-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Selecting an ŌĆ£equivalentŌĆØ variable speed drive to an ABB VFD is not just a catalog exercise; it is a system decision that touches motor reliability, process stability, and power quality. When I review upgrade or replacement proposals in plants, the most common problems are not caused by the brand itself, but by mismatched ratings, overlooked environmental conditions, or underŌĆæestimated harmonic impacts.

This article walks through how to think about ABB VFD equivalents, how to map ABB drive families to comparable offerings from other manufacturers, and how to make sure the replacement is truly compatible with your motors, your process, and your power system.

A variable frequency drive is a power electronic converter that takes fixedŌĆæfrequency AC, rectifies it to DC, stores that energy on a DC bus, and then inverts it back to AC at a controlled frequency and voltage. As explained in material from CoastApp and several industrial guides, this lets you control motor speed, torque, acceleration, and deceleration while reducing mechanical stress compared with acrossŌĆætheŌĆæline starters.

Across manufacturing, HVAC, water treatment, and general industry, VFDs deliver several consistent benefits. They improve energy efficiency by letting motors run only as fast as the process needs, especially on centrifugal fans and pumps. They extend motor and mechanical life by providing soft starts and controlled ramps. They improve process control and product quality through fine speed regulation. They also reduce maintenance, provided the drive is installed and cooled correctly.

There are tradeoffs. VFDs cost more upfront than simple starters, require more configuration, and introduce harmonic distortion into the power system, which can affect other equipment if not managed. Those realities are emphasized in guides from AutomationDirect, Eaton, and VFDS.com, and they are central to any drive equivalence decision, whether you remain with ABB or move to another brand.

ABB is one of the major global suppliers in this space. Distributor and ABB technical literature describe a portfolio that spans machinery drives like the ACS180, ACS355, and ACS380, generalŌĆæpurpose drives such as ACS480 and ACS580, and applicationŌĆæspecific families such as ACH580 and ACQ580 for HVAC and water. Power ranges in these lowŌĆævoltage lines extend from roughly 0.25ŌĆō22 kW (about 0.33ŌĆō30 hp) for compact machinery drives up to about 500 kW (around 670 hp) for generalŌĆæpurpose ACS580 units. ABBŌĆÖs ŌĆ£allŌĆæcompatibleŌĆØ concept means many of these drives share a common user interface, parameter structure, and PC tools, which makes standardization attractive.

When you talk about an ŌĆ£ABB equivalent,ŌĆØ you are usually asking one of two questions. Either you have an ABB unit in the spec and want to know what other brands can be considered comparable, or you have an ABB drive in the field and need to replace it with a different manufacturerŌĆÖs unit due to availability, pricing, or site standards.

In both cases, brand name is secondary. Compatibility comes from matching electrical ratings, thermal and mechanical duty, control capability, and environmental robustness.

