-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Configuring ABB variable frequency drives is one of those skills that separates a ŌĆ£wires-are-tightŌĆØ electrician from a true power system specialist. When you are responsible for industrial or commercial power supply systems that include UPS, inverters, and sensitive loads, how you select, install, and program ABB drives shows up directly in uptime, energy bills, and maintenance hours.

This article outlines what a serious ABB Drive Configuration Course should cover, based on field experience and established guidance from ABB, Control Engineering, Plant Engineering, and other reputable engineering sources. Think of it as a curriculum roadmap you can use to structure training for your team or yourself.

In most facilities I work with, nearly every major rotating asset is now on a drive: chilled water pumps, cooling tower fans, process blowers, air compressors, and conveyor motors. Industry data consistently shows that close to 70% of industrial electrical energy feeds motors, which is why ABB and many independent engineering authors frame drives as one of the most powerful levers for energy efficiency and decarbonization.

ABB and others routinely report energy reductions in the range of about 20ŌĆō50% for well-executed retrofits, with some pump and fan applications reaching even higher savings when speed is aggressively optimized. Articles from ABB and power-system integrators show that in favorable cases a drive project can pay for itself in less than a year through reduced kWh, lower demand charges, and fewer mechanical failures.

However, most VFD failures I am called in to investigate are not silicon failures. They are configuration errors, poor cable practices, undersized cooling, or a misunderstanding of how a parameter interacts with process dynamics. A good ABB drive configuration course turns those weak spots into strengths: technicians stop guessing at parameters and start applying a structured, repeatable method.

