-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

In many industrial and commercial power systems, the AllenŌĆæBradley ControlLogix family sits at the heart of the control architecture. It is not just a ŌĆ£PLCŌĆØ in the traditional sense; it is a full Programmable Automation Controller (PAC). That distinction matters when you evaluate replacement options.

A classic programmable logic controller is a singleŌĆæprocessor, modular device originally created to replace banks of relays and timers. It leans heavily on ladder logic and is intentionally electricianŌĆæfriendly. Training providers such as BIN95 describe PACs differently: a PAC, such as ControlLogix or its smaller CompactLogix sibling, is closer to an industrial PC in a modular rack. It supports multiple programming languages, multitasking, distributed control, motion control, and uses standard Ethernet networking. In practice, it behaves more like a modern distributed control system than a simple machine PLC.

For power systems, this architecture is attractive. ControlLogix can coordinate generator controls, switchgear, UPS and inverter interfaces, load shedding schemes, and data exchange with SCADA or energy management systems, often in facilities that run around the clock. The same flexibility becomes a liability when plants face aging hardware, rising software costs, or a need to standardize on less vendorŌĆæspecific platforms. A PAC replacement project is fundamentally different from swapping a small PLC on a standalone machine. It has more impact on uptime, cybersecurity, and lifeŌĆæcycle cost, especially when it is supervising UPSŌĆæbacked feeders or critical DC buses.

Before choosing an alternative, it helps to understand why ControlLogix became the default in so many plants, and where its boundaries are.

Several recurring drivers push power and process facilities to consider ControlLogix replacements.

Cost and licensing are usually near the top of the list. Comparative work by PDFSupply and others notes that AllenŌĆæBradley systems, particularly in the Logix family, are often at the premium end of the market. In one study, a comparable Omron PLC solution was estimated at roughly oneŌĆætenth of the hardware and software cost of an equivalent AllenŌĆæBradley system, depending on configuration. Articles comparing leading PLC brands also place AllenŌĆæBradley pricing higher than Siemens, Mitsubishi, or Omron for similar application classes, quoting typical controller price ranges around one to several thousand dollars.

Ecosystem lockŌĆæin is another factor. Industrial Automation Co. points out that choosing a major PLC brand effectively commits you to its broader ecosystemŌĆösoftware, drives, HMIs, support, and sparesŌĆöfor roughly a decade or more. Plants in North America often standardize on AllenŌĆæBradley because of local expertise and part availability; EuropeanŌĆæcentric fleets may lean toward Siemens. When a facility wants to break out of that orbit, for example to harmonize with global standards or reduce license exposure, ControlLogix becomes an obvious replacement candidate.

Serviceability also plays a role. Experienced practitioners on Electrician Talk describe RockwellŌĆÖs line as powerful but ŌĆ£fussy,ŌĆØ with tight coupling between controller firmware, programming software versions, and supported Windows versions. That complexity is manageable in a highly standardized automation group but can be frustrating for a smaller maintenance team focused primarily on power systems and protection.

At the same time, Rockwell has deliberately made migration from older platforms relatively straightforward. ControlLogix and CompactLogix are the natural landing spot for SLC 500 and PLCŌĆæ5 users; RockwellŌĆÖs own conversion tools in Studio 5000 can translate legacy SLC programs into Logix tagŌĆæbased structures. A Control.com technical article notes that this trend has driven many upgrades, even though meticulous verification is still required, particularly for networks such as DeviceNet or ControlNet.

Finally, the human factor matters. BIN95 emphasizes that calling a PAC a ŌĆ£PLCŌĆØ hides the learning curve. They describe cases where plants asked for ŌĆ£PLC ladder trainingŌĆØ only to discover their machines were actually ControlLogixŌĆæclass PACs written almost entirely in structured text. That mismatch can produce both downtime and safety risk when maintenance staff try to ŌĆ£learn on the jobŌĆØ inside a live PAC that is managing switchgear, UPS contactors, or generator interlocks.

When you step back, the core question is not whether ControlLogix is a capable controller; it clearly is. The question is whether it is still the best fit for your scale, team, budget, and longŌĆæterm power reliability goals.

