-

Please try to be as accurate as possible with your search.

-

We can quote you on 1000s of specialist parts, even if they are not listed on our website.

-

We can't find any results for ŌĆ£ŌĆØ.

Industrial and commercial power systems live or die on the humility of their components. In UPS rooms, inverter-fed switchboards, and power protection panels, a single aging contactor can compromise redundancy, let a transfer fail, or weld shut under fault. ABB has a deep, highŌĆæquality contactor portfolio, but like every manufacturer, older series move through the product life cycle into classic and then obsolete status. At that point, engineers face the same question: what is a safe ABB contactor equivalent, and how can you prove it is truly compatible?

As a power system specialist, I have seen projects delayed and entire production lines stopped because someone grabbed a ŌĆ£close enoughŌĆØ replacement from a catalog without matching coil voltage, utilization category, or shortŌĆæcircuit performance. The good news is that reputable sources such as ABB application guides, Proax and Kempston technical notes, RS Components and Smartbuy buying guides, and focused articles from Contactor Depot and Maghispan all converge on a very practical, disciplined way to do this right. This article consolidates those insights into a structured approach specifically for critical power and protection environments.

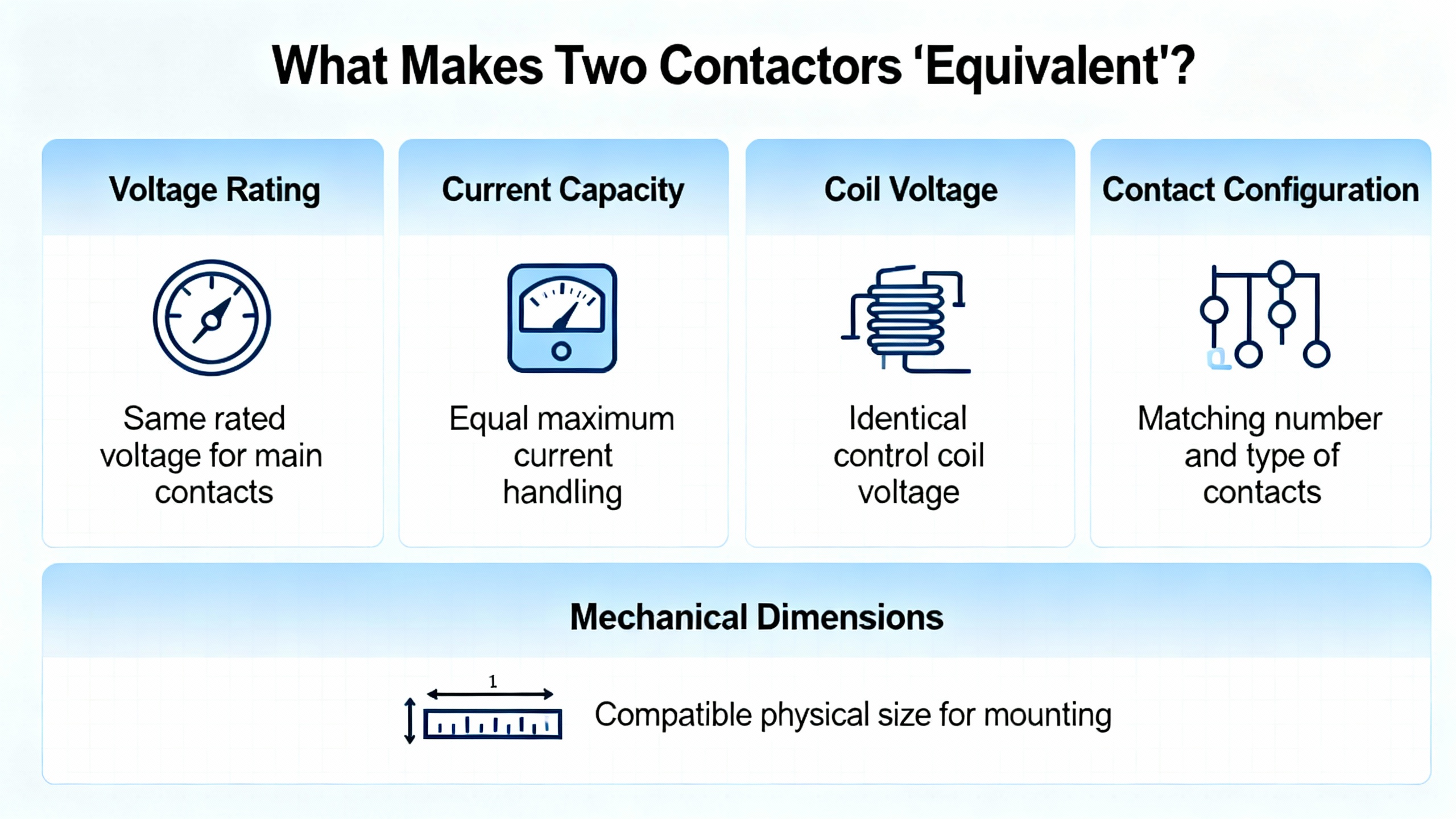

Before you try to crossŌĆæreference an ABB contactor to an AF replacement or a thirdŌĆæparty device, it helps to be precise about what equivalence actually means.

Electrical guides from RS Components and Smartbuy describe a contactor as an electrically controlled highŌĆæpower switch. It uses a magnetic coil to open and close power contacts, letting a lowŌĆæpower control circuit operate highŌĆævoltage, highŌĆæcurrent loads. That definition immediately hints at two distinct sides you need to match: the power path and the control path.

On the power side, RS Components notes that contactors are specified by maximum switching voltage and maximum switching current, with separate ratings for resistive and inductive loads. Smartbuy adds that you should match or exceed the loadŌĆÖs fullŌĆæload amperage, and respect the utilization category such as ACŌĆæ1 for nonŌĆæinductive loads and ACŌĆæ3 for squirrelŌĆæcage motors. ABBŌĆÖs own selection guides, summarized by Proax, reinforce this by tying contactor selection directly to motor nameplate data and ACŌĆæ3 or ACŌĆæ4 categories.

