can even be pre-configured or cloned via IO-Link, further reducing commissioning time.

Is the need routine or exceptional? Routine needs include stocking spares, replacing known-wear items, and supporting planned maintenance. For these, mainstream channelsŌĆöIFM direct, authorized distributors, and online specialistsŌĆöusually provide the best combination of speed and predictability.

Exceptional needs include emergency replacement of obsolete parts, bridging supply disruptions, or restoring systems where redesign is not practical in the outage window. In those cases, specialized obsolete-part distributors like 4 Star Electronics or quote-driven suppliers like Zancot and Industrial Parts R Us become critical. Their value is the ability to locate exact models, validate authenticity, and ship quickly enough to prevent prolonged downtime on legacy systems.

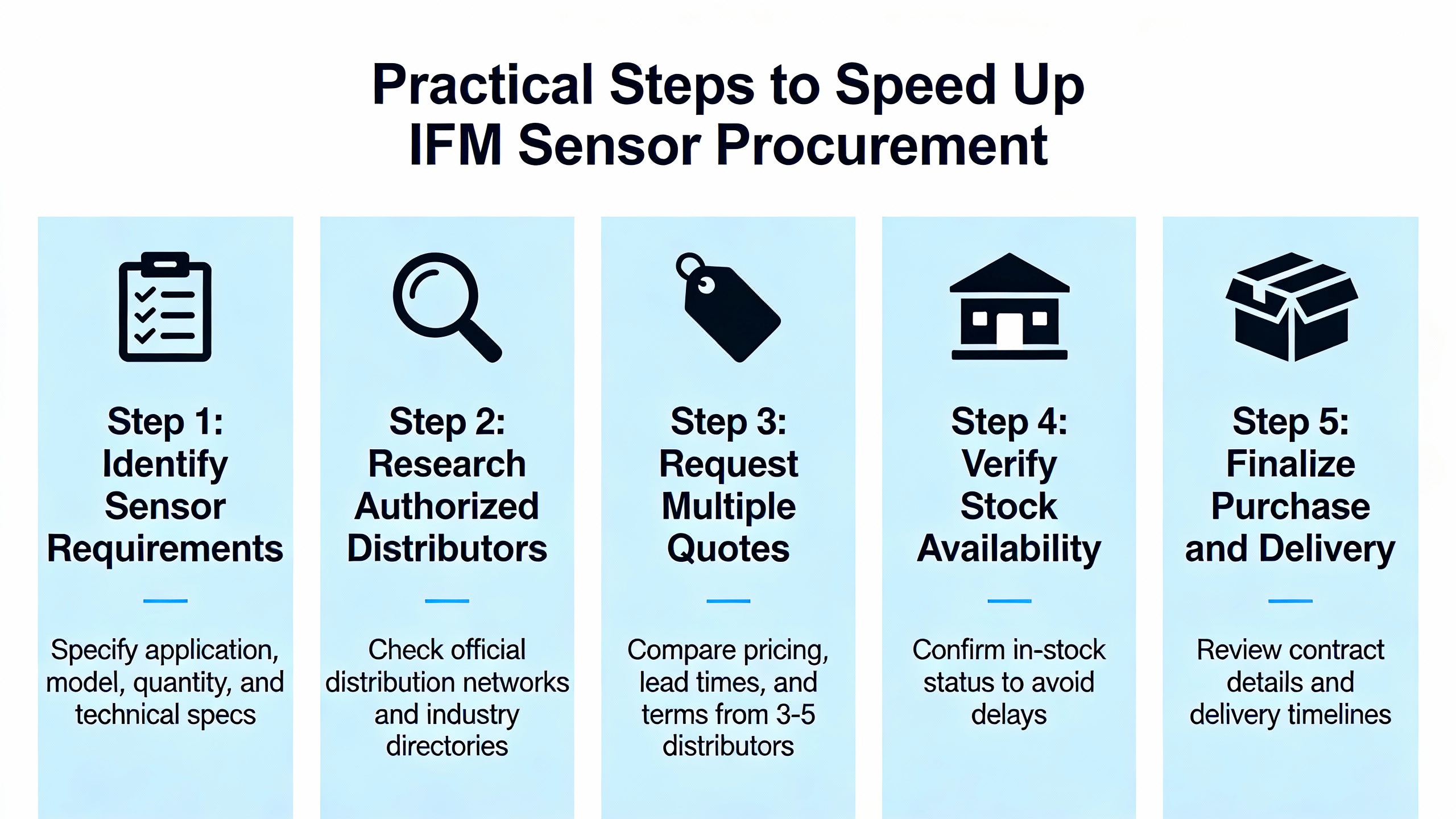

Whatever channel you choose, there are practical habits that consistently shorten the timeline from identifying a sensor need to having a reliable device back in service.