For many facilities, the lowestŌĆærisk alternative to an aging or oversized ControlLogix system is another controller within the Logix ecosystem. That might mean migrating from ControlLogix to CompactLogix, or from legacy MicroLogix or SLC hardware to CompactLogix rather than staying at the high end.

Multiple sources, including RealPars, LadderLogicAI, GBLŌĆæData, and Asteam Techno, describe the positioning of these families consistently. ControlLogix is the highŌĆæend, chassisŌĆæbased PAC platform, engineered for very large and complex systems. CompactLogix is the midŌĆærange platform, intended for standalone machines, skids, and small to midŌĆæsized processes.

RealPars highlights several architectural differences. ControlLogix modules plug into a backplane inside a 1756 chassis with a separate power supply. A single chassis can host multiple controllers, communications modules, I/O, and specialty modules. That allows designs where one chassis coordinates thousands of distributed I/O points and many motion axes, with options for redundancy modules or advanced Model Predictive Control cards that are not available on CompactLogix.

CompactLogix uses a rackless or smallŌĆæchassis architecture. Controllers such as the 5370 and 5380 families connect sideŌĆæbyŌĆæside to local I/O through an integrated bus, sometimes with a small 1769 or 5069 chassis, and then out to distributed I/O over EtherNet/IP. CompactLogix controllers are singleŌĆæCPU systems; you do not put multiple CPUs in one base the way you can in a ControlLogix rack.

From a capacity standpoint, Asteam Techno summarizes typical user memory ranges like this: ControlLogix 5570 controllers span roughly 2 to 8 MB of user memory plus up to 4 MB of safety memory, while 5580 controllers start around 3 MB and go up to about 20 MB plus 6 MB of safety memory, with gigabit Ethernet onboard. CompactLogix 5380 controllers range from roughly 0.6 MB up to about 10 MB of user memory plus 5 MB of safety memory, and CompactLogix 5370 L3 units from about 1 to 5 MB plus 1.5 MB of safety memory. LadderLogicAI notes that older ControlLogix variants went as high as 32 MB or more.

Both families support similar logical structures: tagŌĆæbased variables instead of SLCŌĆæstyle data files, userŌĆædefined types, and up to dozens of tasks with hundreds of programs per task. The real separation is in performance, I/O and network capacity, and specialty modules.

The table below summarizes the roles as described in those sources.

| Platform | Architecture | Typical Scale And Use Case | Notable Features |

|---|---|---|---|

| ControlLogix 5570/5580 | ChassisŌĆæbased PAC | Large plantŌĆæwide control, tens of thousands of I/O, multiŌĆæaxis motion | High memory, multiŌĆæcontroller racks, redundancy and MPC modules |

| CompactLogix 5380 | Compact or small chassis | Small to midŌĆæsize systems, packaging lines, skids, power subsystems | Integrated motion and safety, gigabit EtherNet/IP, SD storage |

| CompactLogix 5370 | Compact chassis | MachineŌĆælevel control, moderate I/O | DualŌĆæport EtherNet/IP switch, midŌĆærange memory |

| MicroLogix / Micro800 | Brick / micro PLC | Standalone small machines, basic power panels | Low cost, limited I/O and advanced features |

For a power system engineer, the key practical takeaway is that CompactLogix can handle a surprising amount of work, especially when you use distributed EtherNet/IP I/O near switchgear, UPS, and inverter cabinets. In many facilities I have worked with, we have replaced oversized ControlLogix racks that were barely using their capacity with CompactLogix 5380 controllers and remote I/O, without sacrificing performance or reliability.

RealPars and GBLŌĆæData both recommend CompactLogix for small to midŌĆæsized systems such as packaging lines, moderately complex material handling, and similar applications. For power systems, the analog is a control scope such as a single mediumŌĆævoltage substation, a UPS plant for one critical building, or a generator pair with transfer switches and load controls.

