-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

In highŌĆæhazard industries, safety and power reliability have always been tightly coupled. A safety instrumented system that trips on demand but loses power at the wrong moment does not really protect anyone, and a highly available power system that feeds a compromised safety controller can quietly amplify risk instead of containing it.

Over the past century, industrial safety performance has improved dramatically. Schneider Electric cites historical accident rates of roughly 329 deaths per 100,000 workers, notably in mining, compared with about 3.7 per 100,000 today. That improvement is driven by regulations, engineered safeguards, and modern safety instrumented systems, yet the only acceptable longŌĆæterm target remains zero accidents.

Against this backdrop, Triconex safety systems have become a reference point for safety instrumented systems in refineries, petrochemicals, power generation, and other critical facilities. When you work through a Triconex safety system distributor, you are not simply buying a controller; you are selecting a stack of certified SIL components, lifecycle services, and cybersecurity practices that will either strengthen or weaken your plantŌĆÖs last line of defense.

As a power system specialist, I view the Triconex discussion through two lenses at the same time. The first is functional safety: can the system reduce risk to an acceptable level when a hazardous event threatens people, equipment, or the environment. The second is power and availability: can the safety system stay energized, deterministic, and trustworthy, even while the rest of the plant rides through faults, UPS transfers, and network disturbances. Certified SIL components and the right distributor partnership sit at the intersection of those two lenses.

