-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

When an ABB variable frequency drive refuses to start a motor, it rarely feels like an electronics issue. It feels like money burning. Production stops, operators are waiting, and someone is staring at a keypad that either shows nothing at all or is flashing a fault code nobody has time to decode. As a reliability advisor working on industrial power systems, I see this ABB VFD ŌĆ£not workingŌĆØ scenario regularly on pumps, fans, compressors, and conveyors that are supposed to run around the clock.

The good news is that most startup problems follow a predictable pattern. By approaching them methodically, you can usually restore operation without guesswork, protect the motor and drive from damage, and learn enough about the incident to prevent a repeat.

This guide walks through a practical, field-tested way to troubleshoot ABB VFDs at startup, grounded in best practices highlighted by manufacturers, service organizations, and power quality specialists such as Fluke, Emotron, Apex Electric and Mechanical, UpFix, and others. Although examples here are broadly applicable to modern drives, you should always refer to ABBŌĆÖs specific manuals for modelŌĆæspecific details and safety instructions.

A variable frequency drive is fundamentally a power converter and controller. Sources such as DoSupply and Industrial Electrical Company describe the same core building blocks you will find inside ABB drives.

Incoming AC power feeds a rectifier stage, which is typically a bank of diodes that converts AC into DC. That DC feeds a DC bus with capacitors that smooth ripple and store energy. From there, an inverter section built from IGBTs or similar power devices chops the DC into a pulseŌĆæwidthŌĆæmodulated waveform that behaves like an adjustable frequency threeŌĆæphase AC source. Control circuitry monitors voltages, currents, temperatures, and feedback signals, then commands the inverter to deliver the right frequency and voltage to the motor for the demanded speed and torque.

Startup failures happen wherever this chain is broken. Typical failure domains include no power to the drive, DC bus not building correctly, inverter inhibited due to a fault, missing run or speed reference, open safety or stop circuits, poor analog or digital signal handling, and external issues such as motor wiring faults, mechanical binding, or water or dust in the enclosure. Many sources, including Emotron and Apex Electric and Mechanical, emphasize that environmental stress and wiring issues are at least as common as internal electronic failures.

Understanding that ABB drives follow this same architecture helps you troubleshoot logically instead of randomly resetting or replacing parts.

The phrase ŌĆ£ABB VFD not workingŌĆØ covers several very different realities. Before you touch tools, define the symptom precisely. Does the display stay completely dark even though upstream power is supposed to be on? Does the drive power up but sit in a ready or stop state and refuse to run the motor? Does it attempt to start but immediately trip on an error such as overcurrent, undervoltage, or overtemperature?

UpFix points out that common failure symptoms include motors not starting, frequent tripping, unexpected shutdowns, abnormal noises, and overheating smells. Emotron adds that many issues can be grouped by whether the drive is indicating electrical faults, thermal faults, mechanical overloads, or control errors. In practice, you can think of three main startup categories: drive does not power up, drive powers up but will not run, and drive starts then trips.

That classification is not academic. It guides what you check first and helps you distinguish between a supply issue, a control issue, a motor or load issue, and a genuine drive hardware failure.

When an ABB VFD will not start a motor, a structured process is indispensable. EECOŌĆÖs fiveŌĆæstep method, EmotronŌĆÖs sevenŌĆæstep guide, and troubleshooting practices from DoSupply, Fluke, and others are very consistent. The following approach is adapted from those sources and applied explicitly to ABB drives.

Every serious VFD troubleshooting guide, from EECO to UpFix, starts with the same instruction: respect energized equipment. Only qualified personnel with appropriate training and personal protective equipment should troubleshoot live ABB drives.

Before measuring anything, deŌĆæenergize the system where possible and open the enclosure for a visual inspection. UpFix recommends looking for burn marks, soot, cracked boards, bulging capacitors, and obvious physical damage. Apex Electric and Mechanical also stresses checking for dust accumulation, blocked fans and heat sinks, and signs of overheating or moisture.

