-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

When you design or upgrade industrial and commercial power supply systems, Yokogawa hardware is often in the middle of everything: it supervises UPS systems, controls inverters, and protects critical feeders that cannot go down. In that environment, spare parts lead time is not a purchasing detail. It is a design parameter that shapes your entire project schedule and your risk profile once the plant is running.

In practice, most schedule slips and painful startŌĆæup delays I see in UPS and power protection projects do not come from sophisticated engineering challenges. They come from simple shortages of OEM modules, communication cards, or power supply boards that nobody ordered early enough. Several reliability and maintenance sources underline the same pattern: weak spare parts management drives severe downtime, wasted labor, and emergency spending. One guide on spare parts management notes that poor practices can contribute to losses on the order of $300 million in a single year when downtime and inefficiencies compound across a large operation. Another study cited by a critical spares provider found that 78% of manufacturers experienced shutdowns specifically because they did not have the right spare parts available.

For Yokogawa-based projects that also include UPS, static transfer switches, and inverters, you cannot afford to be in that majority. The good news is that lead time is manageable if you treat it as a planning input from the beginning instead of an unpleasant surprise at the end. This article walks through what lead time really means for Yokogawa spare parts, why it behaves the way it does, and how to use it deliberately in project planning and long-term reliability strategies.

People often talk about lead time as a single number, but for OEM hardware it is actually a chain of intervals. Practically, your Yokogawa spare part lead time is the total elapsed time between approving a purchase and having a tested, tagged part ready to install in your UPS room or control cabinet.

There is almost always an external component and an internal component. The external portion is what many articles on manufacturing and warehousing call supply chain lead time: the interval from when your order hits the supplierŌĆÖs system to the moment the part arrives at your dock. For an OEM module, this can include manufacturing or configuration, quality checks, packing, and transportation. Work focused on reducing lead time in warehouses points out that shipping alone can stretch from a few days with local suppliers to 30ŌĆō40 days when goods move overseas by ocean, even before you consider customs or export controls.

The internal portion is everything that happens inside your organization. Even after the truck arrives, parts must be received, inspected, registered in your inventory or CMMS, sometimes preŌĆæconfigured or tested, and placed in the correct storeroom. On the front end, internal approvals, budget releases, and supplier onboarding can add days or weeks before the purchase order goes out. Maintenance authors who study spare parts performance consistently emphasize that these internal steps are often more variable than the external ones, especially when processes are still paperŌĆæbased.

For project planning around Yokogawa hardware and power systems, you should therefore think about three related concepts. First, supplier lead time, which is usually what appears on quotations. Second, internal processing time, which you can estimate from your own procurement and warehouse history. Third, requiredŌĆæby date at site, which is driven by your construction, commissioning, or outage schedule. The difference between that requiredŌĆæby date and the sum of supplier and internal times is your real latestŌĆæorder date. If that difference is negative, you are already late.