On the control side, Contactor Depot stresses that coil voltage must match the control circuit, not the load. They highlight typical coils at 24, 110/120, and 220/240 V, while the motor or UPS bypass circuit could be 240, 480 or higher. RS Components and Smartbuy agree that typical coil voltages include 12, 24, 48, 110, 230, and 400 V, and that coil voltage can be entirely different from the load voltage.

Two contactors are genuinely equivalent in a critical power application only if they meet or exceed the original device on both of these axes, plus a small set of mechanical, environmental, and safety criteria. Anything less is a compromise, even if the terminal layout looks nearly identical.

When I review a proposed ABB equivalent for a UPS input contactor or inverter bypass, I always start by reconstructing the original duty. The sources above converge on a consistent set of data points you should capture from the existing device and its documentation.

First, determine the operational current and utilization category. Smartbuy recommends sizing on rated current with about a 15ŌĆō20 percent margin, while ABBŌĆÖs motor selection guides via Proax emphasize using the nameplate fullŌĆæload amps and ACŌĆæ3 or ACŌĆæ4 duty. For a motor feeder, ACŌĆæ3 is typical; heavy jogging or plugging pushes you toward ACŌĆæ4 or an upsized ACŌĆæ3 device. For predominantly resistive loads such as heater banks or many lighting circuits, ACŌĆæ1 ratings apply. In a UPS or inverter application, the downstream loads often have motorŌĆælike behavior (fans, pump motors, compressors), so ACŌĆæ3 is usually the right reference.

Next, check voltage ratings on both the main contacts and the coil. Manufacturer data sheets referenced by RS Components and Smartbuy list separate contact voltage ratings (for example up to 690 V AC) and coil voltages. Contactor Depot explains that coil labeling is often printed near terminals A1 and A2, while the power path runs from L1, L2, L3 to T1, T2, T3. Never assume the coil runs at line voltage; many control systems use 24 V or 110/120 V control, even when switching 480 V feeders.

Then, confirm the number of poles and auxiliary contact configuration. Guides from RS Components and Proax call out main poles for the power path and auxiliary NO/NC contacts for signaling, interlocking, and safety functions. In ATS panels, UPS transfer schemes, and motor control centers, those auxiliary points are often wired into logic or protection chains. Dropping an auxiliary inadvertently can defeat an interlock, while adding one without updating the logic can create spurious signals.