In these cases, CompactLogix gives you tagŌĆæbased programming, integrated motion (if needed for breakers or disconnect drives), integrated safety, and modern Ethernet communications. Asteam Techno notes that CompactLogix 5380 processors ship with USB ports and SD card slots for nonŌĆævolatile program storage, with superŌĆæcapacitors instead of batteries. Program images can be moved between controllers by moving the SD card, which is attractive when you want quick replacement after a failure without reŌĆælicensing software in the field.

If your existing ControlLogix system is underŌĆæutilized, has modest I/O counts, and does not rely on specialty modules available only in ControlLogix, CompactLogix is often the simplest internal replacement. You stay within Studio 5000, keep EtherNet/IP integration with existing HMIs and drives, and reuse much of your existing Logix code.

There are many applications where a ControlLogixŌĆæclass platform remains the right answer, even when you explore alternatives. The RealPars comparison emphasizes that ControlLogix is designed for large, complex systems and is the preferred choice when you need to coordinate large processes across many units, execute advanced process control, or manage a high number of motion axes.

Asteam Techno and DoSupply both highlight highŌĆæavailability features such as redundancy modules, higher connection limits, and richer communication options. ControlLogix 5570 controllers, for example, support hundreds of controllerŌĆætoŌĆæcontroller and controllerŌĆætoŌĆædevice connections, and both 5570 and 5580 families support a mix of legacy and modern networks, including EtherNet/IP, ControlNet, DeviceNet, and Data Highway Plus. For critical power systems that span multiple substations, cogeneration assets, and large UPS plants, those capabilities and connection limits can be decisive.

If your power system spans an entire campus with thousands of I/O points, hard realŌĆætime interlocking between feeders, or extensive integration with drives and relays, staying with ControlLogix or moving to a newer 5580 controller is often the most conservative risk posture. In that case, your ŌĆ£alternativeŌĆØ is not a different brand but a newer generation with more memory, gigabit networking, and improved diagnostics.

When plants decide to move away from ControlLogix entirely, they usually do so for reasons of cost, standardization across regions, or strategic alignment with other OEM equipment. Based on the research notes, three families show up repeatedly as realistic alternatives: AutomationDirectŌĆÖs Productivity and related PLCs, Siemens S7ŌĆæ1500ŌĆæclass systems, and OmronŌĆÖs NJ/NX and CS/CJ families.

On Electrician Talk, experienced contractors describe AutomationDirect as ŌĆ£hard to beat all around.ŌĆØ Their PLCs, many manufactured by Koyo, are considered more than capable for small and midŌĆæsized systems, with attractive pricing and a company that is easy to work with. The author of that thread argues that for smallŌĆæ to mediumŌĆæsized contractors working on systems of similar complexity, it can make more sense to invest in AutomationDirect skills than in Rockwell, particularly when clients are sensitive to capital cost.

In an AutomationDirect community question, a machine builder who had been heavily invested in Rockwell looked for a lowerŌĆæcost alternative for plants with little existing automation. After initially dismissing AutomationDirect PLCs as low quality, they found, through research and community feedback, that the CLICK, DoŌĆæmore, and Productivity series are technically solid. Feedback indicated that all three families are viable; selection depends on the specific application. The builder decided to start with the Productivity series, then explore CLICK and DoŌĆæmore.

Inductive AutomationŌĆÖs Ignition forum offers additional nuance. Users there praise AutomationDirectŌĆÖs Productivity series for strong functionality at low cost, free programming software and videos, and easy online ordering without distributor friction. However, they also point out a key limitation: many Productivity PLCs do not include builtŌĆæin OPC UA servers, so SCADA integration often falls back to Modbus TCP with manual tag configuration, which becomes timeŌĆæconsuming at scale.

For ControlLogix replacements, this implies that AutomationDirect is attractive when you are costŌĆæconstrained and your system is modest in scale or uses a SCADA package that can live with ModbusŌĆæoriented integration. Productivity controllers can certainly run powerŌĆæsystem logic for switchboards, small generator plants, or UPS control where I/O counts are moderate and highŌĆæend redundancy is not required. But if you rely heavily on native EtherNet/IP integration with existing drives, relays, or thirdŌĆæparty PACs, or you want OPC UA as a firstŌĆæclass protocol, you should factor that into your choice.