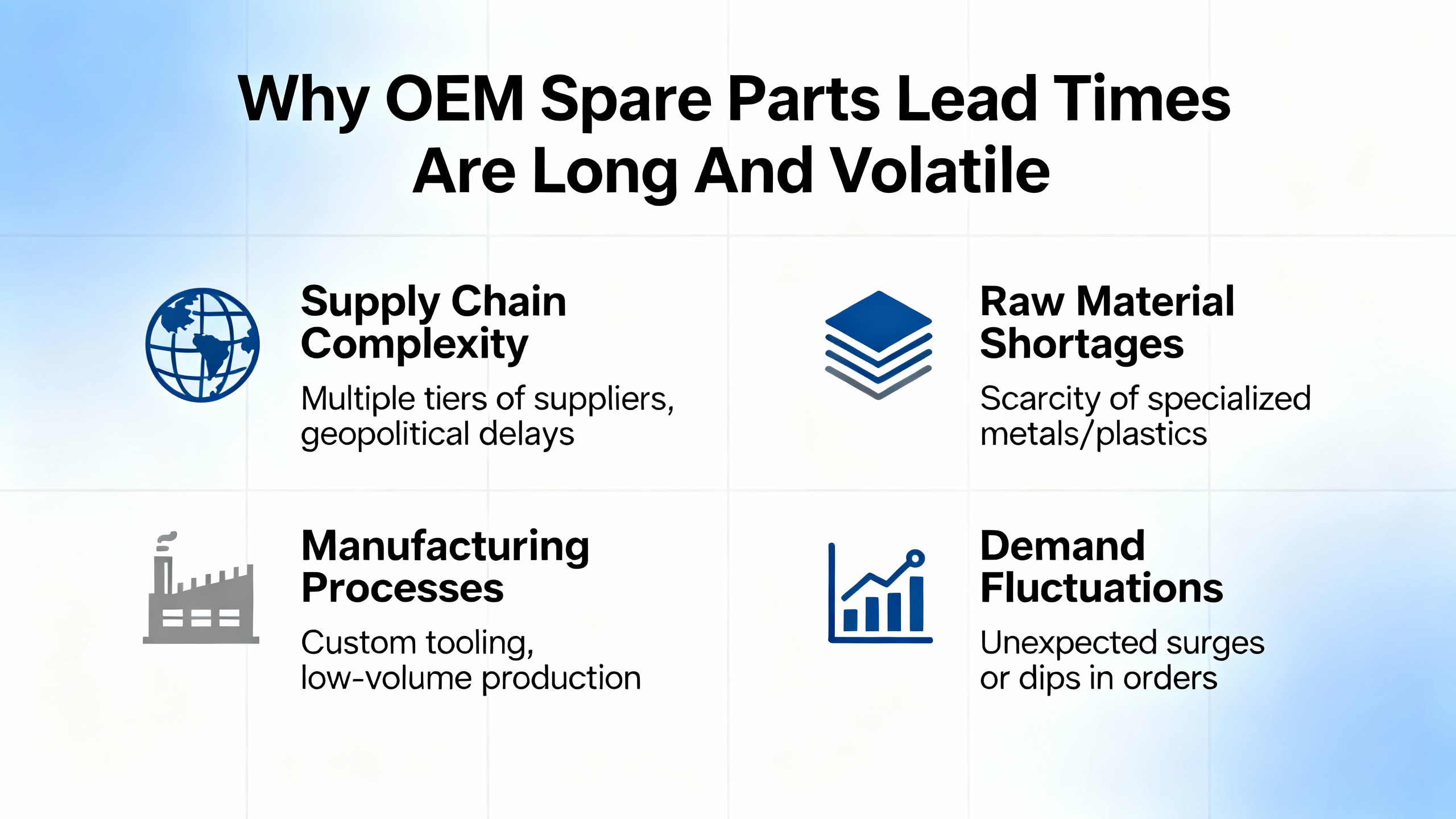

Lead times for Yokogawa spare parts behave much like other industrial MRO items: they are often longer and more volatile than standard production materials. Several recurring structural reasons show up across reliability, inventory, and supply chain literature.

Spare parts demand is notoriously intermittent. Multiple inventory optimization and forecasting experts note that service parts demand tends to sit at zero for long stretches and then spike when a failure occurs or a fleet of similar assets reaches a certain age. Traditional forecasting tools designed for regular, finishedŌĆægoods demand are poor at handling this pattern.

To cope with this, many OEMs and distributors do not manufacture every Yokogawa card, module, or accessory in large batches. Instead, they produce in smaller runs, or even on demand, using specialized facilities. Advanced planning case studies from the service parts world show that organizations often carry hundreds of thousands of SKUs with highly erratic demand. Without probabilistic forecasting and modern analytics, the safest option for a manufacturer is to take a conservative stance and stretch standard lead times so they rarely commit to dates they cannot meet.