If you see clear evidence of combustion or damaged boards, do not attempt repeated resets. Shut down the supply, lock out the circuit, and treat this as a repair or replacement case. Otherwise, note any contamination, corrosion, or loose terminations. Many cases where ŌĆ£nothing happensŌĆØ on an ABB keypad trace back to a straightforward supply issue or a damaged board that is visually apparent once the cover is off.

If the ABB drive display is off or flickering, the next question is whether it is being fed correctly. EECOnline, UpFix, and Fluke all highlight the importance of verifying incoming power with a proper digital multimeter instead of assuming that a breaker in the ŌĆ£onŌĆØ position means good power.

With safe work practices, confirm that upstream disconnects, fuses, and breakers are intact and sized appropriately. Measure lineŌĆætoŌĆæline voltages at the VFDŌĆÖs input terminals and compare them to the ABB nameplate range and manual. Fluke emphasizes using a trueŌĆæRMS meter and appropriate category ratings, since VFD environments often involve distorted waveforms and higher fault levels.

DoSupply and Joliet Technologies note that overvoltage or undervoltage conditions are classic troublemakers. If the supply is outside specification, unstable, or missing a phase, the ABB drive will either refuse to start or will trip with high DC bus or undervoltage faults. If incoming power is incorrect, solve that problem before going any further. Drives are not designed to compensate for fundamental supply defects.

Most ABB drives, like other modern VFDs, provide fairly detailed fault or alarm codes. Several sources, including UpFix, EECOnline, Emotron, and Franklin, stress that the driveŌĆÖs diagnostics are your best starting point.

Rather than immediately clearing faults, record the exact code, any descriptive text, and the operating condition when it appeared. EECOnline defines typical faults found across drives: overvoltage when the DC bus is too high, undervoltage when it is too low, overcurrent when motor current exceeds limits, overtemperature when drive or motor are overheating, motor overload when current remains high for too long, and ground fault when unintended conduction to ground is detected.

Emotron further classifies alarms into urgency levels, where some indicate immediate risk while others are informational. Use the ABB manual to crossŌĆæreference the code and confirm whether it is likely linked to power, motor, control, or environment. As UpFix cautions, a reset is a diagnostic step at best. If the same ABŌĆæstyle fault returns, you are dealing with a real root cause that must be corrected, not just acknowledged.

One of the more frustrating field calls is an ABB VFD declared ŌĆ£deadŌĆØ when in reality it has never received a valid command to run. EECO explicitly calls out the run and frequency reference signals as the most commonly overlooked causes of nonŌĆæstarting drives.

Three conditions must be met for a healthy ABB drive to start and accelerate a motor. It must have all safety and stop circuits satisfied, a valid run command, and a valid speed or frequency reference. If any of these are missing or misconfigured, the inverter will remain inhibited.

In practice, that means checking local and remote control modes on the ABB keypad, verifying whether the run command is wired to the expected digital input or being issued over a fieldbus, and confirming that a speed reference is present and scaled correctly. FranklinŌĆÖs guidance on analog signals in pump systems is instructive here. If a 4ŌĆō20 mA pressure transducer is misŌĆæscaled, the drive can interpret the feedback incorrectly and either chase the wrong setpoint or refuse to operate.

As a diagnostic, EECO suggests switching to local control at the keypad and commanding the drive to run at a moderate speed while safely monitoring the load. If the ABB drive runs locally, the root cause is almost certainly in external controls, field wiring, or automation logic rather than in the drive hardware.

Modern ABB VFDs are usually tied into an array of safety and permissive signals: safe torque off, thermal switches in motors or gearboxes, emergency stop circuits, door switches, and process interlocks. EECO emphasizes that these circuits are designed to keep the drive from running when something is unsafe.

If the ABB VFD shows no faults but will not start despite a run command, review all safety inputs. An open safety circuit is typically performing exactly as designed and must not be bypassed without understanding the condition it is indicating. For example, a tripped thermal sensor in a motor or a lowŌĆæpressure switch in a pumping system may prevent the drive from running until the underlying issue is resolved.

