-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Industrial and commercial power systems rarely fail because a transformer or UPS suddenly gives up. More often, the weakest link is the control layer coordinating switchgear, inverters, static transfer switches, and backup generators. For many facilities, that layer is built on Invensys technology that is now well into middle age.

Since Schneider Electric acquired Invensys for about $5.2 billion and integrated it into a broader portfolio, owners of Invensys-based systems have been asking a simple but difficult question: what is the smartest path forward for my control and power protection architecture?

As a power system specialist, I see this at data centers, process plants, and missionŌĆæcritical buildings that depend on clean, uninterruptible power. The goal of this guide is to translate market and vendor moves into concrete technical options you can act on, without drama or wishful thinking.

Before the acquisition, Invensys sat at the heart of many industrial operations. LNS Research noted that its software brands Wonderware, SimSci, and Avantis had an installed base in more than twoŌĆæthirds of the worldŌĆÖs plants and facilities, including most of the top global oil and gas, chemical, pharma, food and beverage, and mining firms. Invensys also supplied control and safety systems into highŌĆærisk assets such as oil platforms and nuclear power plants, according to Schneider ElectricŌĆÖs own commentary.

SchneiderŌĆÖs acquisition strategy was not just about buying another automation vendor. It was about combining InvensysŌĆÖs strength in industrial automation and software with SchneiderŌĆÖs strengths in power distribution, energy metering, and protection. In SchneiderŌĆÖs words, this is where ŌĆ£energy meets automationŌĆØ: the convergence of efficiencyŌĆæfocused power management with intelligent control and analytics.

Practically, that meant several things for Invensys users.

First, Schneider gained a huge footprint in electroŌĆæintensive industries where UPS systems, inverters, and protection relays are missionŌĆæcritical. That footprint is a platform for crossŌĆæselling energy management and power quality solutions on top of existing Wonderware or ArchestrA System Platform deployments.

Second, Schneider inherited overlapping portfolios. Wonderware HMI and SCADA, Vijeo Citect, and ClearSCADA occupied similar spaces; Wonderware MES and EMI overlapped with SchneiderŌĆÖs Ampla offerings. LNS Research highlighted portfolio rationalization as a key challenge and expected Schneider to bridge its StruxureWare architecture with InvensysŌĆÖs ArchestrA, preserving interfaces while moving toward a nextŌĆægeneration, objectŌĆæbased platform.

Third, the talent and job market around Invensys shifted. One laborŌĆæmarket snapshot showed that only about 0.1% of Control Engineer job ads explicitly mentioned Invensys. That does not mean your system is unsupported, but it does mean you cannot assume a deep bench of Invensys specialists will be available forever.

Bottom line: your Invensys system is not suddenly ŌĆ£dead,ŌĆØ but it sits in an ecosystem that is evolving quickly. That makes structured replacement and lifeŌĆæextension planning essential, especially where power reliability is nonŌĆænegotiable.

From a power perspective, aging control systems introduce three kinds of risk.

The first is technical obsolescence. The Consyst team, writing about Rockwell PLCŌĆæ5 and SLC 500 controllers, described challenges that every legacy platform eventually faces: shrinking availability of spare parts, declining vendor and thirdŌĆæparty support, and difficulty integrating with newer networks and smart devices. You see the same pattern with many Invensys-era controllers and HMIs. When a legacy controller fails and the only replacement is a used module from an online marketplace, your UPS and switchgear suddenly depend on components that nobody guarantees.

The second is functional mismatch with modern power demands. Schneider has emphasized that the convergence of energy management with automation is what enables ŌĆ£more output from less inputŌĆØ through analytics and smarter controls. That convergence is hard to realize if your control architecture cannot easily ingest detailed breaker, UPS, and metering data or if it runs on operating systems that nobody wants to expose to the network.

The third is human and organizational risk. HallamŌĆæICS, in their guidance on replacing obsolete control systems, notes that multiŌĆæyear upgrades are the norm and that keeping the plant running at each step is the hardest part. Operators are your first line of defense for power anomalies and transfer events. If your HMI is fragile, inconsistent, or split between old and new screens, you are raising the odds that an operator facing a voltage sag, UPS alarm, or static transfer will hesitate or act on the wrong display.

In my own work on brownfield UPS and switchgear upgrades, the most painful incidents almost always trace back to one of those three issues rather than a failed breaker or rectifier.