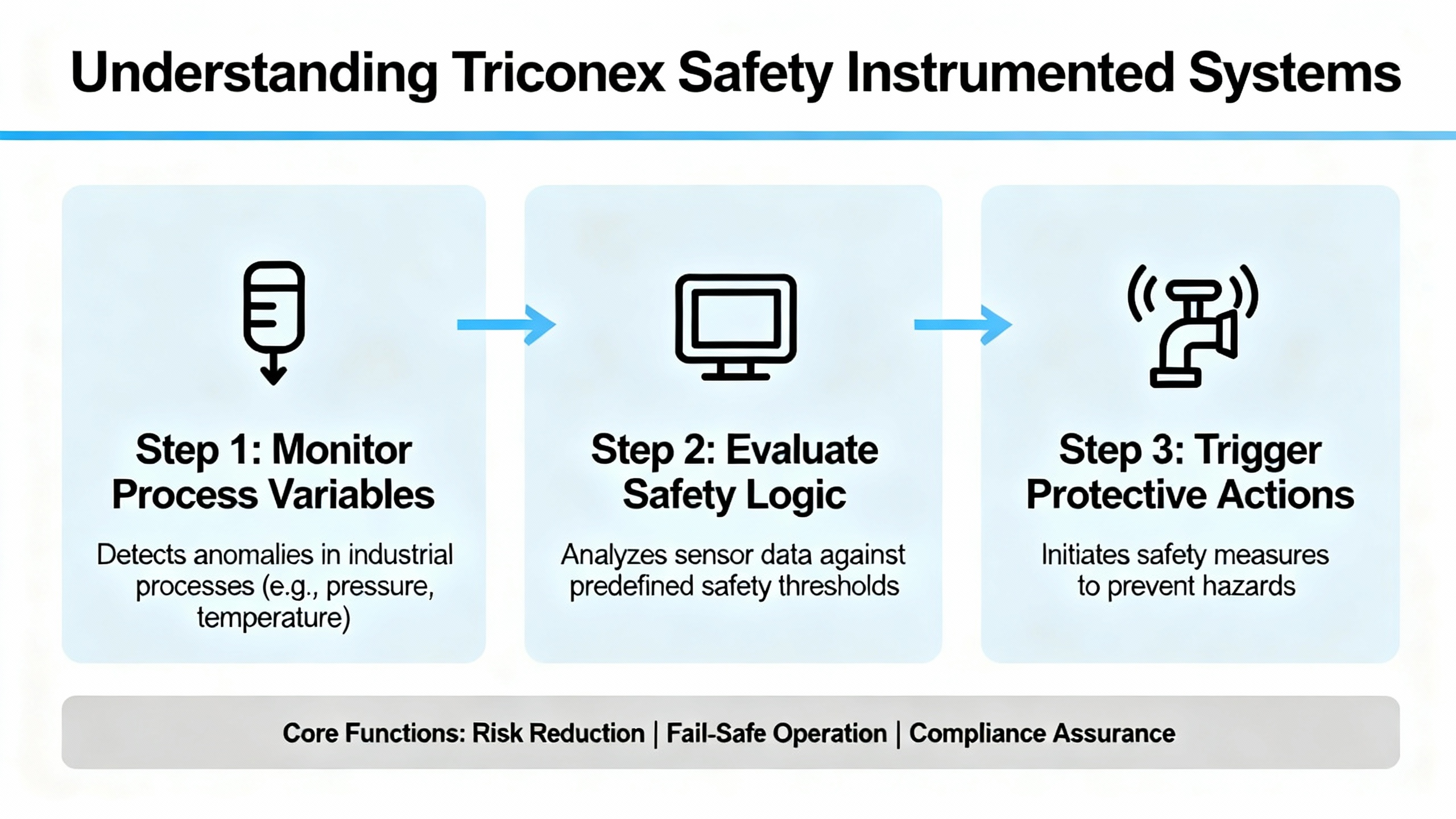

A safety instrumented system, or SIS, is not there to run the process. According to Schneider Electric, a SIS is an independent, last line of defense that detects outŌĆæofŌĆæcontrol conditions and automatically brings the process to a safe state. That distinction matters in plants where power systems, drives, and UPSŌĆæbacked controls are increasingly interconnected through digital networks.

At the core of any SIS is at least one safety loop known as a safety instrumented function, or SIF. Each SIF has three building blocks. Sensors detect hazardous conditions such as high pressure, high temperature, or gas release. Logic solvers, often implemented using safety PLCs, decide whether the conditions have crossed a threshold that demands action. Final elements, such as actuated valves, contactors, or breakers, physically move the process into a safe state by shutting off fuel, venting pressure, or isolating energized equipment.

In real plants, these safety loops protect emergency shutdown systems, fire and gas detection, burner management, turbomachinery control and protection, and highŌĆæintegrity pressure protection. EcoStruxure Triconex Safety and Critical Control systems, built on triple modular redundancy, are used in exactly these duties and have accumulated more than one billion safe operating hours without a known dangerous failure on demand. That operating history is one reason so many operators are hesitant to touch legacy Triconex installations: they appear almost too reliable to justify modernization.