Finally, verify environmental, mechanical, and approval constraints. Smartbuy and ABB selection notes emphasize ambient temperature, enclosure protection (IP rating), and mechanical vibration. ProaxŌĆÖs Canadian guide suggests designing for outdoor temperatures roughly from -40┬░F up to about 104┬░F and specifying higher IP enclosures where humidity or dust is significant. Smartbuy also insists that industrial contactors carry proper certifications such as UL and IEC; for critical power, I treat those as mandatory.

When all of these aspects match the original ABB device, you are close to an equivalent. If any are weaker than the original, you are trading away reliability or safety.

Across HVAC systems, industrial controls, and UPS panels, the most common contactor replacement mistake I see is coil mismatch. Contactor DepotŌĆÖs coilŌĆævoltage guidance describes the exact symptoms: if you feed a 24 V coil with 120 V, it can burn out almost instantly and create a fire risk; if you feed a 120 V coil with 24 V, it may never energize and the load simply will not start. UnderŌĆævoltage causes chattering and failed starts, while overŌĆævoltage drives overheating and premature coil failure. Incorrect frequency can have similar effects.

This problem shows up because people confuse load voltage with coil voltage. ProaxŌĆÖs ABB selection guide highlights that you might have a 400 V or 600 V motor, but the coil could be 24 V DC for PLC control or 120 V AC for legacy hardŌĆæwired control. RS Components and Smartbuy both stress that coil voltage is entirely independent of the load voltage; you can have a 24 VDC coil controlling a 400 VAC motor circuit without any issue.

In the field, I make a point of doing exactly what Contactor Depot recommends. Before touching any wires, I take clear photos of the existing contactor from all sides. I then read the coil label carefully around the A1 and A2 terminals, and I still verify the control circuit voltage with a multimeter while the system is in a safe, energized state. When the label is worn or ambiguous, this measurement is the only way to be certain.

The lesson for ABB equivalents is simple. No matter how perfect a replacement looks mechanically, if the coil voltage and frequency do not match the control circuit, the contactor is not an equivalent. In critical power equipment, it is safer to delay the restart than to energize a coil on the wrong supply.

