-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Vibration monitoring for turbines is not just an instrumentation project; it is a reliability strategy that directly affects power quality, uptime, and the health of every downstream asset, from switchgear to UPS and inverter systems. In many plants, people casually refer to ŌĆ£Bently Nevada vibration monitoringŌĆØ when they mean a dedicated turbine protection and condition monitoring platform. This article takes a vendorŌĆæneutral view and explains the engineering behind such systems so you can make better decisions about how to design, operate, and maintain vibration monitoring for gas and steam turbines and other critical rotating equipment.

Drawing on recent guidance from Industrial Service Solutions, a detailed review in PubMed Central, and practical resources from Metrix Vibration, MDPI, and others, we will walk through how vibration monitoring works, what it catches, and how to turn it into a predictive maintenance backbone rather than a noisy alarm source.

Rotating machinery sits at the core of industrial productivity. A review in MDPI notes that maintenance can account for roughly fifteen to sixty percent of manufacturing cost, and in heavy industry it can approach about half of total production cost. Turbines and large generators are at the top of that pyramid: a single forced outage can ripple through your entire power supply chain, overload backup UPS capacity, and disrupt critical loads.

Vibration analysis is consistently identified as the most widely used predictive maintenance tool for rotating machinery. The PubMed Central review describes it as the most effective way to detect mechanical defects in rotating equipment, while Industrial Service Solutions calls it a core predictive maintenance technique for motors, pumps, compressors, fans, and conveyor systems. For highŌĆæinertia assets like turbines and large generators, the stakes are higher: excessive vibration not only shortens component life but also jeopardizes safety and power system stability.

In practical terms, a robust turbine vibration monitoring system gives you three levers. It provides early warning before a minor issue becomes a forced outage; it supports more precise repairŌĆæversusŌĆæreplace decisions on highŌĆævalue components; and it creates a defensible basis for conditionŌĆæbased maintenance, so you are not opening machines that are still healthy or running at risk because ŌĆ£the calendar says they should be fine.ŌĆØ

Vibration monitoring, as described by G3 Soilworks and IBM, is the continuous and systematic measurement and interpretation of vibration behavior in machinery. Sensors mounted on bearings, housings, and casings measure how the machine is moving relative to a reference position. Over time, you build a baseline of ŌĆ£normalŌĆØ behavior, then look for deviations that indicate developing faults.

Vibration itself is simply motion caused by forces acting on the machine. The PubMed review explains that machines always produce some oscillatory motion during normal operation. These benign vibrations include bladeŌĆæpassing frequencies in turbines, gear mesh frequencies in gearboxes, or broadband turbulence in fluidŌĆæhandling stages. What matters is not the existence of vibration but its amplitude and pattern. When amplitudes drift above normal or new frequency components appear, you are seeing the mechanical signature of a developing fault.

Three core properties are used to characterize these signals. Amplitude tells you how severe the vibration is and is expressed as displacement, velocity, or acceleration. Frequency describes how many cycles occur in a specific time and is often linked to turning speed or its multiples. Phase captures the timing relationship between vibration at different points, which can help pinpoint whether a problem is at a particular bearing, coupling, or structural support.

From a turbine operatorŌĆÖs perspective, the monitoring system translates this physics into clear, actionable information: is this vibration level acceptable, trending worse, or dangerous; what failure mode is likely; and how urgent is the intervention.