FranklinŌĆÖs work on water systems illustrates the effect of underload or dryŌĆæwell protection. When a pump runs unloaded because a well is drawn down or a suction line is blocked, current drops below an underload threshold and the drive legitimately trips. ABB drives configured with similar protections will behave the same way. Treat these as process and mechanical issues, not ŌĆ£VFD failures.ŌĆØ

Several sources, including UpFix, Emotron, Joliet Technologies, and DoSupply, stress that ŌĆ£VFD faultŌĆØ does not always mean the electronics are the problem. Motor insulation breakdown, phase imbalance, mechanical binding, and misaligned couplings all show up as electrical faults in the drive.

With power secured, inspect the motor connections for tightness and corrosion. Check that phases are correctly landed and that there are no damaged or oilŌĆæsoaked cables. Use insulation testers where appropriate to look for ground faults or moisture in windings, as recommended by Emotron and FlukeŌĆÖs motor and insulation guidance. Measure coil resistances and compare between phases.

On the mechanical side, Franklin and DoSupply both highlight that overcurrent and high starting load faults often stem from mechanical drag, blocked impellers, or material jammed in a conveyor or pump. If the drive trips on overcurrent during acceleration, the safest response is to stop, unload or free the equipment, and then restart with a gentler acceleration ramp. Pushing an ABB drive to force a stuck machine to move is a recipe for repeated tripping and potential damage.

Control Engineering, Apex Electric and Mechanical, PCTX, and others all identify overheating as a leading cause of VFD issues. Vents clogged with dust, failed fans, high ambient temperatures, and corrosive or moist environments will all shorten the life of both ABB drives and their motors.

Industrial Electrical CompanyŌĆÖs maintenance guide explains that NEMA 1 drives, which are vented and intended for indoor use, are especially vulnerable to dust ingress and require more frequent cleaning with a vacuum. NEMA 12 enclosed drives are better sealed but still require periodic inspection.

During troubleshooting, verify that cooling fans run when expected, air paths are unobstructed, and the surrounding air temperature remains within ABBŌĆÖs published limits. FlukeŌĆÖs motor reliability work emphasizes using thermal baselines to distinguish between naturally warm equipment and true overheating. Thermal imaging, as suggested by PCTX and others, can quickly identify hotspots caused by loose connections or blocked airflow that may trigger overtemperature faults.

While each ABB model uses its own specific fault codes, the underlying issues align closely with those documented in EECOnline, DoSupply, Joliet Technologies, Maxivolt, Franklin, and Emotron.

Overcurrent at startup usually means the motor is drawing more current than the drive rating allows. EECOnline and DoSupply link overcurrent to mechanical overload, sudden load changes, or short circuits. The practical response is to look for mechanical binding or jams, confirm that the motor is correctly sized, reduce acceleration rates, and inspect wiring and motor insulation for shorts.

Overvoltage or high DC bus faults often arise when a motor decelerates too quickly and regenerates energy back into the DC bus or when the line voltage experiences spikes. Joliet and DoSupply note that extending deceleration times and adding braking resistors are common remedies. Maxivolt goes further, explaining how DC link chokes, smoothing capacitors, AC line reactors, and surge protective devices cooperate to tame power quality and transient events. For ABB drives, the same principles apply: if high DC bus faults arise during deceleration or power disturbances, revisit ramp profiles, consider braking resistors, and evaluate upstream power quality.

Undervoltage faults indicate that the drive is not receiving enough DC bus voltage. UpFix and Joliet recommend verifying that supply voltage matches the driveŌĆÖs rating, checking for loose or undersized conductors, and investigating broader power system issues. AC line reactors can introduce voltage drops, as Maxivolt notes, so they must be sized correctly to avoid triggering undervoltage trips on weaker supplies.