Several comparisons, including Industrial Automation Co., DoSupply, and a 2025 PLC brand review, position Siemens as the primary peer to AllenŌĆæBradley at the midŌĆætoŌĆæhigh end. Siemens S7ŌĆæ1200 is roughly comparable to CompactLogix and S7ŌĆæ1500 to ControlLogix.

HardwareŌĆæwise, the S7ŌĆæ1500 is described as a modular, highŌĆæperformance PLC with strong diagnostics and native PROFINET and PROFIBUS networking. Sources comparing Siemens S7ŌĆæ1500 and ControlLogix note that S7ŌĆæ1500 offers very fast instruction execution and up to about 32 MB of work memory in higherŌĆæend CPUs, along with modern connectivity such as OPC UA and MQTT. TIA Portal provides a unified engineering environment covering PLCs, HMIs, drives, and safety, which can simplify lifecycle management when you standardize on Siemens.

Industrial Automation Co. stresses that geography and skill base should drive this decision. In North America, ControlLogix and CompactLogix often win because parts are quicker to source and more technicians are comfortable with Studio 5000 and ladder logic. In Europe and many international OEM markets, the opposite is true: Siemens is the default, and S7ŌĆæ1500 is a natural choice for new plants.

For power system replacements, S7ŌĆæ1500 can be a strong ControlLogix alternative if your facility is already SiemensŌĆæheavy, or you want to lean into PROFINET and IECŌĆæstyle integration. You trade off the tight coupling with Rockwell drives and HMIs for closer ties to Siemens SINAMICS drives and SIMATIC HMIs, and you move from EtherNet/IP to PROFINET. That shift has ripple effects on relays, meters, and thirdŌĆæparty equipment, so it should be evaluated carefully in substations and UPS rooms where many devices still skew toward EtherNet/IP or Modbus.

PDFSupply provides a detailed comparison of AllenŌĆæBradley and Omron lineups. Omron offers compact brick PLCs (CP series), modular CJ1/CJ2 controllers, and rackŌĆæmount CS1G/CS1H and CS1D platforms, along with newer motionŌĆæcentric NJ and NX controllers. Their systems emphasize multiŌĆæaxis motion, robotics, vision, safety, and flexible networking.

One notable point from that comparison is cost: the authors estimate that an Omron PLC system, including both hardware and software, can be about oneŌĆætenth the cost of an equivalent AllenŌĆæBradley system, acknowledging that actual ratios depend on details. OmronŌĆÖs CP series and midŌĆærange controllers are particularly costŌĆæeffective for small and midŌĆæsize applications.

In terms of networking, Omron supports a wide array of protocols, including EtherNet/IP, PROFINET IO, DeviceNet, PROFIBUSŌĆæDP, CCŌĆæLink, and Modbus TCP/IP, plus USB and serial links. That breadth makes it easier to integrate with heterogeneous power equipment fleets. The CS1D family adds highŌĆæavailability features such as dual power supplies, duplex CPUs with automatic synchronization, and redundant communications. According to PDFSupply, the CS1D can switch to a standby CPU within one scan cycle, making it suitable for highŌĆæavailability applications.

For ControlLogix replacements in power systems where redundancy and cost are both important, Omron CS1DŌĆæclass platforms deserve serious consideration. They can deliver redundant control in substation or plantŌĆæwide power management roles at a significantly lower hardware and software price point, provided your team invests in OmronŌĆÖs CXŌĆæProgrammer or Sysmac Studio tools and the associated learning curve.

The table below summarizes the positioning of these alternatives relative to ControlLogix based on the research notes.