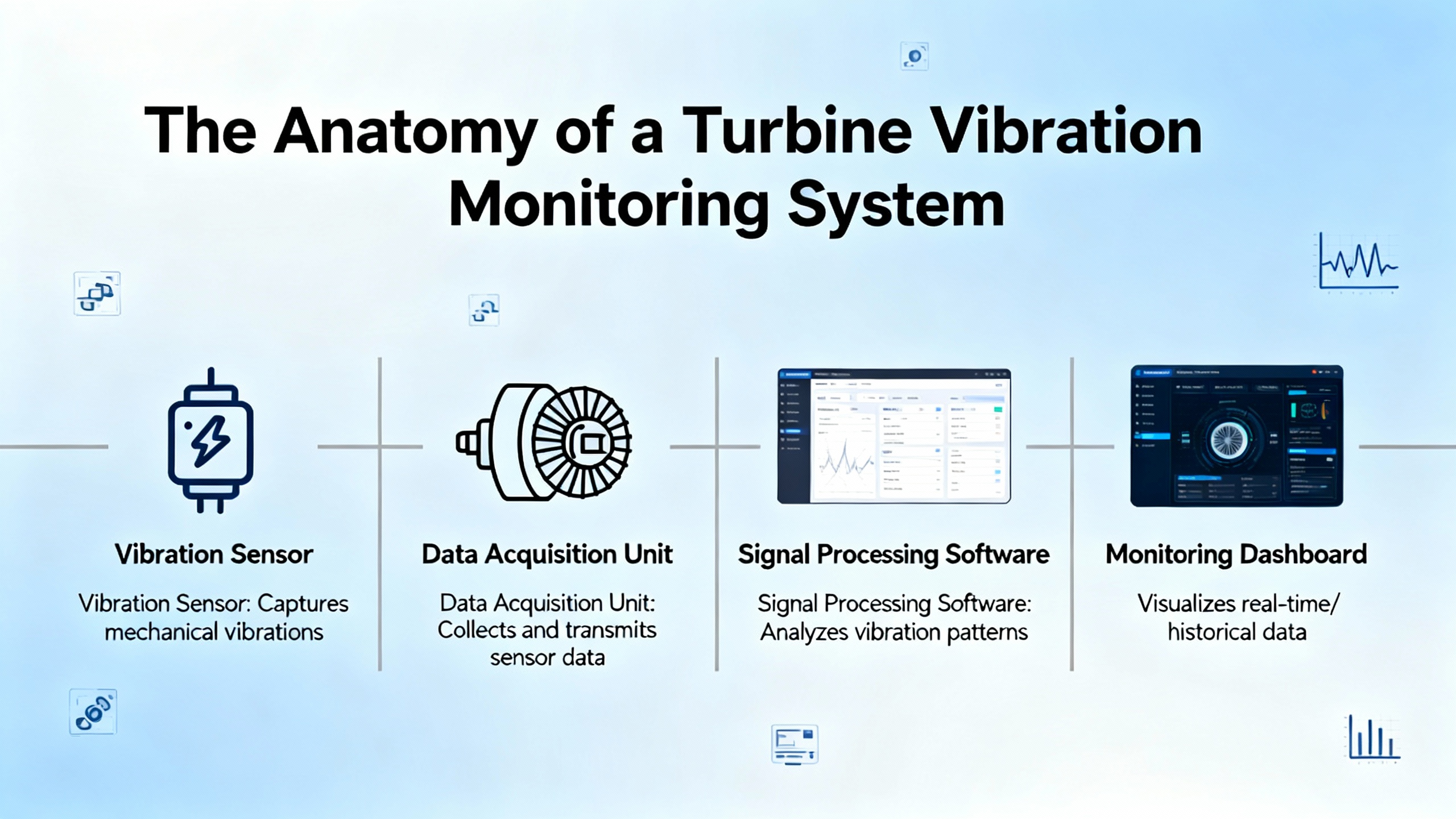

The path from a vibrating shaft to a maintenance decision follows a wellŌĆæestablished chain: sensing, acquisition, signal processing, and diagnostics.

First, sensors convert mechanical motion to electrical signals. The PubMed and MDPI reviews describe three main sensor categories. Displacement probes measure the exact movement of a shaft relative to the bearing, typically used on journalŌĆæbearing, highŌĆæspeed turbomachinery. Velocity pickups respond directly to vibration speed and are useful for generalŌĆæpurpose monitoring. Accelerometers measure acceleration over a wide frequency band and are especially sensitive to highŌĆæfrequency faults such as rollingŌĆæelement bearing damage or gear defects.