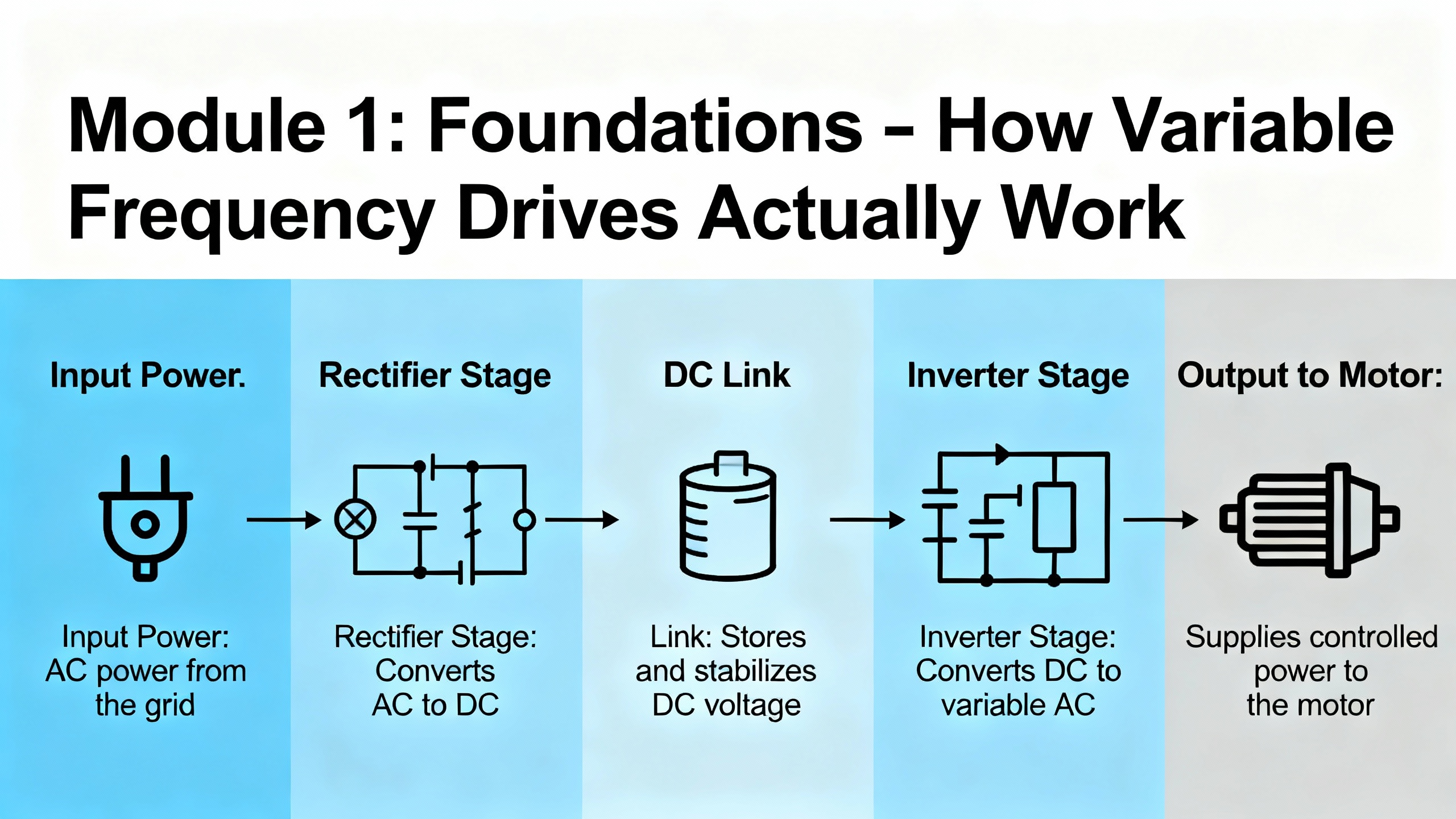

Any serious course starts by demystifying what a drive does electrically and why that matters to configuration.

A variable frequency drive takes fixed-frequency AC from the utility or upstream UPS and converts it in three stages. First, rectifiers turn AC into DC. Second, DC-link capacitors smooth that energy. Third, insulated gate bipolar transistor (IGBT) switches reconstruct a new AC waveform with variable frequency and voltage. By adjusting that synthesized frequency, the drive proportionally adjusts motor speed and torque.

Control Engineering and other sources emphasize that despite the complexity under the hood, most industrial applications need only a small set of well-chosen parameters to run correctly. Drives are engineered so that factory defaults will already work for a typical pump or fan if the motor data and a handful of ramp settings are correct.

An ABB-focused course should ensure participants can explain, without reaching for a manual, what the rectifier, DC bus, inverter, and control board each contribute, and why that matters for issues like harmonics, DC-bus overvoltage, and the residual charge that remains on capacitors for several minutes after power is removed.

A useful early comparison for students is how drives differ from traditional starters and basic soft starters.

| Start method | Key characteristics | Typical use in a modern ABB system |

|---|---|---|

| Across-the-line | Full voltage at start, inrush current up to several times running current, high mechanical shock | Simple small motors where process and power system can tolerate current spikes |

| Soft starter | Reduced voltage ramp, lower mechanical stress, limited speed control once at full frequency | Occasional-start pumps or compressors without variable-speed requirements |

| ABB VFD | Full speed range, precise torque control, integrated soft start/stop, energy optimization, extensive I/O | Pumps, fans, conveyors, compressors, high-efficiency and reliability-critical loads |

From day one, students should understand that a drive is not just a ŌĆ£fancy starter.ŌĆØ It is a speed, torque, and energy optimizer that also introduces new power-quality and EMC considerations.

Before you ever touch a parameter, you must have the right drive on the wall. Articles from Darwin Motion, Winn-Marion, and ABB partners repeatedly stress that most chronic drive issues start with poor selection, not poor programming.

A good course walks through these decisions using real equipment data sheets and ABB catalog examples.

First, match the drive to the motor and load. The motorŌĆÖs full-load amperage, voltage, and insulation rating are the primary selection anchors, not just horsepower. Sources that specialize in drive selection emphasize that improper sizingŌĆöespecially ignoring duty cycle and torque profileŌĆöleads to nuisance trips, overheating, and short motor life. For variable-torque loads such as pumps and fans, you want a drive rated appropriately for that torque pattern; for conveyors and compressors you need constant-torque capability.