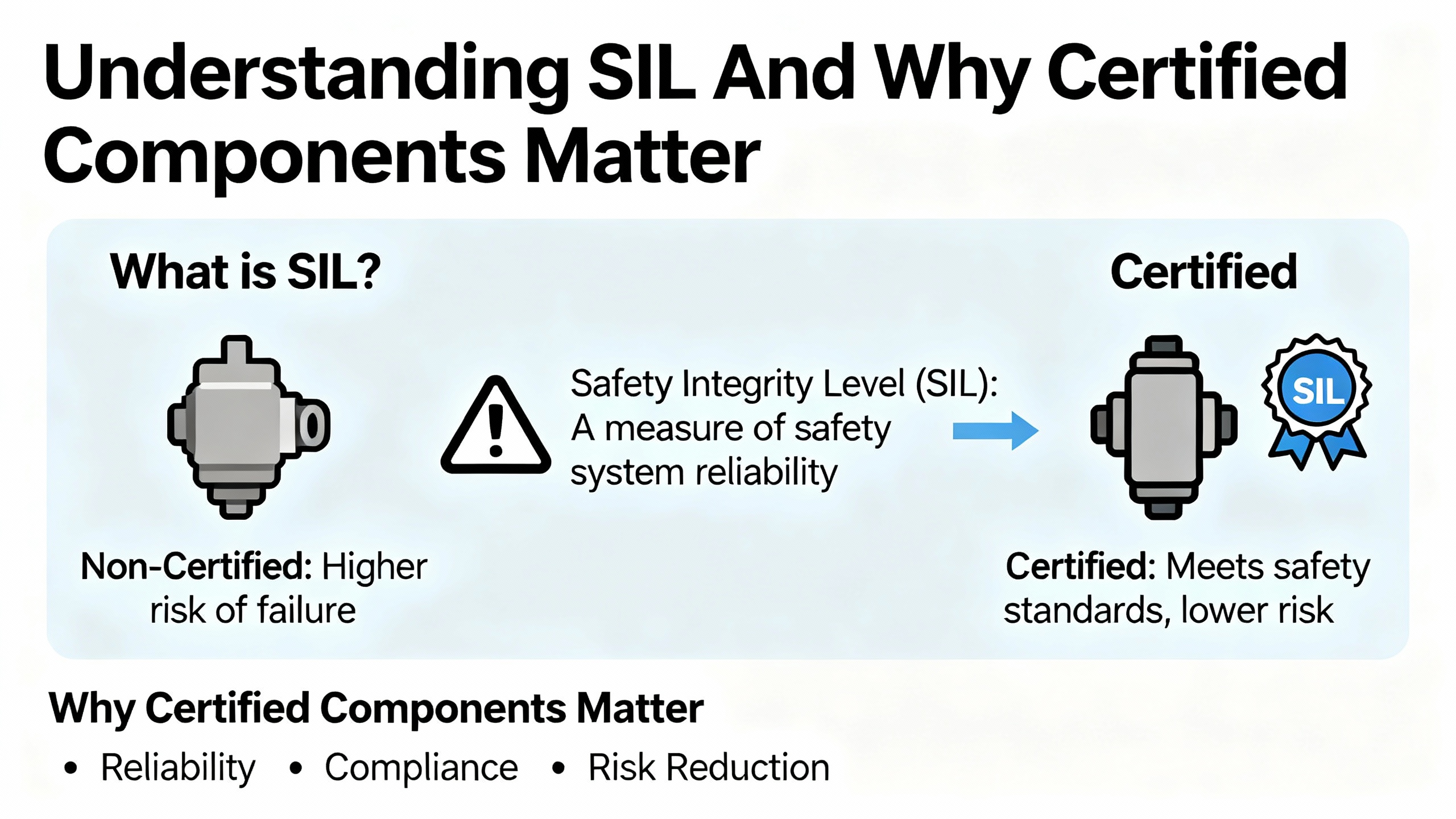

Safety Integrity Level, or SIL, is the quantitative language that connects risk assessment and technical design. Under IEC 61508, SIL levels from SIL 1 to SIL 4 define tolerable failure rates and the required probability of failure on demand for a given safety function. SIL 1 provides the least risk reduction, and SIL 4 provides the highest, usually reserved for extremely hazardous applications.

EcoStruxure Triconex safety PLCs and the unified Tricon CX platform are T├£VŌĆæcertified to SIL 3. That single certification allows you to implement SIL 1, SIL 2, and SIL 3 functions with the same family of components, as long as your overall design, proof testing, and lifecycle management follow the standard. The certification is not a marketing label; it is the outcome of rigorous thirdŌĆæparty testing and ongoing assessment of hardware, software, diagnostics, and failure behavior.

When you purchase through a Triconex distributor, you are effectively sourcing a set of SILŌĆæcapable building blocks: safety controllers, I/O modules, communications modules, and engineering tools. Their certification does not automatically make your plant SIL 3, but it means the components can support that performance if you engineer and maintain them correctly. In practice, that means the distributor must be able to support you in applying IEC 61508 and IEC 61511 requirements from concept through decommissioning, not just ship boxes.

One of the most common misunderstandings I see in power and process projects is the assumption that any PLC can be configured to ŌĆ£act likeŌĆØ a safety system. Schneider ElectricŌĆÖs functional safety guidance is explicit that this is not true.

A standard PLC is designed to automate processes. It may reveal a problem only when a hazardous condition demands action, and it is not inherently safetyŌĆærated. Its internal diagnostics and failure modes are not engineered or proven to meet a defined probability of failure on demand.

A safety PLC, by contrast, is designed from the ground up for safety duties. It is normally energized and fails to a safe state. It uses internal diagnostics, automatic testing, and voting of independent signals, and it implements redundancy specifically to achieve high availability when demanded.