Second, those analog signals are conditioned, filtered, and digitized. To preserve diagnostic content, the sampling rate must be at least twice the highest frequency of interest; if it is lower, aliasing creates misleading lowŌĆæfrequency signatures. AntiŌĆæalias filters remove frequency content above half the sampling rate before digitization. Windowing functions and averaging techniques then reduce spectral leakage and noise, making subtle patterns easier to interpret.

Third, vibration profiles are analyzed in time and frequency domains. TimeŌĆædomain waveforms show amplitude versus time and are useful for impacts, rubs, and other transient phenomena. FrequencyŌĆædomain spectra, derived with Fast Fourier Transform (FFT) as discussed in the PubMed and IBM sources, express the same signal as amplitude versus frequency. Distinct peaks at shaft speed, harmonics, and characteristic component frequencies form a kind of fingerprint for each fault.

Advanced analyses described in the PubMed reviewŌĆösuch as shortŌĆætime Fourier transform, wavelet transforms, and other timeŌĆōfrequency methodsŌĆöcan provide better insight for nonŌĆæstationary signals, such as turbines going through startŌĆæup and shutdown.

The last step is interpretation. Industrial Service Solutions emphasizes three core diagnostic parameters: amplitude (severity), frequency (what is vibrating), and phase (where and when relative to other points). IBM further notes the role of envelope analysis for early bearing defects and modal analysis for understanding natural frequencies and resonance. In practice, these tools allow you to determine not just that vibration is high, but whether you are dealing with imbalance, misalignment, bearing issues, looseness, resonance, or other problems.

The same principles apply to turbines, generators, and other rotating equipment such as pumps and compressors. The sources consistently highlight several dominant categories of faults that vibration analysis can reveal early.

Imbalance and uneven loading are among the most common issues in highŌĆæspeed rotating machinery. The SimScale material describes uneven mass distribution around the center of rotation as a major driver of excessive vibration, energy loss, and noise. On a turbine, imbalance may result from blade fouling, erosion, or repair work that changed the weight distribution. In spectra, this often appears as vibration at shaft speed, sometimes with harmonics if the imbalance interacts with other nonlinearities.

Misalignment occurs when shafts do not share a common axis due to installation errors, thermal growth, or shifting supports. SimScale notes that misalignment increases reaction forces on bearings and shafts and often produces vibration at multiples of running speed, especially around twice shaft speed as misalignment worsens. In turbineŌĆægenerator trains, misalignment between turbine, gearbox, and generator can be particularly destructive, leading to both mechanical and electrical consequences.

Bearing defects are a critical focus. The Industrial Service Solutions guide and the PubMed review both highlight bearing issuesŌĆölooseness, improper lubrication, manufacturing defects, and fatigue damageŌĆöas major contributors to harmful vibration. RollingŌĆæelement bearings produce characteristic fault frequencies associated with inner race, outer race, cage, and rolling element impacts. In journal bearings, changes in orbit shape and subŌĆæsynchronous components can indicate oil whirl or whip. Left unchecked, these conditions can accelerate wear and cause catastrophic failures.

Mechanical looseness and structural problems, such as cracked foundations or loose mounting hardware, introduce lowŌĆæfrequency, often broadband vibration. The PubMed review describes dividing the spectrum into subŌĆæsynchronous (below running speed), synchronous (integer multiples of turning speed), and nonŌĆæsynchronous components. Looseness and certain lubrication problems tend to show up in subŌĆæsynchronous energy, while imbalance and misalignment dominate the synchronous region.

Electrical faults in generators, such as issues in rotor windings or stator components, produce distinctive vibration patterns as well. Industrial Service Solutions notes that irregular magnetic attraction between rotor and stator can generate vibration tied to electrical frequency rather than mechanical turning speed, giving analysts another layer of diagnostic information.

Because each fault manifests as a particular combination of frequency, amplitude, and phase, a wellŌĆædesigned turbine vibration monitoring system effectively becomes a nonŌĆæintrusive stethoscope, listening continuously for signatures of trouble.

While vendor implementations differ, most systems that monitor turbines and other critical rotating assets share a similar architecture: sensors at the machine, data acquisition and protection logic, analytical software, and integration with maintenance workflows.