Second, consider the environment. Industry guidelines highlight that dust, moisture, corrosive vapors, and high ambient temperature are silent killers of drives. ABB and others supply enclosures with ratings roughly analogous to IP20, IP54, or higher; in North American practice this corresponds to different NEMA types. A course should teach how to read an ABB driveŌĆÖs environmental rating and reconcile it with the actual installation: a hot mechanical room, a roof-mounted outdoor enclosure, or a clean electrical room backed by UPS.

Third, address integration and communication. Modern ABB drives can speak common industrial protocols such as Modbus-based links, fieldbus, or Ethernet-based variants. A course should frame communications as part of selection, not an afterthought, particularly when the drive participates in building management, SCADA, or is backed by intelligent UPS and power monitoring.

Finally, tie selection to energy and reliability goals. Articles from ABB and energy-efficiency specialists highlight that combining high-efficiency motors with ABB frequency drives yields significant energy and COŌéé reductions. For a configuration course, that means students should learn to interpret efficiency classes, understand where high-efficiency motors are worth the premium, and identify which loads are true energy ŌĆ£low-hanging fruit.ŌĆØ

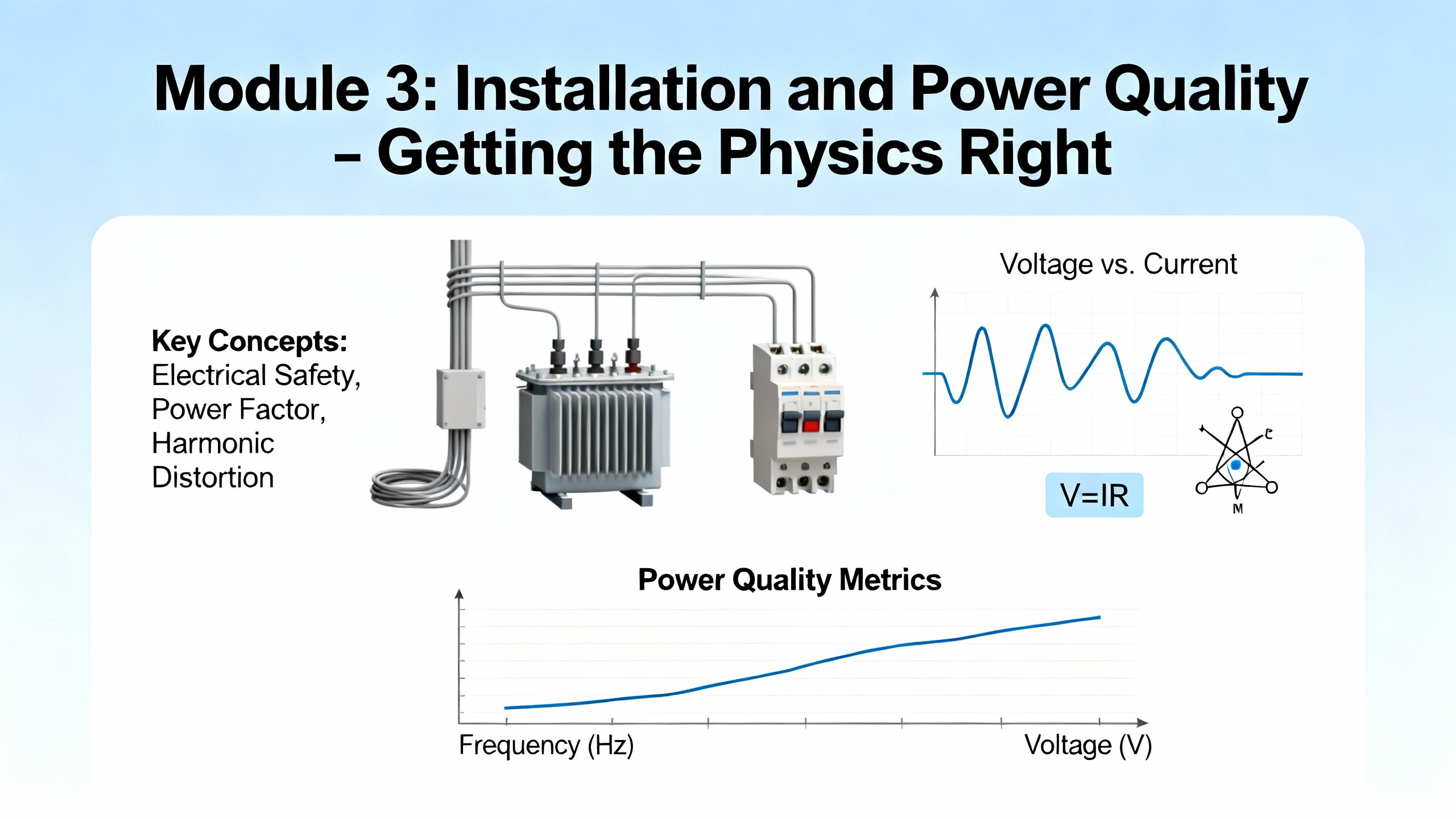

Configuring parameters on a poorly installed drive is like tuning a race car with flat tires. Industry best-practice documents on VFD installation emphasize wiring and EMC as much as programming.

Course content should begin with cable and grounding choices. Multiple sources stress the importance of using VFD-rated, shielded motor cable with robust insulation and low capacitance. Shields must be bonded correctlyŌĆötypically terminated at the drive end and referenced to a low-impedance ground. Grounding should be direct and dedicated from the drive and motor back to the panel ground, avoiding shared or daisy-chained paths that create loops and noise.