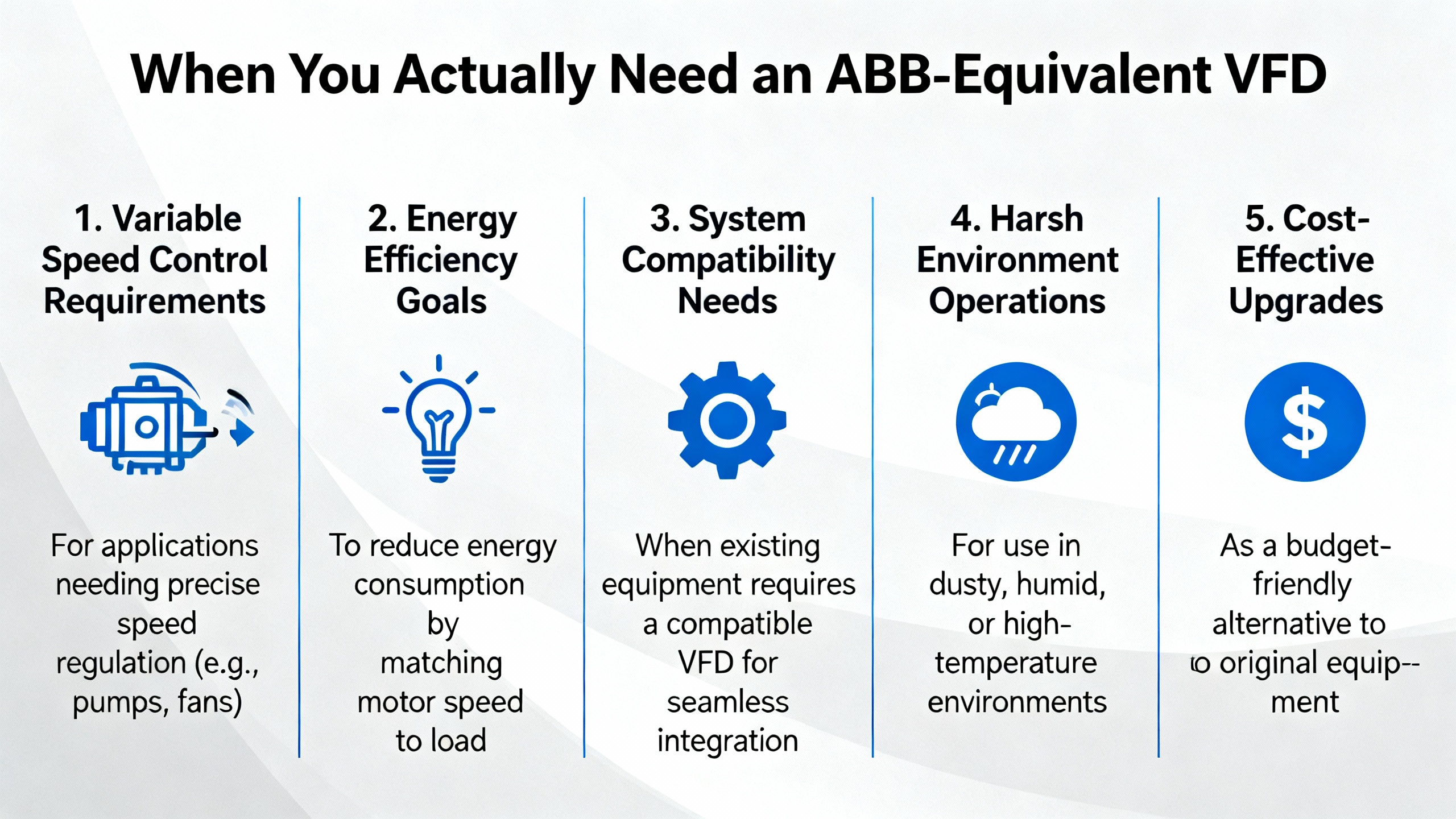

In practice, ABBŌĆæequivalent drives are sought in a few recurring situations.

One scenario is supply chain disruption. A project may be specified around ABB ACS580 drives for building pumps and fans, only to find long lead times. Engineers then look at comparable generalŌĆæpurpose drives from Siemens, Schneider Electric, Danfoss, Eaton, or others to keep the schedule on track.

Another scenario is brownfield modernization. A facility may be standardizing on one nonŌĆæABB vendor for future plantwide support, yet it has legacy ABB drives installed. When a legacy unit fails or becomes obsolete, the team asks what drive from the new house brand can replace the existing ABB model without rewiring the plant or retuning the process.

A third scenario is application fit. ABB machinery drives like ACS180 are compact and OEMŌĆæfriendly. An equipment builder might ask what alternative drive family from Yaskawa, Rockwell Automation (PowerFlex), or similar brands can offer equivalent footprint and features for the same motor range.

In all of these cases, the safest way to define ŌĆ£equivalentŌĆØ is: a drive that can deliver the same motor performance across the same speed and load profile, withstand the same environment, integrate into the same control architecture, and meet the same powerŌĆæquality expectations as the ABB unit you are replacing.

Although catalogs present many data points, several stand out as nonŌĆænegotiable if you want true equivalence. Industry guides from AutomationDirect, VFDS.com, Eaton, and ABBŌĆÖs own technical documentation are consistent on these.