The PubMed and MDPI reviews, along with Metrix VibrationŌĆÖs guidance, describe sensor selection as a function of frequency range, machine design, and failure modes.

A typical turbineŌĆægenerator train with journal bearings on the turbine and generator, and rollingŌĆæelement bearings in auxiliary equipment, might be instrumented as follows.

| Sensor type | Typical turbine application | Strengths | Limitations |

|---|---|---|---|

| Displacement probe | Shaft motion in journalŌĆæbearing, highŌĆæspeed turbomachinery | Direct relative shaft orbit, excellent for lowŌĆæfrequency motion | Installation complexity, surfaceŌĆædependent calibration |

| Velocity pickup | General purpose monitoring of housings and frames | Flat response in mid frequencies, simple 4ŌĆō20 mA outputs | Less accurate at very low and very high frequencies |

| Accelerometer | RollingŌĆæelement bearings, gearboxes, highŌĆæfrequency defects | Wide frequency band, sensitive to early bearing and gear problems | Requires integration for velocity, mounting quality critical |

The PubMed article recommends displacement for motion below about 10 Hz, velocity for roughly 10 to 1,000 Hz, and acceleration for frequencies above that range. In turbine applications, journal bearings and structural modes often live in the lower frequency band, while bearing and gear defects can generate highŌĆæfrequency content that is best captured by accelerometers.

For highŌĆæcriticality machines, Metrix Vibration advises multiŌĆæaxis coverage. On a large turbine, you might see two orthogonal probes at each radial bearing, thrust position probes, and a keyphasor or phase trigger. Auxiliary equipment may justify fewer points, but the principle is the same: the number of sensors should reflect the economic and safety risk if the machine fails.

Once signals reach the monitoring rack, they are processed for both protection and predictive maintenance. Metrix Vibration explains that overall vibration amplitude can be converted to a 4ŌĆō20 mA signal and tied into a control system for simple alarms and trips. This is useful for immediate protection: if vibration exceeds a set limit, the system initiates a controlled shutdown before damage becomes catastrophic.

For deeper diagnostics, systems capture full waveforms and spectra. IBM describes how timeŌĆædomain analysis can expose impacts and transient events, while frequencyŌĆædomain analysis via FFT highlights specific fault frequencies. Envelope analysis extracts highŌĆæfrequency impact content, which is particularly valuable for early bearing faults. Modal and harmonic analyses characterize natural frequencies and responses to periodic loads, helping engineers avoid resonance conditions.

The PubMed review emphasizes the importance of proper sampling, windowing, and averaging. Sampling too slowly introduces aliasing, where highŌĆæfrequency components masquerade as lowerŌĆæfrequency peaks, potentially sending analysts on a wild goose chase. Window functions reduce spectral leakage from finite data segments, and averaging across multiple records improves signalŌĆætoŌĆænoise ratio for subtle features.

Metrix Vibration draws a practical distinction between simple monitoring and full condition monitoring. A basic system might only trend overall vibration via 4ŌĆō20 mA loops into a control system, suitable for alarms and shutdowns but weak on root cause analysis. More sophisticated systems correlate vibration with process variables such as load, flow, pressure, and temperature, providing context for vibration changes and enabling better diagnostics.

Advanced platforms integrate multiŌĆæchannel data, capture transient events during startŌĆæup and shutdown, and allow engineers to perform onŌĆædemand diagnostics. They may also transmit data to enterprise asset management systems or cloud analytics for broader pattern recognition, as seen in the IoTŌĆæbased approaches discussed by TRACTIAN and MDPI.

For a turbine, where the cost of a misdiagnosed trip or a missed fault is extremely high, investing in the higher end of this spectrum is typically justified.

Vibration monitoring becomes predictive maintenance when you stop reacting to single alarm points and start using trends and patterns to forecast future behavior.

