-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Industrial and commercial facilities that standardized on ABB variable frequency drives often reach a crossroads. A production line expands, a drive family reaches end of support, an energy audit shows room for savings, or corporate standards shift toward a different automation ecosystem. At that point, the question becomes practical and uncomfortable: if you are replacing an ABB VFD, which alternative drives can you trust, and how do you choose them without compromising reliability, motor life, or power quality?

As someone who spends most of my time between MCC rooms, pump galleries, and rooftop HVAC plants, I see the same pattern repeatedly. ABB drives have set a high bar for torque control, overload performance, and integration. Replacing them with a cheaper ŌĆ£boxŌĆØ chosen only by horsepower and price is a good way to trade one problem for three new ones. This article walks through how VFDs work, what makes ABB a benchmark, and how to select and commission alternative drives so that you maintain or improve reliability instead of eroding it.

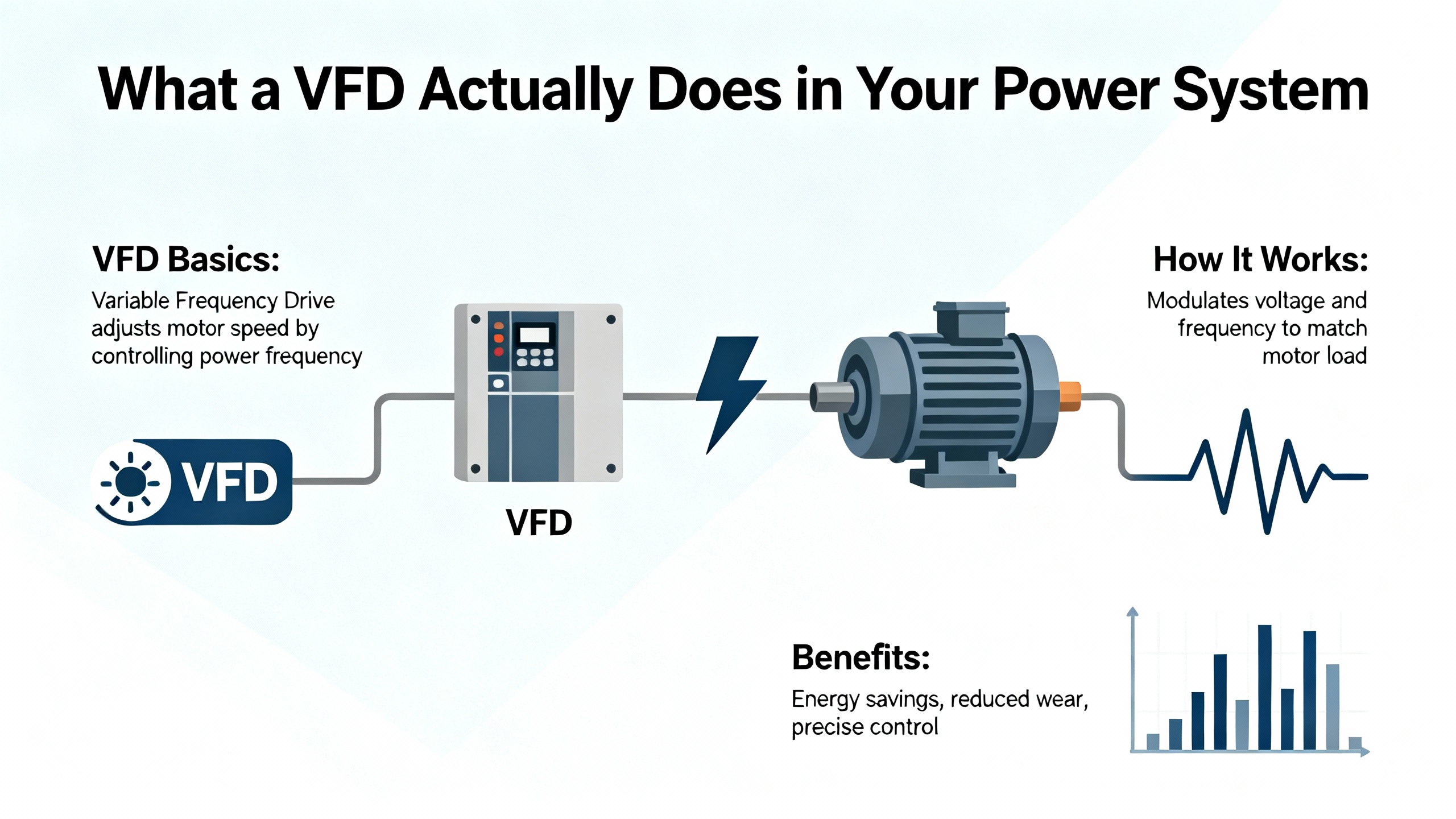

A variable frequency drive is an electronic motor controller for AC motors. It takes fixedŌĆæfrequency AC from the supply and produces a controlled, threeŌĆæphase output with adjustable frequency and voltage. According to introductory guidance from CoastApp and similar engineering primers, the power stage is conventionally split into three sections. A rectifier converts the incoming AC to DC. A DC bus smooths and stores that energy with capacitors and sometimes inductors. An inverter stage, typically using IGBTs, reconstructs threeŌĆæphase AC at the desired frequency and voltage so you can set motor speed and torque.

VFDs are now standard in manufacturing, HVAC, water and wastewater treatment, mining, and oil and gas. Instead of running motors at full speed and wasting energy with throttling valves or dampers, a drive can slow a fan or pump to match actual demand. Industry sources such as UNIDO note that electric motor systems account for the majority of industrial electrical consumption, which is why VFDs have become one of the fastest ways to cut energy use.