Ground faults and insulation issues typically present as unexpected tripping or erratic behavior. EECOnline and Emotron both advise disconnecting the motor and testing insulation with appropriate equipment. Moisture, damaged cable jackets, and aged motor windings are common culprits. ABB drives with sensitive ground fault protection will shut down rather than tolerate leakage that could harm people or equipment.

Overtemperature faults can relate to the drive, the motor, or both. Apex, Control Engineering, PCTX, and others stress the importance of cooling system maintenance and ambient control. Once fans and airflow are verified, look at load levels, duty cycles, and harmonics, since excessive harmonics can raise motor temperature even when average current appears within limits.

Communication errors are also common in ABB installations integrated with PLCs or building management systems. Apex and Joliet Technologies both point to loose or faulty communication cables, mismatched protocol settings, and firmware compatibility as root causes. Troubleshooting here involves verifying that the drive sees the expected digital and analog inputs, checking network parameters, and, if necessary, updating firmware per vendor recommendations.

Even if an ABB VFD appears to struggle only at startup, broader power quality problems may be lurking underneath. AdmengŌĆÖs work on VFDŌĆærelated harmonics shows how nonŌĆæsinusoidal currents from drives can lead to motor heating, bearing damage due to induced shaft currents, and elevated insulation stress. These effects can shorten motor life and trigger protective functions inside both ABB drives and upstream protection equipment.

Maxivolt focuses on overcurrent and overvoltage faults driven by poor power quality, especially disturbances from short circuits, grid switching, lightning, and frequent start or stop operations. It explains how DC link chokes, smoothing capacitors, AC line reactors, and transient voltage surge suppressors each address different dimensions of power quality. Surge protective devices clamp transient overvoltages, while chokes, reactors, and capacitors shape current and reduce harmonics.

An Electric Power Research Institute study cited by Maxivolt found that VFDs were better able to ride through transient events when AC reactors and surgeŌĆæclamping devices were used together. For ABB drives feeding critical motors, especially on weak or noisy grids, coordinated harmonic filters and surge protection are not luxury accessories. They directly influence whether the drive starts cleanly, trips unexpectedly, or fails prematurely.