A key step, emphasized by several sources including G3 Soilworks and Metrix, is establishing a baseline. Baseline data captures the vibration signature of healthy operation at different loads and conditions. Without it, you are essentially flying blind, unsure whether a reading is ŌĆ£highŌĆØ or just ŌĆ£normal for this machine.ŌĆØ

Once a baseline is established, trends in overall levels and specific spectral components are tracked over weeks and months. Industrial Service Solutions notes that increasing intensity, changes in expected patterns, abnormal noise, and new shaft vibrations are all warning signs. IBM further explains that alarm thresholds can be set in three ways: fixed absolute limits based on standards or manufacturer guidance, trending thresholds that flag sudden changes, and statistical limits derived from historical mean and standard deviation.

When a vibration parameter crosses a warning threshold, maintenance planning can begin while the machine is still operating safely. As it approaches a critical threshold, a planned outage can be scheduled at a time that minimizes impact on production and power system stability.

This creates a conditionŌĆæbased maintenance loop. Instead of pulling a turbine apart every fixed number of hours, you allow its actual conditionŌĆöreflected in vibration, temperature, oil analysis, and other indicatorsŌĆöto guide the timing and scope of inspections. MDPI highlights this predictive approach as a way to maximize availability while reducing total maintenance cost.

The right monitoring strategy depends on machine criticality, environment, failure modes, and available staff. ACOEM stresses that environmental and accessibility conditionsŌĆöharsh temperatures, confined spaces, radiation, or remotenessŌĆöstrongly influence whether you rely on portable data collection, permanently mounted sensors, or fully automated online monitoring.

For turbine and generator trains, continuous online monitoring is generally the standard. These assets exhibit failure modes that can develop quickly and have severe consequence. WalkŌĆæaround collection once a month is appropriate for many motors and pumps; it is insufficient for a turbine where a bearing cage cracking can progress from defect to failure in hours.

Metrix Vibration describes a spectrum of options. At one end, periodic walkŌĆæaround measurements with handheld analyzers provide rich data but rely on humans being in the right place at the right time. In the middle, continuous monitoring with 4ŌĆō20 mA outputs into a control system offers basic protection and trend data. At the high end, multiŌĆæchannel systems with process data correlation, waveform capture, and transient recording provide full diagnostic capability and integration with plant information systems.

A pragmatic approach, consistent with guidance from Technomax and MDPI, is to match monitoring complexity to asset criticality. For a turbine, that usually means permanently installed, highŌĆæquality sensors feeding a dedicated monitoring platform with strong diagnostic tools. For less critical auxiliaries, wireless sensors or routeŌĆæbased measurements may provide sufficient coverage at lower cost.

Technology alone does not deliver reliability. The Vibration Institute underscores that training in vibration analysis is essential for engineers and technicians responsible for interpreting the data. Understanding how misalignment, imbalance, bearing defects, and resonance actually show up in spectra and waveforms is what turns raw measurements into accurate diagnosis.

Training also has a safety dimension. Excessive vibration can pose risks not only to equipment but also to personnel through structural fatigue, noise, and in extreme cases, mechanical failure. By learning to recognize early warning signs in vibration data, engineers can protect both people and plant.

The PubMed and MDPI reviews also point to the growing role of advanced signal processing and machine learning. These tools can reduce dependence on a handful of experts by embedding diagnostic knowledge into algorithms. However, successful deployment still requires people who understand the machines, the process, and the limitations of the models, so they can validate and refine automated recommendations.

In turbine applications, I have seen the best results when plants pair an advanced monitoring platform with at least one inŌĆæhouse vibration champion who works closely with OEMs and service partners. That combination of technology and human expertise is what catches subtle issues, such as a slowly shifting rotor mode or a resonance problem in a support structure, before they turn into serious events.