Beyond energy savings, drives bring soft start and stop, reduced mechanical shock, better process control, and the ability to respond to changing conditions in real time. Typical loads include HVAC fans, pumps, compressors, conveyors, mixers, CNC spindles, and even elevators and presses where smooth speed control improves safety and uptime.

The tradeoffs are real. Drives introduce harmonic distortion on the power system, they require more careful installation than simple starters, and their configuration demands real motor and application knowledge. Those tradeoffs are manageable, but they must be designed for deliberately, especially when replacing a wellŌĆæbehaved ABB drive with a different brand.

Independent comparisons, including analyses that contrast ABB with Siemens and Schneider, consistently highlight ABBŌĆÖs strength in control and energy performance. ABB drives are described as offering very accurate speed and torque control with stable output and strong lowŌĆæspeed torque, backed by advanced vector control algorithms and generous overload capability. DoSupplyŌĆÖs summary of ABB versus AllenŌĆæBradley makes a similar point: ABB lowŌĆævoltage drives are designed for threeŌĆæphase induction motors, deliver high torque at low speed, and integrate cleanly through common fieldbus interfaces.

A separate comparison from an automation distributor notes that ABB tends to lead in energy optimization and durability, particularly for pumps and compressors, while Siemens emphasizes deep integration into its own ecosystem and Schneider positions itself as a solid, costŌĆæeffective choice for standard duty. The message is that ABB is not just ŌĆ£another brand,ŌĆØ it is one of the reference platforms in the market.

That matters when you are planning a replacement. If your installed base used ABBŌĆÖs vector control to wring stable torque out of a heavily loaded conveyor, sliding in a basic voltsŌĆæperŌĆæhertz drive without checking torque and overload capability can easily expose mechanical weaknesses you have not seen in years.