The difference is easier to see in a simple comparison.

| Aspect | Standard PLC | Safety PLC (e.g., EcoStruxure Triconex) |

|---|---|---|

| Design intent | Process automation | Functional safety and risk reduction |

| Safety rating | Not inherently safetyŌĆærated | T├£VŌĆæcertified for use up to SIL 3 under IEC 61508 |

| Failure behavior | Not guaranteed to fail safe | Normally energized, designed to fail to a safe state |

| Diagnostics and testing | Basic, focused on availability | Extensive diagnostics, automatic testing, and defined failure modes |

| Redundancy and voting | Optional, for uptime | Integrated triple modular redundancy with voting of independent paths |

Triconex safety systems extend this safety PLC philosophy with a triple modular redundant architecture across the main processors, I/O modules, and communications. Three parallel channels compute the same logic, and a voter determines the output. If one channel fails or disagrees, the system can continue safely on the remaining healthy channels. That is a powerful attribute when you rely on these systems to protect gasŌĆæinsulated switchgear, turbineŌĆædriven generators, or UPSŌĆæsupported critical loads where nuisance trips have real cost but failure to trip is unacceptable.

Certified SIL components are only as effective as the engineering and lifecycle practices around them. Schneider Electric emphasizes that all EcoStruxure Triconex SIS solutions are designed and managed according to IEC 61508 across the entire lifecycle, from concept through operation and decommissioning. In practice, much of that lifecycle is executed through integrators and distributors.

A capable Triconex safety system distributor should be able to do more than provide quotations. They should understand how safety instrumented functions are derived from hazard studies and layers of protection analysis. The Layers of Protection model frequently used in process safety illustrates that the SIS is only one of several independent barriers, alongside basic process control, alarms and operator intervention, mechanical relief devices, containment, and emergency response. The distributorŌĆÖs role is to ensure that the SIS layer they help you implement is engineered at the right SIL, with the right diagnostics, proofŌĆætest intervals, and bypass controls, so it genuinely complements these other barriers.

Schneider ElectricŌĆÖs own SIS modernization guidance highlights how organizational dynamics can undermine that goal. Many SIS platforms installed in the late 1980s and early 1990s, including early generations of Triconex, still operate reliably today. That reliability makes it harder to justify upgrades and often leads to complacency, especially when corporate engineering teams are stretched thin across multiple legacy systems. Project proposals that position modernization as simple ŌĆ£replacement in kindŌĆØ rarely get approved because they appear to deliver no incremental value.

A strong distributor helps you break that stalemate by framing SIS upgrades around business and safety outcomes. Instead of proposing a oneŌĆæforŌĆæone swap, they can help perform a frontŌĆæend loading study to clarify scope, cost, schedule, and risk; align stakeholders in operations, maintenance, safety, and corporate leadership; and position modernization as an enabler of digital transformation, improved uptime, and lower total cost of ownership. For Triconex, that often means moving toward platforms like EcoStruxure Tricon CX, which Schneider Electric presents as a futureŌĆæready SIS that unifies safety and critical control, scales up to roughly 750,000 I/O points, mixes copper and fiber networks for flexibility, and supports online firmware upgrades to minimize downtime.

From a power perspective, these modernization projects are the ideal moment to tidy up UPS architectures, segregate safety power from nonŌĆæessential loads, and verify that inverter transfers and generator start sequences do not inadvertently compromise SIS availability.

For years, SIS platforms enjoyed a special level of trust. They were often isolated, rarely changed, and assumed to be too obscure to attract attackers. The TRITON malware family, also called HatMan or TRISIS, destroyed that assumption.

In 2017, investigators uncovered TRITON at a petrochemical facility in the Middle East. According to CISA and independent researchers such as FireEye and Nozomi Networks, this was the first publicly known malware designed specifically to target safety instrumented systems, in this case Schneider Electric Triconex controllers. The attackers followed a multiŌĆæstage industrial control system kill chain, starting with a foothold in the corporate IT network, moving laterally into the operational technology network, compromising a WindowsŌĆæbased SIS engineering workstation, and then using SchneiderŌĆÖs proprietary TriStation protocol to communicate with the controllers.

Rather than exploiting only simple software bugs, the TRITON operators abused legitimate engineering functions. Research from Google CloudŌĆÖs threat intelligence team shows how extensive the TriStation command set is, covering downloads, configuration changes, program control, diagnostics, event logs, and time synchronization. TRITON implemented its own TriStation stack, giving the attackers the ability to read and write SIS memory, deploy malicious logic, and attempt to maintain covert persistence while making their activities resemble normal engineering work.