Before talking about replacement options, you need a clear map of what ŌĆ£the Invensys systemŌĆØ actually is in your facility. In practice it is not one product, but a stack of layers.

At the top, many sites use Wonderware for HMI and SCADA, sometimes with MES or enterprise manufacturing intelligence functions layered on top. LNS Research pointed out that Wonderware can scale to very large systems with more than one million I/O points, which is more than enough to cover power distribution, generator controls, UPS status, and building systems in a large campus.

At the operations level, some Invensys installations also use specialized applications such as the OffŌĆæsites Software solution described by Automation.com. Invensys updated that suite with batch tracking, advanced line management, and blend optimization, along with a tank information system that supports redundant level measurement and synchronized alarms. Although that example is drawn from refinery and terminal operations, the pattern is relevant to power: a DCSŌĆæindependent operations layer that complements rather than replaces the base control system.

At the control and asset level, Avantis provides asset performance management and mobile workforce capabilities, while SimSci adds process design, simulation, and advanced control. Schneider has suggested that linking SimSci tools with StruxureWare configuration could create an endŌĆætoŌĆæend engineering environment, including realŌĆætime energy optimization.

Mapping your stack in this way helps you decide what to preserve, what to modernize, and what to replace outright.

The first option is evolutionary rather than revolutionary: stay with SchneiderŌĆÖs combined portfolio and move along their preferred migration paths.

Analysts like LNS Research expect Schneider to maintain and extend key Invensys assetsŌĆöWonderware, SimSci, Avantis, and the ArchestrA System PlatformŌĆöwhile rationalizing overlaps with Vijeo Citect, ClearSCADA, and Ampla. Schneider itself talks about combining Wonderware industrial energy management software with its own energy metering hardware and smartŌĆægrid services to enhance industrial energy optimization.

For a powerŌĆæcritical facility, this approach typically involves a few patterns.

One pattern is a softwareŌĆæled upgrade where you move Wonderware or other Invensys software to supported operating systems, update runtimes and historians, and connect them to Schneider energy meters, power quality analyzers, and buildingŌĆæmanagement gateways. The underlying I/O and field wiring remain, but you get better visibility into UPS loading, breaker status, and energy intensity.

Another pattern is portfolio consolidation. If your site has a mix of Wonderware, Vijeo Citect, and perhaps niche SCADA packages, Schneider will encourage you to standardize. That makes life easier for operations and for cybersecurity teams, but it requires careful migration planning so that powerŌĆærelated screens and alarms remain consistent throughout.

The main advantage of staying in the Schneider/Invensys family is continuity. You keep vendor support, reuse many engineering objects, and benefit from SchneiderŌĆÖs long experience in both power distribution and automation. The main drawbacks are vendor lockŌĆæin and the possibility that some niche Invensys products will be phased out in favor of Schneider-preferred platforms over time. That is why LNS Research recommended that existing Schneider and Invensys users proactively evaluate future software needs and provide early feedback on desired strategic directions.

For a site whose power and protection systems are already deeply integrated with Schneider gear, this is often the lowestŌĆærisk pathŌĆöas long as you insist on a documented roadmap for every critical component, including how it will handle UPS, inverter, and genŌĆæset integrations over the next decade.

HallamŌĆæICS, in their series on replacing obsolete control systems, argues strongly for upgrading the SCADA or HMI front end before you start ripping out controllers. That advice is particularly sound for power systems.

The front end is the most visible window into plant operations. When voltages sag, a breaker trips, or a UPS enters bypass, operators do not stare at control panels; they look at the screens. HallamŌĆæICS describes two broad approaches.

In the first approach, you upgrade the front endŌĆöSCADA or HMIŌĆöso that it can talk to your existing obsolete system. Operators learn the new interface while the underlying PLCs or DCS remain unchanged. As you then upgrade each ŌĆ£chunkŌĆØ of the control system and add new controllers, the new logic simply replaces the signals and graphics behind screens that operators already know.

In the second approach, you upgrade hardware in chunks and attach those chunks to a new front end as you go. Operators then have to juggle new hardware, a new interface, and potentially two different HMIs at once. HallamŌĆæICS rightly describes this as unnecessarily annoying to operators and, by implication, risky.

To make the first approach work technically, you need protocols and gateways. HallamŌĆæICS mentions HMS AnyBus ŌĆ£black boxesŌĆØ that translate between protocols and network types, as well as OPC Servers that sit between legacy controllers and modern SCADA systems. Vendors like Matrikon provide specialized OPC Servers for many obscure legacy systems. These tools let you build a modern HMI on top of an old Invensys or thirdŌĆæparty controller landscape.