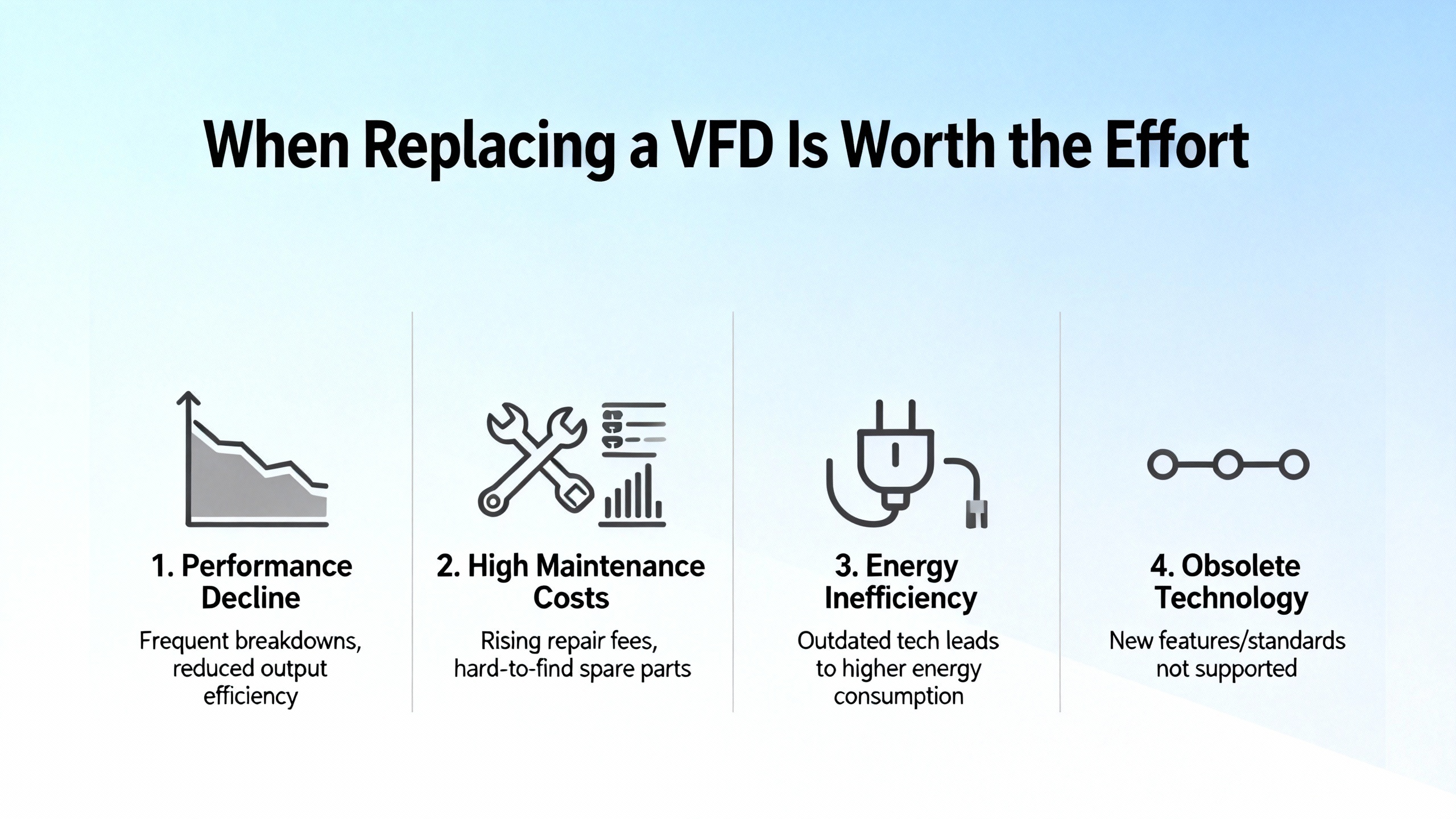

Not every aging drive deserves a wholesale replacement program. Some ABB units, especially in clean environments with appropriate cooling, will run for decades. But several situations should prompt a structured evaluation of alternatives.

One trigger is missing functionality. Newer drives from many vendors now implement onŌĆæboard logic, highŌĆæresolution analog inputs, extensive digital I/O, and fieldbus interfaces. A STEP iAstar drive example from JAARIS Automation shows how a modern VFD can act as a miniŌĆæcontroller: it accepts 0ŌĆō10 V and 4ŌĆō20 mA references, has flexible digital I/O for interlocks and alarms, includes relay outputs, and communicates over Modbus. When used properly, the drive can centralize motor logic that used to sit in separate relays and small PLCs. If your ABB fleet predates these capabilities, an alternative drive with richer control may simplify panels and cut failure points.

Another trigger is lifeŌĆæcycle energy cost. Rockwell AutomationŌĆÖs energyŌĆæefficiency guidance provides a concrete illustration. Consider a VFD and motor combination delivering about 100 kW to an application, operating for roughly 36,800 hours over seven years at a 60 percent duty cycle. With a combined efficiency of 90 percent, that system consumes around 4.088 million kWh. At 91 percent efficiency, the consumption drops to about 4.043 million kWh, a reduction of roughly 41,000 kWh. Using a conservative energy price of $0.10 per kWh, that single percentage point of efficiency yields about $4,100 in lifetime savings. For large fans or pumps, the economics of moving from an older drive to a modern highŌĆæefficiency alternative can be compelling even if the original ABB unit is still operational.

