-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Programmable logic controllers may not look impressive sitting in a cabinet next to your UPS, switchgear, or drives, but they are the digital ŌĆ£brainŌĆØ that keeps your power system and production assets behaving. When that brain glitches, a rockŌĆæsolid UPS or inverter will not save you from nuisance trips, frozen logic, or a production line that simply refuses to start.

As a power system specialist, I have walked into plants where a single PLC fault brought down entire production lines, took a UPS into bypass at the worst moment, or disabled an automatic transfer scheme. The pattern is consistent: once the PLC fails, everyone suddenly cares about who is allowed to touch it. That is exactly where authorized, factoryŌĆætrained PLC repair services earn their keep.

This article unpacks what ŌĆ£authorizedŌĆØ and ŌĆ£factoryŌĆætrainedŌĆØ really mean in the PLC world, how professional repair actually works, and how to choose the right partner when your automation is tied directly to critical power supply and protection equipment.

A programmable logic controller is a rugged industrial computer designed for realŌĆætime control. Allied Reliability describes PLCs as the heart of production facilities, originally created to replace hardŌĆæwired relays and timers in automotive plants. Modern PLCs continuously read inputs from sensors, switches, and humanŌĆæmachine interfaces, execute programmed logic, and drive outputs such as contactors, valves, and variableŌĆæfrequency drives.

Guides from eWorkOrders and others outline how PLCs sit at the center of industrial processes: assembly lines, robots, feed systems, HVAC, utilities, and more. In many facilities, that list now includes UPS control panels, static transfer switches, emergency generator controls, and automatic loadŌĆæshedding schemes. When the PLC misbehaves, the plant does not just lose a motor; it can lose visibility and control over its power path.

PLC failures also tend to be highŌĆæimpact and deceptively subtle. Global Electronic Services notes that warning signs usually appear before outright failure: intermittent resets, fault codes, flaky communication, unresponsive I/O, overheating, and inconsistent behavior. HorizonŌĆætype repair guides add power supply issues, noiseŌĆæinduced I/O faults, corrupted programs, and network errors to the list. These symptoms look like random gremlins until someone with the right training follows a structured troubleshooting process and finds the root cause.

Because the PLC coordinates so many devices, a misstep in repair or programming can ripple across your entire electrical system. That is why the qualifications of the person repairing your PLC are not a paperwork detail; they are a riskŌĆæmanagement decision.

Several reputable providers position their PLC teams as factoryŌĆætrained. Global Electronic Services explicitly highlights factoryŌĆætrained technicians who are continuously learning best techniques, while AES emphasizes decades of industrial electronics experience backed by ongoing training. In practice, this type of technician brings three advantages.

First, they understand the specific PLC families you actually run. In the United States, AIAutomation notes that Siemens and AllenŌĆæBradley (Rockwell) are the most popular brands because of their durability and the large pool of experienced programmers. FactoryŌĆætrained technicians are fluent in the quirks of these platforms, including their power modules, communication cards, and ladder logic nuances. That familiarity compresses troubleshooting time and reduces ŌĆ£learnŌĆæonŌĆæyourŌĆæequipmentŌĆØ risk.