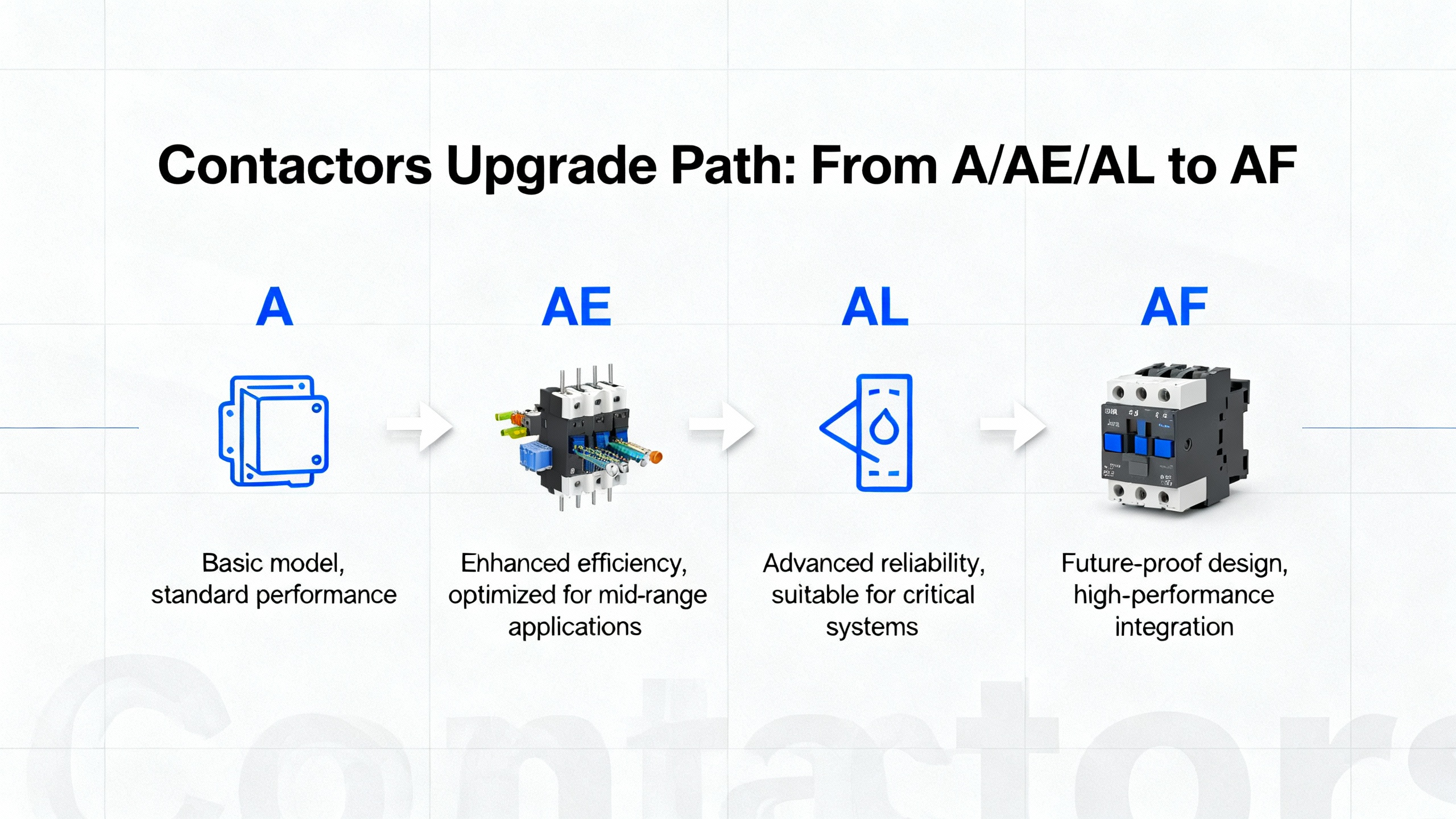

For older ABB installations, the best equivalent is often another ABB product, especially where ABB themselves have defined a migration path. Kempston Controls describes a clear example: the legacy A, AE, AL, TAL, and TAE block contactors.

These AŌĆæseries devices, available in 3ŌĆæ and 4ŌĆæpole variants, were once the workhorses of many plants. According to KempstonŌĆÖs technical article, ABB began phasing them out in the early 2000s, with the phaseŌĆæout accelerating around 2011. All of those legacy devices now have a functional replacement in the ABB AF family of contactors introduced around 2015.

The AF range was designed as a global standard. Kempston explains that only four AC/DC coils cover all common operating voltages from 24 to 500 V AC and 20 to 500 V DC. That dramatically simplifies international stocking and design, and ProaxŌĆÖs ABB selection notes echo the same idea with wideŌĆæband coils in the 100ŌĆō250 V AC/DC range. Kempston also reports substantial performance capabilities: AF contactors can reach up to about 560 kW at 400 V ACŌĆæ3, 900 hp at 480 V under UL/CSA, and currents up to about 2,650 A at 690 V ACŌĆæ1.

Perhaps more important for critical power, the AF platform integrates surge suppression and offers multiple connection options such as screw, pushŌĆæin spring, and ring terminals. BuiltŌĆæin suppression eliminates the need for external coil suppressors that can be misŌĆæwired or forgotten during replacement.

However, Kempston is very clear on one point that many engineers overlook. While AF contactors are functionally equivalent to the AŌĆæseries in terms of what they can switch, they are physically different devices. Accessories such as coils, mechanical interlocks, surge suppressors, and pneumatic timer blocks are not interchangeable between the ranges. This matters for applications like starŌĆædelta starters or reversing starters where mechanical interlocks and timing blocks are critical for safe operation.

Kempston also notes that spares for the A range have been largely run down and that popular accessories are increasingly unavailable. They frame this within ABBŌĆÖs lifeŌĆæcycle concept (active, classic, obsolete) that is described in more detail in ABBŌĆÖs own lifeŌĆæcycle services literature: active products have full support; classic products still have services and spares but are heading toward replacement; limited and obsolete phases bring shrinking support, and ABB recommends planned migration during the classic or limited period.