Standardization and support also matter. Several practitioners on engineering forums warn that buying random drives from online marketplaces is risky because some models are obsolete or have poor documentation. Branded drives from ABB, Siemens, Yaskawa, Mitsubishi, Fuji, Rockwell, Eaton, and others tend to come with local distributors, training, and clear manuals. If your organization is moving toward one of these ecosystems for PLCs and SCADA, consolidating drives for support and spare parts can be a rational reason to replace ABB units, as long as you treat the transition as an engineering project rather than a purchasing exercise.

Once you decide that a replacement makes sense, selection becomes a technical exercise. Reputable manufacturers and application notes from AutomationDirect, VFDS.com, Chint, Eaton, and others converge on a set of nonŌĆænegotiables.

The motor nameplate is the starting point, but horsepower is not the whole story. Both VFDS.com and AutomationDirect stress that fullŌĆæload amps are the primary sizing parameter. The driveŌĆÖs continuous current rating must meet or exceed the motorŌĆÖs fullŌĆæload current; otherwise you invite nuisance trips during starts or heavy load.

Application type matters as much as current. Drives are typically rated for variable torque or constant torque duty. Variable torque ratings apply to centrifugal fans and pumps where torque falls roughly with the square of speed. Constant torque ratings apply to conveyors, extruders, presses, and positive displacement pumps. The same physical drive often has different current ratings depending on which duty class you use. If you are replacing an ABB drive that was supporting a constantŌĆætorque load, erring on the constantŌĆætorque side with the new brand is the safer choice.

Finally, every mainstream VFD produces a threeŌĆæphase output. AutomationDirectŌĆÖs guidance is explicit: even when the supply is singleŌĆæphase, the motor must be threeŌĆæphase. If any ABB drive in your fleet is feeding a special motor type such as a permanent magnet synchronous machine, review that carefully, because not every alternative VFD handles those motors correctly.

The supply side is just as important. VFDS.com highlights that you must match both voltage and phase to the site utility. In the lowŌĆævoltage world, 208, 230, and 460 VAC are common in the United States. Several drives can act as phase converters when you only have singleŌĆæphase supply but need to run a threeŌĆæphase motor. The catch is that they must be derated significantly.

One rule of thumb from that guide is that for singleŌĆæphase input phase conversion you may need a drive with a current rating more than twice the motor fullŌĆæload amps. As an example, a 10 hp motor with 28 A FLA might need a drive with over 56 A output current, roughly a 20 hp drive, when fed from singleŌĆæphase.

ElectronicsŌĆæoriented discussions reinforce this. For instance, when using 120 V singleŌĆæphase supply to generate 220 V threeŌĆæphase output, only specific ŌĆ£voltageŌĆædoublerŌĆØ drives support that topology, and they are available only at relatively low power. They also highlight that input current on a 120 V feed can easily exceed 20 A for a modest motor because the drive corrects power factor and introduces its own harmonic distortion. When replacing an ABB drive that had threeŌĆæphase supply with an alternative on a weaker singleŌĆæphase source, you cannot simply transpose the nameplate and expect identical behavior.

Chint and VFDS.com both emphasize installation environment as a firstŌĆæclass selection factor. Indoors, humidity, ambient temperature, and contaminants like dust or corrosive chemicals drive enclosure choice and cooling strategy. Outdoors, sunlight, weather, and condensation join the list. Drives are offered in IP or NEMA enclosure classes; an IP20 or NEMA 1 unit is only fingerŌĆæsafe and not sealed against dust or water, while washdownŌĆærated enclosures such as NEMA 4 are designed to tolerate water spray and heavy contamination.

RealŌĆæworld experience on machineŌĆætool forums backs this up. Users describe openŌĆæstyle drives running for several years in relatively clean areas, while sealed washdown drives shrug off swarf, grit, and even occasional water exposure in harsher locations. When stepping away from ABB, do not downgrade environmental protection simply because the new drive looks compact or inexpensive. A cheaper drive that ingests grinding dust for a year is not a bargain.