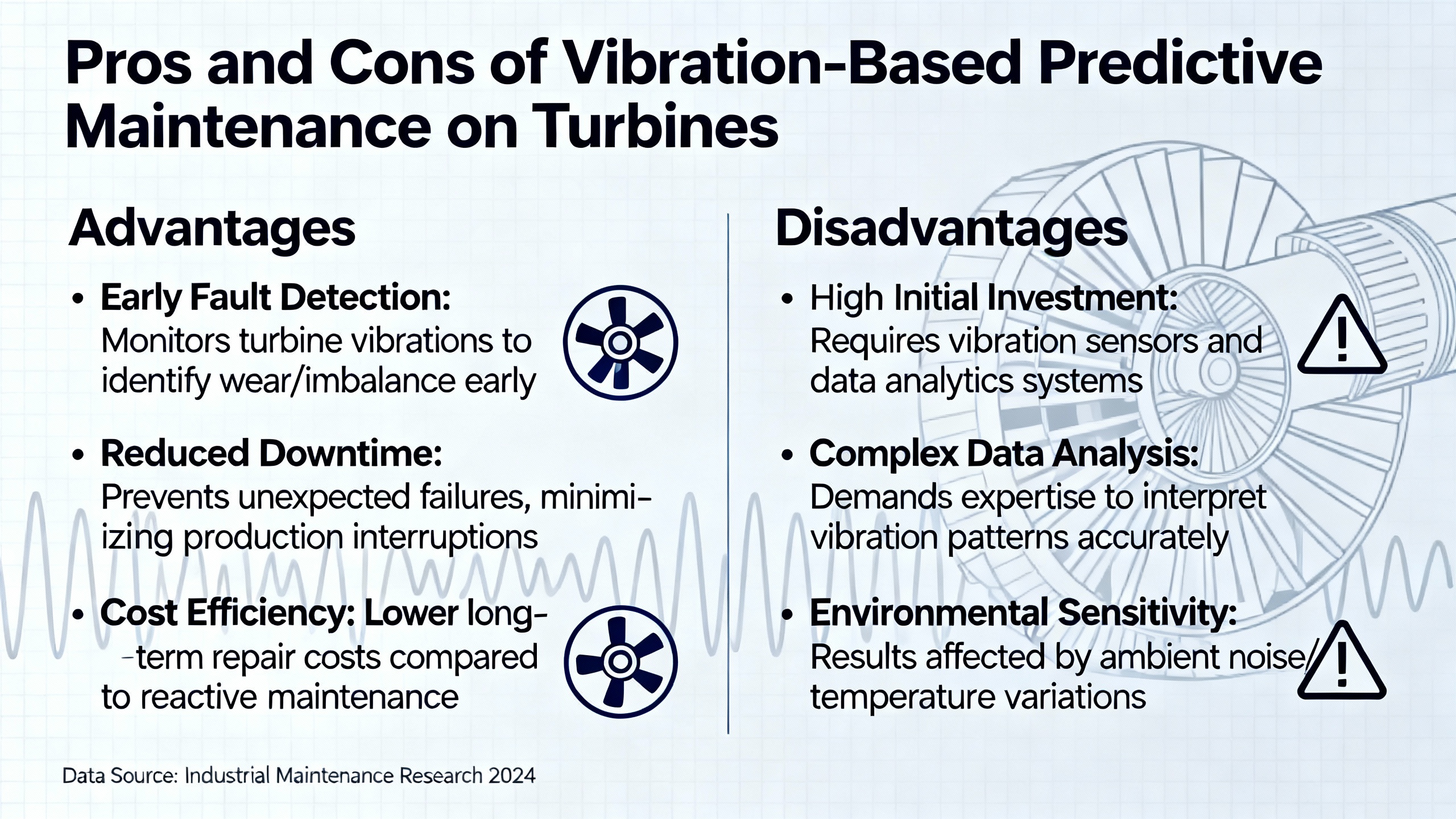

To decide how aggressively to pursue vibrationŌĆæbased predictive maintenance, it helps to compare it with other strategies.

| Maintenance approach | How it works | Advantages for turbines | Limitations and risks |

|---|---|---|---|

| RunŌĆætoŌĆæfailure (reactive) | Repair after breakdown | Minimal upfront cost | High risk of catastrophic damage, long outages, safety concerns |

| TimeŌĆæbased preventive | Service on fixed intervals | Easy to schedule, familiar to many organizations | Can open healthy machines and still miss fastŌĆædeveloping faults |

| VibrationŌĆæbased predictive | Use trends and signatures to forecast faults and plan outages | Early fault detection, targeted repairs, better uptime and cost control | Requires sensors, analytics, training, and disciplined followŌĆæthrough |