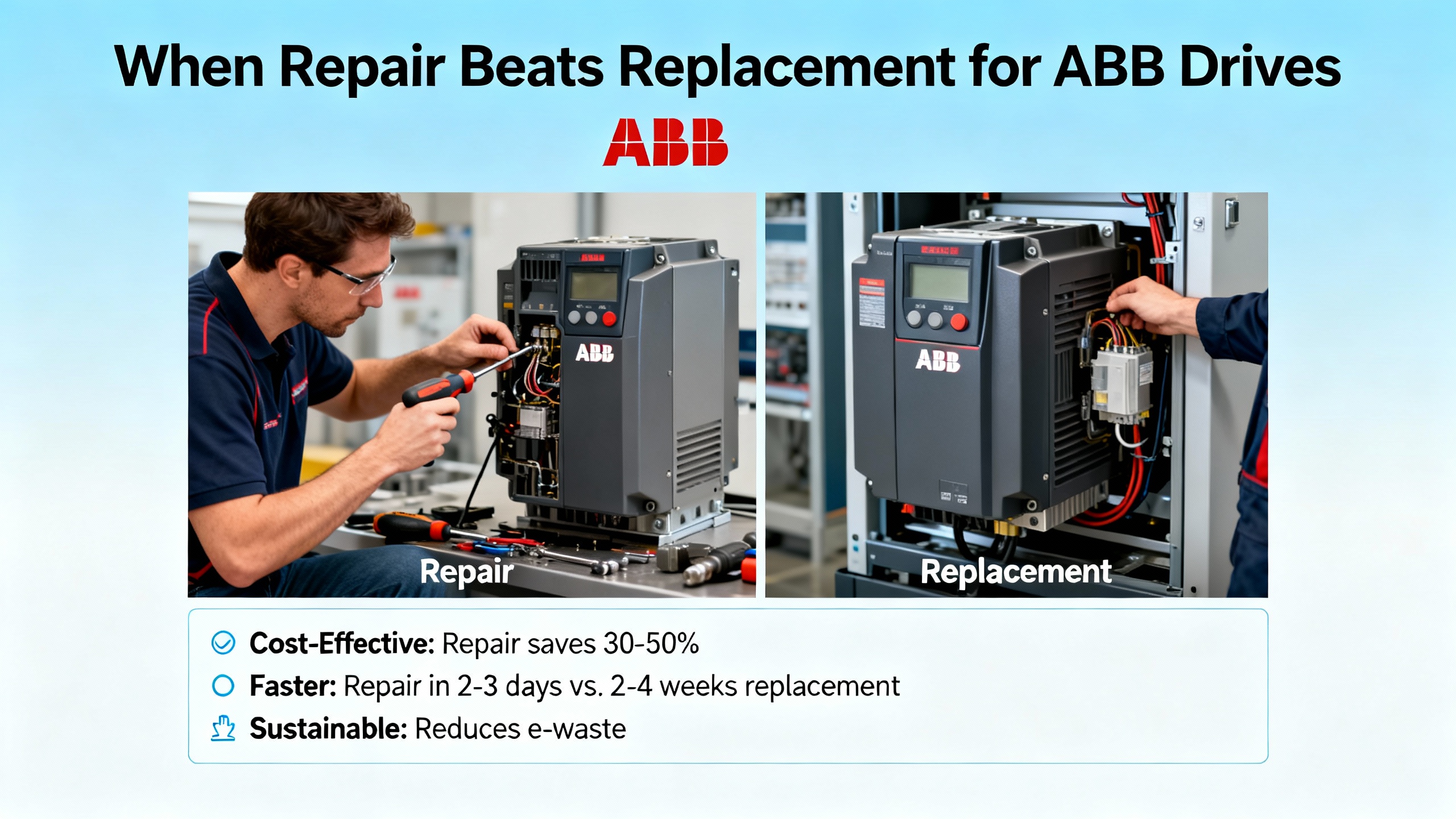

It is tempting to replace an ABB VFD as soon as it refuses to start, especially under production pressure. However, UpFix and other specialized repair providers make a strong case for repair as the default strategy where feasible.

UpFix reports that most VFDs can be restored at a fraction of replacement cost, sometimes delivering savings on the order of dozens of percent versus buying new units, while preserving existing wiring, parameters, and cabinet layouts. They emphasize boardŌĆælevel diagnostics under ESDŌĆæsafe conditions, detailed diagnostic reports, warranties, and turnaround of a few business days for many cases.

Repair is particularly attractive when dealing with ABB drives integrated into complex control schemes or when the exact model is hard to source quickly. The key is to differentiate between external issues that you can fix on site using the troubleshooting steps above and genuine internal failures such as burned power modules, cracked PCBs, or control board faults that recur even after all external issues are cleared. Once you have solid evidence of internal failure, engaging ABB or a qualified thirdŌĆæparty repair service is usually more costŌĆæeffective than repeated ad hoc replacements.

Startup troubleshooting is valuable, but the better outcome is not having the fault at all. The maintenance guidance from Industrial Electrical Company, PCTX, Control Engineering, Joliet, Fluke, and others converges on a few preventive themes that apply directly to ABB drives.

Regular cleaning and inspection keeps drives alive longer. Industrial Electrical Company recommends routine visual inspections for corrosion, condensation, and debris buildup, especially in NEMA 1 enclosures with open vents. PCTX and Control Engineering stress vacuum cleaning of heat sinks, fans, and filters, combined with periodic tightening of terminals and checking for discoloration or signs of overheating. For ABB drives in dusty or humid environments, sealed NEMA 12 enclosures and environmental controls reduce the cleaning burden but do not eliminate the need for inspection.