The result is simple: the more specialized the Yokogawa spare, and the less frequently it moves, the more likely you are to see long or unpredictable lead times.

Lead time is also governed by plain physics and geography. Work on lead time reduction in manufacturing and warehousing stresses that supplier location and transportation mode have a firstŌĆæorder impact. Local or regional suppliers can often ship within days, while overseas shipments add weeks just in transit, plus customs clearance and port delays.

Yokogawa, like most major automation vendors, serves global markets. Parts may move through regional hubs before reaching you, and some may only be built or stocked in specific regions. At the same time, articles on spare parts planning highlight that spare parts networks often span multiple warehouses, distribution centers, and storage rooms, with internal transfers adding another layer of logistics complexity. Whenever a Yokogawa spare must move through several nodes in this network, each handoff adds a little uncertainty and a little time.

Many Yokogawa spare parts are not simple offŌĆætheŌĆæshelf commodities. Control modules, communication interfaces, or power supply units may require factory configuration, firmware loading, or integration with specific system versions. Best practice guides for spare parts emphasize the role of accurate bills of materials and configuration data precisely because any mismatch between the ordered part and the installed system causes rework and delay.

From the OEM perspective, that configuration and validation work is nonŌĆænegotiable. It protects their brand and your plant by reducing the risk of installing incompatible hardware. From your perspective, it lengthens the clock. In lead time terms, every step that is engineeredŌĆætoŌĆæorder rather than purely stockedŌĆæfromŌĆæshelf tends to push you out of the ŌĆ£daysŌĆØ range and into ŌĆ£weeks or months.ŌĆØ

Finally, a surprising amount of lead time pain originates inside the plant, not at the vendor. Several sources on spare parts management point out the recurring problems of incomplete catalogs, duplicate part numbers, and manual spreadsheets. When the plant team does not know exactly which part is installed, or procurement has to clean up descriptions before issuing a purchase order, the calendar keeps moving while the system is down.

Benchmarking work on spare parts procurement shows that topŌĆæperforming organizations put heavy emphasis on data quality, standardized part numbering, and digital workflows. They also highlight the use of integrated inventory management and procurement platforms that remove the need to export everything into spreadsheets. In my own experience with UPS and power protection projects, the difference between a clean Yokogawa part master and a messy one can easily be several weeks of elapsed time across the life of a project, purely from rework and clarifications.

Once you accept that Yokogawa spare parts lead time is structural, the question becomes how to turn it into a planning tool rather than a hazard. Several recurring practices from maintenance, supply chain, and reliability engineering can be adapted directly to YokogawaŌĆæheavy UPS and inverter projects.

The first step is to build a proper spare parts baseline early. Maintenance and reliability authors repeatedly stress the importance of a complete, accurate bill of materials. That means working with Yokogawa and your UPS vendors during design to identify every active module, I/O card, power supply, and network component that could reasonably require a spare during commissioning and the first years of operation. You then tie those parts to specific equipment, drawing on the same discipline advocated for bills of materials and standardized work orders in spare parts literature.

Next, you classify each part by criticality and lead time. Multiple guides recommend combining valueŌĆæbased methods such as ABC analysis with riskŌĆæbased criticality scoring. HighŌĆævalue, highŌĆæimpact parts sit in the A category, moderateŌĆæimpact items in B, and lowŌĆæimpact consumables in C. Overlaying lead time onto this classification is powerful: a lowŌĆæcost but longŌĆælead communication module that can halt a UPS switchover belongs in your highest attention band even if it is inexpensive. Sources focused on critical spares management encourage exactly this type of riskŌĆæbased thinking, where failure impact and lead time trump simple price.

Once you know what each part is and how important it is, you ask Yokogawa or their authorized channel for realistic lead times. In practice, it is wise to request both typical and worstŌĆæcase values and to watch how they change over time. Articles on lead time management and benchmarking suggest treating supplier performance as something you measure and review, not something you accept at face value forever. In large programs, it is common to go further and include lead time expectations in contracts and service agreements.