Research summarized by MDPI, Industrial Service Solutions, and others consistently shows that vibrationŌĆæbased predictive maintenance is particularly powerful for rotating machinery. The tradeoff is investment in instrumentation, data infrastructure, and human capability. For turbines and generators that anchor your entire power system, that investment usually pays back quickly in avoided unplanned outages and reduced collateral damage.

For operators responsible for turbines feeding critical loads, a structured approach to vibration monitoring is essential.

Start by confirming that each turbine and generator has adequate sensor coverage based on its criticality and design. Journal bearings require displacement probes; structural housings and gearboxes need velocity or acceleration sensors; thrust positions and speed triggers support both protection and diagnostics. Use the guidelines from PubMed and MDPI on frequency ranges to ensure sensors match expected fault frequencies.

Next, establish clean baselines under known good conditions. Capture spectra and waveforms across relevant load points and operating modes. Document them and treat them as reference fingerprints. Without this step, future comparisons will be ambiguous and alarms will be less meaningful.

Integrate vibration monitoring with process data and maintenance systems. Metrix Vibration and ACOEM highlight the value of correlating vibration with load, flow, pressure, and temperature. When vibration increases, knowing that it coincided with a specific process upset or load change is often the key to correct diagnosis. Feeding vibration insights into your computerŌĆæbased maintenance system allows you to generate targeted work orders rather than generic ŌĆ£investigate vibrationŌĆØ tasks.

Invest in people. Encourage at least one engineer or technician to complete formal vibration analysis training, as advocated by the Vibration Institute. Their ability to interpret complex signatures and to mentor others will increase the effectiveness of your monitoring platform and reduce dependence on external consultants for every anomaly.

Finally, treat vibration monitoring as part of a broader reliability strategy. Combine it with oil analysis, thermography, electrical testing, and robust operating procedures. For facilities that also depend on UPS systems and power protection equipment, upstream turbine stability reduces stress on downstream assets, extending their life and maintaining cleaner power to sensitive loads.

Does vibration monitoring replace other conditionŌĆæmonitoring techniques on turbines? No. The sources reviewed emphasize that vibration monitoring is often the single most powerful predictive tool for rotating machinery, but it does not capture every failure mode. Oil chemistry, temperature trends, process data, and electrical tests all add complementary information. A strong program uses vibration as the spine and other techniques as supporting ribs.

How often should turbine vibration data be analyzed? For highŌĆæcriticality rotating assets that run continuously, G3 Soilworks recommends moving beyond periodic analysis into frequent or continuous monitoring. Monthly or quarterly analysis can be appropriate for less critical machinery, but for gas and steam turbines a continuous online system, with at least daily or more frequent automated review of trends, is far more appropriate.

What is the difference between basic vibration protection and full predictive monitoring? Basic protection typically uses overall vibration levels connected as 4ŌĆō20 mA signals to a control system. When levels exceed a set limit, the turbine is tripped or an alarm is raised. Full predictive monitoring records detailed waveforms and spectra, correlates them with process conditions, stores historical data, and provides tools to diagnose the underlying fault. As IBM and Metrix Vibration describe, both layers are important: protection to prevent immediate damage and predictive analytics to avoid reaching those critical thresholds in the first place.

In highŌĆæconsequence environments, turbine vibration monitoring is not a luxury or merely a regulatory checkbox. It is an engineering discipline that, when implemented thoughtfully, protects people, stabilizes your power supply, and gives your maintenance team the time and insight to fix problems on your terms instead of the machineŌĆÖs. As a reliability advisor focused on power systems, I see the plants that pair robust vibration monitoring with disciplined maintenance planning consistently outperform those that do notŌĆöin uptime, in cost, and in confidence every time they bring a turbine online.

Leave Your Comment