| Option | Role Versus ControlLogix | Network Orientation | Cost Positioning And Notes |

|---|---|---|---|

| AllenŌĆæBradley ControlLogix 5570/5580 | Baseline highŌĆæend PAC; plantŌĆæwide, high I/O, advanced control | EtherNet/IP, ControlNet, DeviceNet, DH+, more | Premium pricing; strong in North American plants |

| CompactLogix 5380 | Internal downsize option for midŌĆærange systems | EtherNet/IP | MidŌĆætier cost; reuses Studio 5000 and Logix code |

| AutomationDirect Productivity | CostŌĆædriven alternative for small to midŌĆæsized systems | Primarily Modbus TCP; limited OPC UA | Often significantly cheaper; free software; SCADA effort |

| Siemens S7ŌĆæ1500 | Peer highŌĆæend PLC for complex and fast applications | PROFINET, PROFIBUS, OPC UA, MQTT | Broad price range; strong in Europe and global OEMs |

| Omron CS1D / CJ2 / NJ / NX | HighŌĆæavailability and motionŌĆæcentric alternatives | EtherNet/IP, PROFINET IO, DeviceNet, others | Roughly oneŌĆætenth of equivalent AB system in one study |

From a power reliability perspective, your decision is not just about the controllerŌĆÖs instruction set or scan rate. It is about network standards (EtherNet/IP versus PROFINET or Modbus), the depth of redundancy features that matter for UPS and inverter controls, and the availability of local expertise to maintain the system over long service lives.