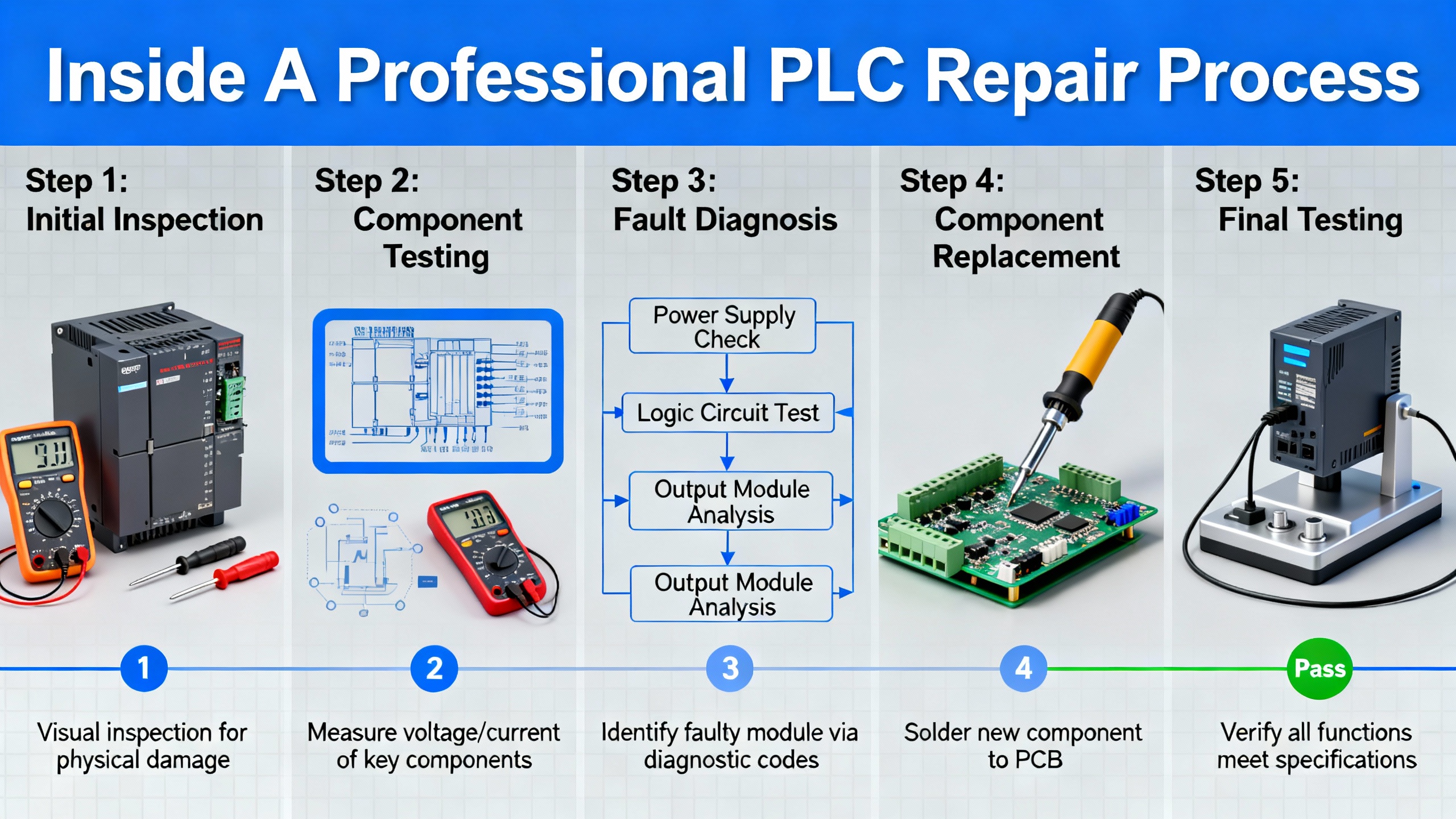

Second, they follow a documented process that aligns with manufacturer expectations. Both AES and Global Electronic Services describe structured repair workflows: controlled powerŌĆæup, inspection of inputs and outputs, componentŌĆælevel repair, program testing, and final verification. That sort of discipline is consistent with how OEMs expect their equipment to be handled and stands in stark contrast to adŌĆæhoc board swaps and trialŌĆæandŌĆæerror.

Third, they are backed by systems, not just resumes. Global Electronic Services assigns barcodes to each unit for inŌĆæprocess tracking, provides a detailed evaluation and quote for approval, and offers an extended inŌĆæservice warranty. AES backs PLC repairs with a 24ŌĆæmonth warranty and publishes typical turnaround windows. These are not generic promises; they are concrete commitments that reflect confidence in both the training and the process.

To make the differences more tangible, it helps to compare authorized, factoryŌĆætrained services with generic repair options.

| Factor | FactoryŌĆætrained, authorizedŌĆæstyle service | Generic or adŌĆæhoc repair |

|---|---|---|

| Familiarity with your PLC brand | Deep experience with specific families like Siemens and AllenŌĆæBradley, plus documented training | Varies widely; may rely on trialŌĆæandŌĆæerror or generic electronics knowledge |

| Repair workflow | Structured evaluation, componentŌĆælevel repair, test programs, full functional verification | Often focused on getting the unit to ŌĆ£power upŌĆØ with minimal systemŌĆælevel testing |

| Access to parts | Large inventories of common and obsolete PLC components | May depend on whatever is on hand or online, with longer lead times |

| Warranty and accountability | MultiŌĆæyear inŌĆæservice warranties and barcodeŌĆætracked processes | Warranty terms may be short, informal, or absent |

| Fit for critical power systems | WellŌĆæsuited when PLC behavior directly impacts UPS, transfer switches, and safety functions | Higher risk when PLC failure can affect power continuity or safety |

Authorized, factoryŌĆætrained does not necessarily mean ŌĆ£OEM only.ŌĆØ ThirdŌĆæparty repair houses like AES and Global Electronic Services combine factory training, broad brand coverage, and structured processes. For most plants, that mix of specialization and flexibility is more practical than sending every failure back to the original manufacturer.