In power projects, I have seen HMIŌĆæfirst strategies pay off in very practical ways. You can standardize how operators acknowledge UPS alarms, view oneŌĆæline diagrams, and initiate transfers long before you touch the protective relay interfaces or automatic transfer switch logic. That reduces training risk and minimizes confusion during staged cutovers where half the switchgear lineup may be on old control hardware and the other half on new.

The tradeŌĆæoff is that you are temporarily adding complexity. Gateway boxes and OPC layers add points of failure, so they must be engineered and monitored carefully. However, as a temporary scaffold for a multiŌĆæyear upgrade, this approach aligns strongly with both reliability and humanŌĆæfactors best practice.

Many InvensysŌĆæcentric plants do not rely solely on Invensys controllers. It is common to find Wonderware HMIs sitting on top of Rockwell PLCŌĆæ5 or SLC 500 platforms, especially for discrete power functions like switchgear interlocks, generator start sequences, or UPS bypass logic.

Consyst highlights why this matters. PLCŌĆæ5 and SLC 500 controllers are now considered legacy. Hardware, software, and vendor support are being phased out. SpareŌĆæpart scarcity makes failures harder and slower to repair, increasing downtime. New engineers are trained on modern architectures, so troubleshooting expertise is declining. Compatibility issues with newer protocols and smart devices constrain integration and data exchange.

Consyst positions the ControlLogix platform as a modern successor with higher processing power, more memory, faster communications, and richer diagnostics, plus a more userŌĆæfriendly programming environment. They recommend migrating to ControlLogix to maintain efficiency, reliability, and competitiveness.

If your Invensys front end depends on these legacy PLCs for power functions, a staged migration to ControlLogix or an equivalent contemporary platform can be a key piece of the overall modernization plan. A typical pattern in power applications is to migrate one switchgear lineup or one generator pair at a time, while gateways or SCADA adjustments keep the HMI view consistent for operators.

The main advantage is that you decouple critical power logic from legacy hardware that is hard to support. The main constraints are reŌĆævalidation effort and cutover risk; protective schemes and transfer sequences must be retested thoroughly, especially in facilities like data centers and hospitals where power events cannot be rehearsed lightly.

Sometimes the right answer is a bigger step: migrating from an Invensys-centric control architecture to a different DCS platform, especially if your wider enterprise already standardizes on a vendor such as ABB.

ABBŌĆÖs portfolio of ŌĆ£extensions, upgrades, and retrofitsŌĆØ offers a useful reference point. Their case studies span mining, metals, cement, power generation, pulp and paper, chemicals, food and beverage, oil and gas, and printing. The common theme is modernization without full ripŌĆæandŌĆæreplace, often by evolving older ABB systems and thirdŌĆæparty DCSs to ABB Ability System 800xA or Symphony Plus.

ABB highlights several concrete outcomes. At the Alunorte alumina refinery in Brazil, automation modernization helped boost production capacity by about 75%. At a Hydro Aluminium facility in Norway, a complete power and automation solution improved productivity by around 15% and energy efficiency by about 25%. At Burrows Paper in the United States, a quality control system upgrade delivered more than 50% improvement in crossŌĆædirection basisŌĆæweight control and about 20% improvement in moisture control.

These are process examples, but the same upgrade patterns show up in power applications. One ABB project extended the lifecycle of cycloconverters at an Italian steel mill, improving reliability, usability, performance, and uptime. Others involve hydroelectric power plants and large fuelŌĆæfired plants where control system upgrades improved reliability and information management, sometimes without replacing all field devices or I/O.

ABB emphasizes highŌĆæperformance HMIs, centralized control rooms, virtualization of HMI servers, and integration with data analytics platforms for improved decisionŌĆæmaking. They also underline their ability to handle complex thirdŌĆæparty migrations, including technically challenging modernizations from nonŌĆæABB systems, while often reusing existing I/O and field wiring.

For an Invensys site whose strategic direction points toward ABB, this kind of migration offers two main advantages. You can align your power and process control under one vendorŌĆÖs ecosystem, and you can use proven patterns for staged upgrades with minimal downtime. The main drawbacks are the effort and cost of platform migration and the need to rebuild or translate InvensysŌĆæspecific applications and objects.