Cooling system maintenance is essential. PCTX highlights that blocked fans and heat sinks, failed fans, and restricted ducts are central causes of overheating and even fire risk. Ambient temperature must remain within manufacturer limits, and thermal imaging can help detect hotspots long before they trip alarms. Replacing cooling fans every several years, as suggested in maintenance guidelines, is a lowŌĆæcost way to extend drive life.

Electrical and software maintenance work together. PCTX, Industrial Electrical Company, and Joliet recommend periodic tightening of power and control terminations, checking for corrosion, and monitoring for vibrationŌĆæinduced loosening. They also encourage keeping firmware current, documenting parameter settings, and reviewing parameters whenever process conditions change. This is especially important for ABB drives deployed on systems that have been reŌĆærated or repurposed over time.

Baseline testing and trending allow you to catch drift. FlukeŌĆÖs motor and VFD reliability guidance, drawing on technician Dan OrchardŌĆÖs experience, advocates establishing electrical and thermal baselines when equipment is first commissioned. PhaseŌĆætoŌĆæphase resistance and insulation resistance, starting and running currents, and operating temperatures form a reference set. Periodic retesting, with attention to shifts of more than about five to ten percent, can reveal degradation in motors, cables, or connections before it triggers ABB faults.

Finally, integrating surge protection, harmonic mitigation, and appropriate UPS or power conditioning equipment around ABB VFDs protects the entire power train. MaxivoltŌĆÖs analysis and AdmengŌĆÖs work on harmonic filters both show that coordinated use of line reactors, DC chokes, surge protective devices, and passive or active harmonic filters materially improves rideŌĆæthrough performance and reduces stress on motors, bearings, and insulation. In facilities where UPS systems and sensitive controls share feeders with ABB drives, those measures are doubly important.

If the ABB drive powers up but will not start the motor, most field cases come down to control and interlock issues rather than failed power electronics. EECO and Franklin both emphasize checking three things: that the drive has a valid run command, that it has a valid frequency or speed reference, and that all safety and stop circuits are satisfied. Use the ABB keypad to verify local or remote control modes, inspect digital inputs and analog references for proper scaling, and confirm that safety circuits such as safe torque off and thermal switches are closed and healthy. As a test, try running the drive locally from the keypad at a moderate speed; if that works, the problem lies outside the drive, in controls or process signals.

Yes, they can. Maxivolt and Admeng both document how poor power quality and harmonics can cause overvoltage, undervoltage, or overcurrent events that manifest as trip conditions. When line voltage spikes or the DC bus is stressed by regenerative loads without appropriate braking or filtering, the ABB driveŌĆÖs protective logic does exactly what it is supposed to do and inhibits startup. Combining surge protective devices with line reactors, DC chokes, and properly sized braking resistors greatly reduces these power qualityŌĆæinduced startup problems.

Emotron, UpFix, and Fluke all converge on similar escalation criteria. If an ABB VFD shows visible internal damage, recurring control board or DESATŌĆætype faults that return after you have corrected external wiring, grounding, motor, and environmental issues, or if you detect burning smells or severe overheating, further onŌĆæsite resets are not responsible. At that point, it is appropriate to involve ABB support or a qualified VFD repair specialist with boardŌĆælevel diagnostic capability. Likewise, if troubleshooting would require internal measurements beyond your teamŌĆÖs training and tools, controlled bench repair is safer and more effective than trialŌĆæandŌĆæerror part[2025-11-17T21:43:46] stream error: stream disconnected before completion: stream closed before response.completed; retrying 1/5 in 183msŌĆ”

Planning blog article on ABB VFD Troubleshooting

The user requested a comprehensive blog article about "ABB VFD Not Working: Variable Frequency Drive Startup Troubleshooting." The target persona is a Power System Specialist & Reliability Advisor, with a tone thatŌĆÖs technical yet accessible. The piece should be 1500-3000 words and structured into headings without bullet or numbered lists. I need to be careful to stick strictly to the research notes and interpretations without introducing data outside of those notes. Clarifying article structure requirements