At that stage, you can embed lead time into your project schedule. For every commissioning, cutover, or outage milestone that depends on Yokogawa or UPS hardware, work backwards using the external lead time plus your internal handling buffer. The resulting dates are not niceŌĆætoŌĆæhave placeholders; they are the latest safe order dates. As spare parts management guides explain when they discuss reorder point formulas, the goal is to place orders far enough ahead that you are unlikely to run out even when usage and supply fluctuate. For project work rather than ongoing operations, the same logic applies, but the trigger is a planned activity instead of a stock threshold.

One way to make this tangible is to group parts into leadŌĆætime bands and predefine how you will treat each band. The exact numbers will depend on your risk appetite and supplier mix, but the pattern is consistent.

| LeadŌĆætime band | What it usually implies | Typical planning response |

|---|---|---|

| Days to about two weeks | Stocked in regional warehouses or available from local partners | Order as lateŌĆæstage items but still ahead of site need; rely on standard procurement with modest buffer |

| Roughly three to eight weeks | Built or configured against demand, often shipped regionally | Tie purchase orders directly to key milestones; track closely in your project reviews |

| Roughly nine to twentyŌĆæsix weeks | Specialist modules or constrained items with intermittent demand | Treat as longŌĆælead items; place orders early in design, often before all details are frozen |

| Longer than about six months | Obsolescence, singleŌĆæsource components, or heavily engineered spares | Consider safety stock at site or at a partner, contractual commitments, or design alternatives |

This kind of categorization echoes what advanced service parts planners do when they combine demand patterns, criticality, and lead time to set stocking policies. Case studies in that field show that when organizations move from gut feel to dataŌĆædriven planning, they can reduce inventory by significant percentages while still raising service levels into the high nineties. The same principles apply when you are deciding how aggressively to buy and stock Yokogawa hardware for a major UPS project.

In a plant or data center where Yokogawa systems supervise and protect power, the consequences of a missing spare are different from missing a general instrumentation part. You are not only protecting process variables; you are defending power continuity for critical loads, from control rooms to servers to safety systems.

During commissioning, Yokogawa I/O modules, communication interfaces, and power supply units that sit in the control architecture for UPS, switchgear, and inverters are commissioningŌĆæcritical. If an I/O card used for breaker status or a network module linking the UPS controller to the DCS fails and you do not have a spare on hand, you do not simply delay a test. You stall the entire energization sequence until the part arrives. In that context, a quoted lead time of several weeks effectively becomes a minimum delay to mechanical completion.

In normal operation, certain power electronics spares serve a similar role on the UPS side. Fans, capacitor kits, and contactor assemblies have finite service lives and are often replaced on a scheduled basis. Articles on preventive maintenance and spare parts lifecycle management recommend proactive replacement to avoid emergency outages, which only works if you align lead time with maintenance scheduling. If a knownŌĆælife component has a replacement interval of several years and a replenishment lead time of a few months, your project plan should include early procurement for the first replacement cycle, not a hope that the part will be readily available years later.

There is also the interaction between protection schemes and control hardware. When a UPS feeds critical switchboards under Yokogawa supervision, trip logic and interlocks are often implemented partly in control systems and partly in protective relays. Losing a key controller module without a spare can force you to operate with reduced visibility or protection, which many operatorsŌĆörightlyŌĆörefuse to do. This is where the distinction between capitalŌĆæproject procurement and reliabilityŌĆædriven stocking blurs, and where lead time must inform both.

Managing lead time is not only about buying earlier. It is about choosing the right combination of stocking, sourcing, and digital practices so that your risk and cost curve matches your operational priorities.