From an operations perspective, PLC failures rarely announce themselves politely. Sources such as Global Electronic Services, Horizon, AES, and Polsys highlight a familiar chain of events.

Production teams first see sporadic issues: a transfer switch that refuses to change state occasionally, an inverter that trips on a control fault without a clear power issue, or a conveyor that fails to start even though the MCC and UPS are healthy. Operators acknowledge alarms, cycle breakers, or reboot HMIs. Symptoms disappear for a while, then return.

Technical staff then notice patterns. The PLC logs show intermittent communication timeouts, odd I/O statuses, or memory errors. Status LEDs might flick from green to red without a clear cause. Horizon and AES both note that overheating, poor ventilation, dust buildup, and failing power supplies are common behindŌĆætheŌĆæscenes culprits, along with loose wiring, oxidized connectors, or battery problems.

In harsher environmentsŌĆösteel mills, pulp and paper, cement plantsŌĆöRL Consulting and Allied Reliability describe how conductive dust, humidity, and electrical noise gradually degrade PLC backplanes and I/O modules. A single erratic analog input driven by a corroded terminal or EMI can cause serious process swings, including misŌĆæcoordinated power system behavior.

The temptation in these scenarios is to swap obvious modules and hope the issue goes away. Sometimes that works. More often, the problem moves, mutates, or returns. FactoryŌĆætrained technicians approach the same failure set differently: starting with structured diagnostics rather than guesses.

Both AES and Global Electronic Services describe repair workflows that look very similar to what many manufacturers recommend. Understanding this process helps you judge whether a potential vendor is genuinely operating at a factoryŌĆætrained level.

The first stage is evaluation. The provider powers the PLC under controlled conditions, inspects all inputs and outputs, and uses diagnostic tools to identify visible issues. Global Electronic Services performs a free evaluation, barcodes each unit for tracking, and builds a list of required repairs with a quote that must be approved before work continues.

Next comes componentŌĆælevel repair. AES and Global Electronic Services both call out highŌĆæfailure components such as relays, capacitors, and isolators (or optoisolators). Rather than only swapping entire modules, they replace these components proactively where appropriate. Large inŌĆæhouse inventories of both new and obsolete parts allow them to support older PLCs that OEMs may have long since discontinued.

After repair, a test program is loaded to validate the PLCŌĆÖs CPU and logic. AES emphasizes testing under realistic conditions, including verification of the battery, circuitry, and ladder logic, not just checking whether the device powers up. Global Electronic Services runs similar function checks to ensure the PLC behaves as expected before returning it.

Then comes cleaning and final inspection. Both providers stress thorough cleaning of the PLC and control boards to remove dust and contaminants, followed by a last full test. Finally, the unit is packaged carefully for shipment, with packaging tailored to weight and geometry so a vibration or shock event in transit does not undo the repair.

The entire process is wrapped in service characteristics that matter in real plants: stated turnaround times, rush options for urgent failures, multiŌĆæyear warranties, and transparent pricing. Global Electronic Services, for example, commits to fixed pricing after quote approval and offers a repair price guarantee against lower competitor quotes. AES publishes an 8ŌĆō10 business day standard repair window with rush options of roughly 1ŌĆō3 days and backs work with a 24ŌĆæmonth warranty.

That kind of structure is what you should expect when someone says they provide authorized or factoryŌĆætrained PLC repair.

Deciding whether to repair or replace a PLC module is both a technical and financial exercise. Industrial Automation Co. has laid out a straightforward framework for drives, PLCs, and HMIs that applies nicely to powerŌĆærelated PLCs as well.

From a cost standpoint, they report that repairing industrial automation components typically costs about thirty to sixty percent less than buying new, with HMI repairs often in the thirty to fifty percent savings range. When you factor in the cost of downtime, engineering time to reconfigure new hardware, and integration testing, repair can be the more economical path, especially for legacy or expensive modules.

Repair is usually favored when the part is costly or obsolete, replacement lead times are long, failures are isolated rather than systemic, and you want to preserve existing configuration and wiring. Industrial Automation Co. cites backordered CPUs and legacy drives as examples where repair makes sense to avoid multiŌĆæweek waits. AES similarly recommends repair over outright replacement for aging or complex automation assets, especially when they sit at the center of a broader control scheme.

Replacement becomes the better option when failures are repeated, damage is catastrophic across multiple boards, or the facility is already migrating to modern platforms. Industrial Automation Co. notes scenarios where repeatedly glitching PLCs are replaced with newer architectures as part of a planned modernization, rather than continuing to repair the same legacy hardware.