A VFD is sized first to the motor and the mechanical load, not to the brand.

Every drive, including ABB models, must match the motorŌĆÖs nameplate voltage and fullŌĆæload amperage. Horsepower gets you into the ballpark, but fullŌĆæload current (FLA) is the critical sizing parameter. VFDS.com and other technical guides emphasize choosing a drive whose continuous current rating is at least equal to the motor FLA, often with around 10ŌĆō20 percent margin, particularly for constantŌĆætorque loads.

Motor voltage and frequency must also match the power system. Common lowŌĆævoltage levels described in industry material are 208, 230, and 460 V. Motor type matters too. All AC motors fed by standard VFDs are threeŌĆæphase, even if the VFD has singleŌĆæphase input. Many sources recommend inverterŌĆæduty motors with suitable insulation and bearings to handle the steep voltage pulses and additional electrical stress created by pulseŌĆæwidthŌĆæmodulated VFD outputs.

The mechanical load profile drives the torque classification. VariableŌĆætorque loads, such as centrifugal fans and pumps, draw power that rises roughly with the cube of speed. For these, variableŌĆætorque (VT) rated drives are appropriate, often with overload capability around 120 percent for one minute. ConstantŌĆætorque loads like conveyors, mixers, positiveŌĆædisplacement pumps, and extruders need constantŌĆætorque (CT) rated drives with higher overload capability, often 150 percent or more for one minute, to ride through starting and load spikes. AutomationDirect and VFDS.com explicitly distinguish CT and VT ratings and suggest choosing CT ratings when in doubt for a conservative design.

Any ABB equivalent must offer comparable CT or VT ratings in the same current range. Replacing a CTŌĆærated ABB drive on a conveyor with a cheaper VTŌĆæonly drive from another brand is not equivalence; it is a derating, and it will show up as nuisance trips or overheating.

Drive current ratings and overload capabilities define how hard you can push the system, especially during acceleration and highŌĆæinertia moves.

Many industrial drives, including the ABB families referenced in ABB and distributor literature, are designed for overloads around 150 percent of rated current for up to 60 seconds. Where starting torque demands are extreme or where retrofits are replacing traditional starters on heavy loads, you may need even more overload or a larger frame size.

SingleŌĆæphase input adds another complexity. Several technical sources point out that drives are significantly derated on singleŌĆæphase power. For example, VFDS.com notes that for larger singleŌĆæphase supplies, a common practice is to select a threeŌĆæphase input VFD with roughly twice the motor FLA to keep the rectifier section within its limits. If you are replacing an ABB drive that had specific singleŌĆæphase ratings, any alternative brand must be sized according to that same principle, not just by matching horsepower.

Duty cycle is another subtlety. Some drives are optimized for continuous heavy duty, others for lighter or intermittent service. Selection guidance from Chint and SHCKELE stresses aligning the driveŌĆÖs duty capability with how hard and how long the motor actually runs. When choosing an equivalent to an ABB industrial drive, make sure the replacement is not a ŌĆ£medium dutyŌĆØ product intended for lighter service unless your application genuinely fits that profile.

From a reliability and powerŌĆæprotection standpoint, the environment is where most equivalence attempts fail.

Guides from Affiliated Control, Canroon, Eaton, and ABBŌĆÖs own cabinet design instructions emphasize several environmental factors. These include ambient temperature, altitude, dust and airborne contaminants, humidity, and chemical exposure. Drives generate their own heat, and when mounted inside panels they can raise internal temperatures well beyond ambient. Many drive families can operate at full rating only up to a certain ambient temperature; above that, you must derate them or provide enhanced cooling or flange mounting to keep the heatsink in cooler air outside the enclosure.

Altitude matters because cooling air gets thinner as you go higher. CoastApp notes that many drives are rated for full output up to roughly 3,330 ft; beyond that you either oversize the drive or accept derating. ABB cabinet guidelines highlight cooling and airflow, grounding, electromagnetic compatibility, and vibration damping as critical for reliability and compliance. An ABB equivalent must be able to tolerate the same ambient and altitude, and it must be installed in an enclosure that provides at least the same ingress protection.