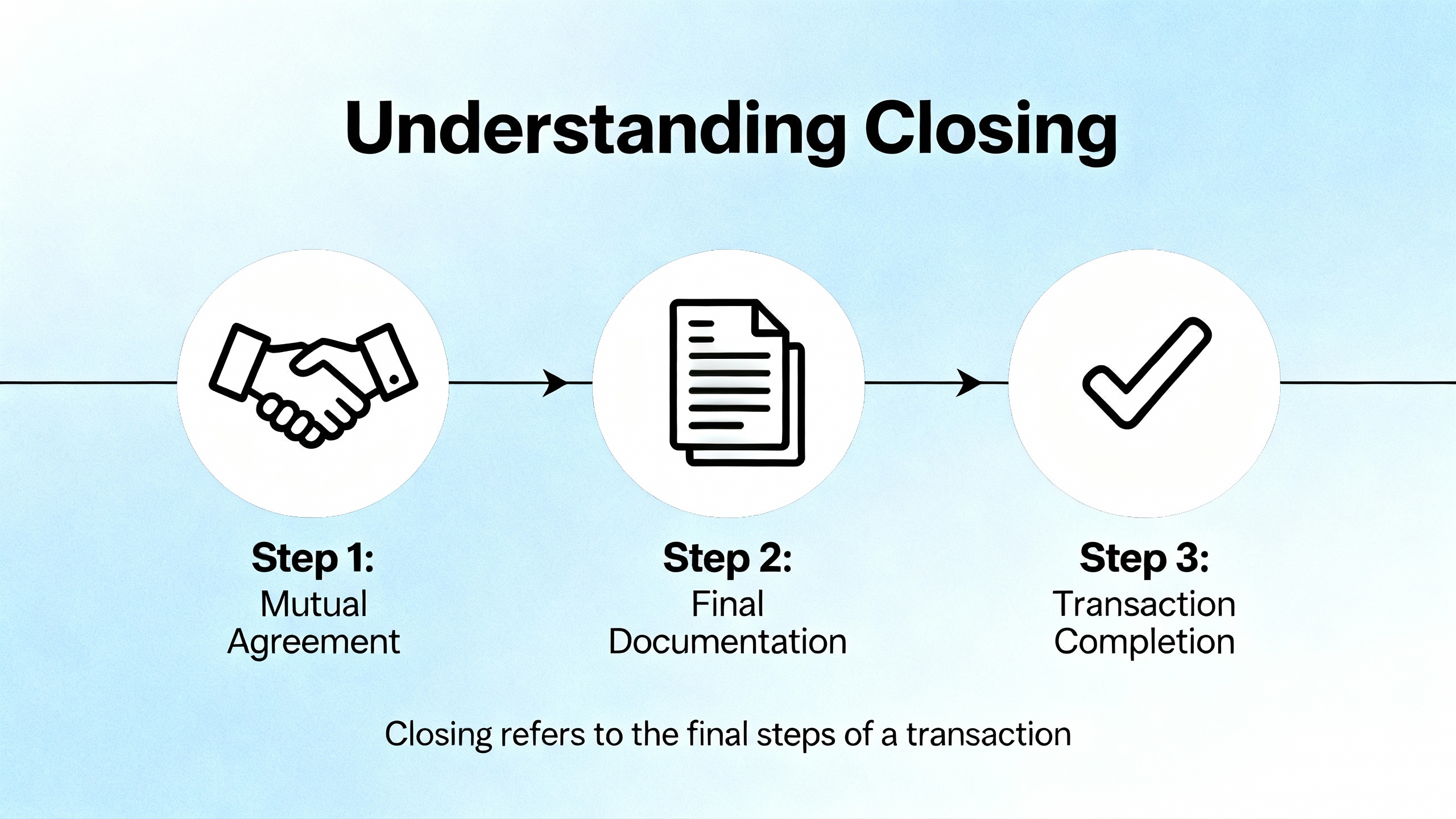

Regardless of which alternative you choose, the way you execute the migration has as much impact on uptime as the hardware itself. The Electrician Talk discussion offers a simple but effective approach: clearly list what you need and what you want from the new system, then rank each requirement by criticality.

In that discussion, the author proposes four categories. The first is true necessities that would be dealbreakers if not met, such as required I/O counts, essential communication protocols, safety integrity levels, or redundant CPU capability. The second comprises highly valuable features that are not strict dealbreakers but strongly influence the decision, such as builtŌĆæin diagnostics, integrated energy metering, or native OPC UA support. The third covers modestŌĆæimpact niceŌĆætoŌĆæhaves that might break ties between otherwise comparable platforms. The fourth consists of features you actively prefer to avoid because they add complexity or risk.

When you apply that method to a ControlLogix replacement, you often see the candidate list shrink quickly. For example, if native EtherNet/IP interoperability with existing relays and drives plus redundant CPUs are nonŌĆænegotiable, certain lowŌĆæcost PLCs fall away. If you must keep the programming environment familiar to an existing RockwellŌĆætrained team, moving from ControlLogix to Siemens becomes a bigger training investment and might shift from ŌĆ£desirableŌĆØ to ŌĆ£dealbreaker.ŌĆØ

The same Electrician Talk thread suggests piloting a small, nonŌĆæcritical system on the proposed alternative platform. For instance, you might convert a single UPS bypass panel or a smaller distribution section to AutomationDirect or Omron as a trial. Because the hardware is relatively inexpensive, you can afford to treat the pilot as both a technical evaluation and a training exercise, while retaining the ability to revert if necessary.

From a power system reliability standpoint, I generally advocate a phased migration path. Start with mirrored control logic and shadow I/O in a test environment; use vendor conversion tools where applicable, as Rockwell does for SLC to Logix. Validate logic thoroughly with offline simulations and, when possible, hardwareŌĆæinŌĆætheŌĆæloop testing before cutting over any real breakers or contactors. Only once you have confidence in both the new platform and your teamŌĆÖs competence should you schedule live switchover windows, ideally on loads backed by UPS or redundant feeders.

The difference between PLCs and PACs is especially important in training programs. BIN95 recommends about forty hours of handsŌĆæon PLC training just to build a solid foundation in PLC safety, reliability, and best practices. Only after that, they suggest, should staff move on to PAC training. A comprehensive PAC curriculum that includes motion control, structured text, networking, and cybersecurity can easily add another forty hours or more, and ISA has similar guidance for deep training in the IEC 61131 languages.

When you replace ControlLogix with another PACŌĆæclass system such as S7ŌĆæ1500 or Omron NJ/NX, you are not ŌĆ£going simplerŌĆØ; you are trading one complex environment for another. Maintenance technicians and power engineers used to ladderŌĆæonly PLCs may initially struggle with tagŌĆæbased architectures, task scheduling, or structured text routines. That is true even when staying within Logix, and even more so when switching brands.

In my experience, the most successful migrations treat training as a design deliverable, not an afterthought. They budget structured, handsŌĆæon training on the target platform, focused specifically on the projectŌĆÖs power system applicationŌĆösuch as load shedding logic, breaker interlocks, or static transfer controlŌĆörather than generic tutorials. That investment pays back quickly in reduced commissioning time and fewer lateŌĆænight calls when a breaker fails to close and the UPS plant is running on battery.