The specific incident was discovered when a flaw in the attackersŌĆÖ manipulation caused the Triconex controllers to enter a failŌĆæsafe mode and shut down the process. That shutdown, while disruptive, likely prevented a more dangerous outcome. Analysts from BlackHat, CISA, CyberArk, and Nozomi Networks have converged on a view that TRITON required detailed knowledge of Triconex hardware and firmware, deep reverseŌĆæengineering of TriStation, and substantial testing to avoid triggering safety trips during development. They assess with moderate to high confidence that a nationŌĆæstate actor was responsible, and that the ultimate intent extended beyond nuisance shutdowns toward the capability to cause physical damage or casualties.

For asset owners, TRITON changed the risk profile of SIS from ŌĆ£highly trusted backstopŌĆØ to ŌĆ£highŌĆævalue cyber target.ŌĆØ It also forced a hard question: what does certification and proven operating history mean in a world where an attacker can program your safety controller as if they were your own engineer.

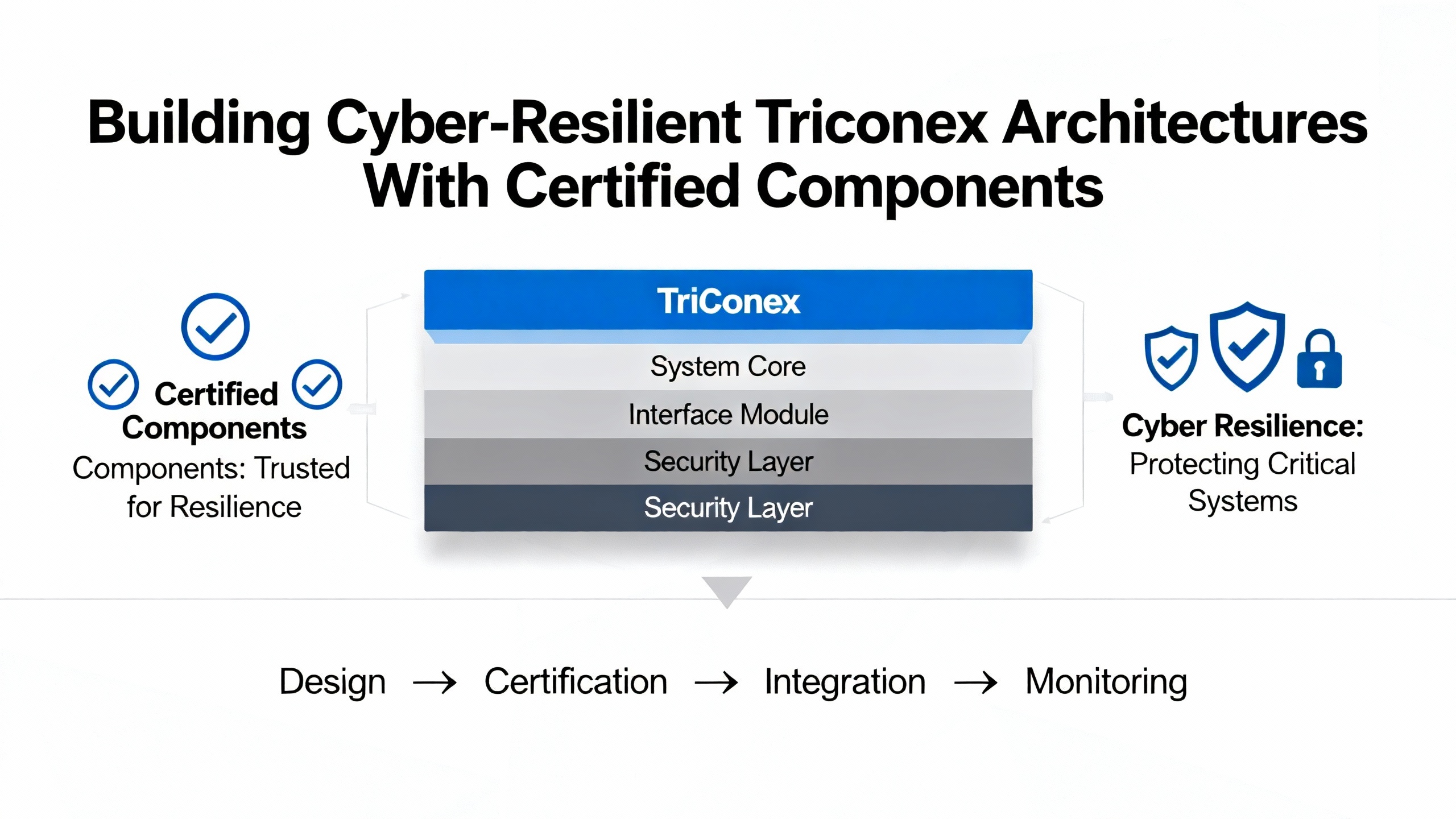

Schneider Electric explicitly recognizes that cybersecurity is now inseparable from functional safety. Their guidance for EcoStruxure Triconex emphasizes endŌĆætoŌĆæend cybersecurity aligned with ISA/IEC 62443 and IEC 61508, and they have published a practical guide focused on maximizing the cyber resilience of Triconex safety systems. IndustryŌĆæwide, the consensus recommendations from CISA, Nozomi Networks, and others fall into a few consistent themes that are highly relevant when you work with a Triconex distributor.

The first theme is strict network and functional isolation. Safety instrumented systems should be segregated from basic process control systems and from corporate IT networks using wellŌĆædefined zones and conduits. Remote access should be minimized or eliminated, and where monitoring data must leave the SIS zone, technologies such as unidirectional gateways should be considered. DualŌĆæhomed engineering workstations that bridge safety and nonŌĆæsafety networks are a recurring weakness exposed in the TRITON case.

The second theme is hardening engineering workstations and TriStation access. Both CISA and CyberArk stress the importance of restricting and logging remote access, enforcing least privilege on engineering accounts, and using application whitelisting on SIS workstations. Change management should ensure that any SIS programming session, especially those involving TriStation operations like downloads, configuration changes, or time adjustments, is traceable to an authorized engineer, reviewed, and documented. Offline, verified backups of Triconex logic and configurations should exist so you can compare live controller states against trusted references.