Enclosure ratings such as NEMA or IP code indicate protection against dust, moisture, and foreign objects. ABB offers both openŌĆætype drives intended for clean electrical rooms and fully enclosed units suitable for harsh areas. Field experience shared in hobby and industrial forums consistently praises sealed NEMA 4 enclosures for machines exposed to dust, grit, and splash, while open IP20 cases are adequate only in clean, protected panels. When substituting another brand for an ABB drive, match the enclosure type and protection level, not just the electrical data.

From a power reliability viewpoint, VFD harmonics are as important as horsepower.

CoastApp and Eaton both call out harmonic distortion as a key drawback of VFDs. VFDS.com adds that when drives are used as phase converters or are widely deployed, they significantly pollute power quality. Common mitigations recommended by Affiliated Control, Canroon, and DOE pumping guidance include the use of line reactors, DC chokes, harmonic filters, or ultraŌĆælowŌĆæharmonic drive designs. In some facilities, adherence to standards such as IEEE 519 or utility total harmonic distortion limits is mandatory.

ABB offers ultraŌĆælow harmonic variants and applicationŌĆæspecific HVAC and water drives that address power quality in sensitive environments like data centers and district energy systems. ABB literature highlights how these solutions help maintain grid power quality and protect sensitive IT and power equipment.

When selecting an equivalent from another brand, you should not just match kW and voltage; you should match the harmonic performance and any existing mitigation. If the original ABB specification used lowŌĆæharmonic drives in a data center cooling plant, substituting basic sixŌĆæpulse drives without reactors is a regression that will show up as transformer heating, nuisance trips, or issues with other sensitive assets.

In modern plants, a VFD is as much a control and data device as it is a power converter. ABBŌĆÖs ŌĆ£allŌĆæcompatibleŌĆØ portfolio underscores this by sharing control logic and tools across models and offering fieldbus and Bluetooth options.

Several sources emphasize the importance of selecting drives with the right control modes. For simple fans and pumps, scalar voltsŌĆæperŌĆæhertz control is often adequate. For more demanding machinery, sensorless vector or closedŌĆæloop vector control delivers better torque response and speed regulation, as described in CoastApp and VFDS.com. ABB machinery drives such as ACS180 and ACS380 are designed around advanced motor control algorithms to suit these applications.

Communications are equally important. Modern drives from ABB and other leading brands commonly support Modbus, EthernetŌĆæbased protocols, BACnet for building automation, and other industrial networks. Articles from VFDS.com, Canroon, and SHCKELE all stress selecting drives that integrate cleanly with your present and future control architecture, including PLCs, building management systems, and remote monitoring.

Safety features such as Safe Torque Off (STO) now come standard on many ABB families, including ACS180 according to ABB documentation. STO allows removal of torque without cutting main power, simplifying safety circuits and compliance with machinery directives. Any equivalent drive considered for a machine with a safetyŌĆæintegrated design must provide matching safety functions and certifications; otherwise, you will have to redesign the safety system.

Although every application is unique, it is helpful to see where ABB drive families sit in the landscape and what kinds of drives from other manufacturers tend to compete in similar roles. Industry summaries from Canroon, IPD, Gibbons Engineering, and others give a reasonable picture, which can be condensed as follows.

| Application focus | ABB drive family examples | Approx. motor range (from ABB/IPD data) | Common alternative brands for similar roles | Notes for equivalence |

|---|---|---|---|---|

| Compact machinery, OEM equipment | ACS180, ACS355, ACS380 | About 0.25ŌĆō22 kW (roughly 0.33ŌĆō30 hp) | Siemens, Yaskawa, Mitsubishi, Delta, Invertek, and other machineryŌĆæoriented lines | Prioritize footprint, advanced vector control, programmable logic, and I/O flexibility |