Not every reliability problem demands a full control system replacement. Sometimes the right move is to augment your existing Invensys system with specialized software that tackles a specific operational issue.

Invensys Operations ManagementŌĆÖs OffŌĆæsites Software solution, as described by Automation.com, is a good example from the hydrocarbon world. It is explicitly positioned as DCSŌĆæindependent, focusing on two key refinery levers: inventory management and product blending. The updated solution introduced batch tracking for materials in transit, detailed line management, enhanced blend optimization for multiŌĆæblend header environments, and a tank information system with redundant level measurements and synchronized alarms. It integrates with the SimSciŌĆæEsscor ROMeo process optimization suite to feed accurate inventory and composition data into refineryŌĆæwide optimization.

The same pattern can be applied to power and energy management. You can keep the underlying Invensys controllers and HMIs in place, but overlay a modern energy management application that gathers highŌĆæresolution data from UPS systems, static transfer switches, power meters, and battery monitoring equipment. That application can handle advanced analytics, reporting, and even optimization, while the DCS continues to execute basic control.

The obvious caveat is that you now operate two layers of critical software. Interfaces between them must be engineered carefully, and alarm responsibilities must be clear: the last thing you want is conflicting alarms from the DCS and the overlay system during a disturbance. However, this approach can deliver significant value and risk reduction when budgets or outage windows do not support a deeper control migration yet.

The table below summarizes the main replacement paths discussed, with a focus on power supply and protection impacts.

| Replacement path | Typical scope | Advantages for power reliability and UPS | Limitations and risks |

|---|---|---|---|

| Stay within Schneider / Invensys | Update Wonderware, SimSci, Avantis; integrate with Schneider energy metering and StruxureWareŌĆæstyle architectures | Preserves engineering investment; strong fit with Schneider switchgear, breakers, and metering; consistent vendor roadmap for power and automation | Continued dependence on one vendor; portfolio rationalization may deŌĆæemphasize some Invensys products over time; must verify longŌĆæterm support for each component |

| HMIŌĆæfirst migration | Replace SCADA/HMI, retain legacy controllers temporarily via gateways and OPC | Operators adapt to one modern interface before hardware changes; can standardize power oneŌĆælines and UPS views early; easier training and humanŌĆæfactor control | Additional complexity from protocol converters; temporary architecture must be engineered and monitored; does not solve controller obsolescence by itself |

| PLC migration to modern platforms | Replace legacy PLCŌĆæ5, SLC 500, and similar controllers that handle power logic while retaining higherŌĆælevel HMIs | Reduces risk from obsolete controllers; improves diagnostics and networking; prepares ground for deeper integration of power devices | Requires rigorous reŌĆætesting of transfer and protection schemes; coordination with relay and breaker settings; may need temporary workarounds to keep legacy HMIs functioning |

| DCS migration to alternative vendor (for example ABB) | Move from InvensysŌĆæcentric DCS to platforms such as ABB 800xA or Symphony Plus, often in phases | Can standardize enterpriseŌĆæwide on one control and power automation stack; ABB case studies show large gains in availability, productivity, and energy efficiency | High engineering and changeŌĆæmanagement effort; need to rebuild logic and graphics; risk if project scope outstrips available outage windows |

| OperationsŌĆælayer augmentation | Keep Invensys core, add specialized applications (for example OffŌĆæsites, advanced energy management, or optimization) | Addresses specific gaps (inventory, blending, analytics, or energy reporting) without touching base control; can improve decision quality quickly | Adds another critical system to run and secure; relies on robust integration; does not resolve underlying hardware obsolescence |

No single row in this table is ŌĆ£the right answer.ŌĆØ In most powerŌĆæcritical facilities, a hybrid strategy emerges: for example, HMIŌĆæfirst migration combined with PLC upgrades in the switchgear and an eventual move to a unified DCS platform in one or two major outages.

When power continuity is central to your business model, you cannot treat control system replacement as an IT refresh. The framework I use with clients is riskŌĆæbased and staged.

Start with criticality and consequence. HighŌĆærisk assets such as oil platforms and nuclear plants, where Invensys has historically supplied control and safety systems, demand the most conservative approach. Any migration path must support proven safety integrity levels and regulatory expectations. That usually points toward staying with SchneiderŌĆÖs safetyŌĆæcertified offerings or migrating to another vendorŌĆÖs safety platform with a strong track record and explicit regulatory acceptance.