The third theme is continuous monitoring and anomaly detection. The detailed TriStation command map published by Google Cloud illustrates how specific command families, such as full or incremental downloads, retentive value changes, or calendar adjustments, can be monitored as highŌĆærisk activities. CISA and Nozomi Networks recommend baselining normal TriStation and SISŌĆærelated network traffic, capturing logs of program downloads and uploads, and using anomaly detection tools to flag unusual controller states or communication patterns that might indicate TRITONŌĆælike activity.

A capable Triconex distributor can help turn those highŌĆælevel recommendations into concrete solutions. That may include selecting certified communications modules that support segregated networks, helping design firewall rules and demilitarized zones around SIS networks, and integrating SIS event logs with plantŌĆæwide security monitoring. For plants where UPSŌĆæbacked networks span both safety and control domains, the distributor can help identify where additional segmentation or optical isolation is needed so that a cyber compromise on one side cannot automatically pivot into the SIS.

Many operators still run Triconex systems installed three or four decades ago. Schneider ElectricŌĆÖs modernization guidance acknowledges that these platforms often operate safely and reliably, which paradoxically makes it harder to argue for replacement. Typical objections include statements that everything is working, that there have been no SISŌĆæcaused outages, or that inŌĆæhouse expertise has retired and documentation is thin.

The modernization framework Schneider Electric outlines is riskŌĆæbased and businessŌĆæfocused rather than technologyŌĆædriven. It starts with determining how to fund the effort, often via a frontŌĆæend loading study rather than an immediate fullŌĆæproject budget request. It continues by involving stakeholders early, from operations and maintenance to safety and corporate leadership, to understand their needs and address objections. It then assesses factors such as system reliability, spare parts availability, physical access constraints, production schedules, standards compliance, cybersecurity posture, and support costs. Imbalances in those factors are signals that it may be time to upgrade.

Crucially, the justification for modernization is strongest when it moves beyond avoiding negative outcomes. Schneider Electric explicitly advises that upgrade proposals framed purely as preventing failures or environmental incidents are often rejected. Instead, modernization should be positioned as enabling reduced support costs, improved operating margins, and increased revenue through better performance, data, and integration with digital initiatives.