Next, introduce physical layout. To control electromagnetic interference (EMI), manufacturers and engineering publications advise separating drive output cables from low-voltage instrumentation cables, crossing only at right angles when necessary, and using grounded metal conduit or tray for motor leads. Proper segregation is especially important in plants where drives share space with PLC racks, power quality meters, and UPS systems feeding critical loads.

Cooling and enclosure design deserve special attention. Real-world carwash and industrial case studies show how easily a cluster of drives in a sealed steel cabinet can cook itself. A single 15 hp, 480 V drive can dissipate heat comparable to roughly a 1,200 W lamp, roughly twenty times a typical household bulb. Multiply that by half a dozen drives and you have a small electric heater bolted to the wall.

A course should include exercises in calculating enclosure heat load and specifying fans, filters, and airflow paths that honor the clearances in the ABB manual. Participants should see how blocked filters, missing fan guards, or installing drives at the very top of a hot MCC chase ambient temperatures toward fault thresholds.

Power quality mitigation is another core capability. Plant Engineering and other sources describe three recurring concerns: input harmonics, DC-bus overvoltage from line disturbances, and reflected-wave overvoltage on long motor leads. To manage these, engineers use line reactors on the input to limit inrush and flatten current waveforms; load reactors or filters on the output for long cable runs, sometimes measured in hundreds or thousands of feet; and careful coordination with upstream transformers, generators, and UPS systems. A configuration course should at least expose trainees to when a simple line reactor is enough and when a dv/dt filter or sine-wave filter becomes necessary.

Throughout this module, safety is non-negotiable. Industry guidance consistently warns that DC bus capacitors can remain charged several minutes after isolation. Any course should drill lockout/tagout procedures, verification of absence of voltage, and respect for manufacturer-specified discharge times before accessing internal terminals.

Once the right hardware is installed correctly, the course can focus on the parameters that truly matter. Control Engineering identifies five parameter groups that cover the overwhelming majority of industrial VFD programming. ABB drives follow the same logic, even if menu structures differ.