I need to ensure I donŌĆÖt include brand-specific features that arenŌĆÖt in the notes. I can refer to "ABB or similar VFDs," but I must avoid details about ABB-specific codes that arenŌĆÖt mentioned. Additionally, I can't use bullets or numbered lists. Instead, IŌĆÖll convert those into paragraphs while keeping markdown headings and tables. Concise markdown tables are allowed, as long as I follow the correct format: starting with pipes for headers and the alignment row using '|' and '---'. Clarifying article guidelines

It's good to know that I can use table alignment rows since they start with a '|'. However, I need to avoid bullet points, numbered lists, or any text starting with a digit. I need to focus on ensuring the article demonstrates expertise, experience, and authority (EEAT) by mentioning credible sources like Fluke or Control Engineering without including URLs. I should convert any metric units to imperial, but voltages and currents will remain in their original units (V, A), while temperatures like "130 ┬░F" will stay unchanged. Outlining blog content and structure

I need to create a 1500-3000 word blog, aiming for around 2000 words, focusing on the scenario of "ABB VFD Not Working." IŌĆÖll apply general VFD startup troubleshooting steps, covering power, display/fault codes, signals, motors, environments, harmonics, filters, maintenance, and when to repair versus replace. I'll use reputable sources like UpFix, EECO, and Fluke. Importantly, I can't fabricate facts, so I can only use fault codes if they appear in the notes. For instance, I can mention the "F4 for under-voltage" code generically from the Fluke article but won't attribute it specifically to ABB. I'll treat ABB as a brand serviced by others, without implying brand-specific details. Structuring the article on ABB VFD troubleshooting

I need to adhere to the guideline of not fabricating details while creating a comprehensive article. IŌĆÖll anchor each concept around general VFD troubleshooting steps, such as visual inspections, power checks, fault codes, and maintenance. I can synthesize information from sources like Admeng, Apex Electric, and UpFix without inventing new concepts. ItŌĆÖs important to reference my experiences in a way that mirrors the provided persona without fabricating facts. For FAQs, IŌĆÖll present them as paragraphs without bullet lists. I'll also ensure to avoid direct URLs and focus solely on the topic of ABB VFDs, emphasizing surge protection over UPS specifics. Structuring the ABB VFD troubleshooting article

IŌĆÖm looking to create an article titled "ABB VFD Not Working: Variable Frequency Drive Startup Troubleshooting," focusing on various aspects of VFD startup issues. IŌĆÖll cover topics like the definition of VFDs, safety precautions, and step-by-step troubleshooting methods. I'll structure it into headings and subheadings, ensuring to use sources like Apex and DoSupply while not inventing new information. The sections will include common fault codes, power quality, and using test instruments effectively. IŌĆÖll present multi-step processes in paragraph format, avoiding bullets or misconstructions. The goal is to keep the word count between 1500-3000 while maintaining clarity and insight. Outlining the ABB VFD troubleshooting article

IŌĆÖm planning to create an article with a clear structure. The introduction will be about 3-4 paragraphs long and will begin with "What an ABB VFD is doing at startup," explaining the VFD structure based on sources like IndustrialElectricalCo and DoSupply. IŌĆÖll follow that with a "structured startup troubleshooting path," breaking it down into stages, each discussed over two paragraphs.

Next, IŌĆÖll decode common startup fault types, including a table summarizing faults, and provide further explanations. IŌĆÖll also discuss power quality and harmonics, instrumented troubleshooting, and when to repair versus replace equipment. There will be a "Preventive practices" section, along with an FAQ featuring three questions.