Temperature and altitude also limit ratings. AutomationDirect notes that many standard drives are rated for full output only up to about 3,300 ft elevation, above which air density drops and cooling is less effective. Above that, you either oversize the drive or provide enhanced cooling. In hot process rooms, drives contribute their own heat inside panels; some models support ŌĆ£flange mounting,ŌĆØ where the heat sink protrudes outside the enclosure so that only the control electronics sit in the panel. This kind of mechanical detail becomes important when you rebuild an MCC or VFD room around a different brand.

Most generalŌĆæpurpose drives can supply about 150 percent of rated current for up to a minute. AutomationDirect calls out that higher overload demands, such as applications that previously used acrossŌĆætheŌĆæline starters, may require up to 600 percent starting current. CanroonŌĆÖs reliability review gives more concrete figures from field practice, noting that compressors may need about 160 percent overload capacity while condenser and evaporator fans can be fine with around 110 percent. If your ABB drive had been sized generously and never complained during jammy starts, replacing it with a more tightly rated alternative can expose overload gaps.

Duty cycle also matters. ChintŌĆÖs guidance frames duty cycle as the pattern of light, normal, and heavy loading over time. Some drives are not suited to continuous heavyŌĆæduty service, while others waste energy or become unstable during long lightŌĆæduty periods. When changing brands, insist on dutyŌĆæcycle information in the datasheet instead of assuming that two drives with the same horsepower rating share the same thermal headroom.

Beyond pure power, integration and power quality decide whether a replacement is a step forward or backward. EatonŌĆÖs selection notes put ease of integration, voltage compatibility, environment, size, cost, and harmonic mitigation at the top of the list. VFDS.com expands on integration options: onŌĆæboard keypads, PLC and buildingŌĆæautomation networks such as EthernetŌĆæbased protocols, analog signals, potentiometers, and serial communications for coordinated control. An alternative drive should be judged on how cleanly it plugs into your existing PLCs, SCADA, and building management systems.

Harmronic distortion is often the forgotten dimension. Both VFDS.com and the Canroon comparison warn that VFDs are significant powerŌĆæquality polluters and can adversely affect other equipment. For highŌĆæpower systems, Canroon recommends using multiŌĆæpulse drives, such as 36ŌĆæpulse units, to meet IEEE 519 harmonic limits. Whether you stay with ABB or migrate to another brand, plan harmonic mitigation when you change drive counts or ratings. That might mean input reactors, active filters, or selecting drives with builtŌĆæin harmonic control.

Efficiency differences in drives and motor control algorithms sound abstract until you translate them into dollars. The Rockwell Automation example mentioned earlier shows that even a one percentage point improvement can save on the order of tens of thousands of kWh over a multiŌĆæyear life at high power. ShckeleŌĆÖs market analysis points to a global VFD market heading toward roughly $29.9 billion by 2026 with a growth rate near 6.8 percent, driven largely by energyŌĆæefficiency regulations and sustainability goals. It also notes faster growth for VFDs with advanced control algorithms and IoT integration, which allow realŌĆætime optimization and predictive maintenance.

When you compare an ABB drive with an alternative, do not just compare purchase price. Ask for drive plus motor system efficiency curves, check whether there are economizer or energyŌĆæsaving modes for lowŌĆæspeed operation as discussed by Rockwell Automation, and consider whether builtŌĆæin energyŌĆæoptimization features can reduce your bills over seven to ten years. A slightly more expensive drive with meaningfully better efficiency and diagnostics is often the more economical choice.

Several independent overviews and vendorŌĆæneutral articles describe how ABB sits among other leading drive manufacturers. While every site has its own perspective, they paint a consistent picture.

The following table summarizes qualitative comparisons synthesized from sources that discuss ABB, Siemens, Schneider, Rockwell, and a group of other recognized manufacturers such as Yaskawa, Fuji Electric, Danfoss, Mitsubishi, Lenze, KEB, Eaton, WEG, and AutomationDirect.