Next, look at obsolescence and support. If your Invensys controllers and HMIs are fully supported, with security patches, spare parts, and engineering expertise readily available, you have more time to optimize and stage your migration. If parts are scarce and engineers are difficult to find, the window for a safe, planned replacement is already closing.

Then assess integration and data needs. SchneiderŌĆÖs ŌĆ£energy meets automationŌĆØ vision, as well as ABBŌĆÖs emphasis on digital platform integration, depends on highŌĆæquality data from breakers, meters, UPS systems, and process instruments. If your current Invensys architecture cannot provide that data reliably, it will be very hard to justify powerŌĆærelated investments such as highŌĆæefficiency UPS systems or harmonic mitigation, because you will lack the measurements to prove their effectiveness.

Finally, plan the human side. Schneider and ABB both stress operator effectiveness, better user interfaces, and realistic training supported by operational data and simulations. For power systems, that translates into simulated transfer scenarios, realistic oneŌĆæline diagrams, and alarm designs that help operators distinguish between nuisance events and genuine threats to loads.

In practice, I rarely recommend a ŌĆ£big bangŌĆØ changeover. Most facilities are better served by two or three carefully planned stages over multiple years, with clear go/noŌĆægo criteria at each stage driven by power risk.

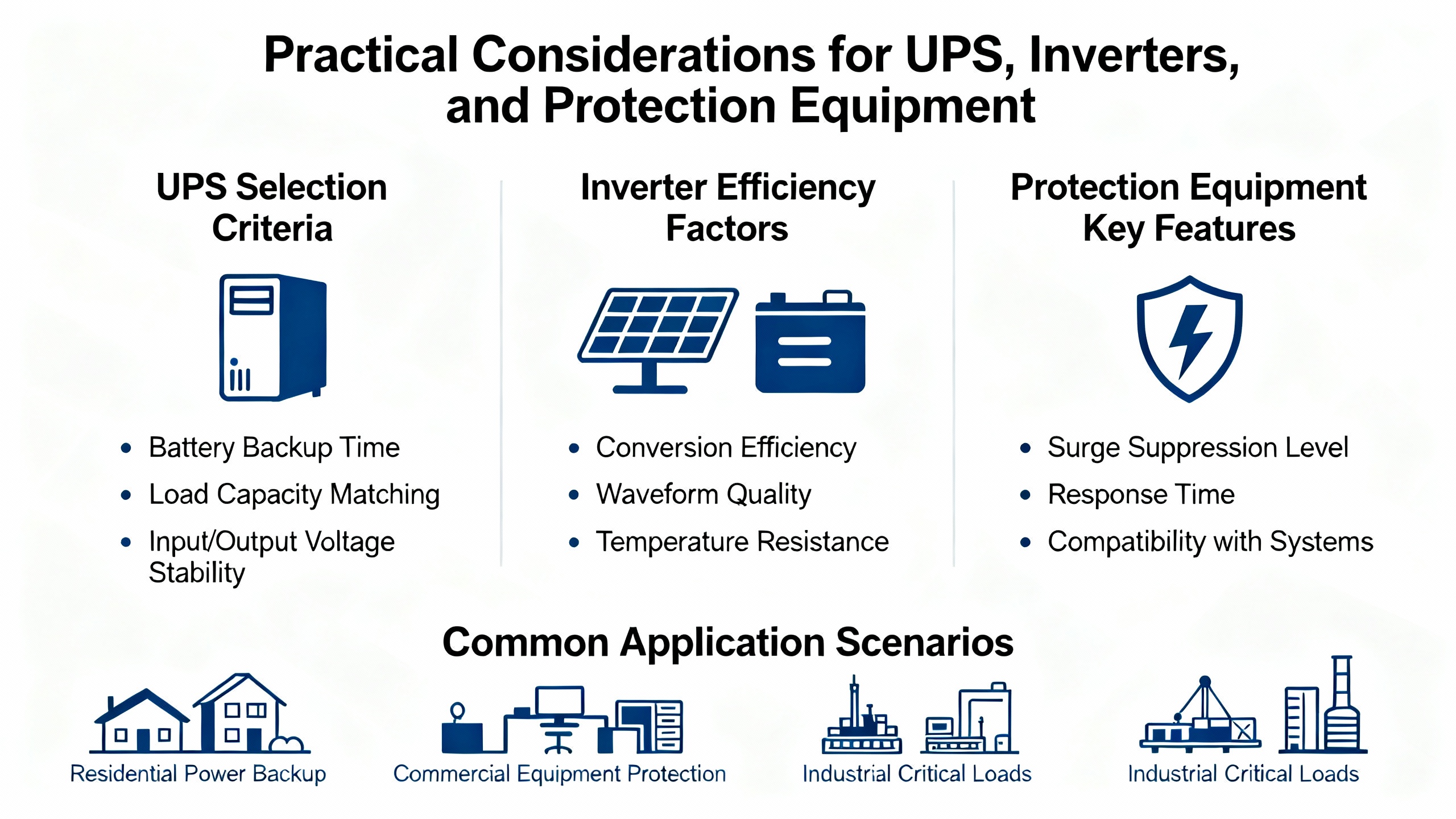

Regardless of which replacement path you choose, a few technical points deserve special attention in power supply projects.

One is transfer behavior. Many Invensys-based systems coordinate automatic transfers between utility, generator, and UPSŌĆæprotected buses. When you change controllers or HMIs, you must validate the timing and logic of transfers, including edge cases where inverters are near overload, batteries are at reduced capacity, or static transfer switches see upstream voltage disturbances.

Another is battery and inverter monitoring. Modern UPS systems expose detailed telemetry on cell voltages, temperatures, and inverter stress through protocols that may not have existed when your Invensys system was first installed. A wellŌĆædesigned replacement or augmentation project should collect that data centrally and use it for both realŌĆætime alarms and longŌĆæterm trend analysis, even if the original control system treated the UPS as a simple ŌĆ£on/offŌĆØ component.

A third is coordination with protection relays and switchgear. Upgrades to control systems are often accompanied by modernization of protective devices and metalŌĆæenclosed switchgear. Independent guidance on aging switchgear emphasizes thorough engineering studiesŌĆöshortŌĆæcircuit and coordination analysis, arcŌĆæflash assessment, and verification of bus and insulation conditionŌĆöwhen upgrading. From a power-reliability perspective, your Invensys replacement project should be tightly linked to those studies so that the new control logic and HMI accurately reflect, and respect, the protection philosophy embedded in relays and trip settings.