EcoStruxure Tricon CX, for example, is presented as a futureŌĆæready SIS platform with flexible and scalable architecture, the ability to unify safety and critical control, support for mixed copper and fiber media, and modular digital lifecycle tools that support design, testing, operation, and maintenance. Those capabilities align well with Industry 4.0 and the digitalŌĆænative workforce, offering more intuitive interfaces, automated processes, and better data for predictive maintenance and performance optimization.

From a power systems perspective, modernization is also the correct moment to rationalize how safety controllers and remote I/O are fed from UPS systems and inverters. Modern Triconex installations can scale to very large I/O counts and geographically dispersed nodes. Aligning that architecture with resilient, selectively coordinated power distribution and energyŌĆæstorage strategies ensures that an upstream disturbance does not defeat the very safety functions you are upgrading.

Translating all of this into project decisions can feel daunting, especially if you are responsible for both power reliability and safety performance. In practice, a few disciplined habits make a disproportionate difference when working with a Triconex safety system distributor.

One habit is to start with the safety lifecycle, not the catalog. Ask the distributor to walk through how their Triconex offering supports hazard analysis, SIF design, SIL verification, factory acceptance testing, proof testing, and decommissioning. Look for evidence that they understand IEC 61508 and IEC 61511 requirements and can support documentation and testing rather than merely selling hardware.

Another habit is to keep cybersecurity and power reliability on equal footing with functional safety. When you specify certified SIL components, include cybersecurity requirements aligned with ISA/IEC 62443 and resilience requirements for UPSŌĆæbacked power supplies, redundant feeds, and grounding. Make sure the distributor can explain how EcoStruxure Triconex cybersecurity guidance and Schneider ElectricŌĆÖs cyberŌĆæresilience recommendations are implemented in engineering workstations, TriStation configurations, and network topologies.

A third habit is to demand clarity on diagnostics and data. Modern SIS platforms, including Triconex, generate rich event logs, sequence of events data, and diagnostics about modules, chassis, and scan times. Work with the distributor to integrate this information with your existing asset management, condition monitoring, and security analytics tools. That integration enables dataŌĆæcentric strategies where AI and machine learning, as Schneider Electric suggests, can drive predictive maintenance and proactive safety interventions rather than waiting for failures.

Education is the final habit that ties the others together. Training courses focused on Triconex safety and critical control systems, such as those centered on TriStation 1131 programming and IEC 61131ŌĆæ3 languages, help engineers move beyond basic configuration toward robust, modular, and testable safety logic. Courses that emphasize alarm and event management, communications integration, and structured testing and validation are particularly valuable in plants where the same engineering teams are responsible for both safety and power controls.

T├£VŌĆæcertified SIL 3 capability under IEC 61508 means Triconex components can be used to implement safety functions requiring high risk reduction, as well as SIL 1 and SIL 2 functions. The certification reflects defined, tested failure modes, diagnostics, and lifecycle controls. It does not guarantee your application is SIL 3 by default, but it provides a qualified foundation if you design and maintain the system according to the standards.

Schneider Electric points out that longŌĆæserving SIS platforms often remain reliable, which can breed complacency. Modernization becomes important when spare parts, expertise, or documentation are scarce, when cyber threats like TRITON change your risk assumptions, or when integration with newer digital systems and power architectures is required. Framing modernization as a way to improve safety, uptime, and business performance, rather than just replacing old equipment, is usually more compelling.

TRITON demonstrated that SIS controllers are attractive targets, not offŌĆælimits. A distributor that understands CISAŌĆÖs and industry recommendations for network segmentation, engineeringŌĆæstation hardening, TriStation monitoring, and disciplined change management is essential. CyberŌĆæresilient design, including how SIS networks and UPSŌĆæbacked power systems are segmented and monitored, should be part of any serious Triconex proposal, not an afterthought.

In critical facilities, power quality and safety performance live or die together. When you select a Triconex safety system distributor focused on certified SIL components, lifecycle rigor, and cybersecurity, you put your plant on a more reliable footing, both electrically and operationally, for the next generation of digitalŌĆænative operators.

Leave Your Comment