In all of this, IŌĆÖll emphasize real-world experience, ensuring that I reference common issues without fabricating information beyond the notes I have. IŌĆÖll keep the voice first-person but stay generic to maintain credibility. Finally, IŌĆÖll avoid bullet lists or enumeration in headings, ensuring everything aligns with the specified guidelines. Clarifying article structure requirements

I need to ensure I donŌĆÖt include brand-specific features that arenŌĆÖt in the notes. I can refer to "ABB or similar VFDs," but I must avoid details about ABB-specific codes that arenŌĆÖt mentioned. Additionally, I can't use bullets or numbered lists. Instead, IŌĆÖll convert those into paragraphs while keeping markdown headings and tables. Concise markdown tables are allowed, as long as I follow the correct format: starting with pipes for headers and the alignment row using '|' and '---'. Clarifying article guidelines

It's good to know that I can use table alignment rows since they start with a '|'. However, I need to avoid bullet points, numbered lists, or any text starting with a digit. I need to focus on ensuring the article demonstrates expertise, experience, and authority (EEAT) by mentioning credible sources like Fluke or Control Engineering without including URLs. I should convert any metric units to imperial, but voltages and currents will remain in their original units (V, A), while temperatures like "130 ┬░F" will stay unchanged. Outlining blog content and structure

I need to create a 1500-3000 word blog, aiming for around 2000 words, focusing on the scenario of "ABB VFD Not Working." IŌĆÖll apply general VFD startup troubleshooting steps, covering power, display/fault codes, signals, motors, environments, harmonics, filters, maintenance, and when to repair versus replace. I'll use reputable sources like UpFix, EECO, and Fluke. Importantly, I can't fabricate facts, so I can only use fault codes if they appear in the notes. For instance, I can mention the "F4 for under-voltage" code generically from the Fluke article but won't attribute it specifically to ABB. I'll treat ABB as a brand serviced by others, without implying brand-specific details. Structuring the article on ABB VFD troubleshooting

I need to adhere to the guideline of not fabricating details while creating a comprehensive article. IŌĆÖll anchor each concept around general VFD troubleshooting steps, such as visual inspections, power checks, fault codes, and maintenance. I can synthesize information from sources like Admeng, Apex Electric, and UpFix without inventing new concepts. ItŌĆÖs important to reference my experiences in a way that mirrors the provided persona without fabricating facts. For FAQs, IŌĆÖll present them as paragraphs without bullet lists. I'll also ensure to avoid direct URLs and focus solely on the topic of ABB VFDs, emphasizing surge protection over UPS specifics. Structuring the ABB VFD troubleshooting article

IŌĆÖm looking to create an article titled "ABB VFD Not Working: Variable Frequency Drive Startup Troubleshooting," focusing on various aspects of VFD startup issues. IŌĆÖll cover topics like the definition of VFDs, safety precautions, and step-by-step troubleshooting methods. I'll structure it into headings and subheadings, ensuring to use sources like Apex and DoSupply while not inventing new information. The sections will include common fault codes, power quality, and using test instruments effectively. IŌĆÖll present multi-step processes in paragraph format, avoiding bullets or misconstructions. The goal is to keep the word count between 1500-3000 while maintaining clarity and insight. Outlining the ABB VFD troubleshooting article

IŌĆÖm planning to create an article with a clear structure. The introduction will be about 3-4 paragraphs long and will begin with "What an ABB VFD is doing at startup," explaining the VFD structure based on sources like IndustrialElectricalCo and DoSupply. IŌĆÖll follow that with a "structured startup troubleshooting path," breaking it down into stages, each discussed over two paragraphs.

Next, IŌĆÖll decode common startup fault types, including a table summarizing faults, and provide further explanations. IŌĆÖll also discuss power quality and harmonics, instrumented troubleshooting, and when to repair versus replace equipment. There will be a "Preventive practices" section, along with an FAQ featuring three questions.

In all of this, IŌĆÖll emphasize real-world experience, ensuring that I reference common issues without fabricating information beyond the notes I have. IŌĆÖll keep the voice first-person but stay generic to maintain credibility. Finally, IŌĆÖll avoid bullet lists or enumeration in headings, ensuring everything aligns with the specified guidelines.

Leave Your Comment