FactoryŌĆætrained technicians make this decision easier. They can distinguish between a stressed but otherwise sound PLC that will run reliably after a proper repair and one whose failures are symptoms of deeper obsolescence or systemic issues, such as poor grounding or power quality.

Multiple sources emphasize that proximity and brand familiarity matter when automation downtime is expensive. AIAutomation recommends working with PLC services that already have handsŌĆæon experience with your specific PLC brands and models, particularly when Siemens and AllenŌĆæBradley dominate your installed base. Melriya highlights the benefits of local PLC repair: shorter response times, avoidance of long shipping delays, and technicians who understand the common equipment and failure patterns in your region.

In practice, using a local, factoryŌĆætrained provider gives you several reliability advantages. They can often respond on site quickly for critical incidents, perform initial triage, and help you decide whether to ship the PLC, repair in place, or activate spares. Their familiarity with regional industries means they are less likely to be surprised by the mix of UPS controls, feeder protection relays, and PLCŌĆædriven interlocks that you might have.

Many services now blend remote and onŌĆæsite capabilities. Companies like Integrity Control Services provide secure remote troubleshooting for PLC issues, with 24/7 availability, complemented by onŌĆæsite visits when needed. That model reduces downtime, especially when combined with factoryŌĆætrained expertise on the specific brands you operate.

From a powerŌĆæsystem reliability perspective, a repaired PLC is only the beginning. The real win comes when you pair highŌĆæquality repairs with structured preventive and predictive maintenance so you are not simply bouncing between breakdowns.

Maintenance guides from eWorkOrders, Global Electronic Services, and Allied Reliability converge on several key practices. You should maintain recent backups of PLC programs and configurations, verify program functionality periodically, and maintain a spareŌĆæparts strategy for critical modules. Regular inspection of plugs, terminals, and wiringŌĆöespecially in highŌĆævibration environmentsŌĆöis essential to catch loose or corroded connections before they cause intermittent faults.

Environmental control is another recurring theme. eWorkOrders and Allied Reliability stress keeping dust and debris out of cabinets, cleaning filters, maintaining ventilation, and monitoring temperature and humidity. Global Electronic Services adds attention to electromagnetic interference and radioŌĆæfrequency interference through good cable routing, shielding, and grounding practices.

Battery maintenance deserves special attention in PLCs tied to power systems. Bastian Solutions explains that PLCs rely on a backup battery to preserve programs and setpoints when main power is off. If both main power and the battery are lost, the PLC can revert to factory defaults, wiping logic and configuration. Although batteries can last several years, Bastian recommends proactive replacement every two to three years and clear monitoring of batteryŌĆæstatus indicators. That small discipline has prevented more than one expensive reprogramming effort in plants I have worked with.

Predictive techniques complement these routines. Global Electronic Services notes that thermal imaging and realŌĆætime performance monitoring can identify hot spots and trends before visible symptoms appear. Allied Reliability advocates using historical data and condition monitoring rather than only timeŌĆæbased replacement, so you replace components when they actually show signs of degradation.

FactoryŌĆætrained technicians are well positioned to help design and execute these programs. RL Consulting emphasizes the value of periodic and eventŌĆæbased PLC inspections, formal backups and version control, and regular reviews of safetyŌĆærelated logic. A good repair provider will not just fix your PLC; they will help build a maintenance approach that keeps it from failing at the worst moment.

Choosing a PLC repair service is similar to choosing a trusted auto or electrical shop, but the stakes for power systems are higher. Several sources outside the PLC world, including Auto SocietyŌĆÖs guidance on auto technicians and Vance ElectricŌĆÖs advice on electrical services, align neatly with the PLCŌĆæspecific recommendations from AIAutomation.

You should look for verifiable experience with your exact PLC brands and models. AIAutomation stresses confirming that any candidateŌĆöemployee, freelancer, or firmŌĆöhas handsŌĆæon experience with your existing hardware. For plants dominated by Siemens or AllenŌĆæBradley, that means you should hear clear, specific examples of past work on those platforms.

Check the depth and structure of their service offering. Global Electronic Services and AES both begin with free evaluations, document findings, seek customer approval before proceeding, and track repairs through barcodes and secure portals. That level of transparency and process is a good benchmark. If a provider resists written estimates or cannot explain their test procedures, treat that as a warning sign.