Clarify the technical specification before you shop. Before contacting any supplier, capture the exact IFM part number if available, the sensing principle (inductive, capacitive, photoelectric, flow, pressure, temperature, distance, vibration), the required operating voltage and output type, and any communication requirements such as IO-Link. The Industrial Parts R Us listing for the IFM IFS204 inductive proximity sensor illustrates how even basic information like voltage range and output configuration must match your PLC input design. Having this information ready allows manufacturers and distributors to confirm compatibility immediately.

Use datasheets and application notes to confirm fit. The DirectIndustry summary of IFM precision distance sensors emphasizes that model-specific datasheets contain critical statistics such as measurement range, resolution, linearity, repeatability, response time, ingress protection class, and operating temperature. If you are substituting models or shifting from one sensor technology to another, verifying those parameters protects you from discovering during commissioning that a device responds too slowly, saturates too early, or lacks the required environmental rating.

Leverage IO-Link and parameterization services. Both IFM and distributors like Automation24 highlight IO-Link as a tool for accessing sensor parameters and diagnostics. For example, IFMŌĆÖs capacitive level sensors can be parameterized via IO-Link, and Automation24 offers to parameterize certain encoders and temperature sensors before shipment. In a power plant with limited outage windows, receiving sensors that are pre-configured for the correct ranges and behaviors can shave hours off commissioning.

Align your spares strategy with supplier strengths. IFMŌĆÖs build-to-stock model, substantial warehouse capacity, and rapid shipment statistics suggest that many standard sensors can be obtained quickly. You might choose to hold only one spare of those standard devices, relying on fast replenishment. By contrast, for older or specialized sensors that you can only obtain from obsolete-part specialists such as 4 Star Electronics or via quote-based suppliers like Zancot, it may be prudent to hold extra spares, because restocking times can be less predictable. Even though the research notes do not provide explicit stocking recommendations, the contrast between high-volume build-to-stock operations and niche obsolete-part sourcing is clear.

Confirm quality controls when using secondary markets. The comprehensive inspection and vendor controls described by 4 Star Electronics, including ISO 9001:2015 certification, multi-inspector visual checks, microscope inspection, and ESD-controlled facilities, show what a robust program looks like. When you must use secondary markets, prioritizing distributors that openly describe similar quality systems materially reduces the risk of installing counterfeit or damaged sensors in critical loops.

Coordinate with existing channel partners. Many organizations already have strategic agreements with electrical distributors or integrators. Advantage Electric Supply and Cross Company each underline their roles as partners, not just component sellers. Folding IFM sensor procurement into those relationships often translates into faster quoting, pre-approved terms, and coordinated logistics, all of which matter when an unplanned outage is unfolding.

Mainstream industrial e-commerce sites also carry IFM products, but the research notes for some of these platforms focus more on access controls and privacy than on product specifics. Digi-KeyŌĆÖs IFM supplier-center page, for example, presents an access-denied screen requiring human verification before showing content, and Grainger emphasizes cookie categories, privacy rights, and opt-out mechanisms.

From a reliability engineerŌĆÖs perspective, these details mean two things. First, some corporate networks and browser configurations may slow down your ability to quickly access product data on such sites if they require specific cookie or verification settings. Second, while these portals can be useful for cross-checking availability or pricing, they may not always be the fastest path to the combination of technical support, quality assurance, and application knowledge you need for critical power and measurement projects.

For industrial measurement in support of UPS, inverter, and power protection systems, IFM sensors offer a broad, robust portfolio. The real leverage comes from pairing that hardware with the right purchasing channel for the situation. Manufacturer direct and authorized distributors deliver speed and depth for standard and strategic needs, online specialists streamline routine replacements and configuration, system integrators accelerate complex or mobile projects, and obsolete-part experts keep legacy systems alive with validated components.

Viewed through a reliability lens, ŌĆ£where to buyŌĆØ is not a purely commercial question; it is a design choice that shapes your ability to recover from faults and maintain safe, continuous operation. If you align your sourcing strategy with application criticality, design stability, and the strengths of each IFM channel, you turn the procurement function into another tool for protecting uptime, not just an afterthought once the alarm has already sounded.

Leave Your Comment