Finally, cybersecurity cannot be an afterthought. SchneiderŌĆÖs commentary on an increasingly connected future and ABBŌĆÖs virtualized HMIs both underscore that modern control systems are deeply networked. Legacy Invensys components often run older operating systems and protocols that were never designed for todayŌĆÖs threat landscape. Any replacement or augmentation should include a clear network segmentation, patching, and accessŌĆæcontrol strategy to protect both the control plane and the power equipment it supervises.

No. The experience of both integrators and major vendors is that phased evolution is not only possible but often preferable. ABBŌĆÖs case studies, for example, show many projects where controllers, HMIs, and information systems were upgraded in stages while production continued. HallamŌĆæICS shows how frontŌĆæendŌĆæfirst strategies can deŌĆærisk multiŌĆæyear upgrades. The key is that each phase must leave the power system in a safe, fully functional state.

There is no calendar date at which an Invensys system suddenly becomes unsafe. The real question is supportability. When spare parts, security patches, and qualified engineers are still available, and your risk assessments say the system meets reliability and safety goals, you can focus on measured evolution. When parts are scarce, specialist skills are rare, or you are forced into adŌĆæhoc repairs, you are effectively gambling with power reliability. At that point, delaying a structured upgrade often increases both technical and financial risk.

Operator familiarity is an asset you should protect. That is one reason HMIŌĆæfirst strategies are attractive: they let operators adapt to a single, wellŌĆædesigned interface before you start modifying the underlying controllers. During design, involve operators in screen layout, alarm philosophy, and navigation decisions. A modern HMI should make their job easier, not harder, especially during power disturbances where rapid, confident action is critical.

Invensys control systems helped build the modern industrial world, but no platform is timeless. The Schneider acquisition, the rise of digital energy management, and the gradual erosion of legacy hardware support have changed the decision landscape for every plant that relies on Invensys technology to keep power flowing.

Whether you evolve within SchneiderŌĆÖs ecosystem, migrate to a different DCS vendor, modernize your PLC layer, or overlay specialized operations software, the right replacement strategy is the one that reduces power risk step by step while respecting the realities of your site. If you treat the project as a powerŌĆæreliability program rather than a software upgrade, you will make better technical choices and keep your critical loads protected when it matters most.

Leave Your Comment