For plant owners, that means the most robust ABB equivalent for an AŌĆæseries contactor is an AF contactor selected by current, utilization category, and coil voltage, plus any AFŌĆæspecific accessories explicitly tested for that combination. Relying on dwindling legacy spares is a shortŌĆæterm patch, not a strategy.

| Aspect | Legacy ABB A/AE/AL/TAL/TAE | ABB AF Series (modern equivalent) |

|---|---|---|

| Coil coverage | Narrow, many coil variants | Four coils covering roughly 24ŌĆō500 V AC / 20ŌĆō500 V DC |

| Surge suppression | External accessories required | BuiltŌĆæin electronic suppression |

| Typical power range | High, but legacy designs | Up to about 560 kW at 400 V ACŌĆæ3, 900 hp at 480 V |

| Accessory compatibility | RangeŌĆæspecific | New accessory ecosystem, not interchangeable with A |

| LifeŌĆæcycle status | Classic / obsolete | Active, with full support and spares |

This table uses figures reported by Kempston Controls and ABB channel partners. When you plan a replacement, you still have to crossŌĆæcheck the exact ratings of the particular sizes you are dealing with.

Replacement is not the only path. For some heavyŌĆæduty ABB contactors, particularly in applications where the mechanical frame is robust but contact wear is the limiting factor, retrofitting can be a rational option.

Maghispan describes this approach for ABBŌĆÖs EH series contactors. They focus on models such as EH 370, EH 550, EH 630, and EH 700, which are discontinued but still widely installed, along with larger EH 800 and EH 1200 units that remain in service. The retrofit concept is simple: instead of discarding the entire contactor, maintenance teams replace worn parts such as coils and contact sets while keeping the main mechanical structure.

Some ABB EH contactors use a threeŌĆæpole set with three moving contacts and six fixed contacts. Maghispan notes that these assemblies can be repaired multiple times with good preventive maintenance. The benefits they highlight are economic and environmental. Retrofitting avoids the cost of purchasing complete new contactors and reduces industrial waste by reusing structural components that often remain mechanically sound. It keeps obsolete or discontinued contactors in service even when original spares are hard to find, provided compatible contact sets are available.

In critical power systems, I view this strategy as particularly attractive when the contactor is deeply embedded in custom buswork or metalŌĆæclad switchgear where replacing the entire frame would drive major outage time and fabrication cost. However, the retrofit components must be engineered and manufactured to at least the same standard as the originals, and you still have to respect the original contactorŌĆÖs electrical ratings and lifeŌĆæcycle status. Retrofitting cannot turn an obsolete 400 A device into a 600 A one, and it does not alter clearances, creepage distances, or insulation design.

Sometimes you simply cannot source an ABB replacement in the required timeframe, or you have standardized on another vendor for the rest of the plant. In that case, it is possible to use crossŌĆæbrand equivalents, but the bar for engineering diligence is higher.

SmartbuyŌĆÖs contactor buying guide offers a pragmatic selection sequence that maps well onto ABB replacements. They advise identifying the load type first, distinguishing motors and other inductive loads from simple resistive or lighting loads. Then they recommend calculating fullŌĆæload current and adding a safety margin, selecting the correct utilization category, choosing the right number of poles and auxiliary contacts, and ensuring the coil voltage matches the existing control circuit. Finally, they emphasize environmental considerations and safety certifications.

RS ComponentsŌĆÖ guide overlaps this advice and lists familiar manufacturers such as ABB, AllenŌĆæBradley, Eaton, Schneider Electric, Siemens, TE Connectivity, and WEG, reflecting a mature supplier landscape. Smartbuy suggests purchasing from authorized distributors such as RS or engineeringŌĆæoriented sellers and using crossŌĆæreference tools when replacing obsolete models.

From a reliability perspective, the procedure for crossing from an ABB contactor to another brand should echo how ABB themselves size their own devices. Use ABB data sheets, Proax application notes, or ABB lifeŌĆæcycle documentation to reconstruct the original deviceŌĆÖs ratings and performance envelope. Then verify, point by point, that the candidate replacement meets or exceeds each requirement: current and utilization, voltage, coil, mechanical endurance, and approvals.

CrossŌĆæbrand equivalence does not mean visual or dimensional similarity; it means functional and safety equivalence documented by two sets of technical literature. This is especially important in UPS and inverter systems where misapplied contactors can introduce hidden failure modes under fault or transfer conditions.