Several bestŌĆæpractice guides on spare parts management propose combining ABC analysis with criticality and lead time assessment. You can apply the same idea directly to Yokogawa spare parts. Start by identifying which modules and cards, if unavailable, could halt UPS operation, prevent safe shutdown, or block commissioning. These inherit high criticality even if they are inexpensive. Then examine their lead times. A highŌĆæcriticality, longŌĆælead module belongs in a category where you either stock at least one spare on site or negotiate robust stocking commitments with your supplier.

Less critical Yokogawa spares with short lead times might instead be planned as ŌĆ£order on detectionŌĆØ items, where you accept some risk of short delays in exchange for lower inventory investment. Spare parts sources that discuss riskŌĆæbased approaches emphasize exactly this tradeoff: you reserve heavy stocking for highŌĆæimpact, longŌĆælead parts and manage the rest more flexibly.

Different stocking and sourcing models have distinct advantages and drawbacks for Yokogawa spares.

Holding spares on site gives you maximum control and minimal response time. ReliabilityŌĆæfocused articles highlight that relatively modest investments in spare parts can prevent very large losses from unplanned downtime. The downside is carrying cost and the risk of obsolescence or degradation if parts are not stored and maintained correctly. Other spare parts guidance stresses the need for proper preservation, controlled access, and regular review to remove obsolete items.

VendorŌĆæmanaged inventory and supplierŌĆæheld stock shift some of that burden to your Yokogawa representative or integrator. Authors who describe vendorŌĆæmanaged inventory note that it can dramatically reduce administrative effort and onŌĆæsite holding cost, but it depends on trust and clear performance expectations. You need transparency into what is actually stocked, how quickly it can be dispatched, and how priorities are set when multiple customers are competing for the same parts.

Lean or justŌĆæinŌĆætime approaches are sometimes promoted for spare parts in general, especially for less critical items. Several sources warn, however, that relying on minimal onŌĆæhand inventory is dangerous for critical and longŌĆælead spares, particularly under supply chain disruption. For Yokogawa modules that underpin power system reliability, it is usually better to reserve lean tactics for noncritical items, while treating key control and power modules as strategic inventory rather than expendable cost.

Some organizations also incorporate repair and refurbishment into their strategy. Reliability case studies describe how sending certain components to specialist repair houses can reduce lead time dramatically compared with waiting for new OEM parts, especially when original components move into late life or obsolescence. The tradeoff is that qualifying repair sources and ensuring quality adds its own work and risk.

Digital maintenance and inventory platforms are repeatedly highlighted as highŌĆæleverage tools in spare parts management. Maintenance articles from ALLSERV and others explain how a computerized maintenance management system ties inventory to work orders and maintenance schedules. When a technician logs a repair, the system can automatically check spare parts inventory, update stock levels, and trigger reorders. For Yokogawa systems coupled with UPS and power equipment, having that integration means you see emerging demand for spares months before a project outage or replacement campaign.

Asset management platforms described by providers such as TRACTIAN extend this idea by combining realŌĆætime asset monitoring, inventory tracking, and automated reorder triggers. They provide visibility into what Yokogawa spares you actually have, where they sit, and how often they are used. When these platforms are fed with accurate lead time and usage data, they can suggest reorder points and safety stock levels that explicitly account for long lead times.

On the planning side, advanced service parts optimization tools use probabilistic forecasting and machine learning to handle the intermittent demand that characterizes OEM spares. Case studies show reductions in inventory on the order of 8% to over 25% while maintaining or even increasing service levels to above 98%. While these figures come from broader spare parts environments, the underlying principle holds for Yokogawa hardware: accurate models of demand and lead time let you position fewer parts more intelligently without increasing the risk of stockouts.

There is also a growing role for parts intelligence and visual identification tools. Authors in that field explain how AIŌĆæbased platforms can normalize messy part data and help technicians quickly identify the right component across multiple catalogs. For Yokogawa projects, that reduces the internal lead time associated with misidentification and rework.