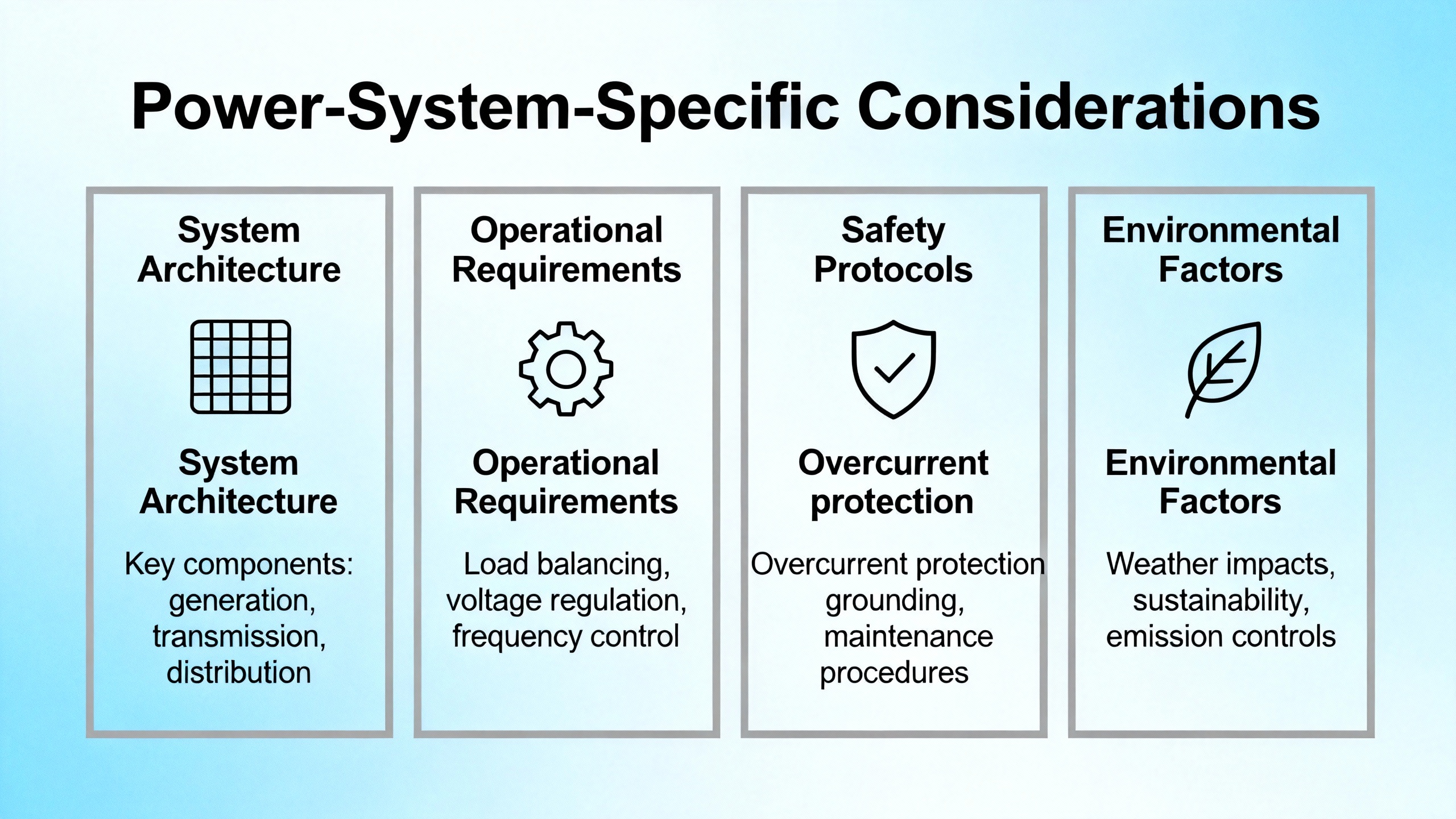

ControlLogixŌĆæclass replacements in power environments have some unique wrinkles that do not always show up in general automation discussions.