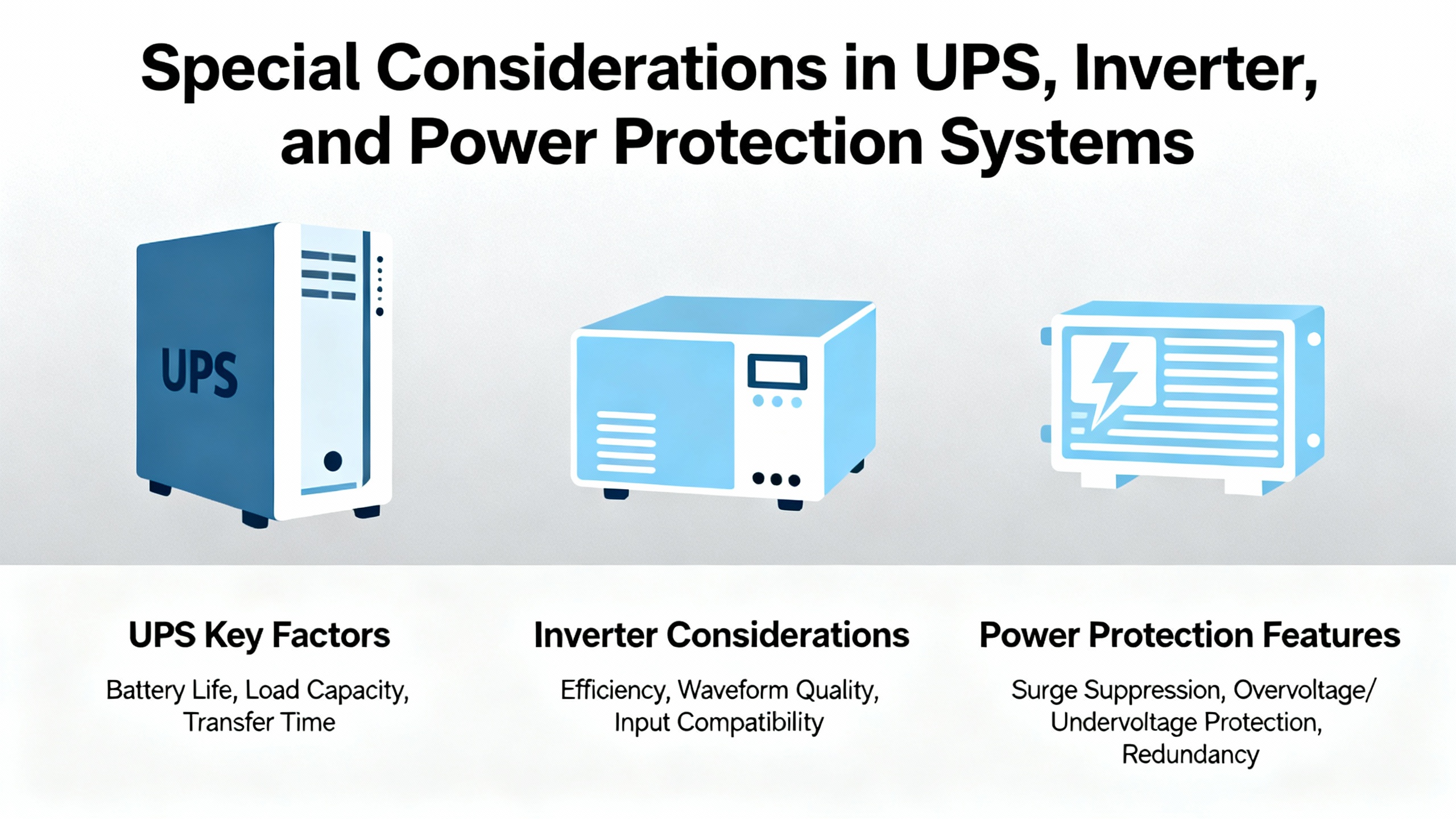

While most public contactor literature focuses on motors, HVAC, and lighting, the same devices sit at the heart of critical power supply systems. ABBŌĆÖs portfolio described by Proax explicitly includes DC switching contactors up to around 1,000 V DC, capacitor switching contactors for powerŌĆæfactor correction, and safety contactors for emergency stop circuits. These are directly relevant in environments with highŌĆæenergy DC buses, capacitor banks, or complex safety architectures.

There are a few patterns that deserve particular attention when selecting an ABB equivalent in these systems.