| Aspect | ABB | Siemens | Schneider | Rockwell (AllenŌĆæBradley) | Other leading brands |

|---|---|---|---|---|---|

| Speed and torque control | Described as having exceptional speed and torque accuracy with stable lowŌĆæspeed torque and advanced vector control, suitable for demanding processes. | Offers similarly high control precision and flexible tuning under varying loads; very competitive where precise regulation is needed. | Considered reliable for general industrial use but portrayed as somewhat less stable than ABB in ultraŌĆæprecise or highly demanding cases. | PowerFlex architectureŌĆæclass drives target flexible torque, speed, and position control for both lowŌĆæ and mediumŌĆævoltage motors. | Yaskawa is highlighted for high reliability and motion control performance; Fuji and Mitsubishi emphasize smooth vector control for heavyŌĆæduty jobs. |

| Energy efficiency | Uses advanced control algorithms and optimization functions to minimize energy consumption, especially in pumps and compressors; often cited as a leader in energy optimization. | Emphasizes regenerative energy recovery and integration into efficient drive systems. | Provides solid efficiency for standard applications but is described as slightly behind ABB in the harshest or most demanding environments. | Positions drives like PowerFlex 755T as tools to lower energy cost and improve uptime in highŌĆædemand applications. | Danfoss and others stress energy savings and sustainability; Lenze case studies report around 30 percent energy reduction in some conveyor systems. |

| Reliability and durability | Designed specifically for harsh industrial conditions with strong components and long life; reliability is a key selling point. | Also highly reliable with advanced overload protection and deep integration into industrial systems. | Viewed as dependable mainly in standard duty cycles rather than extreme duty. | Built for demanding environments, especially in North American process industries, with options like arcŌĆæresistant mediumŌĆævoltage gear. | Fuji Electric offers operation up to about 122┬░F and a threeŌĆæyear warranty; Mitsubishi designs for service lives exceeding ten years; KEB and Yaskawa are known for robust longŌĆæterm operation. |

| System integration | Supports a wide range of industrial protocols such as Modbus, Profibus, and EthernetŌĆæbased networks, easing integration with PLC, DCS, and SCADA. | Excels in integration within its own Totally Integrated Automation ecosystem, with extensive diagnostics and smart connectivity. | Integrates well within SchneiderŌĆÖs broader automation environment and building solutions. | Tightly coupled with Rockwell controllers and software, which simplifies engineering for RockwellŌĆæcentric plants. | Eaton, AutomationDirect, and others offer simpler, costŌĆæeffective drives with good documentation and support, targeting small machines, HVAC, and water plants. |

From a replacement perspective, this means you are rarely moving from ŌĆ£goodŌĆØ to ŌĆ£badŌĆØ if you step from ABB to Siemens or Rockwell, but you are definitely changing personality. ABBŌĆÖs strengths in energy optimization, harshŌĆæduty durability, and broad protocol support set a benchmark. When choosing an alternative, you want to ensure that whatever you gain in ecosystem alignment or cost does not come at the expense of control precision or overload resilience that your process quietly depends on today.

A reliable replacement is much more than a catalog swap. Successful projects tend to follow a repeatable pattern that looks roughly like an engineering study rather than a oneŌĆæline purchasing request.

Start with a circuitŌĆæbyŌĆæcircuit audit. Capture motor nameplate data, including horsepower, voltage, fullŌĆæload amps, base speed, and service factor. Document the load type and duty cycle: is it a centrifugal pump that runs at partial load most of the time, a conveyor that starts and stops under load, or a compressor that draws high starting current. Identify environmental conditions at each location and note whether existing ABB drives are panelŌĆæmounted or in standalone enclosures, and whether they have external bypasses or harmonic filters.

Next, map control and integration. Note how each ABB drive receives its speed reference and commands. Some may use a frontŌĆæpanel keypad only. Others may receive 4ŌĆō20 mA signals from a PLC or DCS, use digital inputs for start and stop, or be networked over a fieldbus. Replacement drives must support equivalent control methods without forcing a wholesale controlŌĆæsystem redesign.

Then specify drives around current and duty rather than horsepower alone. Use the guidance from AutomationDirect and VFDS.com to ensure continuous current ratings exceed motor FLA and that overload capability matches the application. For loads that previously enjoyed generous ABB headroom, consider upsizing the new brand by one frame or selecting a heavyŌĆæduty rating if available.

Plan wiring and grounding to manufacturer recommendations. ElectronicsŌĆæfocused discussions emphasize the value of stranded, flexible cable between drive and motor, especially where vibration is present, and of placing the drive physically close to the motor to avoid exotic connectors. Shielded cable and proper grounding help control commonŌĆæmode noise, protecting both motors and nearby sensitive electronics.