| GeneralŌĆæpurpose pumps and fans | ACS480, ACS580 | About 0.75ŌĆō500 kW (roughly 1ŌĆō670 hp) | Siemens SINAMICS G120, Schneider Altivar, Danfoss generalŌĆæpurpose, Eaton drives | Match CT/VT ratings, overload, and harmonic performance for plantwide deployments |

| HVAC and refrigeration systems | ACH580, dedicated HVACR drives in ABB portfolio | Small to large building pumps, fans, and compressors | Brands with HVACŌĆæspecific VFDs used in buildings and data centers | Check builtŌĆæin HVAC functions, lowŌĆæharmonic options, BACnet and building integration |

| Water and wastewater, pumping | ACQ580 and related waterŌĆæfocused ABB drives | Municipal and industrial pumping ranges | GeneralŌĆæpurpose or waterŌĆæoptimized lines from Danfoss, Rockwell, Siemens, etc. | Look for multiŌĆæpump control, PID, and robust protection against harsh environments |

| HighŌĆæperformance industrial drives | ACS880 and industrial variants | Broad industrial range above standard machinery sizes | HighŌĆæend industrial lines from major brands with advanced control and safety | Focus on process performance, regenerative options, and cabinet engineering |

The alternative brands in this tableŌĆöSiemens, Schneider Electric, Rockwell Automation (PowerFlex), Danfoss, Yaskawa, Eaton, Mitsubishi, Delta, Invertek, and othersŌĆöare cited in industrial overviews as common choices for pumps, fans, conveyors, elevators, and material handling. They are not dropŌĆæin replacements for any specific ABB model, but they occupy similar application spaces. To use them as true equivalents, you must still walk through the sizing, environmental, control, and powerŌĆæquality checks described earlier.

When I review proposed substitutions, I walk through a repeatable process. You can replicate that same approach even if you are not living in drive datasheets every day.

Start with the motor and the nameplate. Confirm threeŌĆæphase motor type, voltage, base frequency, FLA, speed, and service factor. Check whether it is inverterŌĆæduty or has any special construction such as highŌĆæefficiency design or nonstandard insulation. Then characterize the load: is it a fan or centrifugal pump with variable torque, or a conveyor or mixer with constant torque? Does it have high inertia, frequent starts and stops, or bidirectional operation?

Translate that into drive requirements. Use the motorŌĆÖs FLA as the primary sizing input. Compare that to the continuous current capabilities of both the ABB drive being replaced and the candidate alternative. If the power supply is singleŌĆæphase, apply the derating guidance from AutomationDirect or VFDS.com and size up accordingly. Make sure the overload rating suits your starting torque needs.

Next, consider the environment and mechanical integration. Determine where the drive will physically live: in a clean electrical room, on a MCC, in a rooftop or outdoor box, or in a dusty or corrosive production area. Check ambient and worstŌĆæcase internal enclosure temperatures. Review altitude if the site is significantly above sea level; above roughly 3,300 ft, both ABB and competing drives often require oversizing or derating for adequate cooling. Match or exceed the original ABB enclosure rating when selecting the equivalent.

Then address power quality. Review any existing harmonic studies, line reactors, filters, or special lowŌĆæharmonic ABB models that may be in the plant. If the ABB design relied on ultraŌĆælow harmonic drives in sensitive areas such as data centers or tunnel ventilation, the alternatives should provide comparable harmonic mitigation, whether via builtŌĆæin technology or external reactors and filters. If the application uses the drive as a phase converter from singleŌĆæphase to threeŌĆæphase, pay extra attention to input current and harmonics, in line with cautions from VFDS.com and forum experiences.

At this point, move up the stack to control and integration. Inventory how the existing ABB drive is controlled. Is it standŌĆæalone with a keypad and analog input, or is it under PLC or building automation system control via Modbus, BACnet, or EtherNetŌĆæbased protocols? Are there builtŌĆæin application macros, such as multiŌĆæpump control or PID pressure regulation, that the process depends on? Do safety circuits use features like Safe Torque Off?