First, contactors do not provide shortŌĆæcircuit or overload protection. Smartbuy and several motorŌĆæcontrol guides emphasize that contactors must be paired with overload relays and upstream circuit breakers or fuses. In UPS and inverter systems, the protective device selection is often optimized around faultŌĆæcurrent levels and coordination with transfer switches. Any replacement contactor must sit within that existing protective coordination envelope. Upsizing a contactor for extra ŌĆ£safetyŌĆØ without checking its shortŌĆæcircuit making and breaking capabilities can lead to a device that fails violently during a fault.

Second, DC duty is not the same as AC duty. Proax points out that ABB offers specialized DC switching contactors for solar, battery, and EV applications, and NEPSIŌĆÖs ABB vacuum contactor instructions summarize how vacuum interrupter designs are used to switch mediumŌĆævoltage capacitive loads such as capacitor banks and harmonic filters. Using an ACŌĆæoptimized contactor on a DC bus that feeds an inverter can produce severe arcing and welded contacts because DC arcs do not naturally cross zero the way AC arcs do. Any ABB equivalent on the DC side of a UPS or solar hybrid system should carry explicit DC ratings at the relevant voltage.

Third, environmental and dutyŌĆæcycle conditions are often harsher than they appear on a singleŌĆæline diagram. ProaxŌĆÖs Canadian guide underlines the need to account for low ambient temperatures, contamination, and vibration. Smartbuy notes that contactors generate more heat than relays and that thermal performance must be considered in enclosure design. In highŌĆædensity UPS rooms with limited ventilation or in rooftop inverter installations, those conditions can push contactors toward the edge of their temperature range. A ŌĆ£paperŌĆØ equivalent that ignores these derating effects may have a much shorter life in practice.

The most effective replacement processes I have seen look almost identical to the method Contactor Depot recommends for coil selection, expanded to cover all relevant ratings.

Start by capturing all available data from the existing ABB contactor. Photograph the front, sides, and nameplate so you can read the model designation, current rating, voltage, utilization category, coil data, and any accessory codes without revisiting the site. Include the panel nameplate and any nearby labels that indicate system voltage or load description.

Then, confirm the control circuit voltage and frequency. Even if the coil label is legible, use a suitable meter to measure the voltage at the coil terminals under normal operating conditions. Do this from a safe distance and in accordance with lockout/tagout procedures. CrossŌĆæcheck that measurement with the panel schematics where available.

Next, identify the load characteristics. For motors, ProaxŌĆÖs guidance is clear: read the nameplate fullŌĆæload amps, horsepower, voltage, and starting method, and determine whether the duty is ACŌĆæ3 or ACŌĆæ4. For other loads, consider whether they are fundamentally resistive, inductive, or capacitive. In UPS and inverter systems, that includes thinking about inrush behavior and harmonic content, not just steadyŌĆæstate current.

Once you have that picture, consult ABBŌĆÖs current product literature or qualified distributors. Proax, as an authorized ABB partner, and Kempston Controls, with its detailed AF migration guidance, are both examples of distributors that document how to move from legacy models to modern equivalents. Verify that the proposed ABB or thirdŌĆæparty replacement meets or exceeds the original ratings on every critical parameter: current, voltage, utilization category, coil data, mechanical endurance, and approvals.

At that point, evaluate installation and maintenance implications. ABBŌĆÖs installation guides via Proax stress vertical mounting, adequate side clearance for cooling, correct terminal torque, and routing of power and control wiring in accordance with electrical codes. Smartbuy and EiyuŌĆÖs HVAC contactor guide emphasize lockout/tagout, clear identification of terminals such as L1/L2/L3 and T1/T2/T3, and careful transfer of wires from the old to the new device. Retrofitting ABB EH or similar contactors with new contact sets, as described by Maghispan, also belongs in this step, because it affects how long you expect the replacement solution to last before the next outage.

Finally, document the change. In critical power systems, I recommend updating singleŌĆæline diagrams, panel schedules, and asset management records to reflect the new contactor model, ratings, and lifeŌĆæcycle phase. ABBŌĆÖs lifeŌĆæcycle framework reminds us that every replacement is part of a longer journey; recording todayŌĆÖs decision makes tomorrowŌĆÖs equivalent selection much easier.