The control method dictates how the drive regulates motor flux, torque, and speed. Basic Volts-per-Hertz (V/f) control fixes a relationship between voltage and frequency. It is simple, robust, and typically the default on ABB drives shipped for pump and fan service. In this mode, the motor is allowed a small amount of slip away from commanded speed. For centrifugal pumps and fans, that slip barely affects process performance because the control loop simply asks for a bit more speed when needed.

Sensorless or self-sensing vector control adds a layer of sophistication by mathematically estimating motor flux and torque from current feedback. Control Engineering describes this family of methods as able to regulate speed to within about one part in two hundred of rated speed, deliver high starting torque at low speed, and limit current without external devices, once the drive has ŌĆ£learnedŌĆØ the motor through a tuning routine based on nameplate data.

Closed-loop vector control then adds a physical speed feedback device such as an encoder. This allows precise speed control down to about one revolution per minute, true zero-speed holding torque, and tight torque regulation. Extruders, high-speed spindles, and constant-tension unwinding applications benefit from this method, and ABB drives with encoder options support it.

A solid course will walk students through when a simple V/f profile is sufficientŌĆöfor example on a cooling tower fanŌĆöand when they must step up to vector or closed-loop control to avoid quality issues or mechanical stress.

The motor nameplate full-load amperage is not a suggestion; it is the reference for the driveŌĆÖs electronic thermal model. When you program the FLA parameter in an ABB drive, you are telling it how much current the motor can continuously tolerate without overheating.

Control Engineering notes that although drives provide soft-start behavior, there are many legitimate reasons for current to rise above FLA briefly: acceleration, impact loading, or cycling duty. But sustained overcurrent leads to insulation breakdown and short motor life. Setting FLA correctly allows the ABB drive to act as the required motor overload device under electrical codes, often eliminating the need for a separate mechanical overload relay and its associated contacts and maintenance.

Modern ABB drives support different overload curves suitable for variable-torque applications, constant-torque loads, and permanent magnet motors. A configuration course should have participants program FLA and overload class based on real motor data sheets, then watch how the drive responds to artificial overloads in a lab environment.

Drives are natural soft starters because they ramp frequency from zero to setpoint over a programmed time. The acceleration and deceleration parameters define how long that ramp takes and thus how much current and torque are demanded from the motor and power system.

Control Engineering highlights that slower ramps mean lower inrush and less stress on both mechanical and electrical components, but each application has a limit to how slow you can go before the process suffers. Fan and pump drives often ship with longer default ramps, while general-purpose drives ship with quicker ones.

A course should teach students to adjust ramps empirically while watching actual current draw and fault behavior. Too aggressive a ramp on a high-inertia load will trip overcurrent or overload faults. S-curve or ŌĆ£jerkŌĆØ settings soften the transition at the start and end of ramps, stretching the most stressful regions slightly without making the entire ramp painfully slow. Seeing those curves drawn on a whiteboard is helpful; seeing them play out as torque shocks or their absence on a real motor is what makes the lesson stick.

Every drive needs two commands at all times: a run command and a speed reference. Many ABB units ship with defaults that use digital inputs for run and an analog input such as 4ŌĆō20 mA or 0ŌĆō10 V for speed. Control Engineering notes that misconfiguration here is one of the most common causes of ŌĆ£the drive will not runŌĆØ technical support calls.

In a course, trainees should practice deliberately changing these sources: running from the keypad, from hardwired I/O, and from a communications channel. They should see how a missing run bit in a PLC, a broken analog signal, or a misassigned terminal can look like a complex drive fault until someone checks the basics.

Drives protect themselves and the motor by tripping on faults when conditions exceed programmed limits. ABB documentation and third-party troubleshooting guides describe faults like overcurrent when acceleration is too aggressive, overvoltage when deceleration is too fast or the line is high, undervoltage when the supply dips, or overtemperature when cooling is inadequate.