Any equivalent must either replicate these capabilities or be integrated with changes in the control system that preserve functional behavior. ABBŌĆÖs common user interface and tools are a productivity advantage; switching vendors means trading that familiarity for the new vendorŌĆÖs toolchain, so factor in commissioning and maintenance training.

Finally, close the loop with lifecycle cost and reliability. Consider not only purchase price but expected energy savings, downtime risk, and maintenance support. DOE pump guidance and multiple industry articles highlight that the simple payback for VFDs on variableŌĆætorque loads is often on the order of a few years, and that highŌĆæefficiency, betterŌĆæsupported drives can repay their premium through energy, uptime, and reduced troubleshooting effort.

Even with a technically sound equivalence, reliability can suffer if commissioning and maintenance are not handled carefully.

Affiliated ControlŌĆÖs recommendations on commissioning are simple but powerful. Record and back up all parameter sets. Label key settings and network addresses. Trend current, speed, and fault histories during early operation to confirm that the new drive behaves as expected compared with the ABB baseline. Keep ventilation paths clear and schedule periodic inspections to remove dust and verify that fans, filters, and terminations remain in good condition.

ABBŌĆÖs documentation also highlights specific maintenance concerns such as reforming the DC bus electrolytic capacitors after long storage. This step protects capacitors from damage when drives have been shelved for extended periods, and similar requirements exist for many other manufacturers. When using nonŌĆæABB equivalents, follow their capacitor reforming and storage procedures as closely as you would follow ABBŌĆÖs guidance.

Installation best practices from Canroon and VFDS.com apply regardless of logo. Avoid inadequate cooling, loose wiring, and poor grounding. Use appropriately shielded and routed motor cables to minimize electromagnetic interference and bearing currents. Do not underestimate the impact of improper parameter programming; misŌĆæset acceleration times, current limits, or PID parameters can lead to trips that are blamed on the drive brand when the real cause is configuration.

If you are replacing a failed ABB drive, take the failure mode seriously. Overvoltage DC bus trips, repeated overcurrent faults, or overheating alarms can be symptoms of deeper system issues: mechanical binding, misapplied drive ratings, ventilation problems, or harmonic interactions. Simply dropping in another brand without addressing root cause is likely to result in another failure, regardless of the nameplate.

Can I replace a failed ABB drive with a higherŌĆæhorsepower drive from another brand? Within reason, yes, but you must respect current and overload ratings. Industry Q&A and selection guides indicate that using a drive with higher horsepower than the motor is usually acceptable as long as the driveŌĆÖs motor parameter ranges cover your motor and the current rating is appropriate. However, a much larger drive may have different minimum current and protection thresholds, and it can increase shortŌĆæcircuit energy. Always program the motor nameplate data into the new drive and verify that it can accurately protect the motor.

Is buying a used ABBŌĆæequivalent drive safe to save money? Experts caution that buying used VFDs from online marketplaces is risky. Some units may be obsolete models with known design issues or poor documentation. Selection advice from engineering forums recommends buying only models with readily downloadable manuals and clear parameter ranges, and, for industrial use, favoring brands with local dealer support. For critical systems, the risk and hidden labor of integrating and troubleshooting a used or obscure drive often outweigh the apparent savings.

Can one replacement drive run multiple motors that used to be on separate ABB drives? Technical guides note that one VFD can run multiple motors only if they start and stop together and if each motor has its own overload protection. The drive must be sized for the combined load and the starting profile. However, consolidating separate ABB drives into a single multiŌĆæmotor drive can reduce redundancy and flexibility. Before doing this, consider process implications, fault selectivity, and how a single point of failure affects uptime.

Choosing an ABB VFD equivalent is less about matching brand hierarchies and more about understanding the motor, the load, the environment, and the power system you are tying into. When you match fullŌĆæload current, overload and duty ratings, environmental robustness, harmonic performance, and control features, you can confidently substitute between ABB and other major manufacturers without compromising reliability. In critical industrial and commercial power systems, that disciplined, specificationŌĆædriven approach is what keeps drives, motors, and the entire process running predictably over the long term.

Leave Your Comment