The technical sources discussed here are remarkably consistent about the mistakes that undermine contactor replacement projects.

One recurring issue is treating coil voltage casually. Contactor Depot warns explicitly about installing a coil with the wrong voltage or frequency and lists buzzing, chattering, overheating, and outright burnout as predictable outcomes. ProaxŌĆÖs troubleshooting section adds that coils with low voltage can chatter and fail to pull in, while proper diagnosis requires checking both control voltage and coil resistance. The antidote is simple but often skipped in a hurry: treat the coil as a separate, critical design choice and verify it electrically, not just visually.

Another pitfall is ignoring utilization categories and load type. Smartbuy differentiates between resistive ratings for heaters and inductive ratings for motors and transformers, echoing RS ComponentsŌĆÖ explanation of ACŌĆæ1 versus ACŌĆæ3 duty. ProaxŌĆÖs guide ties premature contact wear and welded tips to underrating or choosing the wrong utilization category, especially when duty cycles are high or starting is frequent. In power protection systems, that same mistake can surface when a contactor originally selected for a motor is asked to switch heavily capacitive loads or nonŌĆælinear inverter output without verifying suitability.

Accessory incompatibility is another hidden trap highlighted by KempstonŌĆÖs comparison of ABB A and AF ranges. Engineers sometimes attempt to recycle old mechanical interlocks, timers, or surge suppressors from a legacy AŌĆæseries contactor onto a new AF device. Kempston explicitly cautions that the ranges are physically different and that accessories are not interchangeable. For starŌĆædelta and reversing starters in particular, mixing accessory families can compromise safety functions in ways that are hard to detect until a fault occurs.

A final, more strategic pitfall is treating each contactor failure as an isolated maintenance task. ABBŌĆÖs lifeŌĆæcycle services literature advocates for planning migrations based on product lifeŌĆæcycle status: active, classic, limited, and obsolete. Kempston applies that logic specifically to the AŌĆæseries, and MaghispanŌĆÖs retrofit approach for EH contactors is a different response to the same lifeŌĆæcycle reality. In critical power systems, waiting until spare parts dry up before planning replacements almost always leads to rushed decisions and higher risk.

The choice between retrofitting an existing ABB contactor, finding a direct ABB equivalent, or crossing to another brand is often a strategic one.

Retrofit, as described in the Maghispan article on ABB EH contactors, makes sense when the mechanical frame is robust, the application is well understood, and compatible contact sets are available. It offers strong economic and environmental benefits by reusing most of the device and reducing waste. In my experience, this can be a good fit where downtime is expensive and the contactor is mechanically integrated into custom switchgear or bus structures that are otherwise in good condition.

Direct replacement within ABBŌĆÖs portfolio, such as moving from an AŌĆæseries to an AF contactor using Kempston and ABB migration guidance, is the safest route when longŌĆæterm support, certifications, and documentation matter most. It positions you to take advantage of ABBŌĆÖs activeŌĆæphase services, including spares, training, and future upgrades, as outlined in their lifeŌĆæcycle services documentation.

CrossŌĆæbrand equivalents are sometimes unavoidable, especially when corporate standards or existing inventory push you toward a particular vendor. SmartbuyŌĆÖs buying guide and RS ComponentsŌĆÖ overview suggest that this is acceptable as long as ratings, approvals, and applications all align and you use reputable manufacturers. In critical UPS and inverter systems, I treat this option as viable only when properly engineered and documented, not as an emergency shortcut.

Whichever path you choose, the quality of your equivalence decision depends on how rigorously you follow the rating, coil, and application matching principles drawn from ABBŌĆÖs own guides and the independent sources summarized here.

Finding a compatible ABB contactor equivalent is not about chasing lookŌĆæalike catalog pictures; it is about understanding exactly what the original device was doing in your power system and then matching or improving on that performance with documented engineering. When you take coil voltage as seriously as current rating, respect utilization categories and lifeŌĆæcycle status, and lean on credible sources such as ABBŌĆÖs selection guides, Proax and Kempston application notes, RS Components and Smartbuy buying guidance, and specialist retrofit providers like Maghispan, you can modernize aging contactor installations without sacrificing reliability. In critical power systems, that discipline is what keeps transfers clean, protection dependable, and uptime where it needs to be.

Leave Your Comment