Many ABB drives allow you to configure automatic fault reset: the drive will try to clear the fault and restart after a programmable delay and a set number of attempts. A configuration course must stress the difference between using this feature judiciouslyŌĆöfor example, to ride through nuisance undervoltage from a weak feederŌĆöand using it recklessly in ways that repeatedly slam a stalled machine into torque until something mechanical fails. Students should learn to pair fault reset settings with root-cause analysis, not as a band-aid.

By this point in a course, participants should be ready to commission an ABB drive systematically rather than experimentally. Field-proven best practices from ABB partners, HARS VFD installation guidance, LinkedIn engineering articles, and carwash industry case studies converge on a repeatable sequence.

First, verify power and wiring before energizing the drive. That means checking line voltage, phase rotation, and motor winding resistance, along with confirming that shielded cables, grounds, and terminal tightness all match the drawing. Many apparent ŌĆ£drive faultsŌĆØ are simply loose lugs or swapped phases.

Second, power up in local/keypad mode with the motor uncoupled when possible. Enter motor nameplate data carefully, run the built-in tuning routine recommended for the selected control method, and confirm no abnormal noise or current spikes appear during a low-speed test. Verifying correct motor rotation without the process load attached prevents expensive mishaps such as pumping backwards against non-return valves.

Third, integrate control. Connect the run and speed signals as designed, whether those are analog references, digital contacts, or a network command. Test start, stop, and speed changes at a low maximum frequency first, then gradually open up the range once behavior is stable.

Fourth, exercise protection and alarms. Intentionally provoke safe test conditions such as an open feedback signal or a command beyond the allowed range to prove that the drive and supervisory system respond as expected. At this stage, students should also learn how to back up parameters, either via the keypad, removable memory, or vendor software where available, so a known-good baseline is always at hand.

Finally, tune for efficiency and process performance. Energy efficiency articles from ABB and independent sources point out features such as energy-optimization modes, PID control loops, and sleep functions for intermittent loads. During commissioning, these should be introduced carefully: for example, letting a pump drive stop automatically at low demand and wake when pressure falls, or allowing a fan drive to adjust speed based on duct static pressure rather than running flat out.

Even the best-installed drive will eventually encounter abnormal conditions. An effective course spends time not just on how to clear faults, but how to think about them.

Delta AutomationŌĆÖs ABB troubleshooting guidance, along with ABBŌĆÖs own documentation, describe fault codes that map to familiar physical issues. Overcurrent faults often trace back to sudden torque demands, mechanical binding, or ramps that are too aggressive. Overvoltage faults sometimes arise when a decelerating load regenerates energy into a full DC bus without adequate braking resistors or longer decel times. Undervoltage typically indicates feeder issues, missing phases, or loose upstream connections. Overtemperature faults point to blocked filters, failed fans, or ambient temperatures exceeding the driveŌĆÖs rating.

A configuration course should provide a lab setup where learners can see representative faults and use the ABB keypad or HMI to inspect event history, timestamps, and live values such as DC bus voltage and heat sink temperature. They should learn the discipline of checking the simplest causes first: mechanical load, wiring, and environment, before assuming there is an obscure firmware bug.

For higher-performance ABB models such as the ACS880, documentation and practitioner articles highlight advanced diagnostic tools and parameter logging that help isolate intermittent issues. Students should be introduced to these tools conceptually, even if hands-on time is limited, so that they know when to escalate to specialized software or vendor support.

Throughout, the emphasis must remain on root-cause elimination and preventive actions: adjusting ramps, installing reactors, improving cooling, or revising FLA and overload curves. Simply resetting a fault without understanding it is not acceptable in a reliability-focused culture.