Finally, do not treat Yokogawa spare parts lead time as a black box. Benchmarking work in maintenance procurement emphasizes the value of comparing your practices and performance to top performers, particularly when it comes to supplier reliability and inventory processes. Organizations that consistently achieve strong uptime tend to cultivate strategic relationships with a smaller number of reliable suppliers, share demand forecasts, and monitor performance metrics over time.

Practical recommendations from logistics and peakŌĆæseason readiness articles echo this. They encourage operations teams to obtain OEMŌĆærecommended spare parts lists early, reconcile them with actual inventory, and then request updated quotes that include current lead times and availability. In power projects, I recommend doing that as part of frontŌĆæend engineering rather than waiting for detailed design. It lets you pull genuinely longŌĆælead Yokogawa items into the earliest procurement waves and gives suppliers time to prepare.

Putting all of this together, there is a repeatable way to deal with Yokogawa spare parts lead time in power supply projects.

Start during conceptual or early frontŌĆæend design by asking two questions: which parts of this project depend on Yokogawa hardware, and what happens to power system reliability if those parts are late or fail without a spare? Use that to identify your commissioningŌĆæcritical and operationŌĆæcritical items. Then work with Yokogawa and your UPS and inverter OEMs to assemble bills of materials and recommended spare lists, ensuring that each part is clearly specified and tied to a location and function.

Once you have that list, classify parts by criticality and ask for realistic lead times, including both typical and worstŌĆæcase values. Map those lead times onto your project schedule so that procureŌĆæby dates appear alongside engineering, construction, and outage activities. Where lead times extend beyond what your schedule can tolerate, consider mitigating measures such as ordering extra spares up front, adjusting the sequence of work, or changing design choices to standardize on parts with better availability.

Finally, make sure the knowledge is not trapped in the project team. Load the Yokogawa spare parts data, lead times, and stocking decisions into your CMMS or asset management platform, and ensure that maintenance, operations, and procurement all have access. Schedule regular reviewsŌĆöespecially after major supply chain disruptions or vendor changesŌĆöto refresh lead time data. Several authors emphasize that spare parts environments are dynamic; what was a fourŌĆæweek item last year can quietly become a fourŌĆæmonth item if you do not pay attention.

Catalog or list lead times are a starting point, but they are rarely sufficient for projectŌĆæcritical decisions. Industry experience and multiple spare parts sources show that real lead times drift as demand patterns, production capacity, and logistics conditions change. For commissioningŌĆæcritical Yokogawa parts tied to UPS and power protection, it is safer to treat catalog figures as optimistic and to confirm current values through formal quotations or supplier communication, especially before major outages or retrofit windows.

There is no universal number, but the guiding principle from critical spares management is to cover at least one full cycle of expected consumption or risk exposure. For longŌĆælead, highŌĆæimpact parts, some practitioners recommend holding safety stock that covers a year or more of projected demand. For projects, that translates into placing orders as soon as the parts are technically defined and funding is available, often during early design rather than waiting for construction. The longer and more volatile the lead time, the earlier you should commit.

Very few organizations can, or should, buy every recommended spare on day one. This is where classification and riskŌĆæbased planning matter. Focus first on Yokogawa spares that have both high criticality and long lead times, because these pose the greatest threat to UPS and power system reliability. For less critical, shortŌĆælead items, consider relying on supplier stock, vendorŌĆæmanaged arrangements, or leaner policies. Several inventory and finance case studies show that using probabilistic planning tools and good data lets you reduce overall inventory while still protecting service levels, rather than simply cutting across the board.

Yokogawa spare parts lead time is not a nuisance parameter to be left to procurement at the end of a project. It is a core design constraint for any UPS, inverter, or power protection system that depends on OEM hardware to keep critical loads energized. When you treat lead time as data, link it to risk and criticality, and embed it in both your project plan and your maintenance strategy, you move from hoping parts will be there to knowing how you will keep your system running. That shift is at the heart of power system reliability, and it is one of the most costŌĆæeffective upgrades you can make to your next YokogawaŌĆæbased project.

Leave Your Comment