Evaluate the shopŌĆÖs organization and cleanliness. Auto Society notes that a tidy, wellŌĆæorganized auto repair facility often correlates with better workmanship. The same holds true for PLC repair labs. A clean, orderly environment suggests systematic testing and careful handling of your hardware, which is especially important when boards and backplanes are already stressed by age and contaminants.

Warranty and support policies matter as well. AESŌĆÖs 24ŌĆæmonth limited warranty and Global Electronic ServicesŌĆÖ twoŌĆæyear inŌĆæservice warranty are examples of strong commitments. Industrial Automation Co. recommends favoring repair providers that offer at least yearŌĆælong warranties and can explain what is covered. Extended warranties are not only a marketing line; they are a proxy for confidence in the underlying repair process.

Finally, pay attention to communication style. Both Auto Society and Vance Electric recommend asking questions and trusting your instincts. A reputable PLC repair partner will welcome detailed discussion of symptoms, share findings clearly, and explain repair versus replace options without pressure. Unclear answers, dismissive attitudes, or reluctance to discuss specifics signal that it may be safer to look elsewhere.

To see how all this comes together, it is helpful to walk through a few familiar scenarios from industrial and commercial power systems.

Imagine a mediumŌĆævoltage switchgear lineup where a PLC supervises feeder breakers, communicates with protective relays, and coordinates with a UPS and standby generator. Over time, metallic dust accumulates in the PLC cabinet. Allied Reliability describes how such contamination can cause intermittent logic anomalies, including random program deletions. One day, an unexplained PLC reset leaves the switchgear in an unsafe state. A factoryŌĆætrained repair provider will not only clean and repair the PLC but also trace the root cause to dust ingress, improve cabinet sealing, and recommend procedural changes for work near control panels.

In another plant, a data center relies on a PLCŌĆæcontrolled static transfer switch to move critical loads between dual UPS systems. Operators start seeing sporadic transfer failures that do not correlate with power quality data. A generic electronics shop may replace the obvious suspect board and declare success. A factoryŌĆætrained technician, armed with guidance similar to AESŌĆÖs troubleshooting steps, works methodically through power supplies, I/O, communication modules, and firmware versions. They discover a marginal power supply and a noisy communication link between the PLC and position sensors, correct both, and then validate behavior with a dedicated test program that simulates realistic transfer scenarios.

In a process plant, a PLC controls multiple drives on a common bus, with the drives powered through a UPSŌĆæbacked feeder. Industrial Automation Co. notes that repair is usually attractive for legacy drives and PLCs when failures are isolated. A trained technician may recommend repairing a single failing I/O module and refreshing highŌĆæfailure components while leaving a proven legacy CPU in place. At the same time, they might flag repeated controller faults as a sign that it is time to plan a structured migration, rather than waiting for a catastrophic failure to force an unplanned shutdown.

Across all these examples, the common thread is not just technical skill but structured, experienceŌĆæbased troubleshooting that respects the tight coupling between PLC behavior and power system performance.

Do I always need an authorized, factoryŌĆætrained service for PLC repair? Not every minor issue requires sending hardware to a factoryŌĆætrained provider. For simple wiring faults, configuration mistakes, or easily swapped lowŌĆæcost modules, inŌĆæhouse technicians can often resolve problems. However, when the PLC coordinates critical power or safety functions, when failures are intermittent or complex, or when warranty and longŌĆæterm reliability matter, working with a factoryŌĆætrained, processŌĆædriven service is the safer choice.

What is the difference between an OEM repair and a thirdŌĆæparty factoryŌĆætrained provider? OEM repair typically means sending the unit back to the original manufacturer. ThirdŌĆæparty providers like AES or Global Electronic Services combine factory training and multiŌĆæbrand experience with broader flexibility in supporting legacy and discontinued models. Both can be effective; what matters is adherence to structured repair procedures, quality of components used, and the strength of the warranty and support.

How does PLC repair interact with my UPS and power protection strategy? If your PLC participates in load transfer, generator start sequences, or coordinated tripping, its reliability directly affects power continuity. A flawed repair or incomplete test can leave you with hidden vulnerabilities that surface only during faults or switching events. Integrating PLC health into your overall power reliability planŌĆöthrough proper repair, maintenance, and testingŌĆöis essential for facilities that cannot afford downtime.

In powerŌĆæcritical environments, a PLC is not just another piece of electronics; it is a decisionŌĆæmaking engine for your entire system. When it fails, you want more than a quick fix. You want a repair performed by technicians whose training, process, and accountability have been proven across many plants like yours. Authorized, factoryŌĆætrained PLC repair service is one of the most effective ways to protect your automation investment, safeguard your UPS and power infrastructure, and keep your operations reliably online.

Leave Your Comment