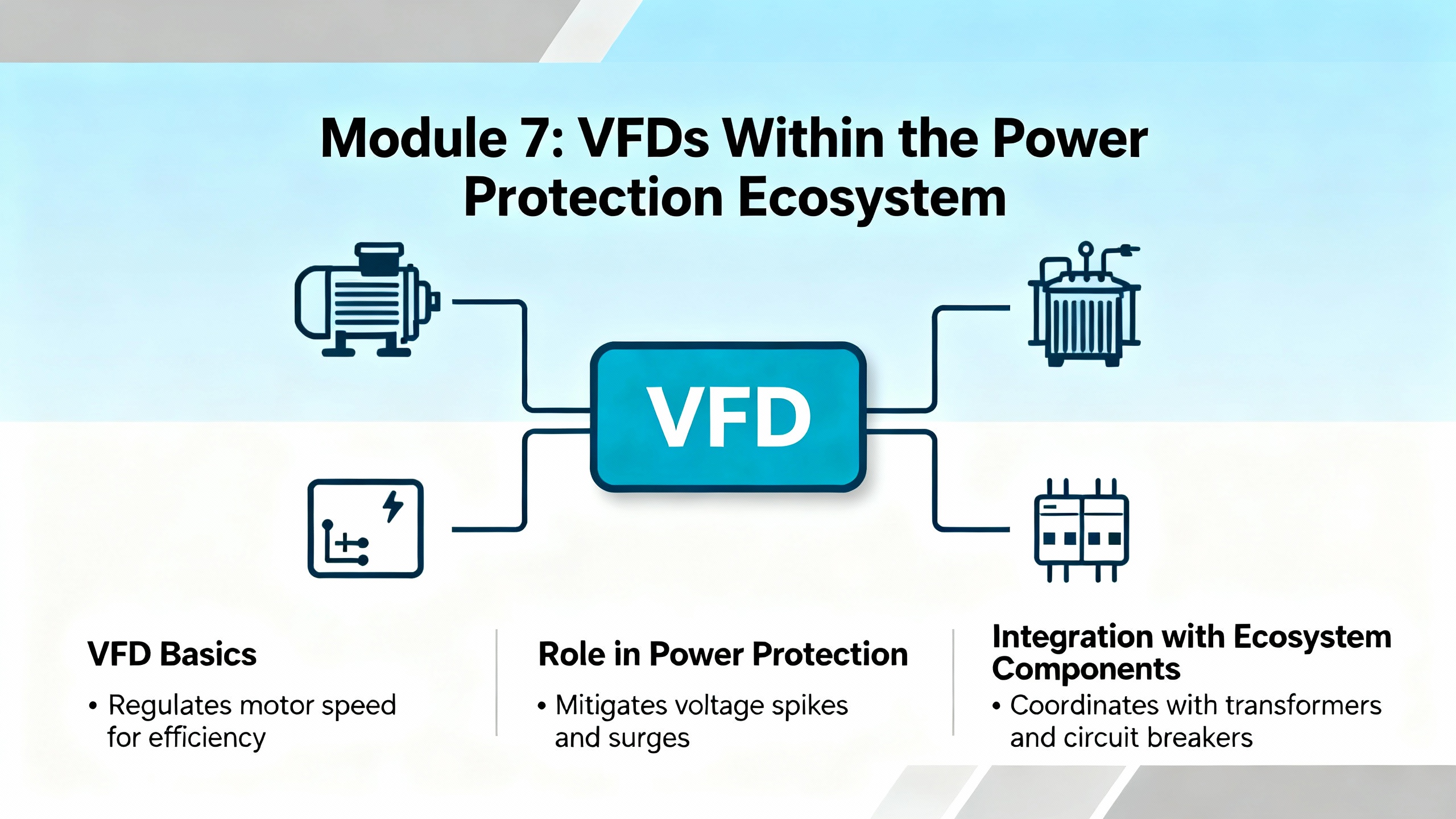

In real facilities, ABB drives rarely stand alone. They often sit downstream of switchgear backed by UPS systems, engine-generators, and transient voltage surge suppressors that protect sensitive loads.

From a configuration perspective, there are several implications.