First, consider how the new controller will behave during abnormal power events. A highŌĆæend PAC that manages transfer schemes, breaker interlocks, or inverter control should be powered from a robust UPS or DC control supply. When you change platforms, verify that power supply ratings, rideŌĆæthrough behavior, and startŌĆæup characteristics are compatible with your existing UPS and battery systems. The PDFSupply comparison notes typical operating temperature ranges for AllenŌĆæBradley controllers around minus 13┬░F to 158┬░F and relative humidity up to roughly 95 percent, with Omron units often specified for about 14┬░F to 131┬░F and about 85 percent relative humidity. While those ranges are adequate for most electrical rooms, you should still confirm environmental ratings, particularly for outdoor switchgear lineups or harsh industrial sites.

Second, pay close attention to communications with protective relays, meters, and UPS or inverter controllers. Many modern relays speak multiple protocols, but in practice plants often settle on one or two. ControlLogix and CompactLogix natively favor EtherNet/IP and can integrate with a broad array of AllenŌĆæBradley drives and I/O via that network, whereas Siemens S7ŌĆæ1500 leans on PROFINET and Omron often integrates via EtherNet/IP plus a mix of other fieldbuses. PDFSupply lists extensive protocol support for both families, including DeviceNet, PROFIBUS, Modbus, and others. You want to select a replacement platform that aligns with the protocols your power equipment already uses or can support without awkward gateways.

Third, think through how the replacement will interact with your power monitoring and SCADA systems. An Inductive Automation forum discussion highlights the value of PLCs that include native OPC UA servers when integrating with Ignition SCADA. Ignition can also talk to AllenŌĆæBradley controllers via tagŌĆæbrowsable EtherNet/IP drivers, but cheaper PLCs that only expose Modbus TCP require more manual tag handling. If your energy management system is OPC UAŌĆæcentric, that might tilt the decision toward Siemens or Omron rather than a lowŌĆæcost platform without OPC UA.

Finally, do not overlook cybersecurity. Several sources on modern PLCs and brand comparisons emphasize features such as secure boot, encrypted communications, and roleŌĆæbased access control, particularly in newer Siemens and AllenŌĆæBradley platforms. As more power systems connect to corporate networks or remote monitoring centers, those capabilities move from ŌĆ£nice to haveŌĆØ to essential.

CompactLogix 5380 controllers can handle substantial I/O counts, integrated safety, and modern EtherNet/IP I/O, and RealPars and GBLŌĆæData both position them for advanced midŌĆærange systems. For a single substation, a mediumŌĆæsized UPS plant, or a generator pair, CompactLogix is often sufficient. However, if your application depends on ControlLogixŌĆæonly specialty modules, very high connection counts, or multiŌĆæcontroller architectures, staying on ControlLogix or moving to a newer 5580ŌĆæseries controller is the safer choice.

Industrial Automation Co. and PDFSupply both point out that brand choice locks you into an ecosystem for many years. Leaving Rockwell tends to make sense when the rest of your plant is already aligned with another vendor, when you can realize significant hardware and software savings with alternatives such as Omron or AutomationDirect, or when you want to standardize globally on something like Siemens TIA Portal. The tradeoff is the training and integration work needed to adapt your team and devices to new tools and protocols.

The Electrician Talk guidance is a practical place to start: clearly document your required I/O, processor performance, communications, HMI interfaces, redundancy needs, and environmental constraints, then separate absolute necessities from strong preferences. Use that list to screen candidate platforms down to a manageable set. From there, consider piloting a nonŌĆæcritical portion of your power system on the leading candidate, verify integration with relays, meters, UPS controllers, and SCADA, and invest in focused training on the chosen platform before you migrate any critical feeders or UPSŌĆæprotected loads.

Replacing an AllenŌĆæBradley ControlLogix system is less about chasing the newest controller and more about aligning control architecture, networks, and team skills with the longŌĆæterm reliability targets of your power system. Whether you stay within the Logix family, move to Siemens or Omron, or adopt a costŌĆædriven platform like AutomationDirect, the most resilient outcomes come from sober requirement analysis, realistic training plans, and disciplined migration and testing rather than from any particular badge on the front of the controller.

Leave Your Comment