Finally, schedule commissioning and testing with the same seriousness you would give to a new line. Drives should be parameterized according to the motor nameplate, acceleration and deceleration ramps, braking options, and protection limits. If the alternative drive offers autoŌĆætuning or advanced vector control, use those features judiciously after reviewing the manual. Field testing should include startŌĆæstop under realistic load, speed changes, fault simulations, and verification that upstream protective devices still operate correctly.

Replacing ABB drives is as much about risk management as about cost and efficiency. Reliability commentary from Canroon and user communities yields several practical lessons.

First, brand reputation and support matter. Guides aimed at industrial buyers consistently recommend established brands such as ABB, Siemens, Yaskawa, Mitsubishi, Fuji Electric, Lenze, KEB, Eaton, WEG, Rockwell, and AutomationDirect. These manufacturers have broad installed bases and track records in harsh environments ranging from oilfields and car washes to cranes and rock crushers. They back their products with warranties that can extend to three years or more and invest in documentation and afterŌĆæsales support.

Second, matching the drive to the torque profile is nonŌĆænegotiable. CanroonŌĆÖs review points out that compressors and heavyŌĆæduty loads often need higher overload margins than fans and pumps. UnderŌĆæsizing an alternative drive or selecting a variant intended for light variableŌĆætorque duty can move you from ABBŌĆÖs comfortable margin to a system that trips on every disturbance.

Third, environmental robustness is not just about IP ratings on paper. Fuji ElectricŌĆÖs experience with drives running at high ambient temperatures without derating, and the success of sealed washdown enclosures in dirty shop environments, underline the importance of selecting hardware that matches reality rather than a generic catalog description. If the ABB drive you are replacing has long proven reliable in a hot, dusty corner of a plant, do not substitute a minimal IP20 openŌĆæframe unit simply because it is readily available.

Fourth, engineering support and documentation make the difference between theoretical capability and realŌĆæworld performance. Practitioners who buy used drives from auction sites stress the importance of clear, complete manuals and accessible parameter structures. Reports of lowŌĆæcost drives with confusing documentation or weak protection features serve as a caution against choosing alternatives purely on upfront price.

The answer depends on power level, duty cycle, and the efficiency gap between your existing drive and candidate replacements. Rockwell AutomationŌĆÖs example shows that for a system delivering around 100 kW for roughly 36,800 hours over seven years, a one percentage point efficiency improvement can save about 41,000 kWh, or around $4,100 at $0.10 per kWh. If your drives are controlling large fans or pumps with similar duty cycles, and newer alternatives demonstrably improve system efficiency by several percentage points, the energy savings over their life can justify replacement even before reliability becomes a concern.

Experience summarized in engineering discussions indicates that modestly oversizing a drive relative to the motor is usually safe and sometimes beneficial, as long as you configure current limits correctly. A 2 hp drive can safely operate a 1.5 hp motor if adjusted properly. UnderŌĆæsizing is riskier and generally only acceptable if you deliberately limit the driveŌĆÖs current and accept reduced available torque. All credible selection guides agree that matching or exceeding motor fullŌĆæload amps with the driveŌĆÖs current rating is the safest approach, especially for constantŌĆætorque loads.

Any VFD, regardless of brand, injects harmonic currents back into the supply. VFDS.com and Canroon both note that drives are substantial powerŌĆæquality polluters and that highŌĆæpower installations may need multiŌĆæpulse input stages or dedicated harmonic mitigation to meet standards such as IEEE 519. When you change drive counts, ratings, or topologies, revisit your harmonic study. Options include drives with lowŌĆæharmonic rectifiers, input line reactors, active filters, or multiŌĆæpulse configurations. Treat harmonics as a systemŌĆælevel design issue rather than a brandŌĆæspecific quirk.

Replacing an ABB VFD with an alternative is not about trading a premium logo for a cheaper one. It is about reŌĆæengineering motor control with clear eyes on current, torque, environment, integration, efficiency, and support. When you anchor the decision in those technical realities and lean on reputable manufacturers with strong documentation, you can safely move away from ABB where it makes sense while preserving the reliability and power quality that your processes depend on.

Leave Your Comment