First, harmonic currents from multiple drives can interact with UPS rectifiers and generator voltage regulators. Plant Engineering and other sources describe how input reactors and harmonic filters reduce these effects by smoothing the current waveform that the upstream system sees. A course should teach students to read basic harmonic distortion figures and understand, conceptually, why a facility with many drives may need system-level mitigation.

Second, starting behavior matters when loads are on a UPS or generator. While drives dramatically reduce inrush compared with across-the-line starters, aggressive acceleration ramps or high-speed commands immediately after a power transfer can still tax upstream capacity. In a training environment, it is valuable to model how conservative ramp settings and staggered restarts after a power event protect not just the drive but the entire power system.

Third, integration with power monitoring and controls closes the loop. Drives that expose energy and status data allow facility teams to correlate events such as voltage sags, transfer switches operating, or UPS alarms with drive faults. A configuration course should encourage participants to think in terms of the entire power chain, not only the motor terminal.

By the end of a course built around these modules, participants should appreciate both the strengths and the trade-offs of deeper drive configuration.

On the positive side, advanced configuration unlocks the efficiency numbers highlighted in ABB energy-efficiency publications and articles from integrators: double-digit percentage reductions in energy consumption, better product quality from precise speed control, reduced wear thanks to soft starts and optimized torque, and improved visibility through integrated diagnostics and logging. In many industrial sites, getting centrifugal pumps and fans under good drive control is one of the fastest ways to reduce both utility bills and mechanical failures.

On the downside, drives introduce harmonics, EMC challenges, and thermal management issues that simple starters never did. They require installers and maintainers who can read manuals, understand parameters such as FLA and vector-control tuning, and think beyond ŌĆ£it runs when I press start.ŌĆØ Misapplied auto-reset, incorrect control-mode choices, or ignoring long cable runs can all lead to subtle and expensive failures.

A well-designed ABB drive configuration course embraces these pros and cons honestly. It does not pretend that drives are plug-and-play in every setting, but shows how a methodical selection, installation, and programming approach turns potential liabilities into controlled, well-understood aspects of the power system.

In industrial and commercial environments where UPS-backed systems and mission-critical processes dominate, this type of course is particularly valuable for plant electricians, facility engineers, controls technicians, and reliability engineers. Electrical contractors who increasingly find ABB drives specified on commercial HVAC, water, and process projects also benefit, as do power-system engineers who need to understand the practical behavior of the loads they are modeling.

I have seen the difference in plants where operators simply acknowledge drive faults and call vendors versus plants where in-house staff understand how to interpret ABB diagnostics, trace issues back to harmonics, cooling, or configuration, and resolve them quickly. The latter group consistently reports fewer unplanned outages, more predictable power-system behavior, and better alignment with their energy and sustainability targets.

Engineering articles from ABB and independent experts report typical savings on the order of 20ŌĆō50% when fixed-speed pumps and fans are converted to properly configured drives, with some variable-torque applications achieving even higher savings when speeds are aggressively trimmed. Actual results depend on the load profile and how well the drive is sized, installed, and programmed.

No. For many fan and pump applications, simple V/f control with correct motor data and ramp settings delivers excellent performance and savings with minimal complexity. Vector or closed-loop control is most valuable where speed precision, low-speed torque, or tight torque regulation are critical, such as in extruders, high-speed spindles, and tension-controlled processes.

Participants should already be comfortable with basic three-phase power concepts, motor nameplate data, and safe work practices around energized equipment. Familiarity with reading wiring diagrams and using a meter is important. Detailed programming experience is not required; the course itself should build that capability step by step using live ABB hardware.

A well-structured ABB Drive Configuration Course turns the drive from a black box into a trusted tool in your power-system reliability strategy. When your team understands how to select, install, and program ABB drives with the same rigor you apply to UPS systems and power protection gear, you move from reacting to faults to engineering a power system that runs efficiently, predictably, and for the long haul.

Leave Your Comment